Comprehensive Guide to Homelite XL Chainsaw Parts Diagram

When it comes to maintaining your essential equipment, a thorough comprehension of its elements is crucial. Knowing how each component interacts can enhance performance and prolong the lifespan of your machinery. Whether for professional use or home projects, understanding these intricate systems can save time and reduce frustration.

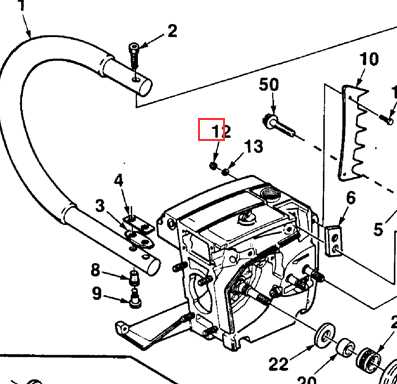

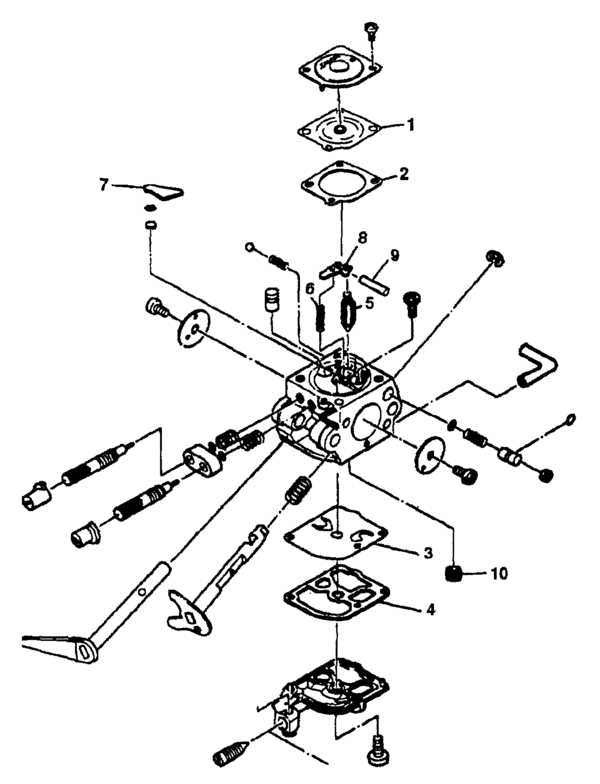

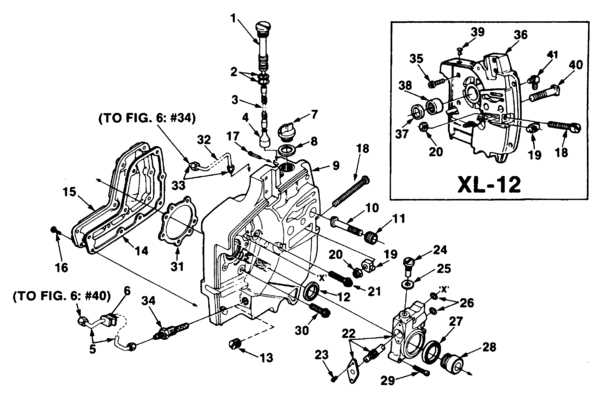

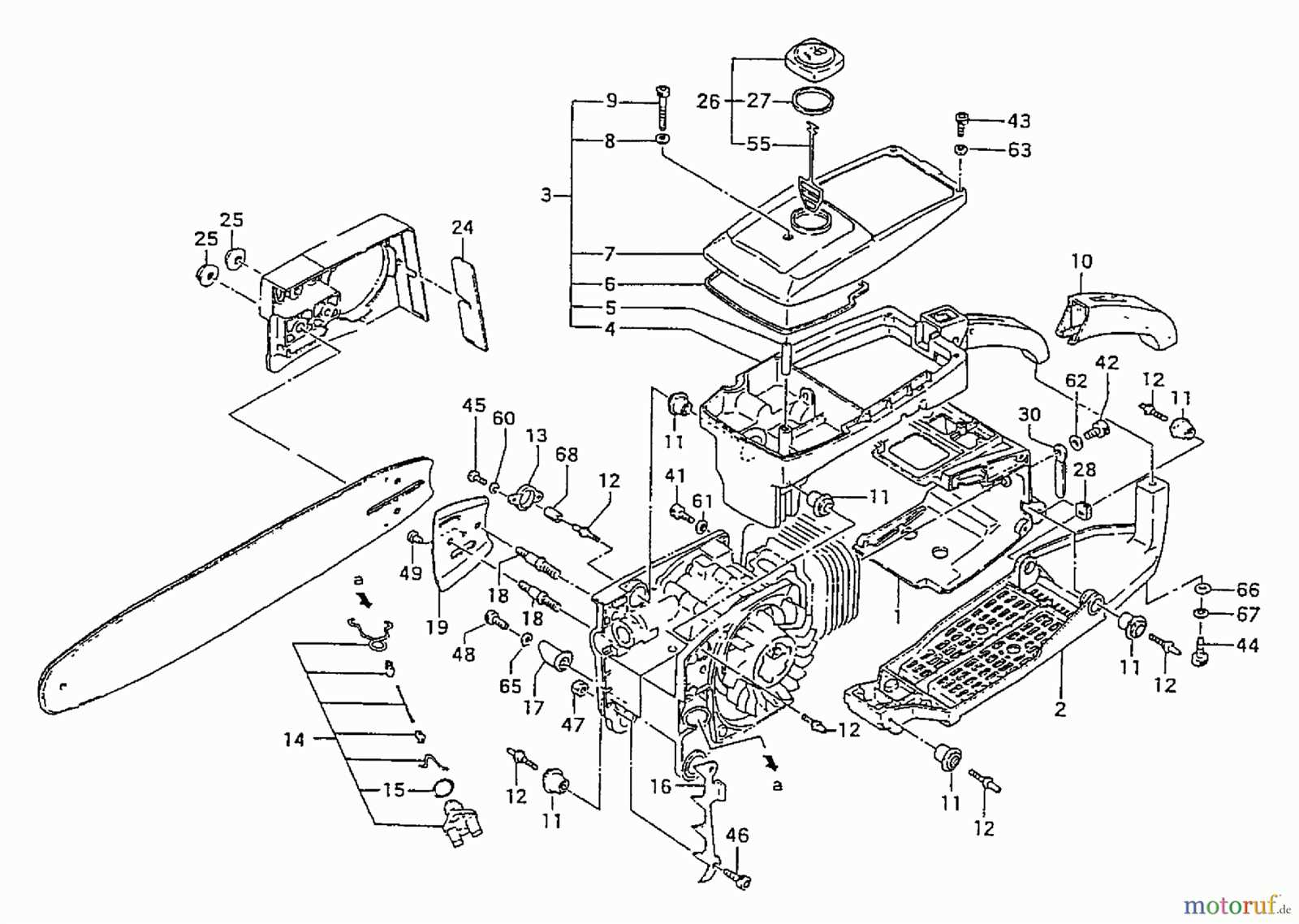

Detailed visual representations of these crucial elements serve as invaluable resources. They provide clarity on the placement and function of each piece, allowing users to identify potential issues quickly. This knowledge empowers you to take appropriate action, whether that means simple maintenance or more complex repairs.

For those who seek to delve deeper into the anatomy of their equipment, visual guides are indispensable. They not only assist in troubleshooting but also foster a deeper appreciation for the craftsmanship involved in such tools. By exploring these resources, you equip yourself with the insights necessary for effective care and handling.

Understanding Homelite XL Chainsaws

This section delves into the essential components and mechanisms of a popular model in the world of outdoor power equipment. By gaining insight into its design and functionality, users can better appreciate its performance and maintenance requirements.

With a combination of innovation and practical engineering, this device offers users a reliable solution for various cutting tasks. Familiarity with its structure not only enhances operational efficiency but also aids in troubleshooting and repairs.

| Component | Description |

|---|---|

| Engine | Powers the unit, converting fuel into mechanical energy. |

| Bar | Guides the cutting chain, determining the width of the cut. |

| Chain | Engages in cutting, featuring sharp teeth for efficient performance. |

| Handle | Provides grip and control, enhancing user comfort during operation. |

| Fuel System | Supplies the engine with a mixture of fuel and air for combustion. |

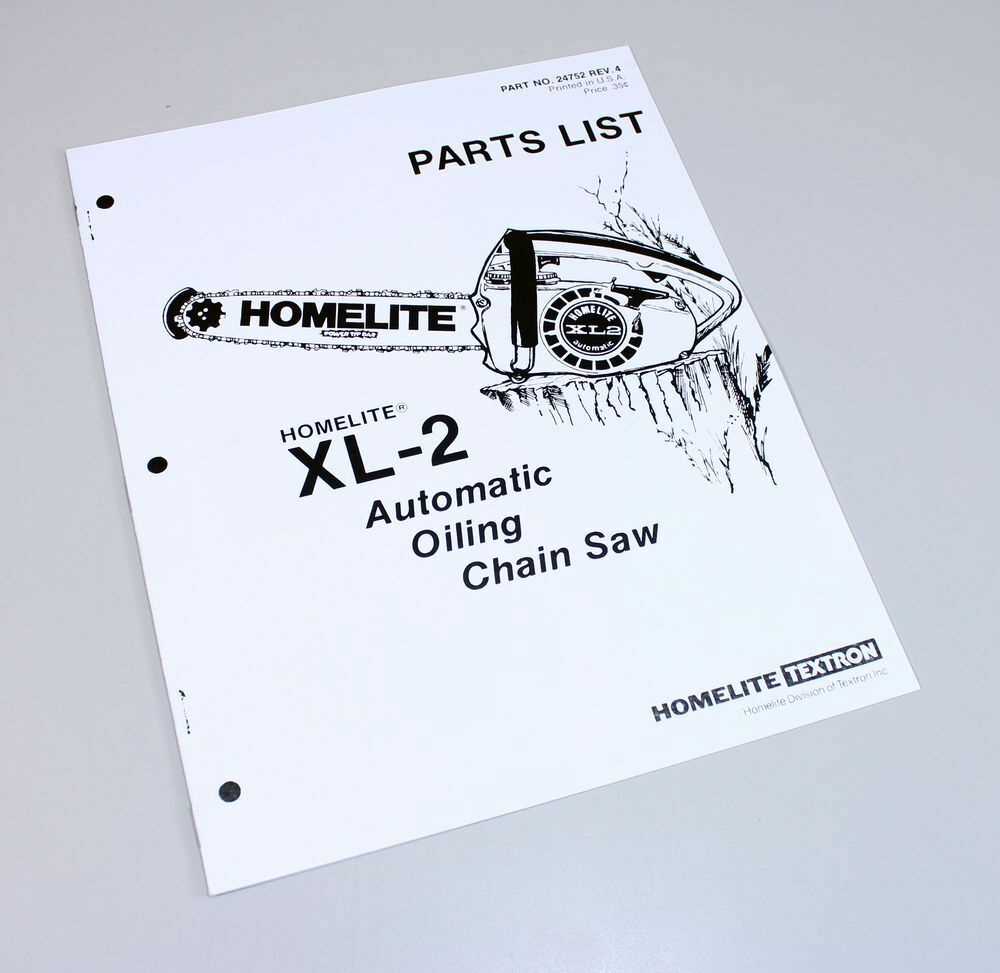

History of Homelite Chainsaws

The evolution of portable cutting equipment has significantly transformed the landscape of woodworking and forestry. This section delves into the origins and advancements of a notable brand in the industry, highlighting its contributions and the impact it has made over the years.

Early Beginnings

Founded in the mid-20th century, the company emerged from a desire to provide efficient tools for laborers. With a focus on innovation, the brand quickly gained recognition for its lightweight and powerful devices, catering to both professionals and DIY enthusiasts alike. The introduction of these tools represented a shift towards more accessible and user-friendly designs.

Technological Advancements

As the years progressed, the brand continued to innovate, integrating new technologies that enhanced performance and safety. The incorporation of improved materials and engineering techniques allowed for more durable and efficient models, further solidifying its reputation in the market. Over time, the brand not only adapted to changing consumer needs but also played a pivotal role in shaping the future of portable cutting machinery.

Key Features of the XL Model

The XL model is designed with a range of characteristics that enhance its performance and usability. These features cater to both professional and hobbyist users, making it a versatile choice for various tasks.

Powerful Engine: Equipped with a robust power unit, the XL ensures efficient operation, allowing users to tackle demanding jobs with ease. Its design focuses on delivering consistent energy while minimizing fuel consumption.

Lightweight Construction: The construction of this model prioritizes a lightweight frame, which facilitates maneuverability and reduces user fatigue. This makes it ideal for extended use without compromising comfort.

Enhanced Safety Mechanisms: Safety is a significant consideration in the XL’s design. It includes features such as a chain brake and anti-vibration technology, which work together to provide a safer experience during operation.

User-Friendly Design: The intuitive layout of controls and components makes the XL model easy to operate, even for those with limited experience. This accessibility promotes confidence and efficiency in handling various cutting tasks.

Durability: Built with high-quality materials, the XL model is engineered for longevity. Its components are designed to withstand rigorous use, ensuring reliability over time and reducing the need for frequent maintenance.

These key attributes make the XL model a favored choice among users looking for efficiency, safety, and reliability in their outdoor tasks.

Essential Parts of a Chainsaw

A cutting tool is composed of several crucial components that work together to ensure optimal performance and efficiency. Understanding these elements can enhance maintenance practices and improve overall operation.

- Power Unit: The heart of the tool, responsible for generating energy.

- Guide Bar: The long metal piece that supports the cutting chain and directs its movement.

- Cutting Chain: A series of sharp teeth that perform the actual cutting action.

- Throttle Control: A mechanism that regulates the speed of the engine, providing control over cutting intensity.

- Fuel System: Comprising the tank and lines, it supplies energy to the engine.

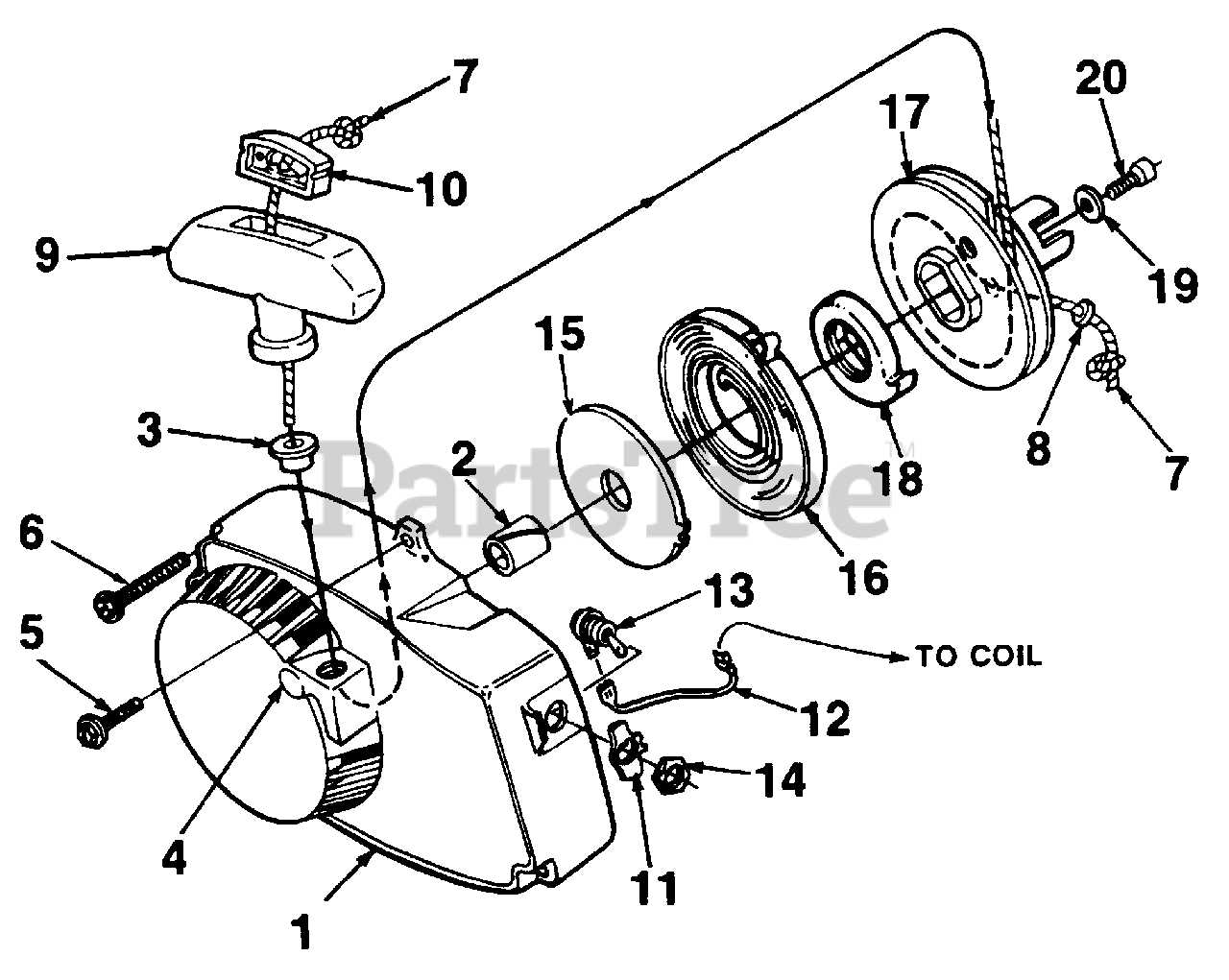

- Starter Mechanism: Facilitates the initial ignition of the power unit, allowing for ease of use.

Each of these components plays a vital role in the tool’s functionality, and understanding their individual contributions can significantly improve both safety and effectiveness during use.

- Ensure regular checks on the power unit for optimal performance.

- Maintain the guide bar to prevent wear and tear.

- Sharpen the cutting chain frequently for efficient cutting.

- Monitor the throttle control for responsiveness.

- Inspect the fuel system to prevent leaks or clogs.

- Test the starter mechanism to ensure reliable ignition.

By paying attention to these essential elements, users can achieve a higher level of efficiency and prolong the lifespan of their cutting tool.

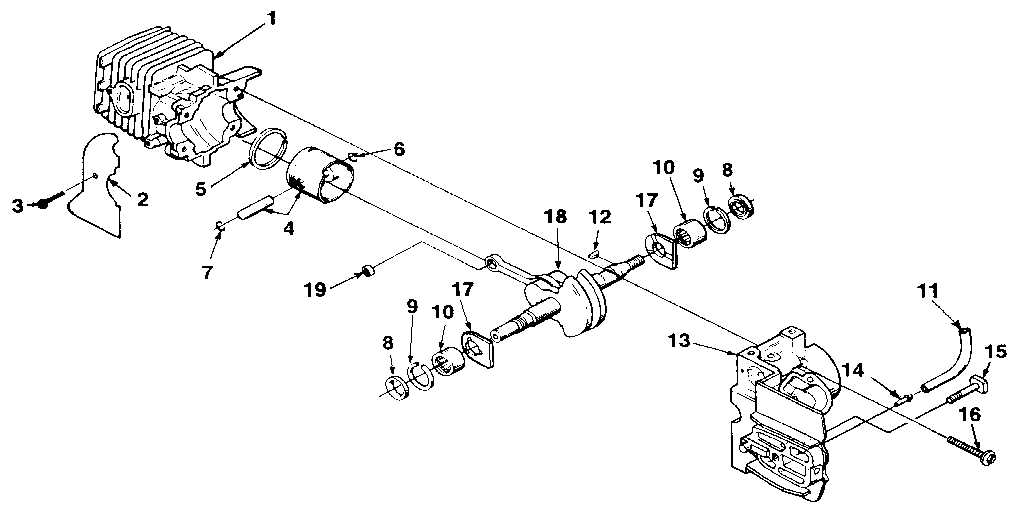

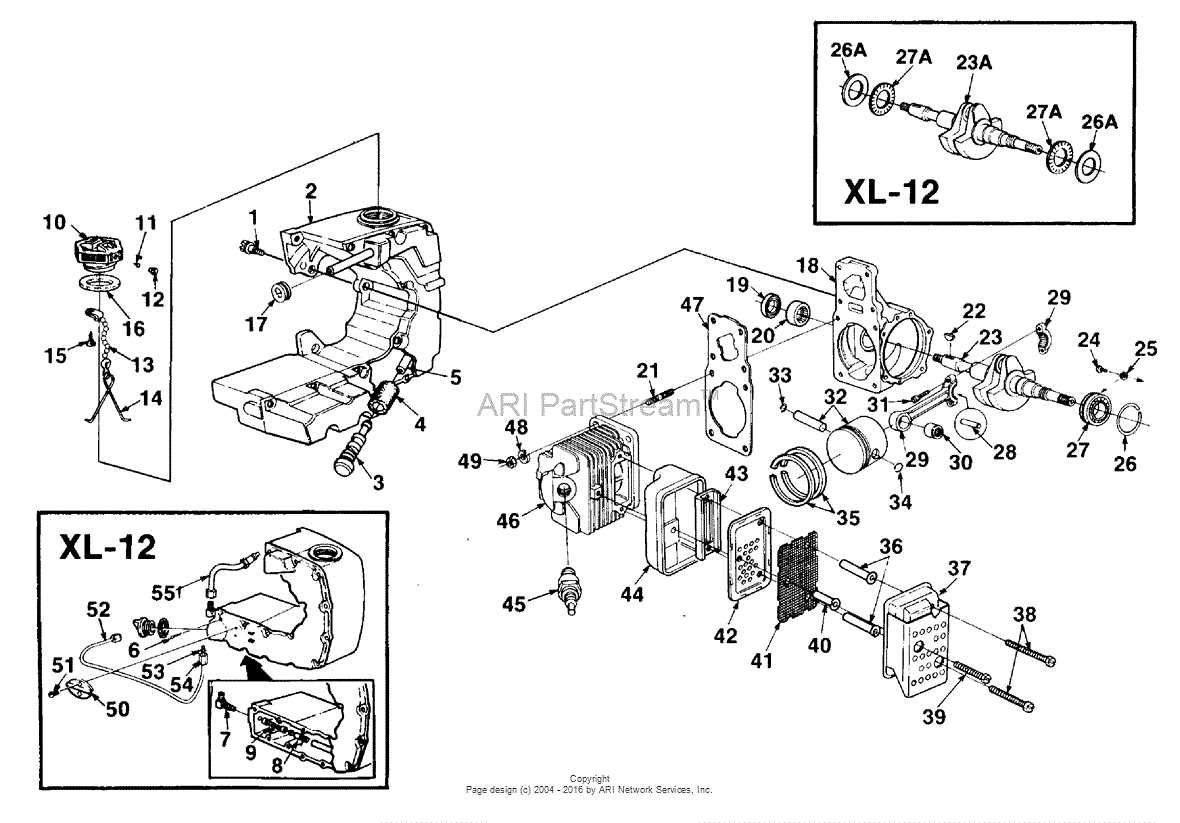

Identifying Components in Diagrams

Understanding the layout of various elements in a schematic representation is crucial for effective maintenance and repairs. Each symbol and line serves a specific purpose, helping users to locate and identify essential features within the system. Mastering this skill allows for smoother troubleshooting and enhances overall operational efficiency.

Key Elements to Recognize

- Labels: These provide vital information about each component, often indicating their function or model number.

- Connections: Arrows and lines depict how different elements are linked, guiding users in tracing flow and interactions.

- Shapes: Different geometrical figures represent various parts, with each shape having a universally accepted meaning.

Steps for Effective Identification

- Start by familiarizing yourself with the overall layout.

- Examine labels closely to understand the function of each element.

- Trace connections to visualize the interaction between components.

- Refer to a legend if available, as it often clarifies symbols and functions.

Common Issues with Homelite XL

When operating outdoor power equipment, users may encounter various challenges that can hinder performance. Understanding these common problems is crucial for effective maintenance and troubleshooting. Below are some frequent issues reported by users of these devices.

Performance Problems

- Difficulty Starting: Often attributed to fuel quality, spark plug condition, or air filter clogs.

- Inconsistent Power: This can result from a dirty carburetor or fuel line obstructions.

- Overheating: Insufficient lubrication or prolonged use without breaks can cause overheating issues.

Mechanical Failures

- Chain Tension Issues: Improper tension can lead to excessive wear or chain derailment.

- Brake Malfunctions: A faulty brake can affect safety and should be checked regularly.

- Vibration Problems: Excessive vibration may indicate imbalanced components or wear and tear on internal parts.

Addressing these common challenges promptly can extend the lifespan of your equipment and ensure it operates effectively.

Where to Find Replacement Parts

When it comes to maintaining outdoor power tools, sourcing the right components is essential for optimal performance. Fortunately, there are several avenues to explore for acquiring the necessary items, ensuring that your equipment remains in top condition.

Online Retailers

Many dedicated online platforms specialize in offering a wide selection of components for various models. Websites like Amazon and eBay often feature a range of options, from original to aftermarket solutions. Be sure to check customer reviews and ratings to ensure the quality of your chosen items.

Local Repair Shops

Visiting local service centers can also be beneficial. These establishments typically stock common components and can provide personalized assistance. Additionally, they might have insights into compatible alternatives that suit your specific needs.

Remember to have your model information handy when searching for components, as this will facilitate a smoother purchasing process and help you find the most suitable replacements.

Using the Parts Diagram Effectively

Understanding the assembly of complex machinery can greatly enhance maintenance and repair processes. A visual reference not only clarifies the arrangement of components but also simplifies the identification of each part’s function. By leveraging such resources, users can ensure efficient upkeep and troubleshoot issues with greater confidence.

Identifying Components

Utilizing a visual reference allows for easy identification of various elements within the machinery. Each section typically includes labels and numbers corresponding to individual components, facilitating quick recognition and sourcing of replacements if needed.

Streamlining Repairs

When undertaking repairs, having a visual guide can significantly streamline the process. Users can follow the illustrated steps to disassemble and reassemble the equipment, minimizing the risk of misplacement or damage to any parts.

| Component | Description | Importance |

|---|---|---|

| Fuel Tank | Holds the fuel for operation | Essential for power supply |

| Guide Bar | Supports the cutting chain | Crucial for cutting accuracy |

| Chain | Drives the cutting action | Vital for effective operation |

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and optimal performance of your equipment. By following a few key practices, you can significantly extend the life of your machinery and enhance its efficiency. Here are some practical tips to keep in mind.

Routine Cleaning

- Remove debris after each use to prevent buildup.

- Check and clean the air filter regularly to maintain airflow.

- Inspect the exterior for signs of wear or damage.

Proper Lubrication

- Use the recommended oil type for the moving components.

- Regularly check lubrication levels and replenish as necessary.

- Apply lubricant in areas prone to friction to minimize wear.

By incorporating these maintenance practices into your routine, you can ensure that your equipment remains in peak condition for years to come.

DIY Repairs for Homelite Chainsaws

When it comes to maintaining your outdoor power equipment, understanding how to tackle repairs can save you both time and money. Engaging in do-it-yourself fixes not only empowers you but also enhances the lifespan of your machinery. This section will guide you through some common repair procedures, enabling you to address issues with confidence.

Identifying Common Issues

Before you dive into repairs, it’s essential to identify the typical problems that may arise. Whether it’s difficulty starting, unusual noises, or performance issues, recognizing these symptoms is the first step toward a successful fix. Regular maintenance checks can help catch these concerns early, preventing more extensive damage.

Essential Repair Techniques

Once you’ve pinpointed the issue, applying basic repair techniques can often resolve the problem. Start by consulting manuals or online resources for guidance on the specific mechanisms involved. Utilizing appropriate tools is crucial; ensure you have everything from wrenches to screwdrivers ready at hand. Safety first! Always wear protective gear and follow safety protocols while working on your equipment.

For those more intricate fixes, like carburetor cleaning or chain adjustments, consider seeking tutorials that can provide visual aids. By taking the time to learn these skills, you can maintain optimal performance and enjoy a more efficient experience.

Safety Guidelines for Chainsaw Use

When operating power tools designed for cutting, prioritizing safety is essential. Understanding proper techniques and following precautionary measures can significantly reduce the risk of accidents and injuries. Familiarity with safety protocols ensures a more efficient and secure working environment.

Preparation Before Use

Before starting, always wear appropriate protective gear, including gloves, goggles, and a hard hat. Ensure that your footwear provides adequate grip and protection. Check the equipment for any signs of wear or damage, and perform routine maintenance to keep it in optimal condition. Having a clear workspace and removing potential hazards will further enhance safety.

Operational Safety Measures

Maintain a firm grip and stance while working, keeping both hands on the tool at all times. Stay focused and avoid distractions, as they can lead to errors. Be mindful of your surroundings, especially regarding bystanders and obstacles. If the tool requires adjustment or if a jam occurs, always turn it off and wait for it to come to a complete stop before proceeding.

By adhering to these guidelines, users can ensure a safer experience while utilizing cutting equipment, thus promoting not only personal safety but also the well-being of those nearby.

Upgrading Your Homelite XL Parts

Enhancing the efficiency and longevity of your outdoor power equipment can significantly improve its performance. With a variety of components available, users can tailor their machines to better suit their specific needs. This section will guide you through the process of upgrading essential elements to achieve optimal results.

Before you begin, it’s important to consider the benefits of upgrading:

- Improved performance and cutting efficiency.

- Increased durability and reliability.

- Enhanced safety features.

- Better fuel efficiency.

Here are some key upgrades to consider:

- Bar and Chain: Upgrading to a high-quality bar and chain can enhance cutting precision and reduce wear.

- Air Filter: A more efficient air filter can improve airflow, leading to better combustion and power output.

- Ignition System: Replacing or enhancing the ignition system can result in quicker starts and smoother operation.

- Fuel System: Upgrading fuel lines and filters ensures better fuel delivery and reduces the risk of clogging.

As you plan your upgrades, make sure to source components that are compatible and of high quality. Consulting with professionals or accessing detailed manuals can provide additional insights into the best choices for your equipment. Taking the time to enhance these critical components will lead to a more efficient and reliable machine for all your outdoor tasks.

Frequently Asked Questions About Parts

This section aims to address common inquiries regarding components essential for maintenance and repair. Understanding these elements can significantly enhance your experience and ensure the longevity of your equipment.

What should I consider when selecting replacements?

When choosing substitutes, it is crucial to examine compatibility with your model. Look for specifications that match your original items, and prioritize quality to maintain performance standards. Researching trusted manufacturers can also provide peace of mind.

How do I identify the right component for my equipment?

Identifying the appropriate element involves checking model numbers and manufacturer details. Utilizing resourceful online platforms or user manuals can simplify this process, ensuring you acquire exactly what you need.