Understanding Jonsered 525 Chainsaw Components

In the realm of outdoor equipment, comprehending the various elements that constitute a cutting instrument is crucial for both maintenance and repair. Familiarity with each segment allows users to ensure optimal functionality and longevity of the device. This section delves into the intricate layout of these components, providing valuable insights for enthusiasts and professionals alike.

Visual representations of these components serve as indispensable resources. They not only clarify the relationships between the different elements but also simplify the process of identifying issues and implementing effective solutions. By breaking down the structure, users can develop a deeper appreciation for the engineering behind their tools, fostering a more informed approach to care and troubleshooting.

Whether you are a seasoned user or a novice, understanding the arrangement and function of these segments can enhance your experience. Mastery of this knowledge empowers individuals to make informed decisions when it comes to repairs, upgrades, or even simple maintenance tasks. Thus, equipping yourself with the necessary information is the first step towards effective management of your cutting device.

Essential Components of the Chainsaw

A cutting tool comprises various critical elements that work together to ensure efficient operation. Understanding these components is vital for maintenance and troubleshooting. Each part plays a unique role in the overall functionality, contributing to performance and durability.

At the heart of the mechanism lies the engine, responsible for generating power and driving the cutting mechanism. The bar is a key element, providing support and guiding the cutting chain, while the chain itself is engineered for precision cutting through wood and other materials. Additional features, such as the air filter, fuel system, and safety components, enhance operational efficiency and ensure user safety during usage.

Regular inspection of these components can prolong the lifespan of the tool and improve performance. Familiarity with their functions allows users to recognize signs of wear or potential failures, making timely repairs easier. Whether for professional tasks or home projects, a well-maintained tool delivers optimal results and user satisfaction.

How to Identify Spare Parts

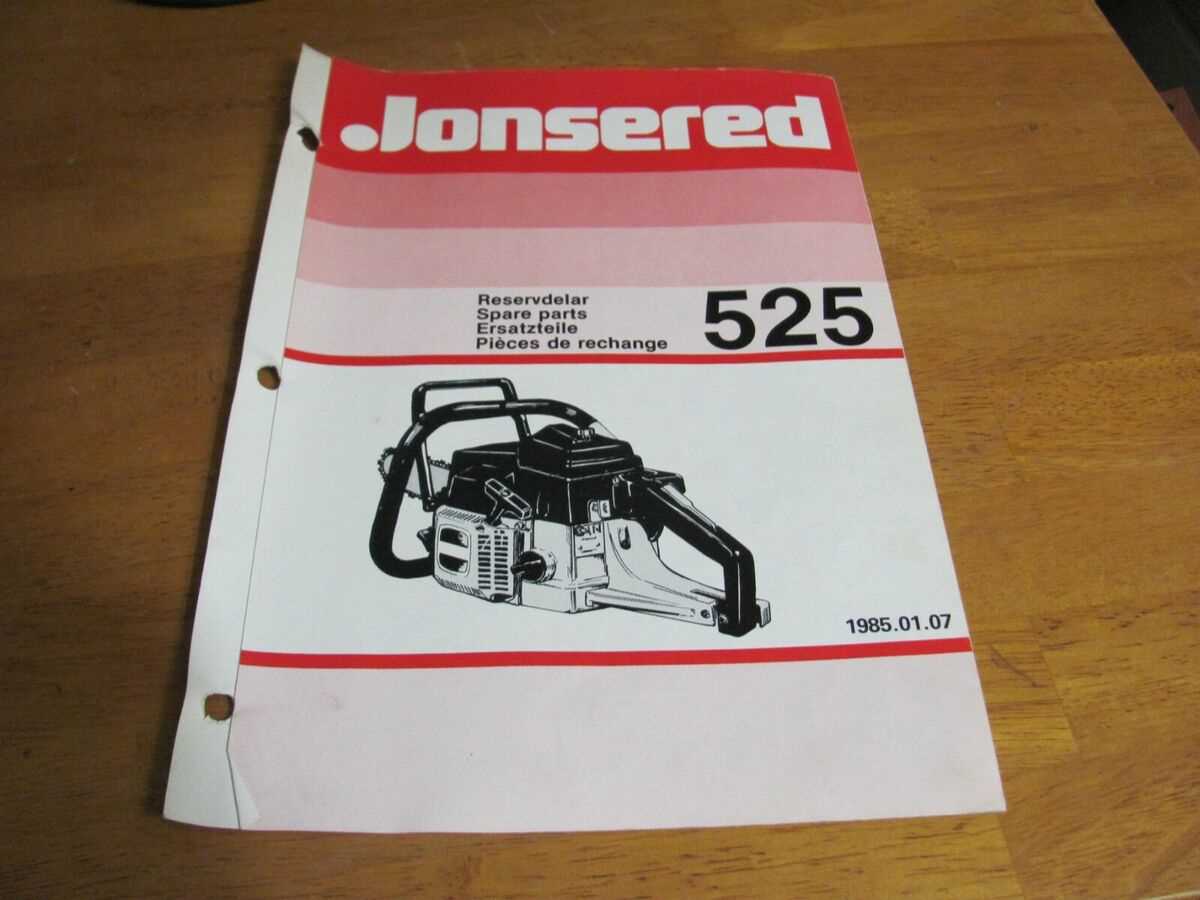

When it comes to maintaining equipment, recognizing the correct components for replacement is essential for proper functionality. Understanding the structure of your tool and being able to match it with compatible replacements can help extend its life and ensure smooth operation.

Examining the User Manual

One of the most reliable ways to determine which component you need is by consulting the user manual. This document often includes diagrams and lists that describe each part and its corresponding code, making it easier to identify exactly what you’re looking for.

Using Model Numbers

Another helpful approach is using the model number of your device. By referencing this number, you can often find detailed charts online or from the manufacturer that specify each part related to that model.

- Check the model and serial number on your tool.

- Difficulty in starting the engine

- Unusual vibrations during operation

- Poor cutting performance

- Excessive fuel consumption

- Overheating of the unit

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the efficiency and longevity of your outdoor power tool. By adhering to specific maintenance practices, you can enhance performance, reduce wear, and prevent unexpected failures. This section outlines key tips to help you keep your equipment running smoothly.

Routine Inspections

Conducting frequent assessments of your equipment is crucial. Look for signs of wear and tear, such as frayed components or loose fittings. Addressing these issues early can prevent more significant problems down the line. Ensure that all connections are secure and that moving parts are free from debris.

Proper Lubrication

Maintaining adequate lubrication is vital for reducing friction and preventing overheating. Use high-quality lubricants as recommended by the manufacturer. Regularly check oil levels and top up as needed. Keeping your tool well-lubricated ensures smooth operation and extends its lifespan.

Common Issues and Solutions

Understanding the typical challenges encountered with power tools can greatly enhance maintenance and operational efficiency. Many users experience similar problems that may arise from wear and tear, improper handling, or environmental factors. This section highlights prevalent issues and offers practical solutions to ensure optimal performance.

Frequent Problems

Proposed Solutions

- Check the fuel quality and replace if necessary.

- Inspect the spark plug for wear and clean or replace it.

- Ensure the air filter is clean and free of debris.

- Verify chain tension and adjust accordingly.

- Regularly lubricate moving parts to reduce friction.

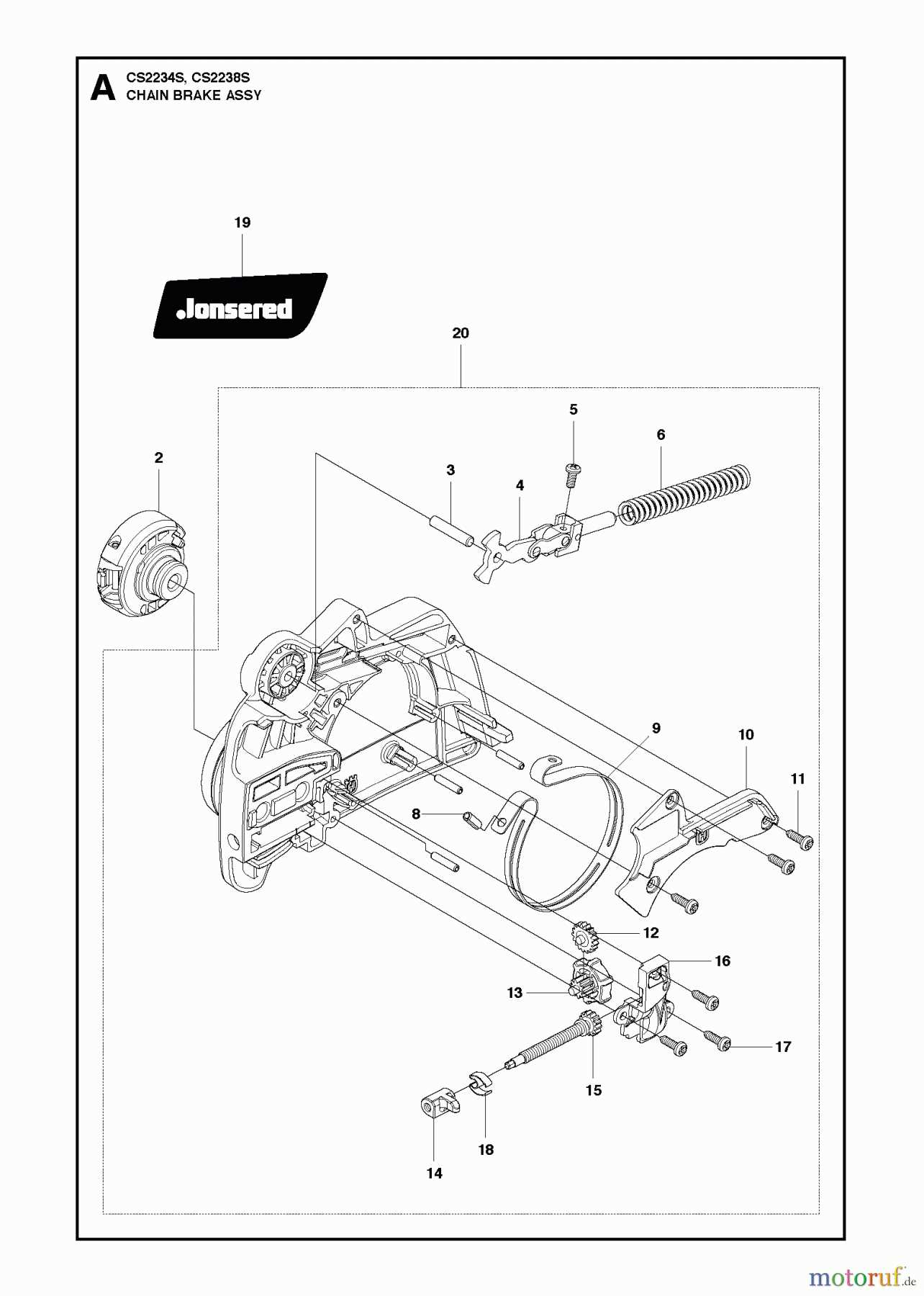

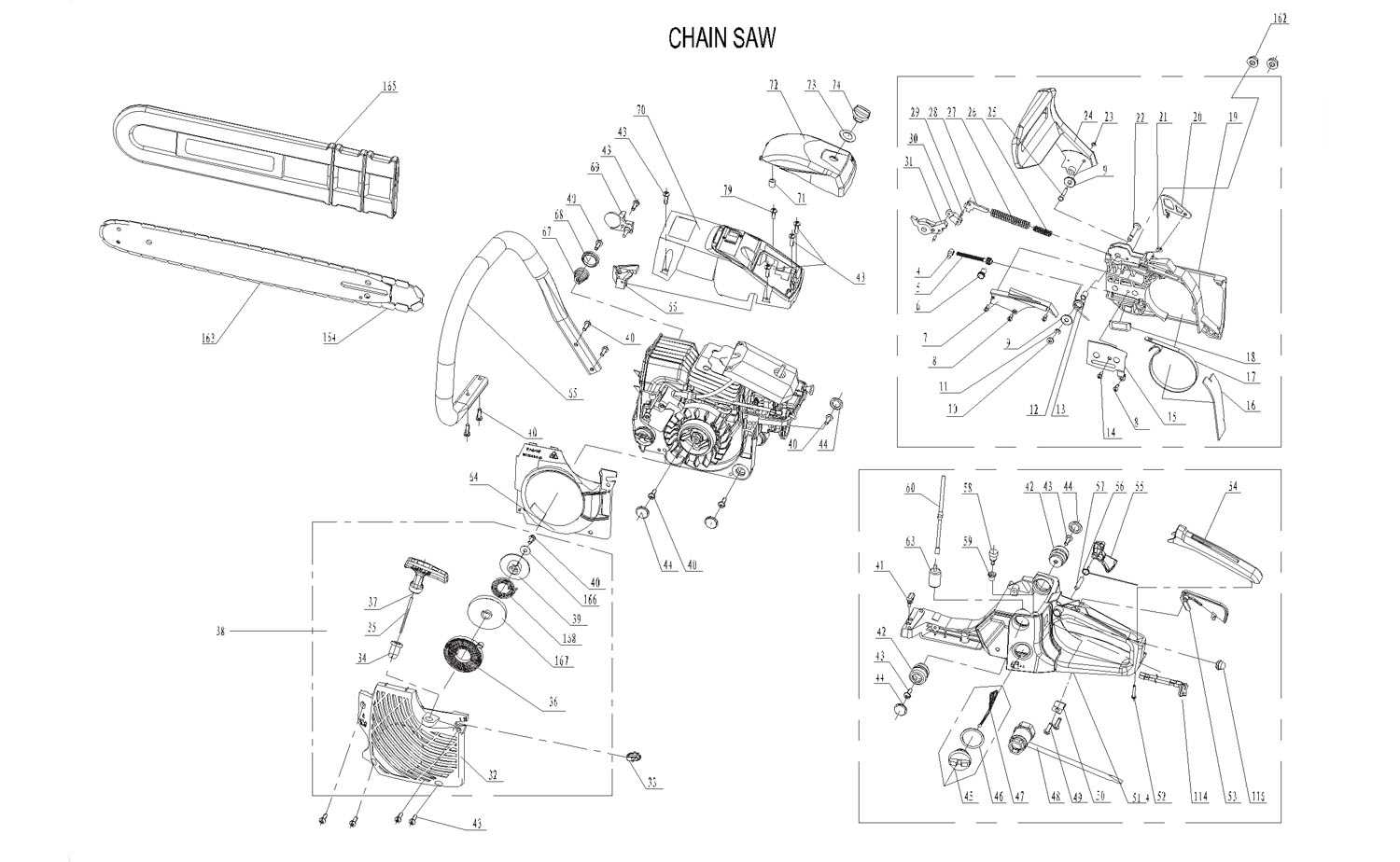

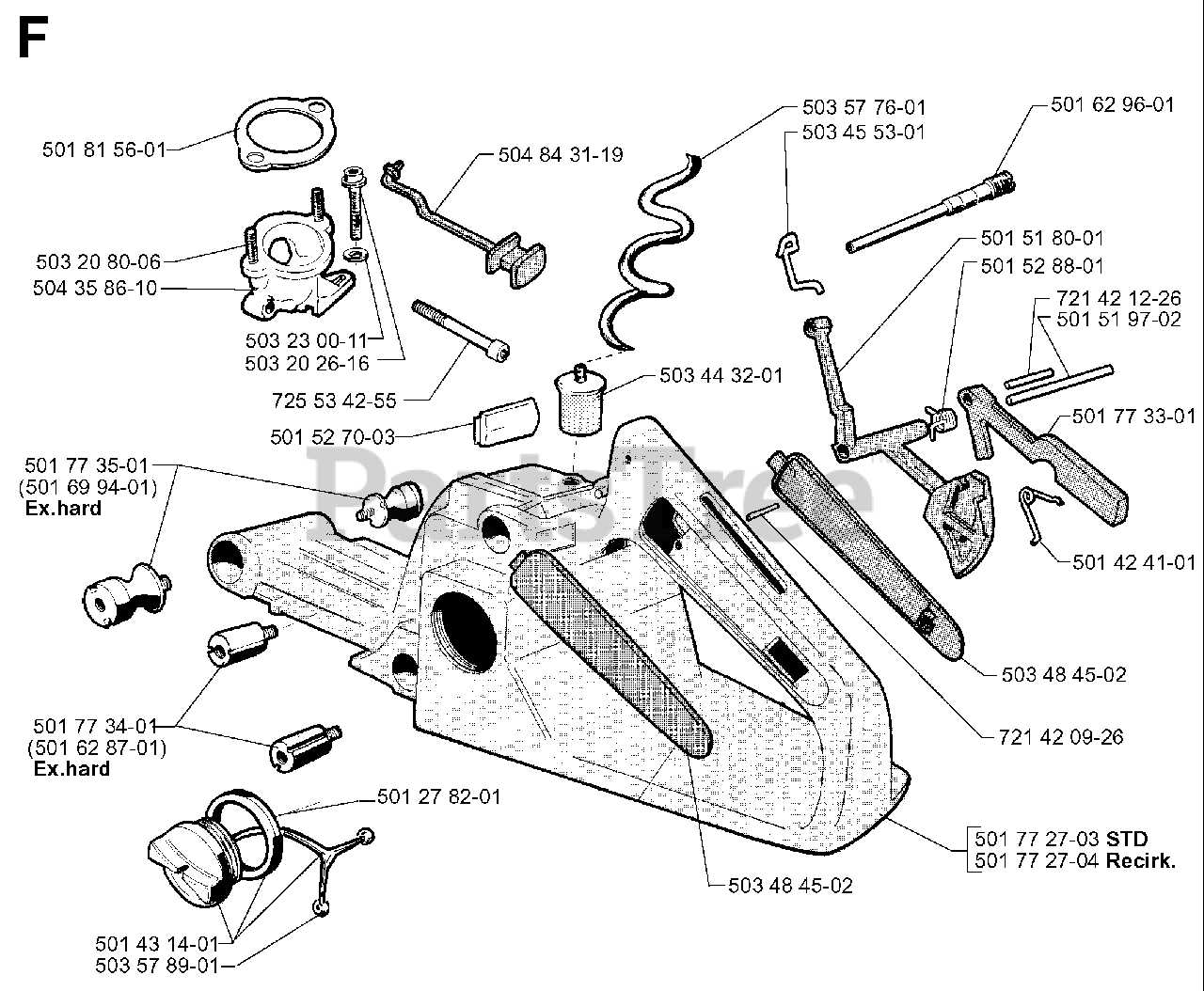

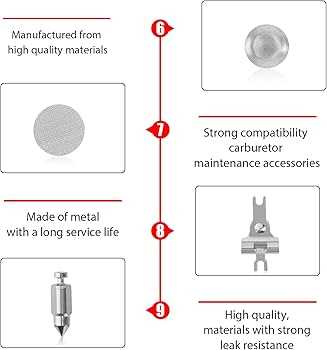

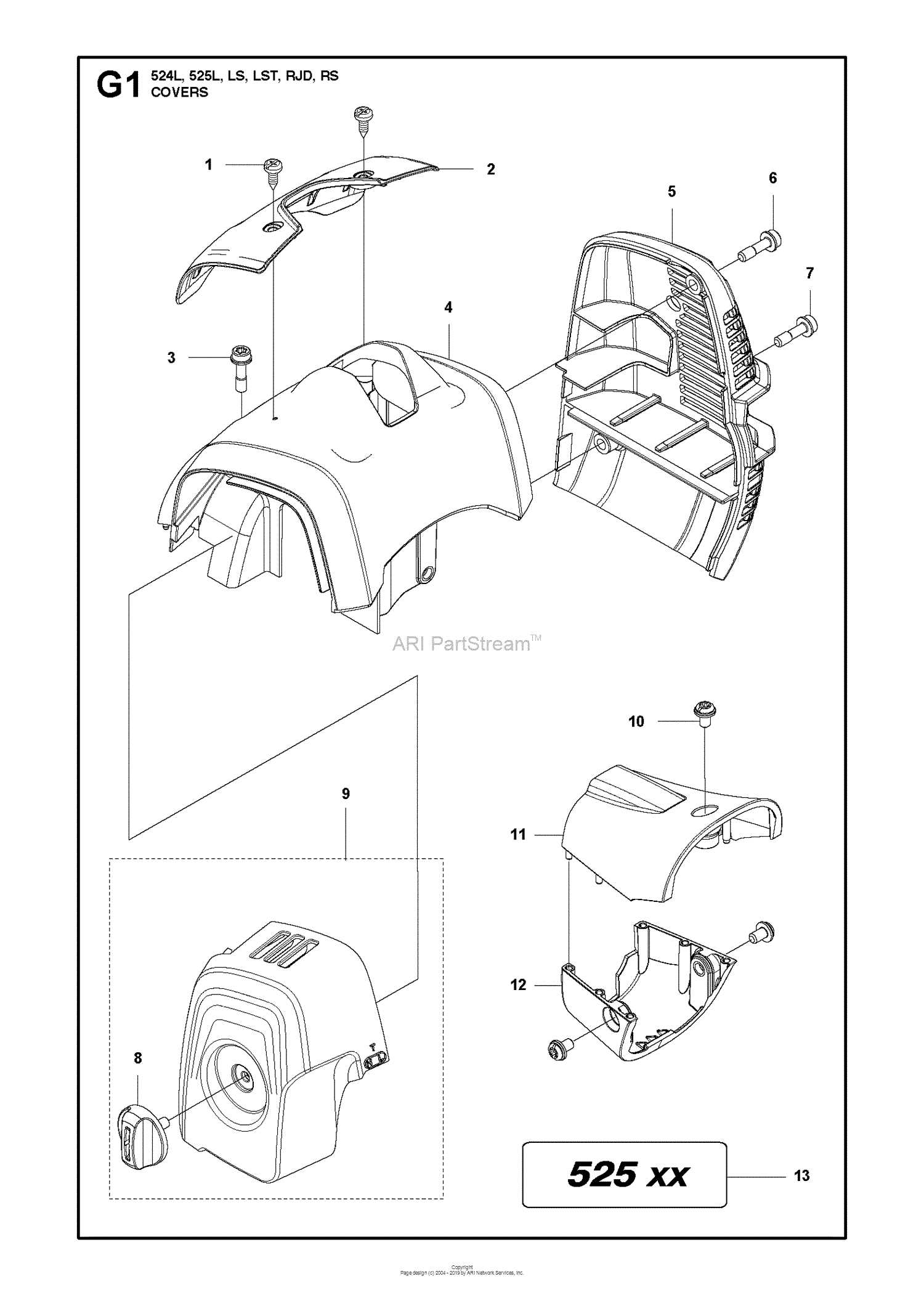

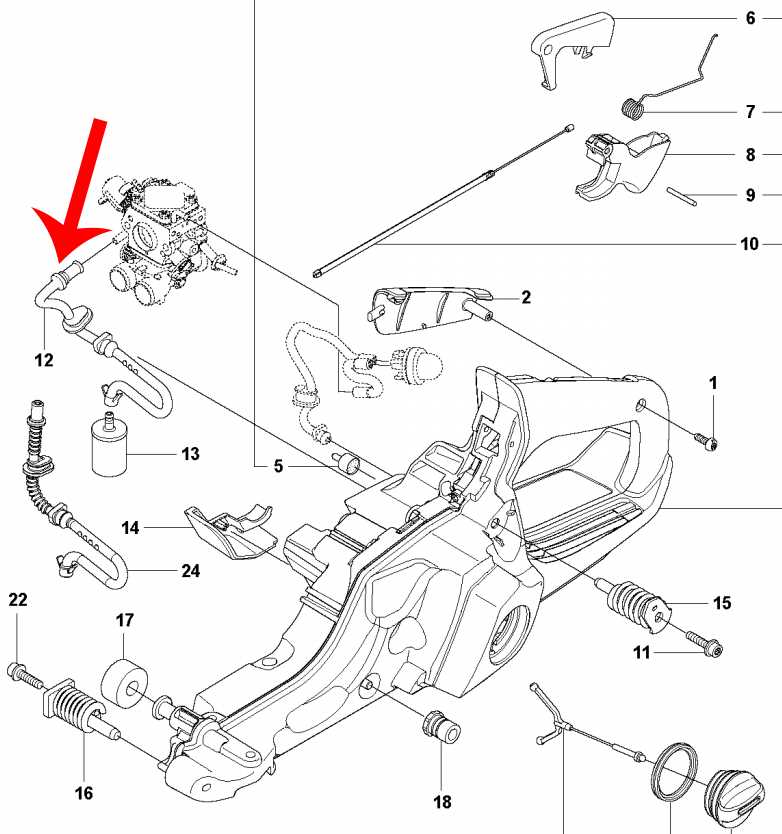

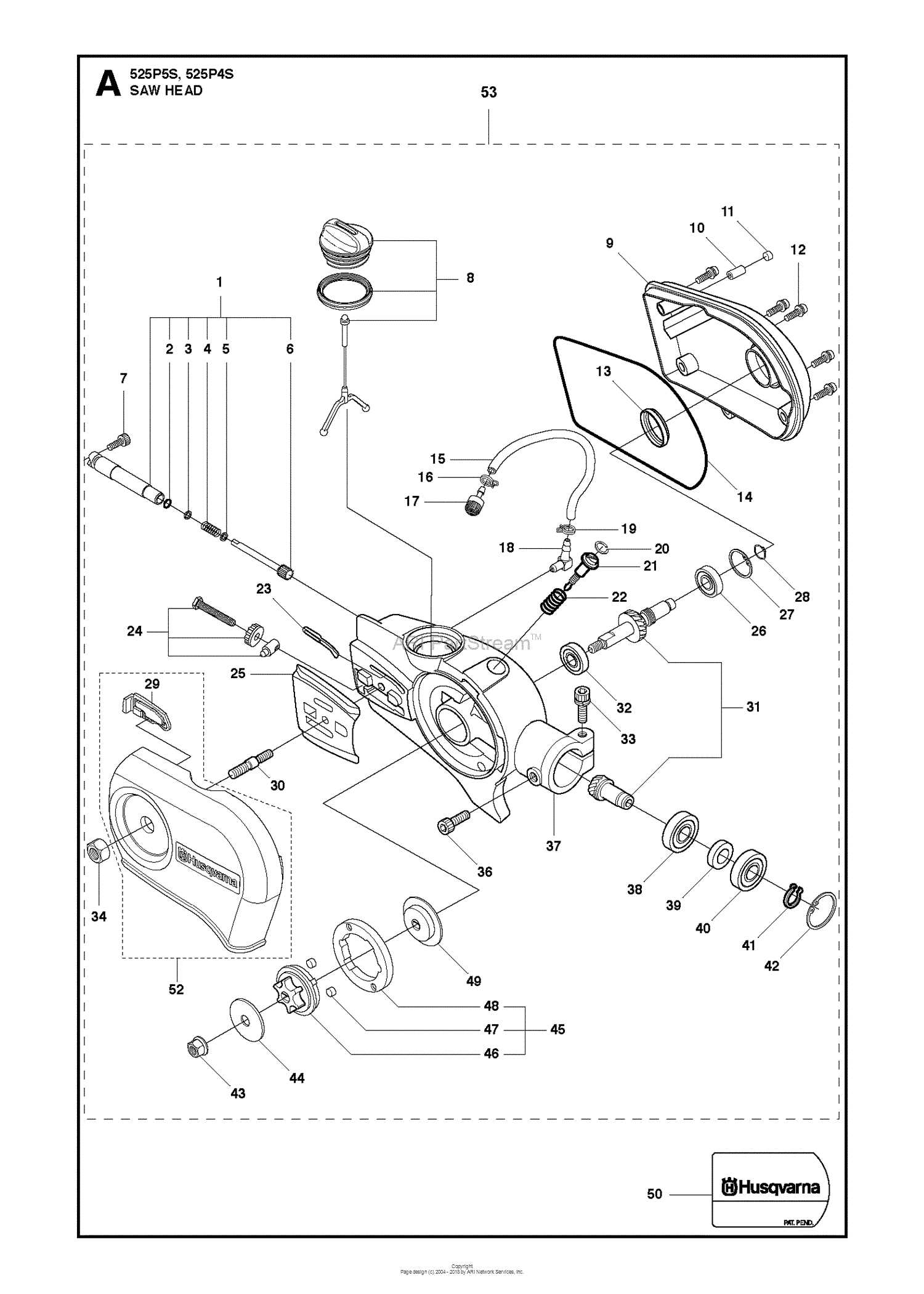

Diagram Overview and Explanation

This section provides a comprehensive overview of the visual representation of components and their relationships within a specific tool. Understanding this schematic is crucial for effective maintenance and repair, ensuring optimal functionality.

The following points highlight the key aspects of the representation:

- Component Identification: Each element is labeled clearly, allowing for easy recognition and understanding of its role.

- Functional Relationships: Lines and symbols indicate how components interact, showcasing the flow of operation.

- Maintenance Guidance: This visual aid serves as a reference for troubleshooting and replacing specific elements.

For a deeper understanding, users are encouraged to refer to the accompanying legends and notations that clarify symbols and terminology used throughout the illustration.

Where to Find Replacement Parts

Locating suitable components for your equipment can significantly enhance its performance and longevity. Whether you are undertaking repairs or conducting maintenance, understanding where to source quality replacements is crucial. This section will guide you through various avenues to explore for obtaining the necessary elements to keep your machinery functioning optimally.

Online Retailers

Numerous online platforms specialize in outdoor machinery components, offering a wide range of products at competitive prices. Websites dedicated to gardening tools and machinery often feature an extensive selection, making it easy to compare different options. When shopping online, ensure that you verify the specifications and compatibility of the items to your model.

Local Supply Stores

Your nearby hardware or home improvement store may stock essential components for various machinery. Visiting these stores allows you to seek advice from knowledgeable staff who can assist in identifying the correct items. Additionally, you can examine products in person, ensuring they meet your quality standards.

Furthermore, connecting with local repair shops can provide valuable insights into where to find reliable components. They may also have connections with suppliers or offer refurbished items that could serve as cost-effective solutions.

Safety Features of Jonsered Chainsaws

When operating power tools designed for cutting, safety is paramount. This equipment is engineered with multiple protective elements that aim to minimize risks and enhance user security. Understanding these features is essential for anyone handling such tools, ensuring a safer and more efficient experience.

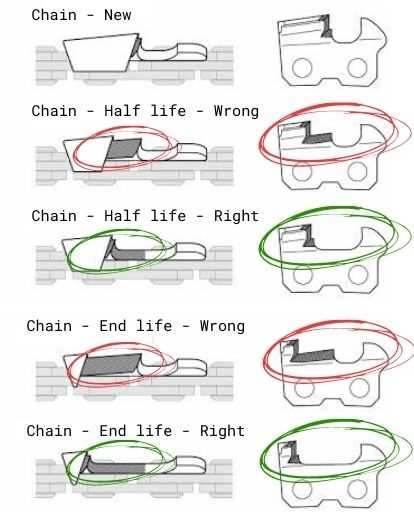

- Chain Brake System: A crucial component that halts the chain’s movement in the event of kickback, preventing potential injuries.

- Hand Guard: This feature shields the user’s hands from accidental contact with the rotating chain, further enhancing safety during operation.

- Anti-Vibration Technology: Reduces the amount of vibration transmitted to the operator, decreasing fatigue and improving control.

- Low Kickback Chain: Designed to minimize the risk of sudden jerking motions, making it easier to maintain stability while cutting.

- Safety Throttle Lock: Prevents unintentional activation of the throttle, ensuring that the tool remains inactive when not in use.

By incorporating these advanced safety features, users can operate cutting equipment with greater confidence, significantly reducing the likelihood of accidents. It is crucial to familiarize oneself with these mechanisms to promote safe practices in any cutting endeavor.

Assembly Instructions for New Parts

Ensuring the proper integration of replacement components is vital for maintaining the functionality and safety of your equipment. Following systematic guidelines can simplify the installation process and enhance the overall performance of your device.

Step 1: Begin by gathering all necessary tools and the new components you intend to install. Make sure you have a clean workspace to facilitate an organized assembly process.

Step 2: Carefully refer to the user manual or service guide to identify the specific areas where the new elements will be fitted. Understanding the layout and connection points will aid in achieving a seamless installation.

Step 3: Remove any existing components that need replacement, taking care to note their original arrangement. This will serve as a reference during the installation of new items.

Step 4: Align the new components with the designated positions, ensuring that all connections are secure and properly oriented. Gently press or fasten each part in place, confirming they are snugly fitted.

Step 5: Once all replacements are installed, conduct a thorough inspection to ensure everything is properly assembled. Test the functionality of the device to confirm successful integration of the new elements.

By adhering to these steps, you can confidently enhance your equipment’s performance and longevity.

Performance Enhancements and Upgrades

Improving the efficiency and capability of outdoor power tools can significantly enhance their overall performance. Various modifications and additions can optimize functionality, extending the life of the equipment while increasing productivity. This section explores several options for upgrading essential components, ensuring better operation and user satisfaction.

Key Upgrades to Consider

When looking to enhance the efficiency of your equipment, several areas can be targeted for improvement. Upgrading critical components not only increases performance but also contributes to a smoother operation.

| Upgrade Component | Description | Benefits |

|---|---|---|

| Fuel System | Upgrading to a higher quality fuel filter and carburetor can improve fuel delivery. | Increased power and efficiency, better fuel combustion. |

| Bar and Chain | Using a more durable bar and a sharper chain enhances cutting efficiency. | Smoother cuts and reduced wear on components. |

| Ignition System | Replacing the spark plug and ignition coil can improve starting and operation. | Faster starts and improved combustion efficiency. |

| Air Filter | Installing a high-performance air filter ensures better airflow and filtration. | Enhanced engine performance and longevity. |

Additional Modifications

In addition to the upgrades mentioned, consider adjusting the tension of the chain and regularly sharpening the cutting edges. These simple maintenance practices can lead to significant improvements in performance, ensuring the tool operates at its best. Always consult the manufacturer’s guidelines before proceeding with any modifications to maintain safety and efficiency.

Resources for Chainsaw Owners

Maintaining and operating a cutting tool can be enhanced significantly by accessing valuable resources tailored for users. These materials can include manuals, instructional videos, and forums where enthusiasts share insights and advice. By tapping into such resources, individuals can improve their understanding of the equipment, troubleshoot issues, and discover best practices for efficient use.

Online Communities and Forums

Engaging with online communities allows users to connect with fellow enthusiasts and professionals. These platforms often host discussions on various topics, from basic maintenance to advanced troubleshooting techniques. Participating in these forums not only provides answers to specific questions but also fosters a sense of camaraderie among users.

Official Manuals and Guides

Accessing official manuals and guides is essential for any owner. These documents typically contain detailed information about the tool’s specifications, maintenance schedules, and safety protocols. Utilizing these resources ensures that users operate their equipment correctly and safely, minimizing the risk of accidents and extending the lifespan of their tools.