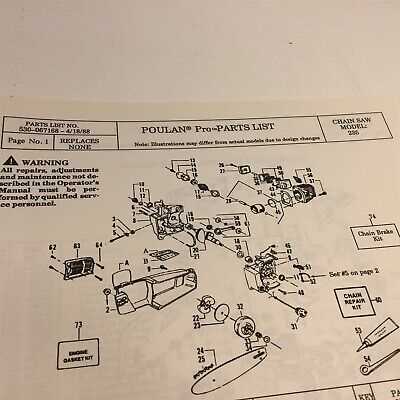

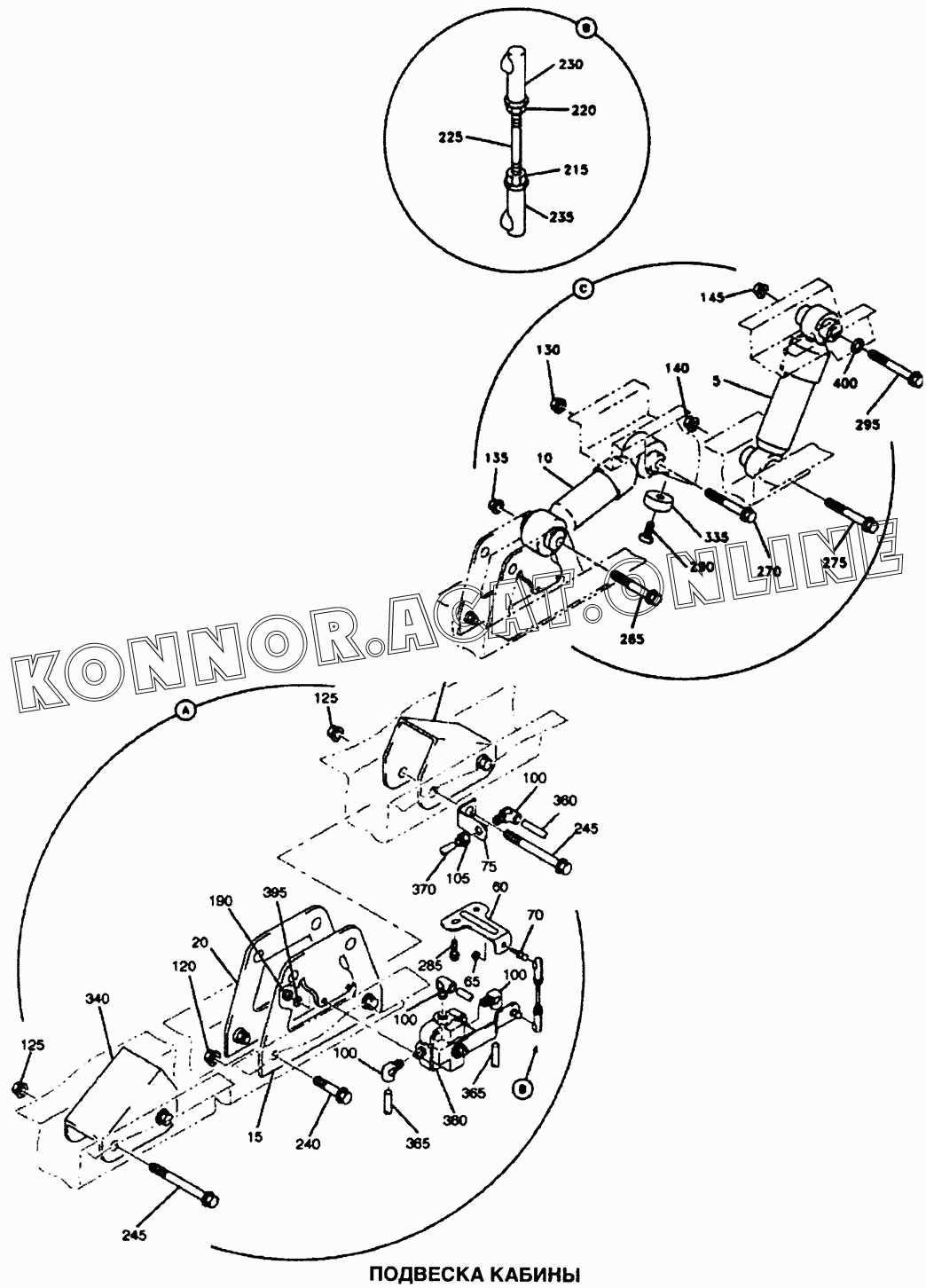

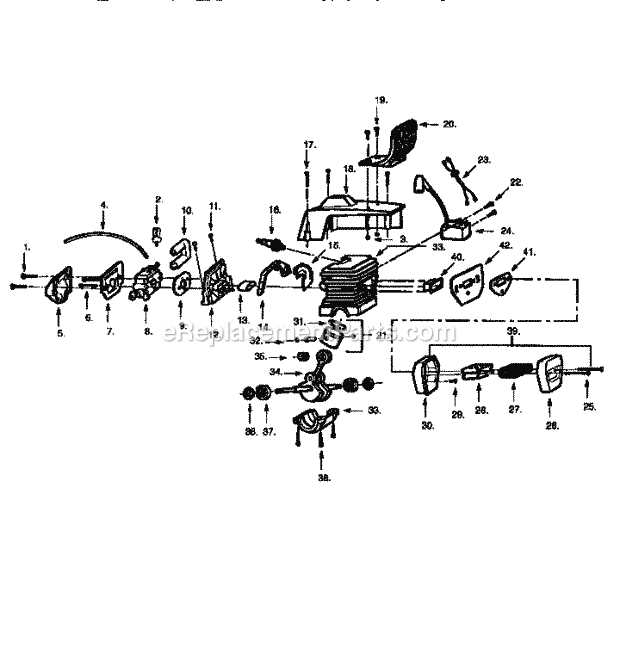

Poulan Pro 295 Chainsaw Parts Diagram Overview

In the world of outdoor equipment, mastering the inner workings of your cutting tool can significantly enhance its performance and longevity. A well-functioning machine relies on a variety of essential elements, each playing a crucial role in its operation. Familiarity with these components not only aids in effective maintenance but also empowers users to tackle repairs with confidence.

Each element is interconnected, contributing to the seamless operation of the device. Whether it’s the engine, the drive system, or safety mechanisms, understanding how these parts interact can prevent potential issues. This knowledge is invaluable for both hobbyists and professionals alike, ensuring that your equipment remains reliable in demanding conditions.

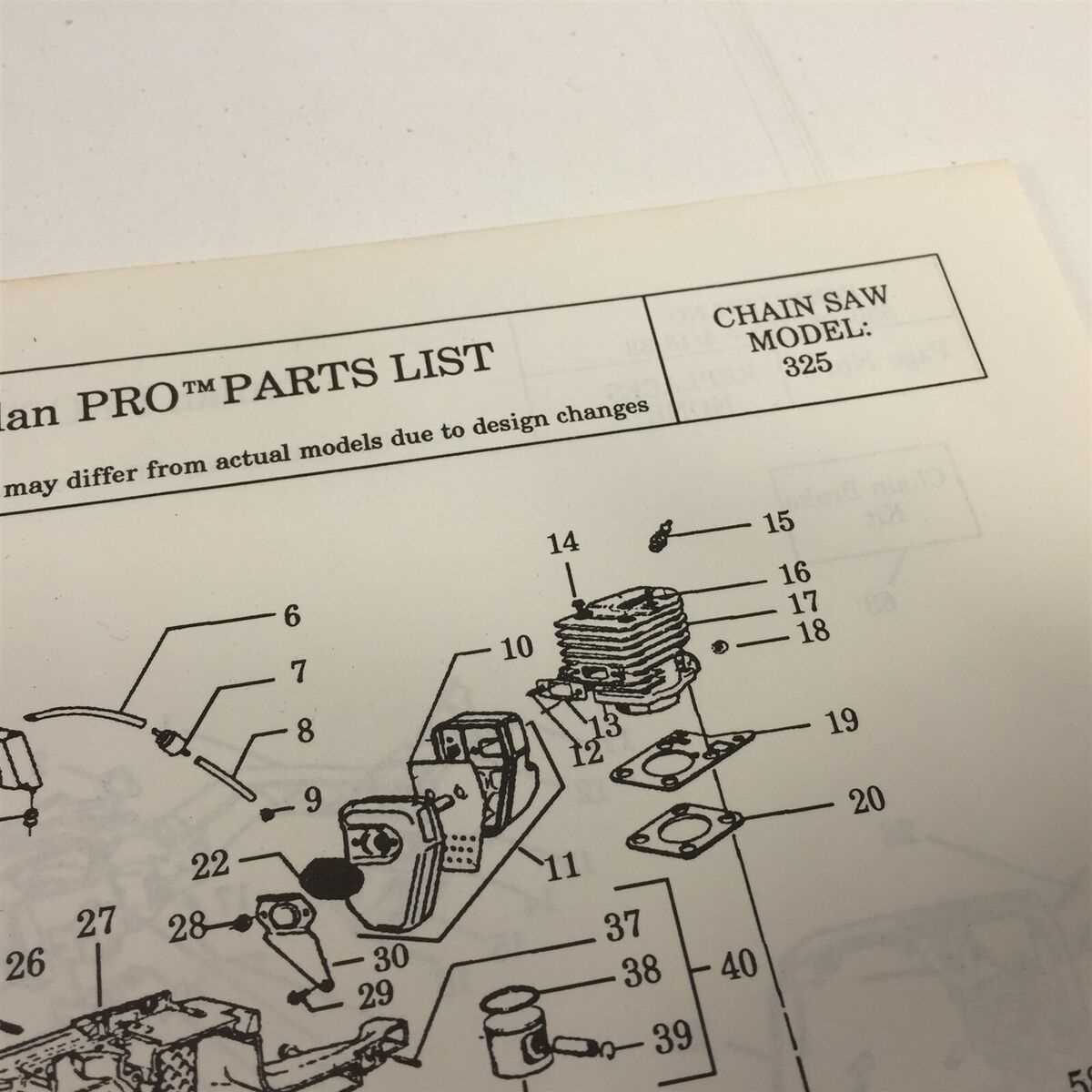

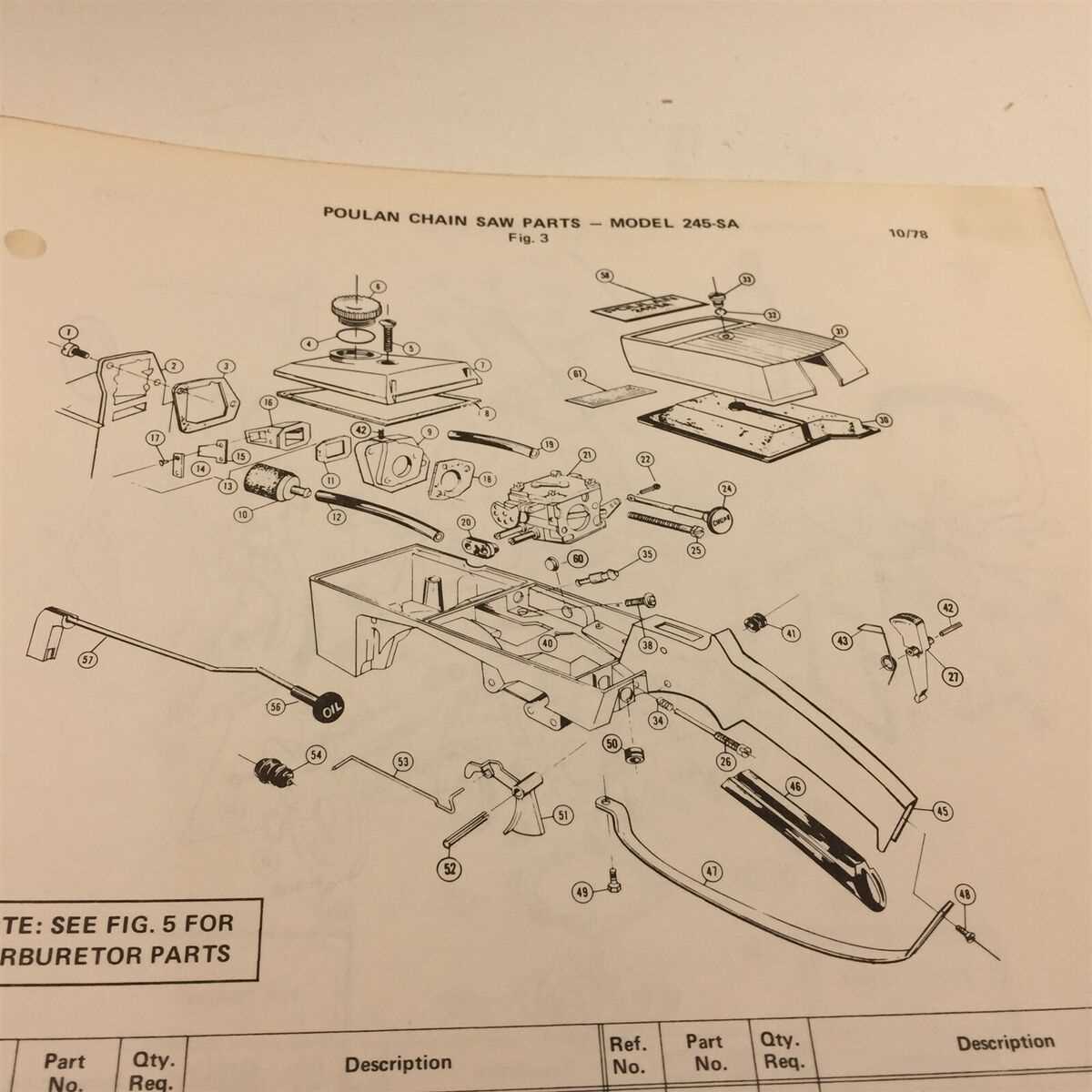

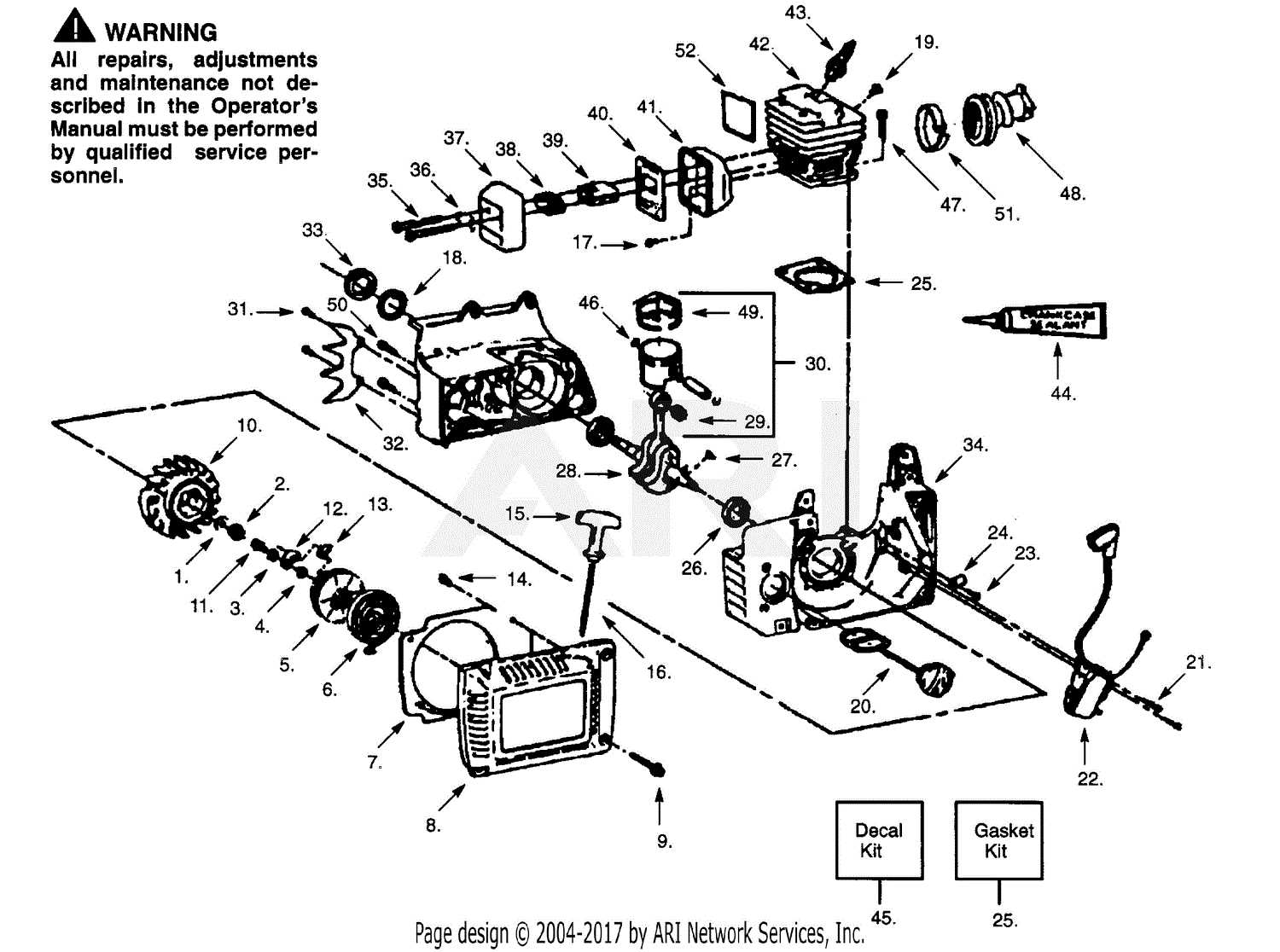

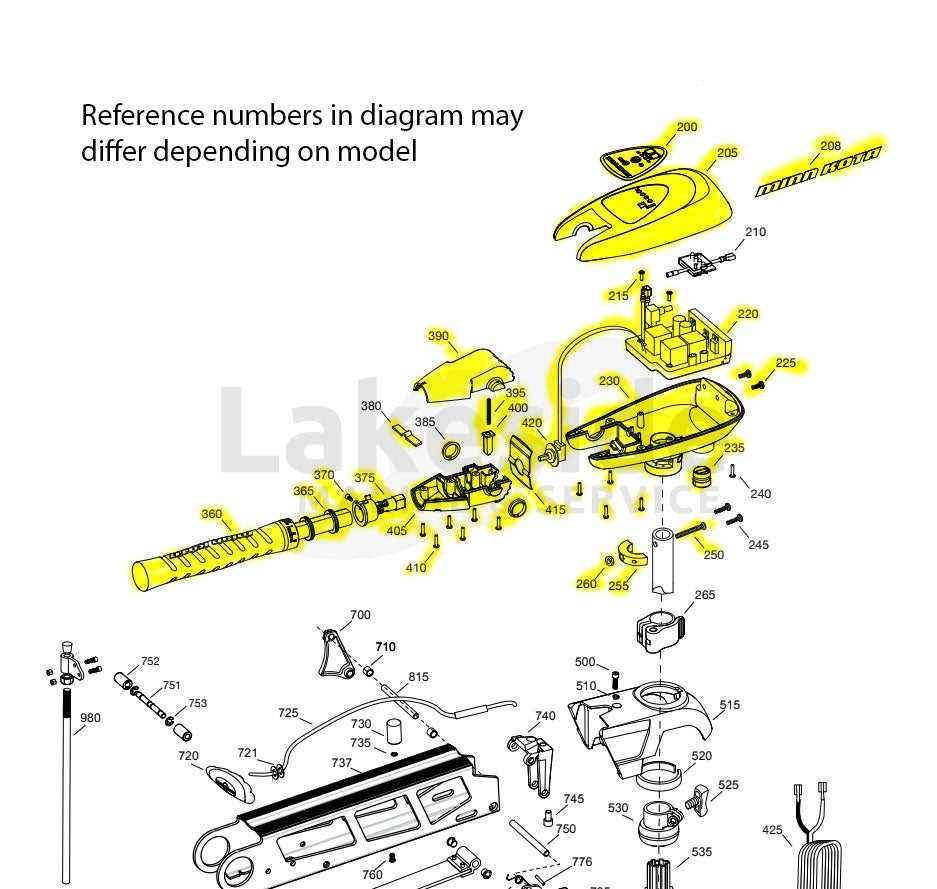

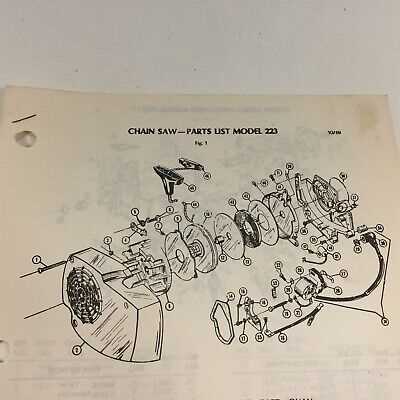

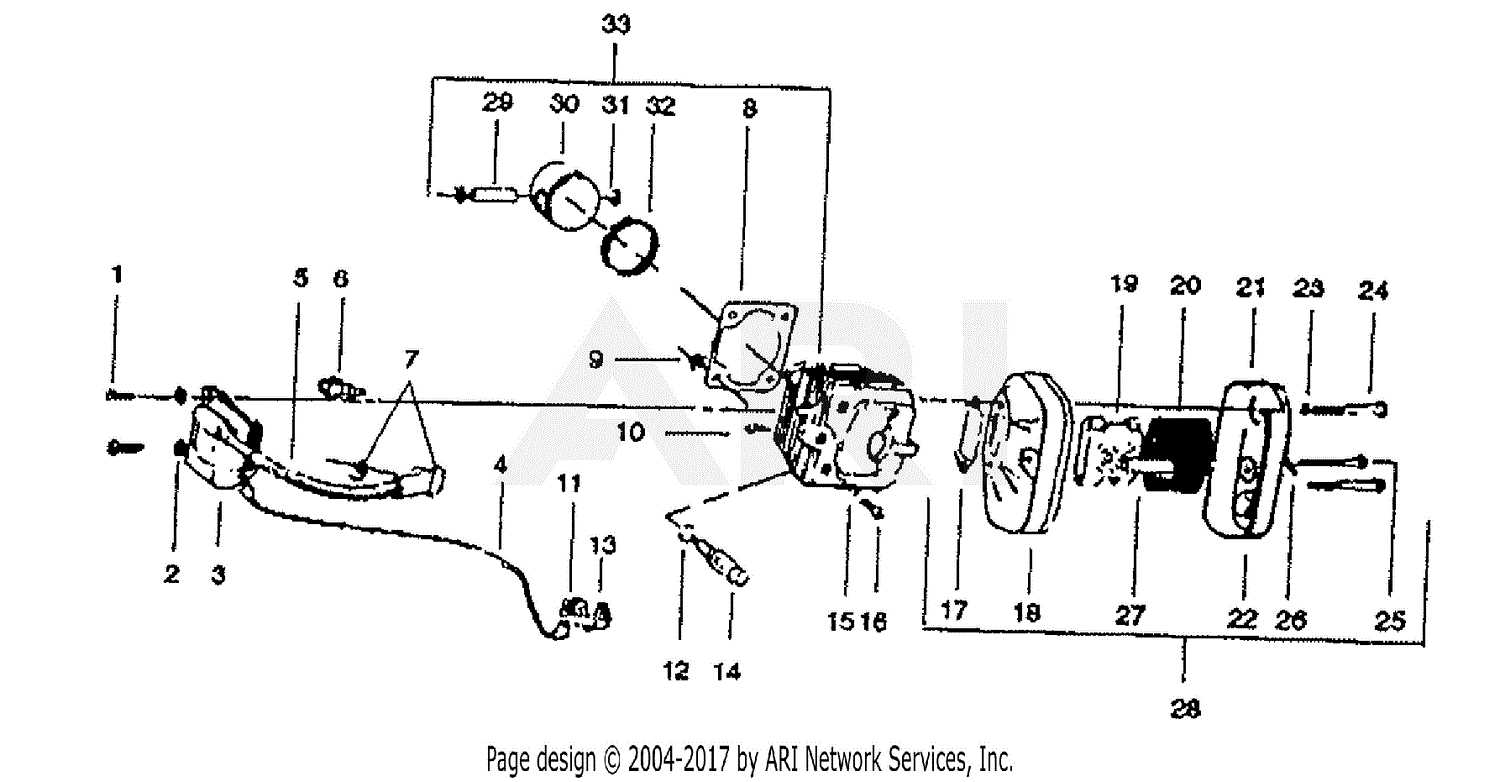

Visual representations of these components can be particularly helpful. By examining detailed illustrations, users can quickly identify specific parts, understand their functions, and recognize when replacements are necessary. This guide aims to provide a comprehensive overview, equipping you with the insights needed to keep your cutting tool in optimal condition.

Poulan Pro 295 Overview

This section provides a comprehensive look at a well-regarded model in the outdoor power equipment category. Renowned for its reliability and efficiency, this tool has become a staple for both professionals and hobbyists alike. Designed to tackle various cutting tasks, it balances performance with user-friendly features, making it accessible to a wide range of users.

Its robust construction and thoughtful engineering ensure longevity, while innovative mechanisms enhance ease of use and maintenance. Whether for heavy-duty applications or routine yard work, this model offers versatility and power, enabling users to achieve optimal results in their projects.

Additionally, understanding the key components and their functions is essential for maximizing the tool’s capabilities. Familiarity with its structure not only aids in efficient operation but also assists in troubleshooting and repair, ensuring that users can maintain peak performance throughout its lifespan.

Understanding Chainsaw Components

To fully appreciate the functionality of a cutting tool, one must delve into its various elements. Each component plays a crucial role in the overall operation, contributing to efficiency and safety during use. By gaining insights into these individual parts, users can enhance their understanding of maintenance and troubleshooting, ultimately extending the lifespan of the equipment.

The engine serves as the powerhouse, driving the tool’s performance. It converts fuel into mechanical energy, enabling the cutting mechanism to function effectively. Coupled with the fuel system, which ensures proper delivery of energy sources, these elements are fundamental to operation.

The cutting assembly is where the action happens. The bar and chain work in unison, allowing for precise and efficient cutting. The bar provides a stable platform, while the chain, equipped with sharp teeth, slices through material with ease. Proper tension and alignment of these parts are essential for optimal performance.

Safety features, such as the brake and guard, are designed to protect the operator during use. Understanding these mechanisms is vital, as they play a significant role in preventing accidents. Regular inspection and maintenance of these safety elements can greatly reduce risks associated with operation.

Finally, the handle and housing are integral for user control and comfort. An ergonomic design ensures that the tool can be maneuvered effectively, minimizing fatigue during extended use. By familiarizing oneself with these components, users can not only operate their equipment more effectively but also troubleshoot issues that may arise.

Importance of a Parts Diagram

A visual representation of components is crucial for understanding the assembly and functionality of complex machinery. Such illustrations provide clarity, making it easier for users to identify individual elements and their relationships within the whole system. This knowledge is essential for effective maintenance and repairs, ensuring that every part works harmoniously.

Facilitating Maintenance and Repairs

Having access to a detailed illustration aids technicians and DIY enthusiasts in pinpointing issues quickly. By visually correlating each component, users can troubleshoot problems more efficiently, saving time and reducing the likelihood of errors during the repair process. This ensures that machinery remains in optimal condition, enhancing its longevity.

Enhancing User Understanding

For those unfamiliar with the equipment, a well-crafted illustration serves as an educational tool. It demystifies the inner workings of the machine, allowing users to gain a deeper appreciation of how different components interact. This foundational knowledge not only empowers users but also promotes safer handling and operation of the equipment.

Common Parts of Poulan Pro 295

Understanding the essential components of a cutting tool is crucial for effective maintenance and performance. Each element plays a vital role in ensuring the machine operates smoothly and efficiently.

- Engine: The heart of the equipment, providing the necessary power for operation.

- Guide Bar: This is the metal rail that supports and guides the cutting chain, essential for precise cuts.

- Cutting Chain: Composed of links with sharp teeth, this element is responsible for the actual cutting action.

- Air Filter: Crucial for keeping dirt and debris out of the engine, ensuring optimal performance.

- Fuel Tank: Holds the necessary fuel for operation, directly influencing runtime.

- Clutch: Engages and disengages the cutting chain, allowing for safe handling when not in use.

- Chain Brake: A safety feature that stops the chain quickly in case of kickback.

- Starter Assembly: Facilitates the ignition of the engine, essential for starting the tool.

Maintaining these components ensures the longevity and efficiency of the machine, making regular checks and replacements vital for any user.

How to Read a Parts Diagram

Understanding a component layout is essential for anyone looking to repair or maintain machinery. These visual representations provide a detailed view of each piece and its relationship to other elements, facilitating easier identification and replacement during service tasks.

Key Elements of a Component Layout

When analyzing these illustrations, pay attention to the following key features:

| Feature | Description |

|---|---|

| Labels | Clear identifiers for each component, often numbered or named for easy reference. |

| Connections | Lines or arrows indicating how components are linked or interact with one another. |

| Parts List | A corresponding list that details each item, typically found alongside the visual. |

| Scale | Information about the size of components relative to one another, helping to ensure correct replacements. |

Steps to Interpret the Layout

To effectively utilize the layout, follow these simple steps:

- Examine the overall view to understand the layout of components.

- Identify and cross-reference labels with the accompanying list.

- Note how parts connect to each other, focusing on the lines or arrows.

- Check the scale to ensure compatibility with replacement items.

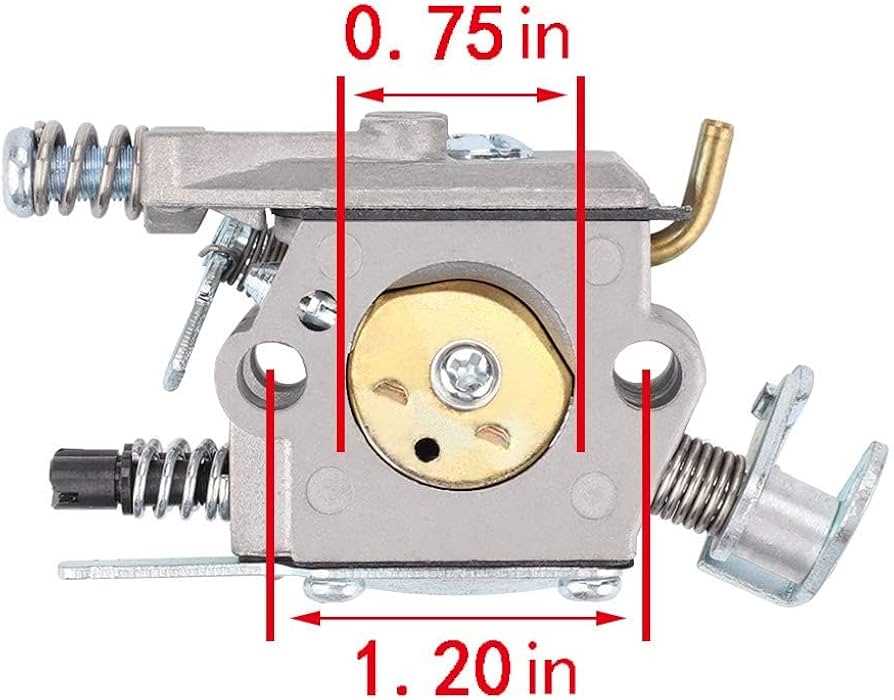

Identifying Replacement Parts

Understanding how to recognize and source the necessary components for your equipment is crucial for maintaining its functionality and performance. When it comes to machinery, knowing the specific elements that may require replacement can save both time and money in the long run.

Start by consulting the user manual, which often contains detailed descriptions and identifiers for each element. If the manual is unavailable, taking clear photographs of the equipment can assist in visual identification. Additionally, online resources and forums can provide valuable insights from other users who have encountered similar issues.

When identifying components, pay attention to markings or part numbers often found on the items themselves. This information can significantly streamline the search for replacements. It’s also beneficial to familiarize yourself with the various systems within your machinery to better understand how each component functions together.

Lastly, consider the quality of replacement components. Opting for high-quality alternatives can enhance the longevity and performance of your equipment, ensuring it operates efficiently for years to come.

Maintenance Tips for Poulan Pro 295

Regular upkeep is essential for optimal performance and longevity of your outdoor power equipment. Proper care not only enhances efficiency but also ensures safety during operation. Here are some crucial tips to maintain your device effectively.

Clean the Air Filter: A clean air filter allows for better airflow, which is vital for efficient operation. Inspect and clean the filter regularly to prevent dirt buildup, which can hinder performance.

Check the Spark Plug: The spark plug is crucial for ignition. Periodically inspect it for wear and replace it if necessary to ensure smooth starts and reliable operation.

Lubricate Moving Parts: Regularly applying lubricant to the moving components reduces friction and wear. Focus on the bar and chain, ensuring they are adequately oiled to prevent overheating.

Sharpen the Cutting Tool: A sharp cutting tool makes work easier and more efficient. Regularly check and sharpen the blade to maintain cutting precision and reduce strain on the motor.

Inspect Fuel System: Ensure that the fuel is fresh and properly mixed. Regularly check the fuel lines and filters for any clogs or leaks, as this can affect performance.

Store Properly: When not in use, store the equipment in a dry, cool place. This helps prevent rust and damage from moisture, ensuring that it remains in good condition for the next use.

By following these maintenance tips, you can enhance the performance and lifespan of your outdoor equipment, ensuring it remains a reliable tool for all your tasks.

Where to Find Genuine Parts

When it comes to maintaining outdoor power equipment, sourcing authentic components is crucial for optimal performance and longevity. Reliable resources ensure that you can restore your machine to its original capabilities without compromising quality. Understanding where to find these components can save both time and effort in the long run.

Authorized Dealers

One of the best places to begin your search is through authorized dealers. These retailers are recognized by the manufacturer and typically offer a wide selection of original components. They can also provide expert advice and support, ensuring that you choose the correct items for your specific model.

Online Retailers

In addition to local shops, numerous online platforms specialize in outdoor equipment supplies. Many of these websites offer an extensive catalog of genuine components with detailed descriptions and compatibility information. Always check for customer reviews and ratings to confirm the reliability of the seller. Look for official manufacturer websites as well, as they often have dedicated sections for ordering authentic components directly.

Tools Required for Repairs

Effective maintenance and repair of outdoor power equipment necessitate a variety of specialized instruments. Having the right tools on hand not only simplifies the repair process but also ensures that each task is performed accurately and safely. Below is a list of essential tools that will aid in various repair activities.

| Tool | Description |

|---|---|

| Wrench Set | Used for loosening and tightening bolts and nuts on various components. |

| Screwdriver Set | Necessary for removing and installing screws of different sizes and types. |

| Replacement Blades | Critical for ensuring optimal cutting performance; must be matched to the equipment specifications. |

| Safety Goggles | Protective eyewear to safeguard against debris and accidents during repairs. |

| Grease Gun | Used for applying lubricants to moving parts to reduce wear and tear. |

| Multimeter | Essential for testing electrical components and diagnosing issues. |

| Cleaning Brush | Helps remove dirt and debris from parts to ensure optimal functionality. |

Equipping yourself with these tools will make the repair process more efficient and effective, allowing for prolonged use of your equipment.

Step-by-Step Repair Guide

This guide is designed to assist you in the process of restoring functionality to your cutting tool. Following these instructions will enable you to identify issues and carry out repairs effectively, ensuring optimal performance.

Tools and Materials Required

Before starting the repair, gather the necessary tools and materials. You will need basic hand tools such as screwdrivers, wrenches, and pliers, as well as replacement components specific to your model. Ensure that you have a clean workspace to keep your parts organized.

Repair Process

Begin by disconnecting the power source for safety. Carefully remove the housing to expose the internal components. Inspect each part for wear and damage, paying special attention to critical areas. Replace any faulty components and reassemble the tool in reverse order. Finally, conduct a thorough check to confirm everything is secure before testing the functionality.

By following this structured approach, you can efficiently address issues and maintain the longevity of your equipment.

Upgrading Your Chainsaw Components

Enhancing the performance and longevity of your cutting tool can lead to more efficient and enjoyable work experiences. By investing in quality enhancements, you can significantly improve functionality, making your equipment more reliable and effective in various tasks.

When considering upgrades, focus on the following key components:

- Bar and Chain: Opt for a high-quality bar and chain that match your needs for cutting speed and precision.

- Engine Performance: Upgrade to a more powerful engine or consider tuning the existing one to boost efficiency.

- Filters: Replace air and fuel filters regularly to ensure optimal airflow and fuel delivery.

- Lubrication System: Upgrade to an automatic lubrication system for consistent and efficient oiling.

Additionally, consider enhancing safety features to protect yourself during operation:

- Chain Brake: Ensure that your tool has a reliable chain brake to stop the chain immediately in case of kickback.

- Hand Guards: Install hand guards to protect your hands from debris and accidental contact with the chain.

- Protective Gear: Always wear appropriate protective clothing, including gloves, helmets, and goggles.

By carefully selecting components to upgrade, you can tailor your tool to meet specific needs, enhancing both performance and safety. Prioritize quality and compatibility to ensure that your enhancements lead to successful outcomes in your cutting tasks.

Common Issues and Solutions

In the world of outdoor power equipment, various challenges can arise that affect performance and reliability. Understanding these common problems and their solutions can help users maintain their tools effectively, ensuring longevity and optimal functionality.

Starting Difficulties

One frequent issue is trouble with ignition. If the engine does not start, the cause may be a clogged fuel filter or spark plug. Checking these components regularly and replacing them when necessary can resolve this issue. Additionally, ensuring the fuel is fresh and properly mixed can prevent starting problems.

Reduced Cutting Efficiency

Another common challenge is diminished cutting performance. This can stem from a dull chain or incorrect tension. Regularly sharpening the cutting edge and adjusting the chain tension can significantly enhance efficiency. If the tool still struggles, inspecting the guide bar for wear may be necessary.

Maintaining awareness of these typical issues and their solutions allows users to enjoy a smoother experience and prolong the lifespan of their equipment.

Safety Precautions During Repairs

Ensuring safety while performing maintenance on power equipment is crucial for preventing accidents and injuries. By following specific guidelines, you can create a secure working environment that minimizes risks associated with repairs. Understanding the importance of protective measures will help in maintaining not only personal safety but also the integrity of the tools being serviced.

First and foremost, always wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and sturdy footwear to protect against sharp objects and falling debris. Additionally, it is essential to work in a well-ventilated area to avoid inhaling harmful fumes or dust particles generated during the repair process.

Before beginning any maintenance tasks, ensure that the equipment is completely powered down and disconnected from its energy source. This precaution prevents accidental starts and potential injuries. Furthermore, keep your workspace organized and free of clutter to reduce the chances of tripping or misplacing tools.

It’s also advisable to familiarize yourself with the equipment’s manual, which often contains vital safety information and guidelines for proper handling. If you’re unsure about any aspect of the repair, seeking assistance from a knowledgeable individual or professional can further enhance safety.

Finally, after completing repairs, double-check that all components are correctly reassembled and securely fastened. This step is essential to ensure safe operation in the future. By prioritizing safety during maintenance, you protect yourself and ensure the longevity of your equipment.