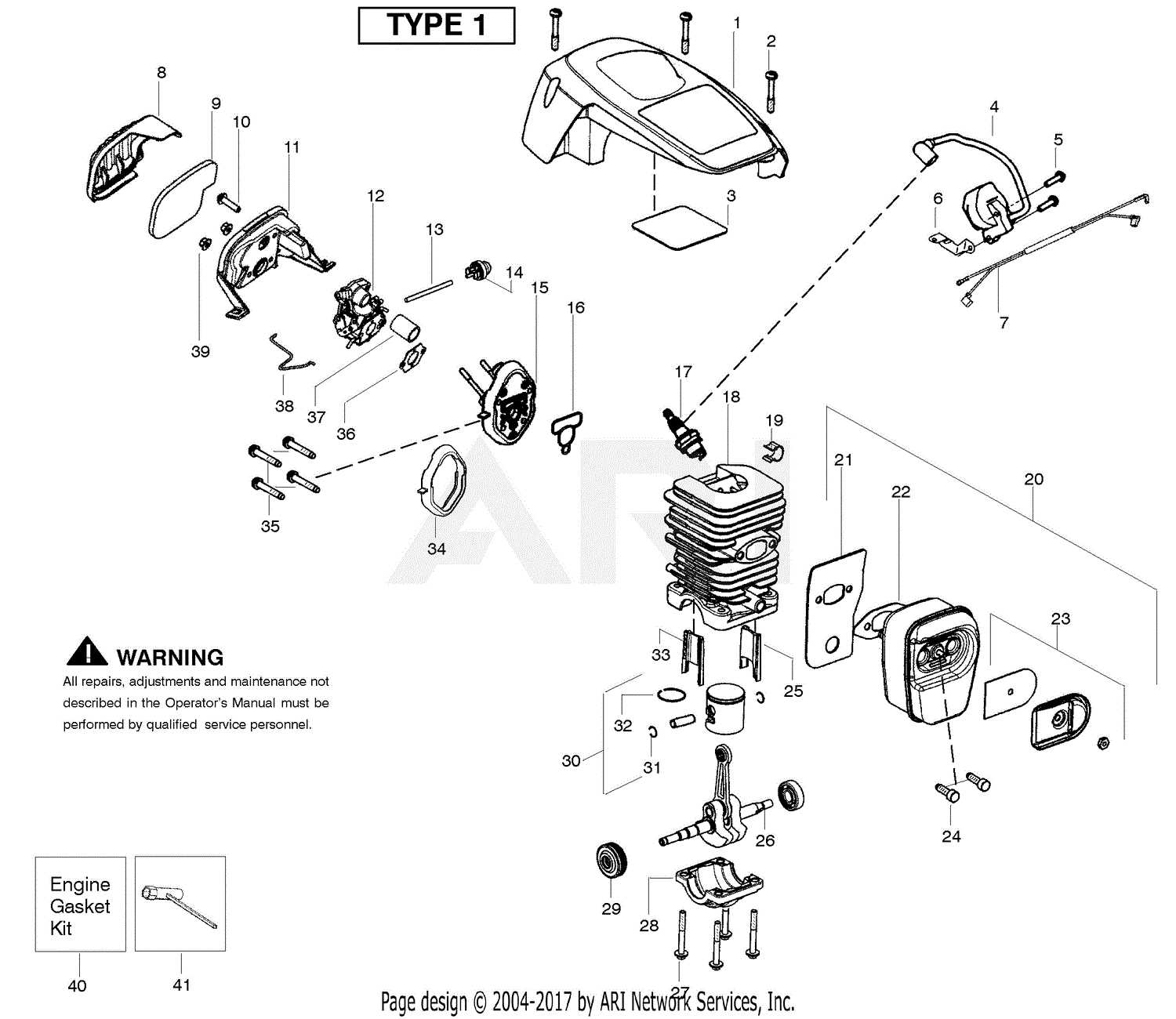

Essential Parts Diagram for Poulan Wild Thing Chainsaw

When dealing with mechanical devices, it’s crucial to have a clear understanding of how various elements are organized and function together. Proper knowledge of each unit’s role ensures efficient operation and allows for easier troubleshooting when needed. This section provides a comprehensive look at the structure and interplay of key elements, making it easier to maintain and repair equipment.

Efficient maintenance requires not only practical skills but also an in-depth knowledge of the internal configuration of the equipment. With a clear overview of the core elements, users can identify critical parts, ensuring their device runs smoothly and with minimal downtime. Recognizing each element’s place in the overall structure is essential for anyone seeking to extend the lifespan of their equipment.

This guide will take you through the essential components, offering valuable insights for anyone looking to better understand their device. By the end of this section, you’ll be equipped with the knowledge to make more informed decisions when handling maintenan

Understanding Key Components of Your Chainsaw

The efficient operation of your cutting tool relies on the seamless interaction between several essential elements. Recognizing how these parts function together can significantly improve performance and ensure smooth maintenance. A clear understanding of each component will not only prolong the tool’s life but also enhance its overall efficiency and safety.

One crucial aspect is the engine, which powers the entire machine. This part converts fuel into mechanical energy, enabling the cutting action. Another key feature is the guide bar, which serves as the track for the cutting mechanism. Without it, the chain would not function properly. The chain itself is responsible for the cutting process, consisting of sharp, rotating links that slice through wood with precision. To ensure proper function, each of these components must be regularly maintained and correctly adjusted.

Exploring Engine Mechanism and Performance

The internal workings of any cutting tool’s motor play a crucial role in its efficiency and reliability. Understanding how the engine functions helps in optimizing its use and maintaining its condition for long-lasting operation. This section delves into the core components and processes that power the tool, offering insights into how each part contributes to the overall performance.

- Combustion Process: The engine operates on a two-stroke cycle, relying on the ignition of fuel and air mixtures to produce power. This process enables rapid revolutions, delivering the force needed for effective cutting.

- Piston and Cylinder: The piston moves inside the cylinder, driving the mechanism that translates combustion energy into mechanical motion. Regular inspection ensures optimal compression and prevents power loss.

- Carburetor Functionality: The carburetor manages the precise air-fuel ratio, ensuring efficient burning of fuel. Proper tuning is essential to maintain smooth operation and minimize engine strain.

- Exhaust System: Exhaust gases are expelled through a designated outlet, helping to maintain engine temperature and performance stability. Keeping the exhaust system cle

Guide Bar: Maintenance and Selection Tips

Ensuring the longevity and performance of your cutting tool requires proper care of the guide bar. This critical component, often overlooked, plays a key role in the smooth and efficient operation of the machine. Regular maintenance and thoughtful selection can significantly extend its life and improve functionality.

- Cleaning the Guide Bar: Regular cleaning is essential to remove sawdust and debris that can accumulate in the grooves. Keeping it free from blockages ensures smoother movement and better cutting performance.

- Inspecting for Wear: Check for uneven wear or damage. Replace the guide if you notice significant wear on one side, which can affect the balance and cutting precision.

- Lubrication: Ensure the bar is properly lubricated to reduce friction and prevent overheating. Use appropriate lubricants to keep it running smoothly.

When selecting a new guide bar, there are several factors to consider for optimal performance and safety.

- Bar Length: Choose a length that suits the type of cutting task. Longer bars provide more cutting capacity but may requir

Chainsaw Chain: Types and Replacement Advice

Understanding the various options available when selecting a cutting chain is essential for maintaining optimal performance. Choosing the right type and knowing how to replace it ensures both efficient operation and long-term durability of the tool.

Different Types of Chains

There are several types of cutting chains designed for different tasks and materials. It’s important to match the chain to the intended use. Here are some common types:

- Semi-chisel Chains: Ideal for general cutting tasks and are known for their durability, especially in dirty or abrasive environments.

- Full-chisel Chains: Provide faster cuts but require more maintenance and are best suited for clean wood.

- Low-profile Chains: These are safer and often used by beginners due to their reduced kickback risk.

Tips for Replacing the Chain

Replacing a worn chain can improve performance and ensure safety. Follow these steps for effective replacement:

- Always ensure the tool

Ignition System: Troubleshooting Common Issues

The ignition system plays a crucial role in ensuring the efficient operation of your equipment. When issues arise, they can prevent the engine from starting or cause erratic behavior during use. Identifying and addressing common problems in this system can save time and effort, leading to more consistent performance.

Issue Possible Cause Solution No spark Faulty spark plug or damaged wiring Check the spark plug for wear or damage and replace if necessary. Inspect wiring connections. Weak spark Dirty or corroded connections Clean all electrical connections and ensure they are secure. Intermittent starting Loose ignition coil Fuel System Overview for Optimal Efficiency

Understanding the fuel system’s role is key to maintaining peak performance and longevity. Proper fuel delivery ensures that the engine runs smoothly, providing consistent power and reducing the risk of overheating or damage. The system must efficiently mix fuel with air, while minimizing waste and maintaining balance for maximum productivity.

Several components work in harmony to achieve this, including the fuel tank, filter, and lines. Regular maintenance of these elements is essential for ensuring smooth operation. Inadequate fuel flow or contamination can lead to inefficient engine performance, increased wear, and potential breakdowns.

Component Function Fuel Tank Stores and supplies fuel to the engine Fuel Filter Prevents dirt and debris from entering the fuel lines Fuel Lines Transports fuel from the tank to the engine Carburetor Mixes fuel with air to create an optimal combustion mixture To maintain optimal efficiency, it’s crucial to periodically inspect these components and replace any parts that show signs of wear or clogging. Keeping the system clean ensures that fuel reaches the engine efficiently, promoting both performance and durability.

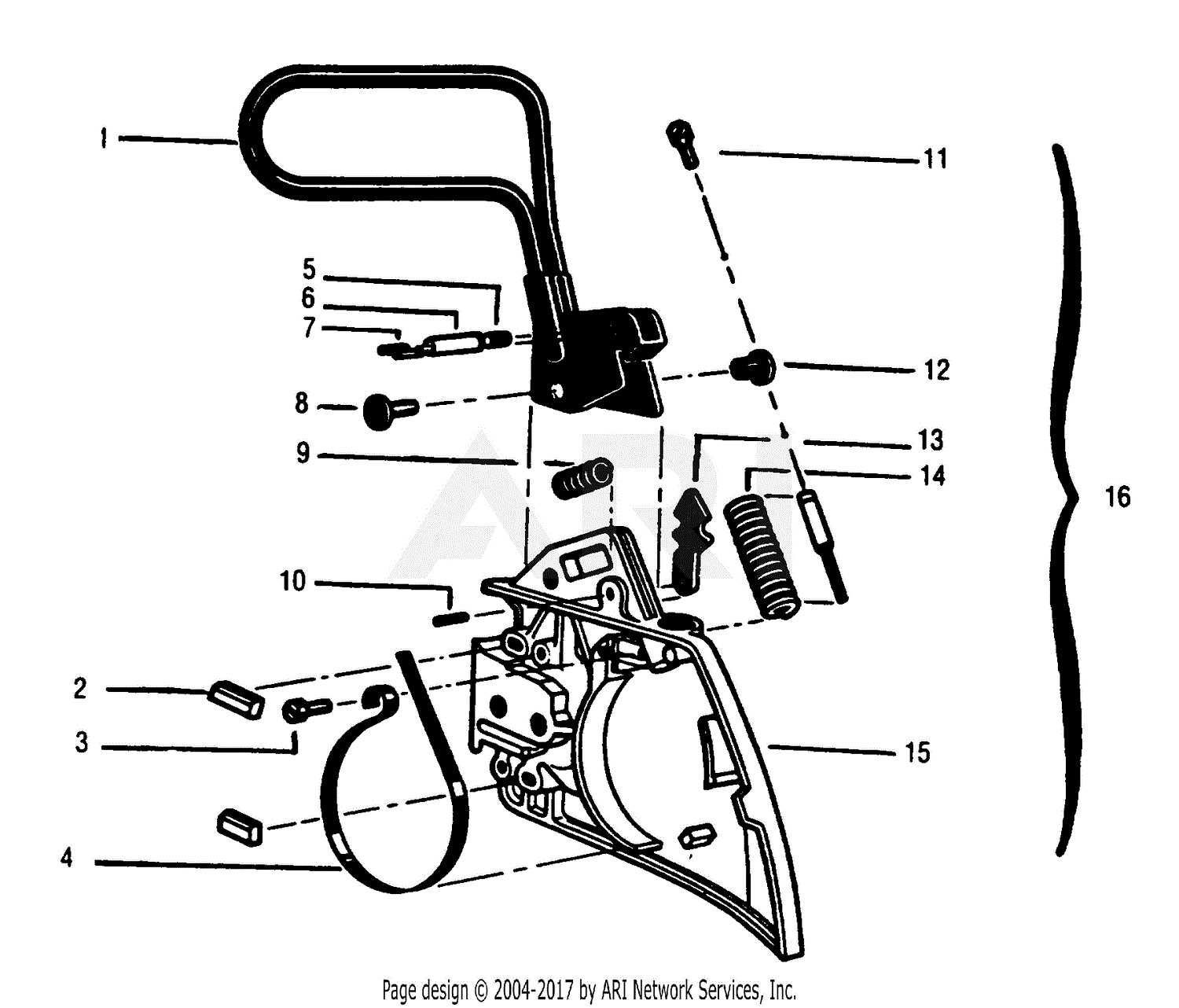

Clutch Assembly: Functionality and Repairs

The clutch assembly is a critical component that connects and disconnects the engine power from the cutting mechanism. Its primary role is to engage or disengage the cutting system based on the operator’s actions. Without a properly functioning clutch, the tool would be inefficient and unsafe to operate.

Over time, the clutch assembly may experience wear, especially if the tool is used frequently or under heavy conditions. Signs of clutch failure can include slipping, difficulty in starting, or unresponsiveness when the throttle is engaged. Regular maintenance and understanding of how to repair or replace parts are essential for keeping the equipment running smoothly.

- Functionality: The clutch assembly works by transferring the engine’s rotational force to the cutting blade or other attachments when needed, while ensuring that the power is disengaged when the tool is idle.

- Wear Indicators: Listen for abnormal sounds or feel vibrations while operating the tool. These could be signs that the clutch is not engaging or disengaging properly.

- Repair Tips: If the clutch is slipping or not engaging correctly, inspect the spring, clutch shoes, and drum. If any parts are damaged, they should be replaced promptly to prevent further damage.

- Step 1: Remove the outer casing of the tool carefully to expose the clutch assembly.

- Step 2: Inspect the clutch shoes for excessive wear or damage.

- Step 3: Replace any worn-out components, ensuring the clutch operates smoothly.

- Step 4: Reassemble the tool and test the clutch performance before full use.

By maintaining the clutch assembly properly, you ensure that the tool remains functional, safe, and efficient for extended periods of use.

Air Filter Maintenance for Better Longevity

Proper care of the air filter is essential to ensure the optimal performance and extended lifespan of your equipment. Regularly maintaining this component can prevent damage to internal mechanisms and keep your machine running smoothly. A clean air filter allows the engine to breathe properly, ensuring that it operates efficiently without strain.

Importance of a Clean Air Filter

Dust, dirt, and debris can accumulate in the air filter, restricting airflow and causing the engine to work harder than necessary. Over time, this can lead to overheating, reduced power, and eventually, costly repairs. A clean filter helps maintain the correct air-to-fuel ratio, which directly impacts performance and fuel efficiency.

How to Maintain the Air Filter

To ensure the air filter remains in good condition, inspect it regularly and clean or replace it as needed. If the filter is clogged, use compressed air to blow out the debris or wash it with water if it’s washable. In cases where the filter is damaged or excessively worn, it’s crucial to replace it promptly with a high-quality replacement part.

Tip: Make sure to follow the manufacturer’s recommendations for cleaning intervals and replacement frequency to avoid any unnecessary strain on the engine.

Safety Features and Their Importance

When working with powerful outdoor tools, ensuring safety is crucial to prevent accidents and injuries. Each component of the device is designed to provide protection for the user, making the experience safer and more efficient. Various mechanisms work together to minimize risk, offering a layer of defense in case of unexpected situations.

Proper safety features help in reducing the chances of accidents and are essential for users who are unfamiliar with operating such machinery. From automatic safety locks to hand guards, these elements create a secure environment for the operator. They not only protect the user but also enhance the performance of the equipment by promoting correct usage.

Understanding and maintaining these safety mechanisms are essential for long-term safety. Regular inspections and adherence to guidelines ensure that all protective functions remain active, minimizing the risk of harm. Ignoring these features can lead to serious consequences, which is why they should always be prioritized during operation.

Starter Mechanism: Common Problems and Fixes

The starter mechanism plays a crucial role in ensuring smooth operation at the beginning of each use. However, like any mechanical system, it is prone to issues over time. Understanding the common problems and their corresponding solutions can help keep the equipment running efficiently and extend its lifespan.

- Rope Not Retracting: This issue often arises when the recoil spring becomes weakened or the rope is damaged. Inspect the spring and rope for wear and replace them if necessary.

- Hard to Pull: A stiff pull can indicate a problem with the starter pawls or the spring tension. Clean and lubricate the components or replace the starter pawls if they are worn out.

- Starter Not Engaging: This may occur due to misalignment or a damaged one-way bearing. Ensure that all parts are properly aligned, and replace the bearing if it’s malfunctioning.

- Broken Recoil Spring: A broken recoil spring will prevent the rope from retracting properly. Replace the spring with a new one, ensuring it is wound correctly.

Regular maintenance and timely repairs can help prevent these issues, ensuring that the starter mechanism functions as intended for each use.

Handle and Grip: Comfort and Control Guide

The handle and grip of a cutting tool play a critical role in ensuring smooth operation and user safety. A well-designed handle provides better control, reduces fatigue, and allows for longer periods of use without discomfort. In this section, we’ll explore how to achieve the right balance between comfort and grip, ensuring an efficient and safe experience.

Key factors that contribute to comfort and control include:

- Ergonomic Design: The shape and contour of the handle should fit comfortably in your hands, reducing strain during extended use.

- Anti-Vibration Features: Vibrations during operation can lead to hand fatigue. Tools equipped with anti-vibration technology minimize discomfort.

- Grip Material: The material used for the grip affects how secure it feels. Rubberized or textured grips offer better traction, especially in wet conditions.

- Handle Position: The position of the handle relative to the cutting mechanism influences how easily you can maneuver the tool. Proper positioning helps with balance and reduces unnecessary strain on your wrists.

For an optimized user experience, consider the following tips for selecting and maintaining a comfortable grip:

- Choose a tool with an ergonomic handle that fits the size of your hands.

- Ensure the grip material is durable and provides adequate traction.

- Regularly clean the grip to prevent wear and tear that could affect performance.

- Check the handle for stability and secure attachment to avoid unnecessary movement during use.