Understanding the Parts Diagram of the Husqvarna 340 Chainsaw

Every outdoor enthusiast knows the importance of a well-functioning cutting instrument. Whether for clearing land, maintaining a garden, or engaging in woodwork, familiarity with the internal structure of these tools can significantly enhance their longevity and performance. This section will explore the various elements that contribute to the efficient operation of such equipment.

By gaining insight into the arrangement and functionality of each component, users can better troubleshoot issues and perform maintenance tasks. An effective grasp of how these parts interact not only aids in repair but also empowers operators to optimize their tool’s capabilities.

In the following sections, we will delve into the intricate details of the assembly, providing a comprehensive overview that will serve as a valuable resource for anyone looking to maximize their cutting experience. Whether you’re a novice or a seasoned user, understanding these intricacies is crucial for effective management and care.

Understanding Husqvarna 340 Chainsaw Components

To effectively operate and maintain your cutting tool, it is essential to familiarize yourself with its various elements. Each component plays a crucial role in the overall functionality and performance, ensuring smooth operation and longevity. Grasping the purpose and interrelation of these parts can significantly enhance your user experience.

Engine: At the heart of the device lies the power source, responsible for generating the necessary energy for cutting tasks. This component’s efficiency directly influences the tool’s performance.

Guide Bar: This elongated metal piece supports the cutting chain, enabling precise and controlled cuts. The length and thickness of the bar are vital for handling different types of jobs.

Cutting Chain: The chain consists of sharp links that rotate around the guide bar, executing the cutting action. Regular maintenance, such as sharpening and tension adjustment, is key to ensuring optimal performance.

Air Filter: To maintain engine health, the air filter prevents debris from entering the power unit, promoting efficient combustion and reducing wear.

Fuel System: This includes the tank and lines that transport fuel to the engine. Proper management of the fuel mixture is essential for smooth operation and avoiding damage.

Handle Assembly: Designed for comfort and control, the handles provide a safe grip, allowing the user to maneuver the tool effectively while minimizing fatigue.

By understanding these essential components and their functions, users can ensure better maintenance, troubleshooting, and overall performance of their equipment.

Key Features of Husqvarna 340 Model

This section highlights the essential characteristics of a popular outdoor tool designed for efficiency and durability. Understanding these features helps users appreciate its functionality and versatility in various tasks.

- Powerful Engine: Equipped with a robust motor that ensures optimal performance for demanding jobs.

- Lightweight Design: Crafted for easy handling, allowing prolonged use without fatigue.

- Ergonomic Grip: Designed with user comfort in mind, promoting better control and precision.

- Quick-Start System: Features technology that enables faster ignition, reducing downtime.

- Advanced Air Filtration: Maintains engine efficiency and extends service intervals, enhancing reliability.

These key attributes make it an ultimate choice for both professionals and enthusiasts looking for a reliable tool to tackle various outdoor projects.

Common Issues with Chainsaw Parts

Understanding frequent problems that can arise with various components of a cutting tool is crucial for maintaining optimal performance. These issues can lead to inefficiency, reduced safety, and even costly repairs if not addressed promptly.

Wear and Tear

Components like the blade and guide bar often experience significant wear due to constant use. Dull blades can hinder cutting efficiency, while worn bars can cause misalignment, leading to further complications.

Fuel System Problems

Issues within the fuel system, such as clogged filters or faulty lines, can impede proper operation. These malfunctions may lead to starting difficulties or inconsistent power delivery during use.

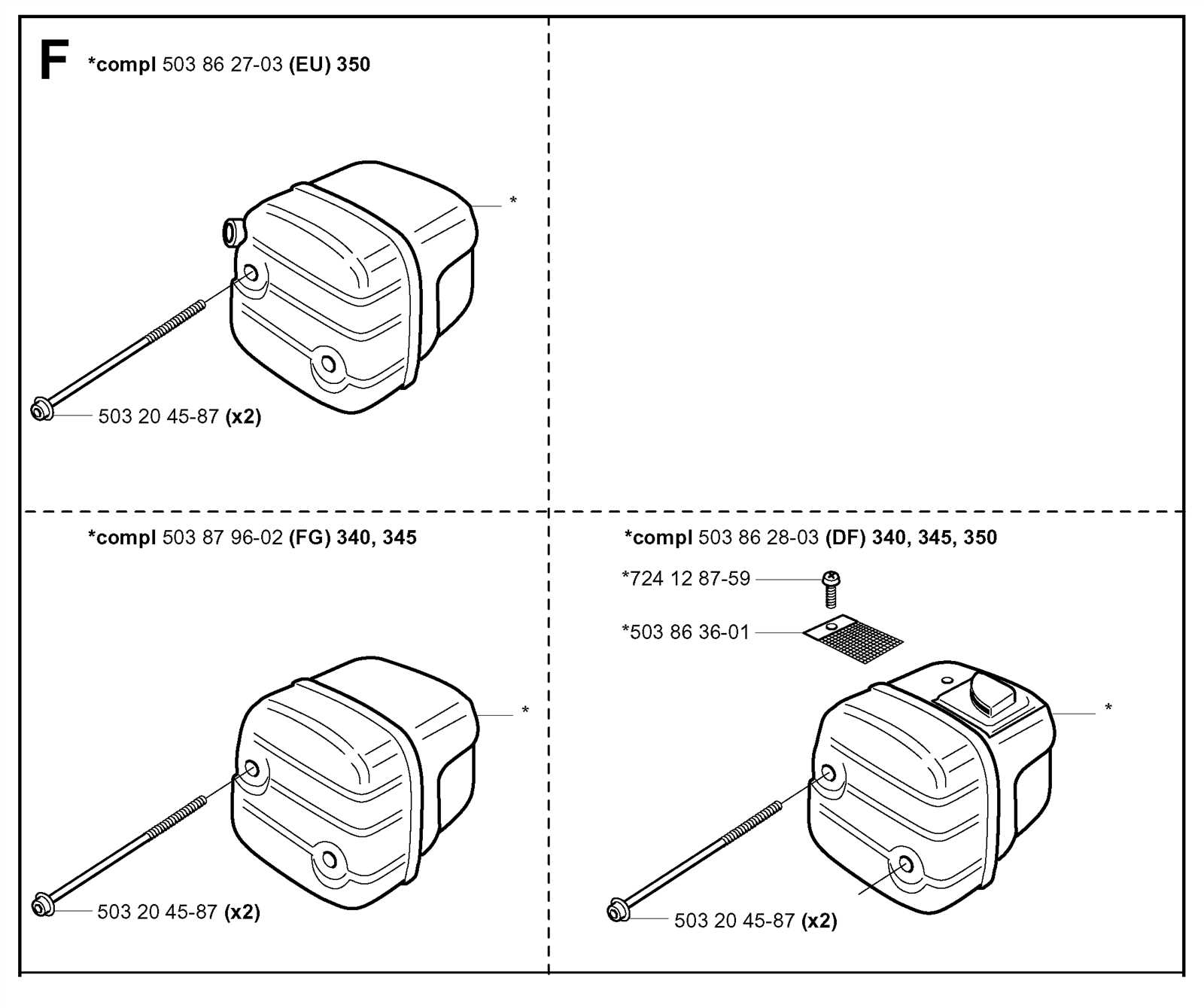

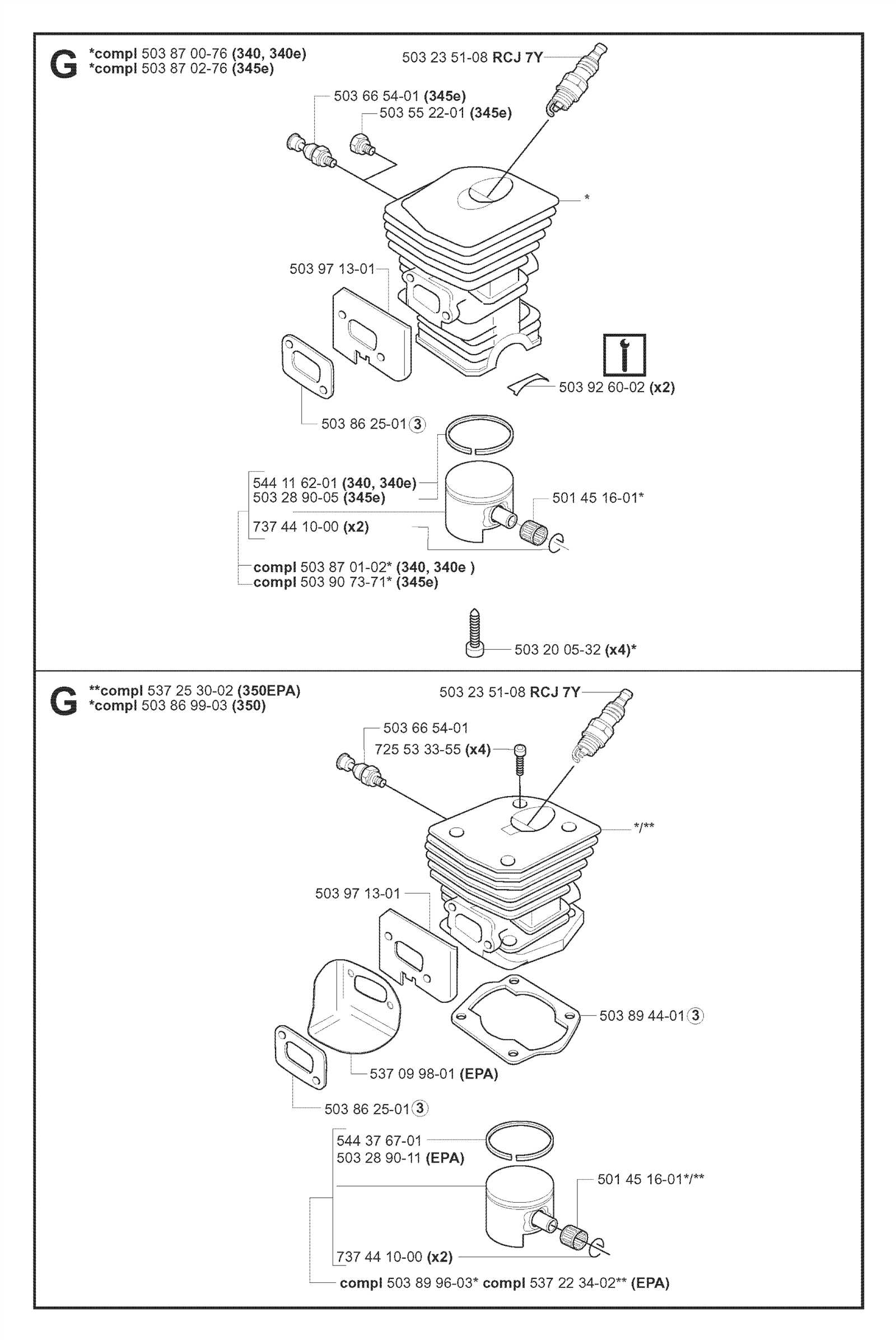

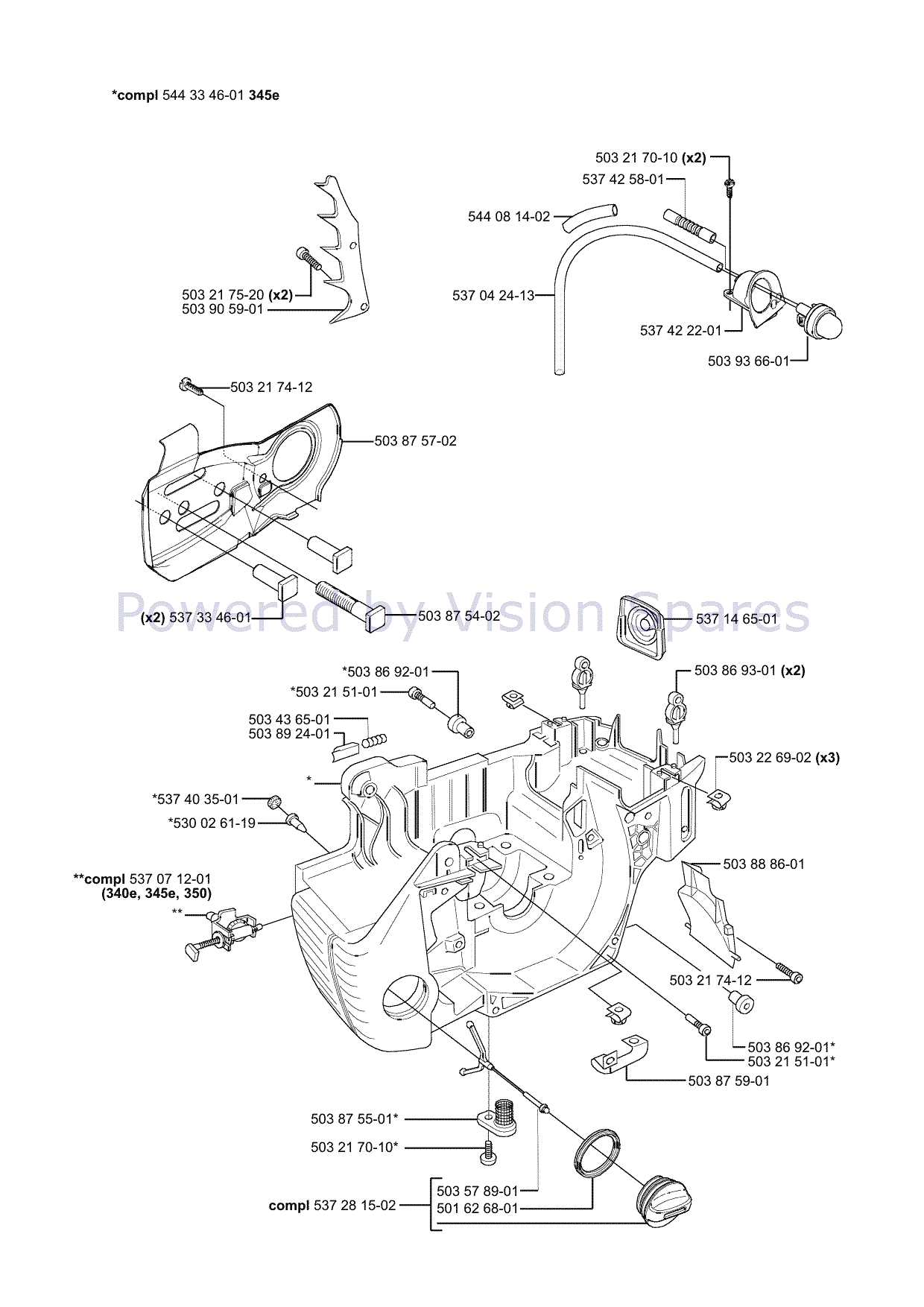

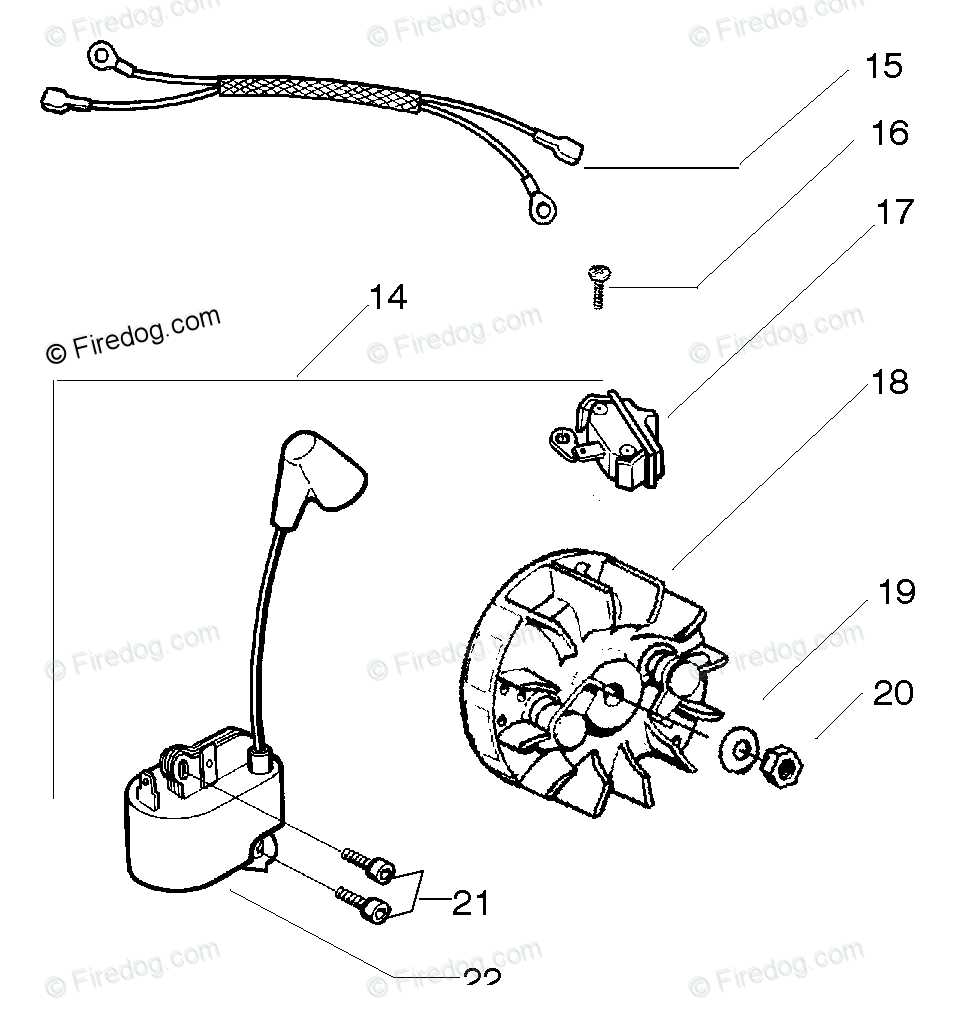

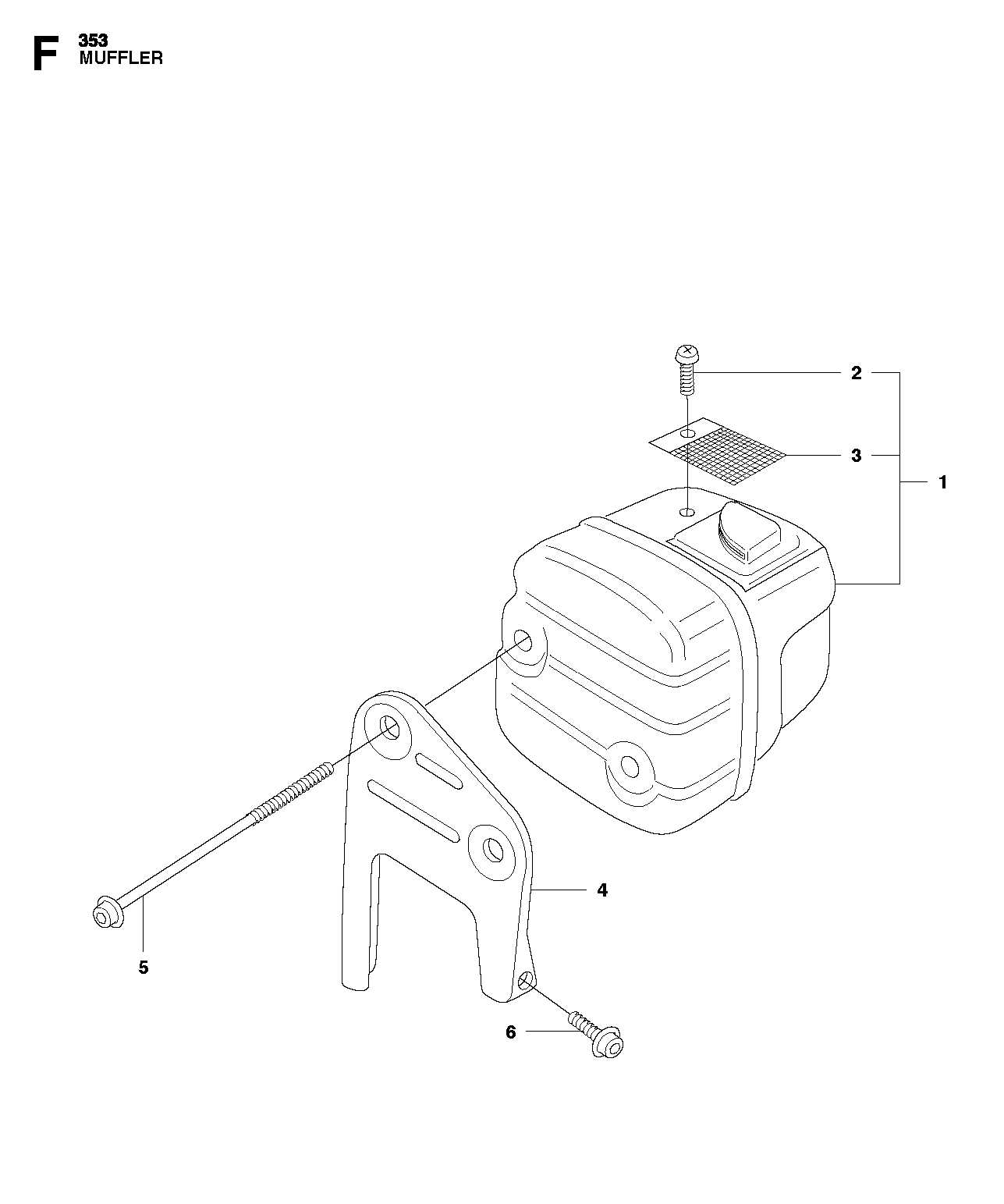

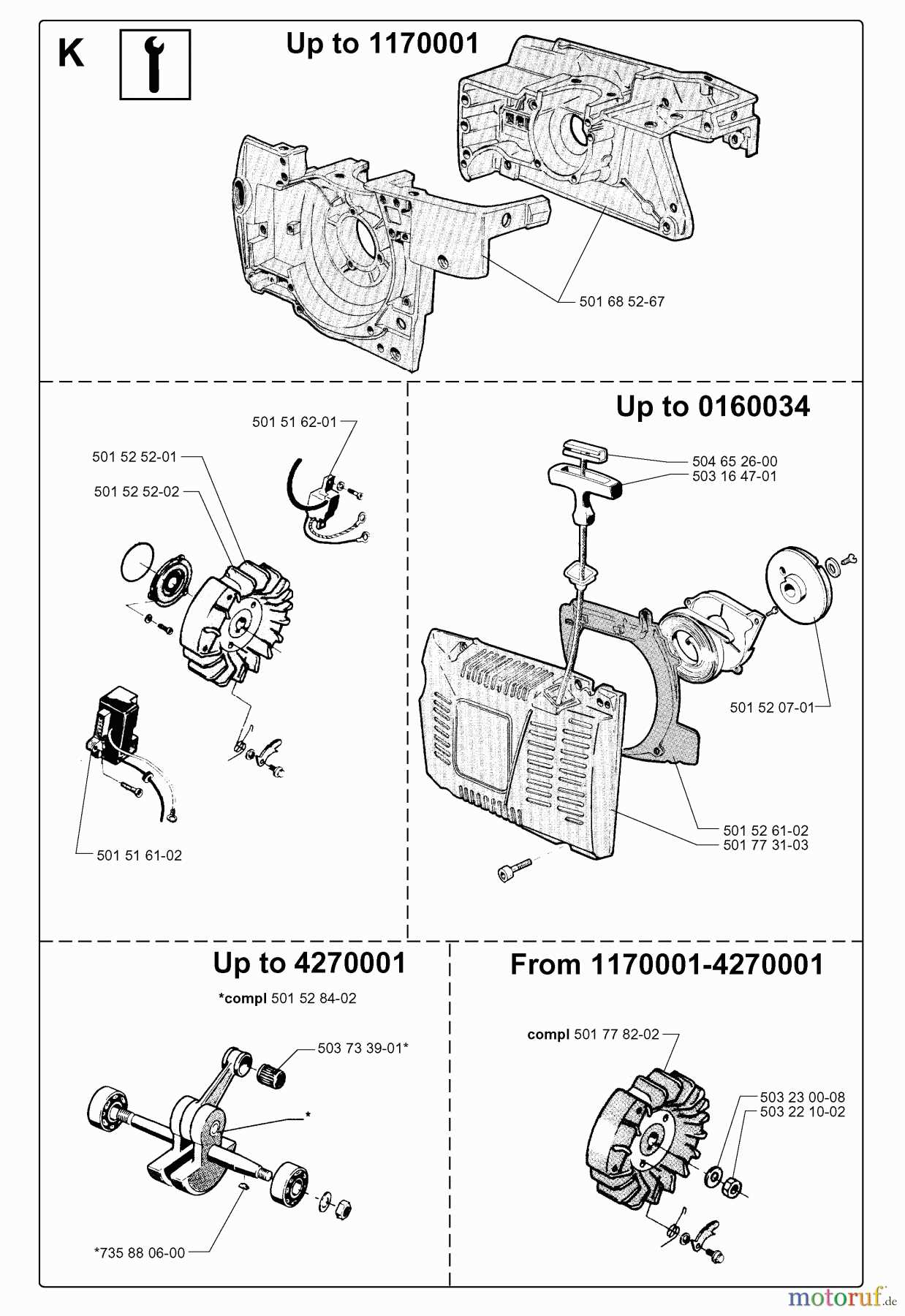

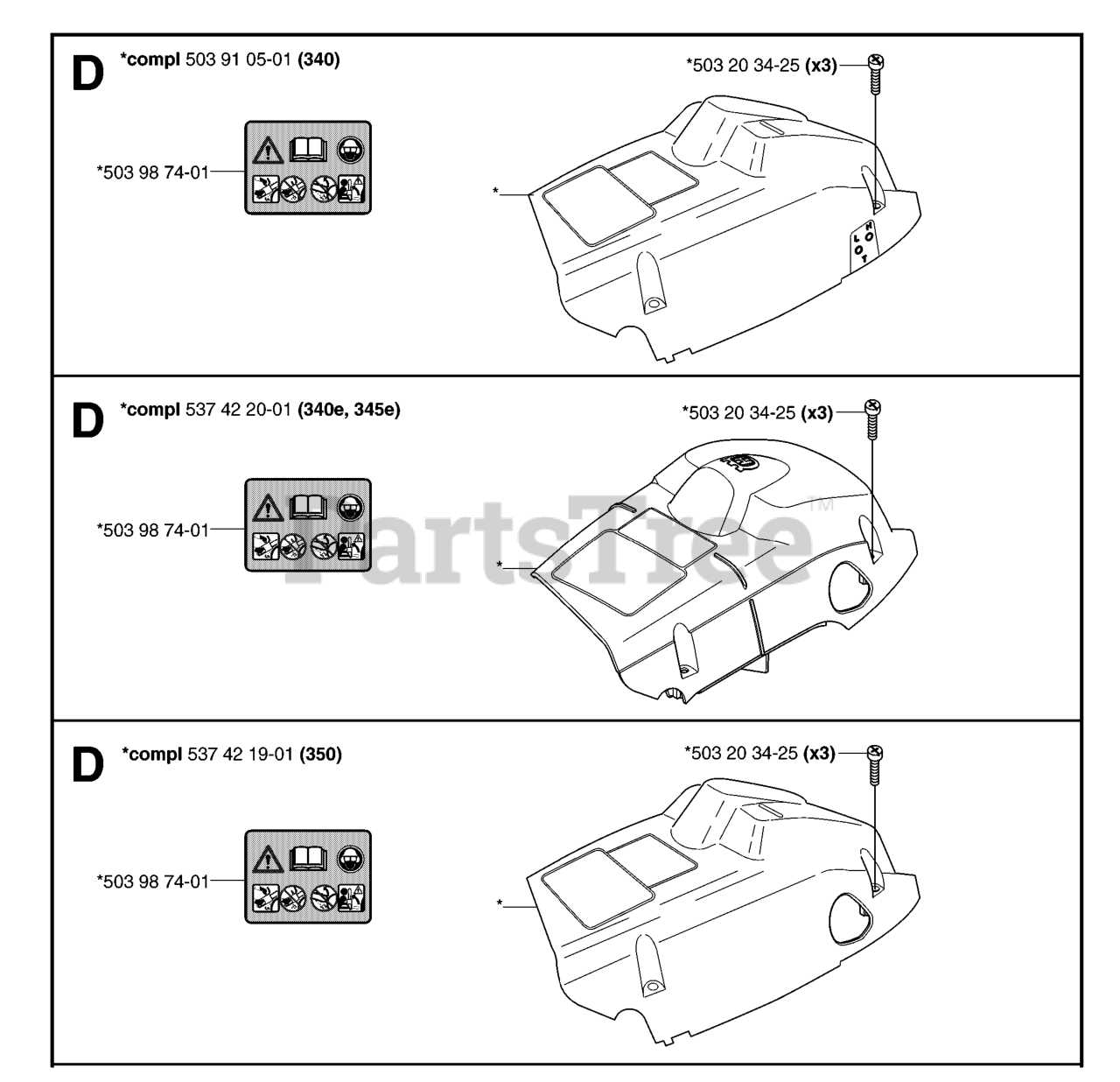

Visual Representation of Parts Diagram

The significance of a clear visual outline cannot be overstated when it comes to understanding the components of any mechanical device. A well-structured illustration not only enhances comprehension but also aids in effective troubleshooting and maintenance. By providing a detailed overview of the individual elements, users can easily identify and locate necessary items, streamlining repair processes.

Importance of Accurate Illustrations

Accurate depictions serve as invaluable resources, especially for those unfamiliar with the intricacies of machinery. A comprehensive visual guide allows users to quickly grasp the arrangement and relationship between different components. This clarity can prevent common errors during assembly or disassembly, ultimately extending the lifespan of the equipment.

Enhancing User Experience

Integrating visual references into manuals or instructional materials enriches the overall experience for users. With enhanced understanding and improved accessibility to information, individuals can approach their tasks with greater confidence. Whether for novices or seasoned experts, a clear representation simplifies complex procedures and fosters a more efficient workflow.

How to Interpret Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair of equipment. These visuals serve as essential guides, allowing users to identify components, their relationships, and how they fit together. Mastering the interpretation of these graphics can streamline the repair process and enhance your overall knowledge of the machinery.

Breaking Down the Visuals

Each illustration typically includes a variety of symbols and labels that correspond to individual components. Familiarizing yourself with these elements is the first step. Pay attention to the numbers or letters next to each item; these often link to a list of specifications or descriptions that provide further details. Observing the arrangement and connections between parts can also reveal how they interact during operation.

Consulting the Reference Guide

Alongside the visual representation, a reference guide usually accompanies the illustration. This guide contains crucial information, such as part numbers, descriptions, and sometimes even installation instructions. Utilizing both the graphic and the accompanying text will enable you to acquire a comprehensive understanding of the system, ultimately aiding in troubleshooting and effective repair strategies.

Essential Maintenance for Optimal Performance

Regular upkeep is crucial for ensuring that your equipment operates efficiently and lasts longer. Proper care not only enhances performance but also minimizes the risk of unexpected failures, allowing for seamless operation during critical tasks.

Key Maintenance Tasks

| Task | Frequency | Description |

|---|---|---|

| Air Filter Cleaning | Every 10 hours | Remove and clean to prevent clogging and ensure optimal airflow. |

| Chain Lubrication | Before each use | Apply appropriate lubricant to reduce friction and wear. |

| Spark Plug Inspection | Every 25 hours | Check for wear and replace if necessary to ensure proper ignition. |

| Fuel System Cleaning | Every season | Flush and clean to remove impurities that could hinder performance. |

Importance of Regular Inspections

Conducting frequent assessments of your equipment can prevent minor issues from escalating into major problems. By addressing wear and tear promptly, you can maintain efficiency and prolong the lifespan of your machinery.

Where to Find Replacement Parts

Locating suitable components for your equipment can be essential for maintaining its functionality and performance. Fortunately, there are several avenues available to source these vital elements effectively.

Online Retailers

Numerous e-commerce platforms specialize in offering a wide array of components for various machinery. Websites like Amazon, eBay, and dedicated tool retailers provide a convenient way to browse and compare options. Make sure to read customer reviews to ensure quality and compatibility.

Local Repair Shops

Visiting local repair centers or hardware stores can yield immediate assistance. Staff members often possess extensive knowledge and can guide you to the right replacements. Additionally, supporting local businesses can strengthen your community ties.

Assembly Instructions for Husqvarna 340

Proper assembly of your equipment is crucial for optimal performance and safety. Following the right steps ensures that each component fits together seamlessly, allowing for efficient operation. This section will guide you through the assembly process, highlighting essential steps and tips for a successful setup.

| Step | Description |

|---|---|

| 1 | Gather all necessary components and tools required for assembly. |

| 2 | Start by attaching the handle, ensuring it is securely fastened. |

| 3 | Next, connect the motor unit to the main body, aligning the connection points accurately. |

| 4 | Install the protective casing, making sure all clips are engaged properly. |

| 5 | Attach the guide bar and chain, following the manufacturer’s specifications for tension. |

| 6 | Fill the fuel and oil reservoirs according to the recommended guidelines. |

| 7 | Finally, perform a visual inspection to confirm that all parts are in place and secure. |

Adhering to these instructions will help ensure your device is ready for use, providing both safety and efficiency during operation.

Comparing Husqvarna 340 with Other Models

When evaluating different models in the world of power tools, it’s essential to consider various factors that influence performance, usability, and durability. This comparison aims to highlight the distinctive features and capabilities of one specific model against its contemporaries, allowing potential users to make informed choices based on their specific needs.

Performance Metrics

In terms of engine power and cutting efficiency, this model stands out with its balanced output, making it suitable for a range of applications. When placed side by side with similar products, the differences in torque and speed become apparent. Many users find that while some alternatives may offer higher horsepower, the overall handling and weight distribution of this model contribute to a more user-friendly experience.

Usability and Features

The ergonomics and design elements also play a significant role in usability. Features such as anti-vibration systems and easy-start mechanisms enhance comfort during prolonged use. Compared to other models, this tool excels in providing a lightweight yet robust option that appeals to both novice and experienced operators. Additionally, maintenance requirements differ; some alternatives may necessitate more frequent servicing, while this model is designed for simplicity, reducing downtime.

In summary, understanding the nuances between different tools helps users select the most appropriate option for their tasks. This specific model offers a compelling combination of performance, ergonomics, and ease of maintenance that sets it apart from the competition.

Identifying OEM vs. Aftermarket Parts

Understanding the differences between original equipment manufacturer (OEM) components and those produced by third parties is essential for optimal performance and longevity of your equipment. This knowledge enables users to make informed choices that can affect functionality, warranty, and overall satisfaction.

OEM components are crafted by the original manufacturer, ensuring a perfect fit and compatibility. They often come with a higher price tag, reflecting the quality and reliability associated with the brand. Conversely, aftermarket alternatives are produced by independent companies and may vary in quality and compatibility. While they can be more affordable, it is crucial to research their performance and durability to avoid potential issues.

When selecting between these options, consider factors such as cost, quality, and warranty implications. Doing thorough research will help you make the ultimate decision that best suits your needs.

Upgrades for Enhanced Chainsaw Efficiency

Improving the performance of your cutting tool can significantly increase productivity and extend the lifespan of the equipment. Various enhancements can be implemented to optimize power, reduce wear, and enhance overall functionality.

Key Areas for Improvement

- Engine Modifications: Upgrading to a higher displacement engine can boost power output, enabling smoother cuts through tougher materials.

- Chain Upgrades: Switching to a low-profile or high-performance chain can improve cutting speed and precision.

- Bar Enhancements: Utilizing a lightweight, durable bar reduces fatigue and increases maneuverability.

Additional Tips for Optimal Use

- Regularly maintain and sharpen the cutting components to ensure maximum efficiency.

- Consider adding vibration dampening features to enhance user comfort.

- Invest in a high-quality fuel system for better fuel efficiency and reduced emissions.

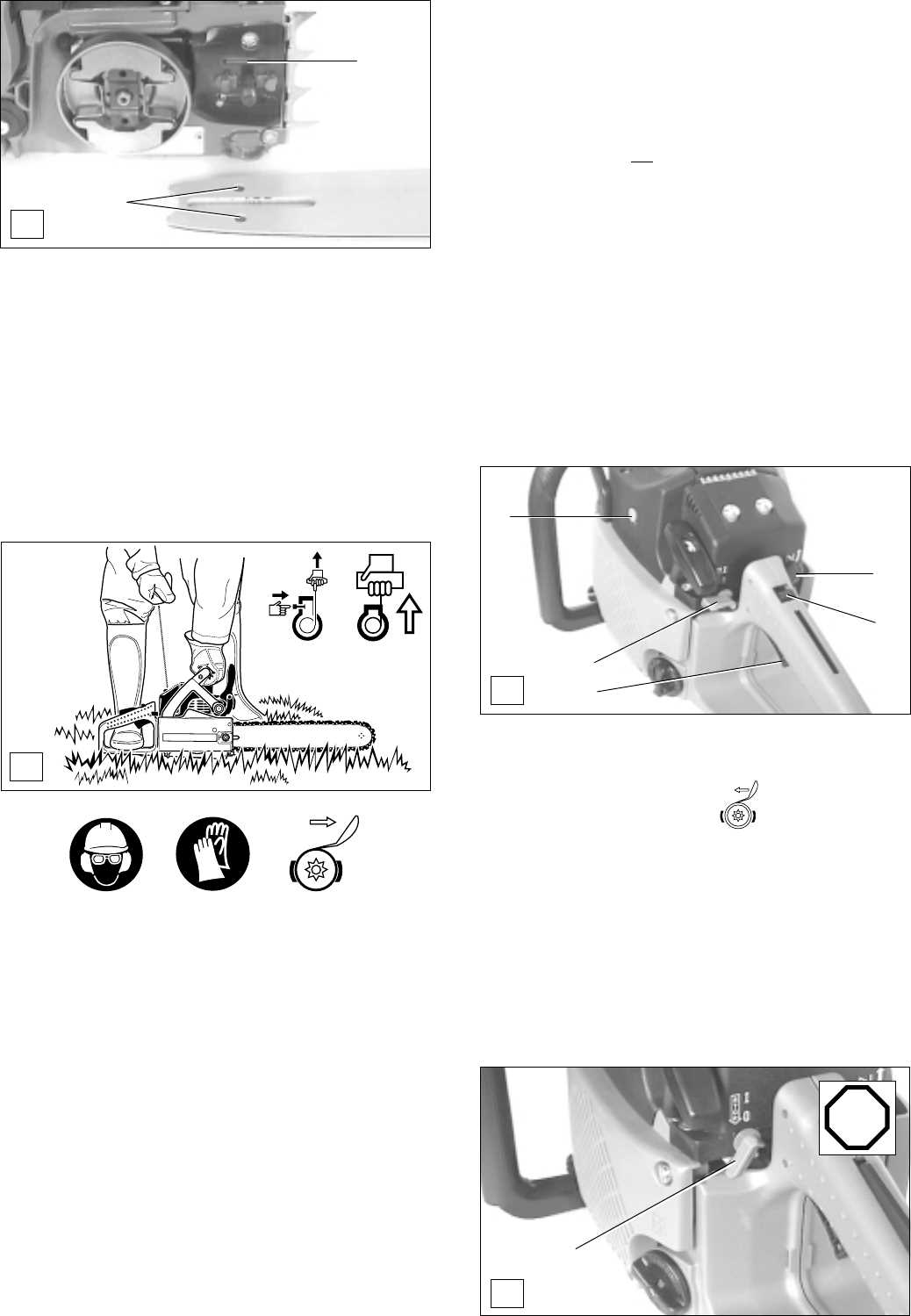

Safety Tips for Chainsaw Users

Operating power tools can be hazardous, and it’s essential to prioritize safety to prevent accidents and injuries. Understanding best practices and protective measures is crucial for anyone engaging in cutting tasks.

Wear Appropriate Gear: Always don safety goggles, gloves, and a helmet to protect yourself from debris and potential injuries.

Maintain a Clear Workspace: Ensure the area around you is free of obstacles to avoid tripping or getting distracted while working.

Check Equipment Before Use: Regularly inspect your tool for any damage or wear. Ensure all safety features are functional before starting.

Be Mindful of Your Surroundings: Always be aware of your environment, including nearby people, animals, and overhead hazards, such as power lines.

Use Proper Techniques: Familiarize yourself with safe cutting techniques to minimize risks. Always maintain a firm grip and stance.

Stay Focused: Avoid distractions while operating your equipment. If you’re tired or under the influence, postpone your task.

Know Emergency Procedures: Be prepared for emergencies by knowing how to stop the tool quickly and having a first aid kit on hand.