Understanding the Husqvarna 55 Rancher Chainsaw Parts Diagram

When it comes to maintaining and operating a high-performance cutting device, having a clear understanding of its individual components is essential. Each element plays a crucial role in ensuring efficiency and safety during use. Familiarity with the arrangement and function of these elements can significantly enhance the user experience and prolong the life of the equipment.

Visual representations of these components provide invaluable insight into how they interact and contribute to the overall functionality of the tool. Whether you are a seasoned professional or a casual user, being able to identify and comprehend these various sections can aid in effective troubleshooting and maintenance.

In this exploration, we will delve into the specific sections that make up this robust instrument, highlighting their roles and how they work together. This knowledge is not only beneficial for repairs but also empowers users to optimize their experience with the device, ensuring it operates at peak performance for years to come.

Understanding Husqvarna 55 Rancher

This section explores a powerful tool designed for cutting and trimming tasks, ideal for both professionals and hobbyists. Its robust construction and efficient performance make it a favorite among users who demand reliability and ease of use.

Key Features: This equipment boasts a strong engine that provides exceptional power, enabling users to tackle various materials effortlessly. Additionally, its ergonomic design ensures comfortable handling during extended use.

Maintenance Tips: Regular upkeep is crucial for optimal performance. Ensure that the blade remains sharp, the fuel is fresh, and all components are inspected frequently to prolong the lifespan of the device.

Key Features of the Chainsaw

This powerful cutting tool is designed to deliver high performance and efficiency, making it an essential asset for various tasks, from felling trees to trimming branches. Its robust design and advanced technology enable users to tackle demanding jobs with ease.

Performance and Power

- High-capacity engine for optimal cutting power.

- Efficient fuel consumption, allowing for longer operational periods.

- Quick acceleration for immediate responsiveness during use.

User-Friendly Design

- Lightweight construction for enhanced maneuverability.

- Ergonomic handle design to reduce fatigue during extended use.

- Easy-to-access controls for straightforward operation.

These features collectively contribute to a reliable and effective tool that meets the needs of both professionals and hobbyists alike.

Importance of Proper Maintenance

Regular upkeep of any mechanical device is crucial for ensuring optimal performance and longevity. Neglecting routine checks can lead to diminished efficiency, increased wear, and ultimately, costly repairs. Understanding the significance of consistent care can enhance both safety and productivity.

Enhancing Performance

Well-maintained equipment operates more efficiently, resulting in smoother functionality. Regular inspection and servicing can identify potential issues before they escalate, ensuring that the machinery runs at its best.

Extending Lifespan

Proper maintenance practices not only enhance performance but also significantly prolong the life of the equipment. Investing time in regular checks and necessary adjustments can yield substantial savings by preventing premature breakdowns and replacements.

Common Issues and Solutions

Operating outdoor power tools can lead to various challenges, often stemming from wear and tear or improper maintenance. Understanding these common problems and their solutions can enhance efficiency and prolong the life of your equipment.

Engine Performance Problems

If you notice decreased power or stalling, check the fuel mixture and air filter. A clogged filter can restrict airflow, while an incorrect fuel ratio may affect combustion. Cleaning or replacing these components can resolve many performance issues.

Chain Malfunction

Inconsistent cutting or excessive vibration may indicate a need for chain adjustment or replacement. Regularly inspect the tension and ensure it is properly aligned. A worn-out chain should be replaced to maintain optimal cutting efficiency.

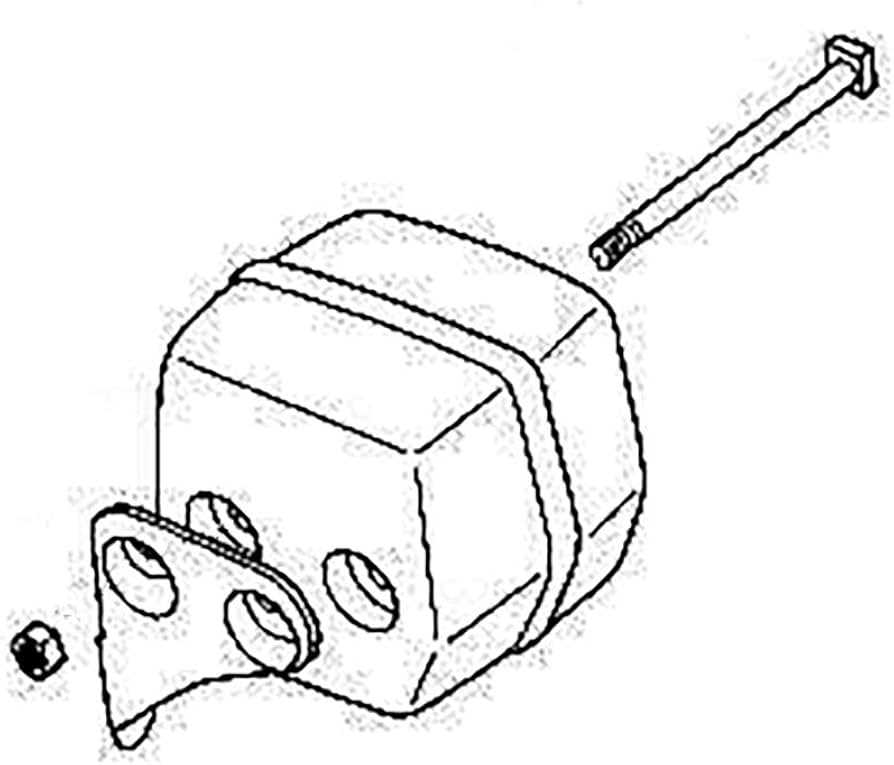

Essential Parts and Their Functions

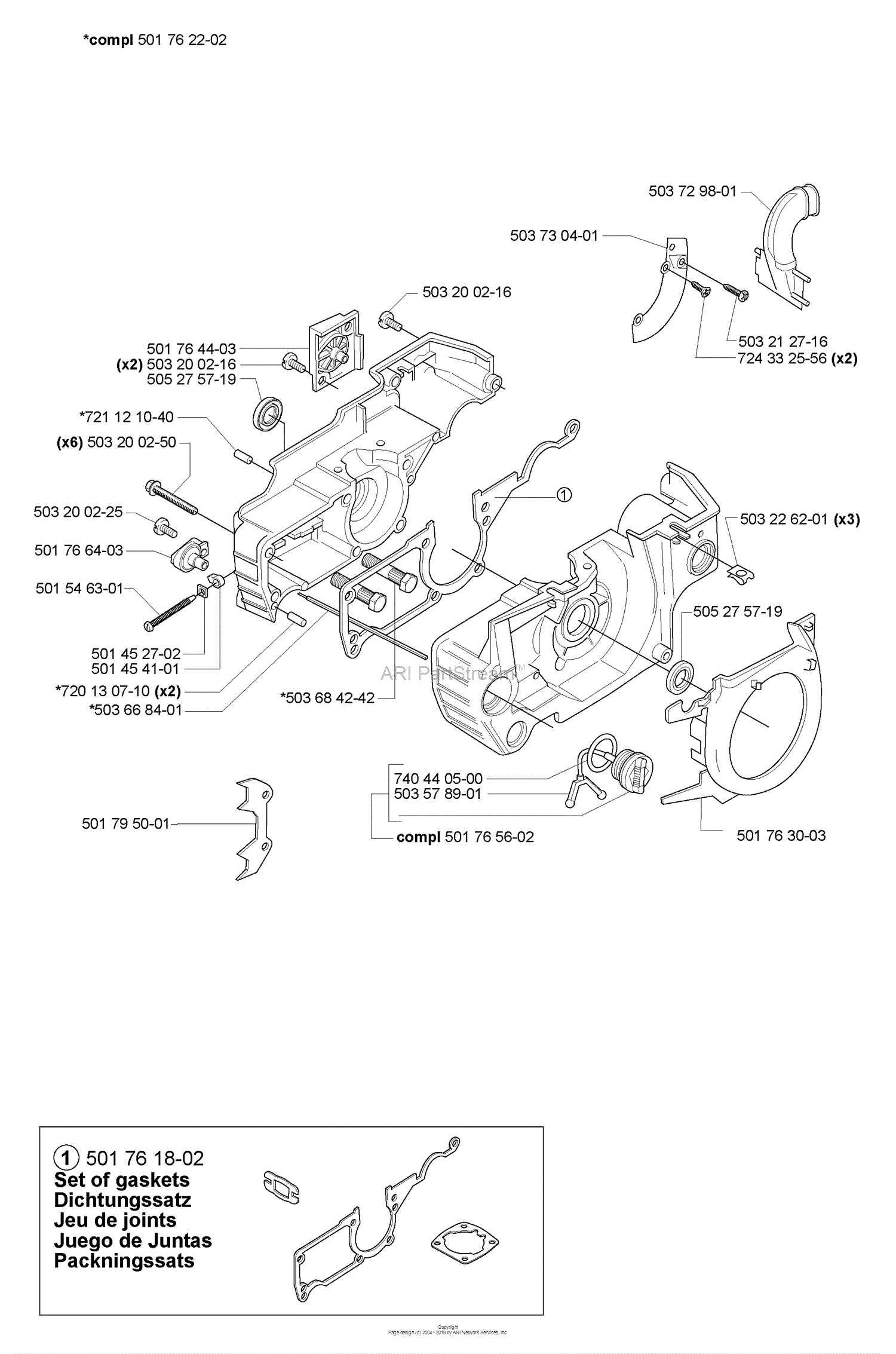

Understanding the key components of a cutting tool is crucial for effective operation and maintenance. Each element plays a vital role in ensuring performance, safety, and longevity. Here, we explore the main elements that contribute to the efficient functioning of this equipment.

Key Components Overview

| Component | Function |

|---|---|

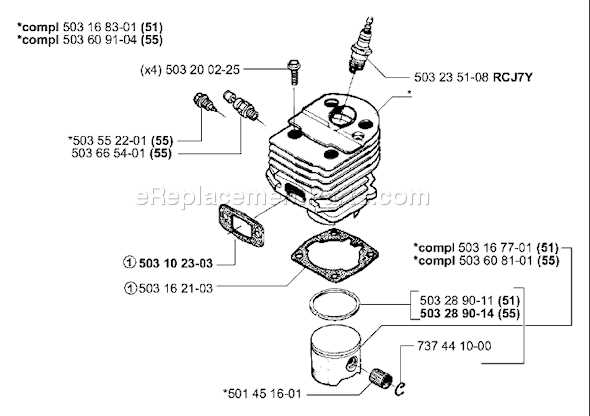

| Engine | Powers the unit and drives the cutting mechanism. |

| Guide Bar | Supports and directs the cutting chain during operation. |

| Cutting Chain | Engages with the material to perform the cutting action. |

| Clutch | Engages and disengages the cutting chain from the engine. |

| Fuel Tank | Holds the mixture of fuel and oil necessary for operation. |

Importance of Maintenance

Regular upkeep of these components not only enhances performance but also prolongs the lifespan of the tool. Ensuring each element is in optimal condition is essential for safe and effective use.

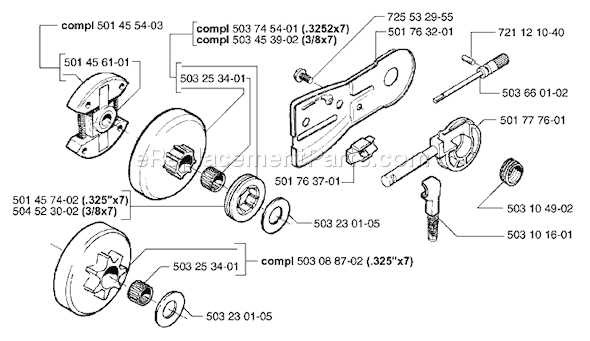

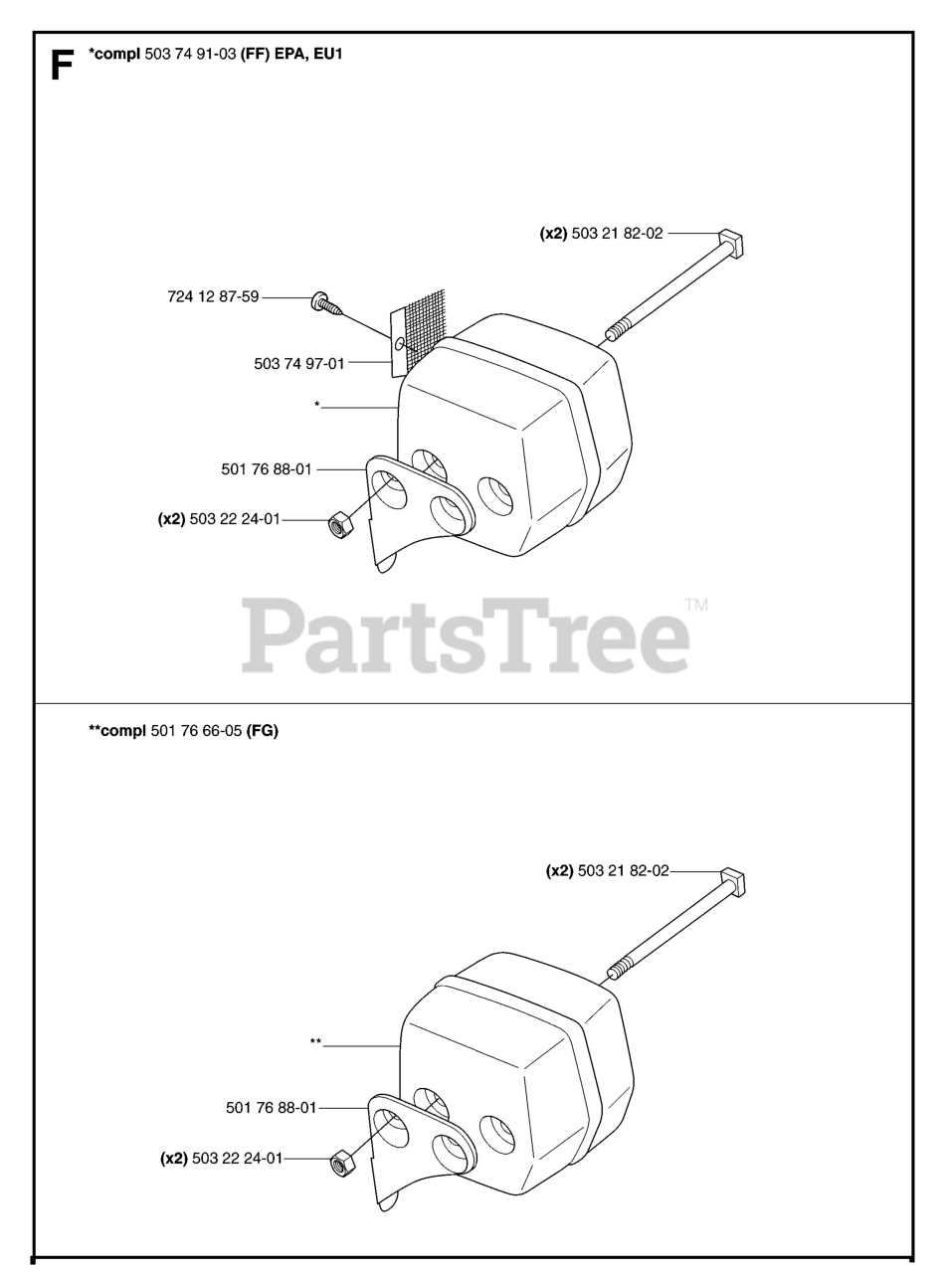

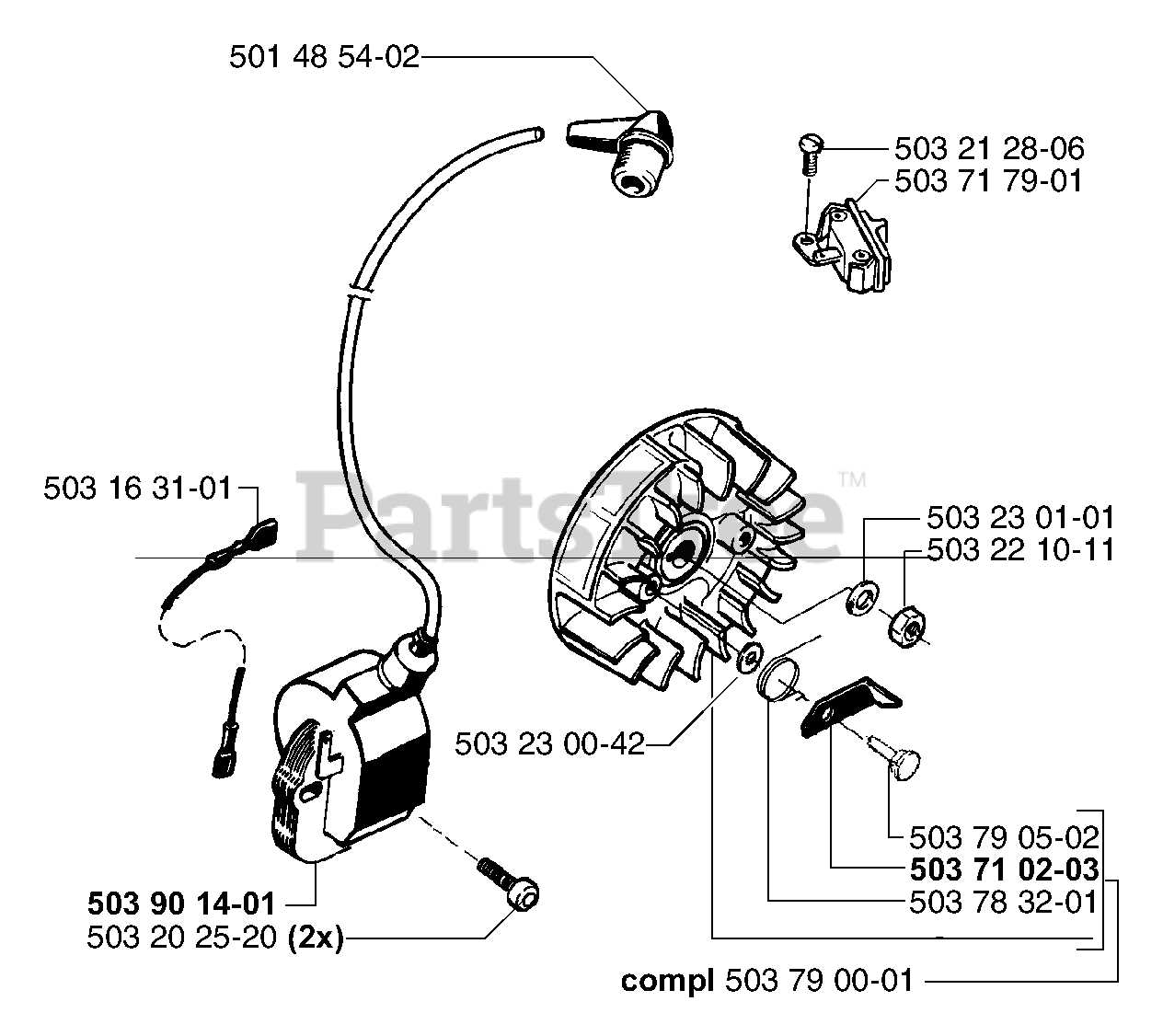

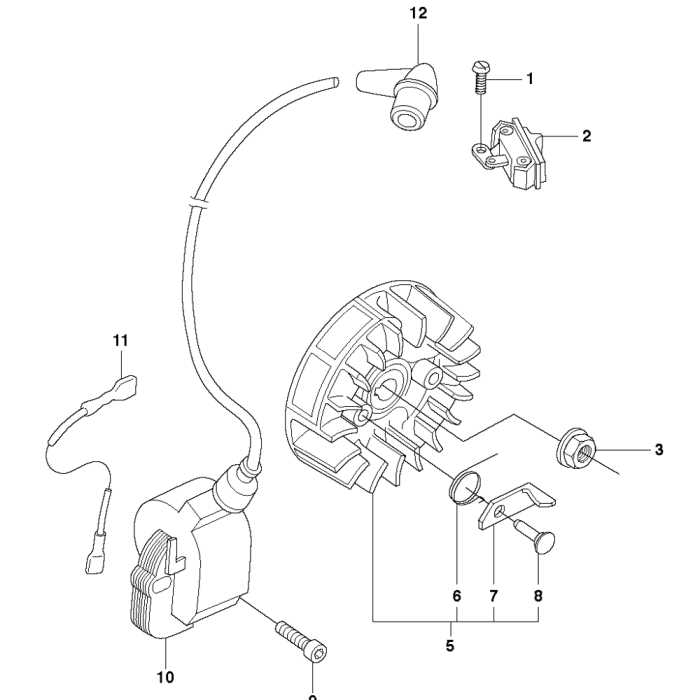

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as a roadmap, guiding users through the assembly and disassembly processes. Familiarity with the symbols and layout can greatly enhance one’s ability to identify and source necessary elements.

Familiarize Yourself with Symbols

Each illustration features a variety of symbols that correspond to specific items. Take time to review the legend, which explains what each symbol represents. This will help you quickly locate the parts you need, ensuring a smoother repair experience.

Follow the Flow of the Illustration

Visual guides often depict components in a logical order, illustrating how they fit together. Pay attention to the sequence in which elements are presented; this will aid in understanding how to disassemble and reassemble the machinery effectively. Following this structure will help you maintain clarity throughout the repair process.

Identifying Compatible Replacement Parts

When it comes to maintaining outdoor equipment, understanding how to find suitable components is essential for optimal performance. Ensuring that each piece fits correctly and functions effectively can enhance the longevity and efficiency of your machine. This section will guide you through the process of identifying the right replacements for your equipment.

Understanding Compatibility

Compatibility is crucial when selecting new components. Here are some key factors to consider:

- Model Specifications: Always refer to your machine’s specifications to find compatible options.

- Manufacturer Guidelines: Consult the manufacturer’s recommendations for preferred replacements.

- Material Quality: Choose high-quality materials to ensure durability and performance.

Where to Find Compatible Components

Finding suitable replacements can be streamlined by exploring various resources:

- Authorized Dealers: Visit local dealers or their websites for genuine components.

- Online Marketplaces: Use reputable online platforms that specialize in outdoor equipment.

- Forums and Communities: Engage with online communities for recommendations and user experiences.

By taking these steps, you can ensure that your equipment remains in excellent working condition, allowing for efficient and reliable operation.

Tools Needed for Repair Work

When tackling maintenance or repair tasks, having the right tools is essential for achieving efficient and effective results. A well-equipped workspace enhances productivity and ensures that each component is addressed with precision.

Essential Tools: Start with a reliable set of screwdrivers and wrenches to handle various screws and bolts. A quality socket set can significantly speed up disassembly. Additionally, pliers are crucial for gripping and manipulating small parts.

Safety Gear: Always prioritize safety with gloves, safety glasses, and a mask to protect against dust and debris.

Specialized Instruments: Depending on the task, consider a torque wrench for precise tightening and a multimeter for electrical diagnostics.

By assembling these fundamental tools, you can ensure a smoother and more effective repair experience.

Step-by-Step Repair Process

Repairing your outdoor power tool can be a rewarding endeavor, allowing you to restore its functionality while gaining valuable skills. This guide outlines a systematic approach to troubleshooting and fixing common issues, ensuring you can tackle repairs confidently.

1. Gather Necessary Tools: Before starting, collect all required tools such as wrenches, screwdrivers, and replacement components. Having everything on hand streamlines the process.

2. Identify the Issue: Examine the equipment thoroughly to determine the exact problem. Look for signs of wear, damage, or malfunctioning parts.

3. Disassemble the Unit: Carefully take apart the tool, noting the location of each component. This step is crucial for effective reassembly later on.

4. Inspect Components: Assess each piece for damage or excessive wear. Replace any faulty items with new or refurbished ones to restore optimal performance.

5. Reassemble the Equipment: Following your notes, put the tool back together, ensuring each part is secure and in its correct position.

6. Test the Tool: Once reassembled, conduct a thorough test to ensure everything operates as intended. Address any lingering issues before returning to use.

7. Maintain Regularly: Implement a routine maintenance schedule to prevent future problems and extend the lifespan of your equipment.

Safety Precautions While Operating

When using powerful cutting equipment, ensuring safety is paramount. Proper precautions not only protect the operator but also those nearby. Understanding and adhering to guidelines significantly reduce the risk of accidents and injuries during operation.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential. Equip yourself with cut-resistant gloves, sturdy boots, and eye protection to shield against flying debris. A hard hat can prevent head injuries, while ear protection safeguards your hearing from loud noise.

Pre-Operational Checks

Before starting any cutting task, perform thorough pre-operational checks. Ensure that the equipment is in optimal condition by inspecting fuel levels, blades, and safety features. Familiarize yourself with the user manual and ensure that all safety mechanisms are functioning correctly to prevent mishaps during use.

Tips for Long-lasting Performance

To ensure optimal functionality and durability of your outdoor power equipment, regular maintenance and care are essential. Implementing best practices can significantly enhance the longevity of your tool, preventing premature wear and ensuring reliable performance over time.

Here are some key recommendations to keep your equipment running smoothly:

| Tip | Description |

|---|---|

| Regular Cleaning | Remove debris and dirt after each use to prevent buildup that can affect performance. |

| Lubrication | Ensure that all moving parts are adequately lubricated to reduce friction and wear. |

| Check Tension | Inspect the tension of the drive mechanism regularly to maintain efficiency and prevent damage. |

| Fuel Quality | Use fresh, high-quality fuel to ensure optimal combustion and performance. |

| Storage Conditions | Store the equipment in a dry, cool place to prevent corrosion and damage from environmental factors. |

By following these guidelines, you can significantly improve the lifespan and functionality of your equipment, ensuring it serves you well for years to come.