2013 Chevy Malibu Engine Parts Diagram Overview

In modern vehicles, the power unit is composed of numerous intricate elements working together to ensure optimal performance and reliability. These components are essential for maintaining efficiency, fuel consumption, and overall driving experience. Proper knowledge of these mechanisms can help car owners make informed decisions when it comes to maintenance and repairs.

Each element within the system plays a critical role in maintaining the vehicle’s overall functionality. From systems responsible for generating power to those ensuring smooth operation, every component is designed to interact seamlessly. Understanding how these pieces fit together can aid in diagnosing issues, preventing potential failures, and optimizing overall performance.

Whether you are looking to enhance your vehicle’s performance or ensure longevity, having a clear grasp of its power unit’s structure and the role of each individual piece is fundamental. This knowledge empowers drivers to address issues more efficiently and prolong the life of their vehicle.

Overview of the 2013 Chevy Malibu Engine Structure

The internal layout of this vehicle’s power source is designed with a focus on performance, efficiency, and durability. Its configuration combines multiple components that work in unison to deliver optimal functionality. Each section plays a vital role in maintaining the overall reliability of the system, contributing to both fuel economy and power output.

Key Components

- Combustion chamber setup

- Cooling mechanisms to regulate temperature

- Air intake and exhaust systems

Functionality and Interaction

The mechanical elements interact through a series of synchronized processes. Proper timing and balanced distribution of power are essential, allowing the entire setup to function smoothly while minimizing wear and maximizing longevity. The airflow system and fuel supply ensure the unit operates under controlled conditions, promoting consistent performance.

Main Components of the Powertrain System

The powertrain is a crucial system that ensures the functionality and efficiency of a vehicle by transmitting energy to its moving parts. This section focuses on the primary components involved in the operation of this mechanism, each playing a vital role in optimizing performance and providing smooth mobility.

Below is an overview of the key elements found within the system, detailing their individual contributions to overall functionality.

| Component | Function |

|---|---|

| Transmission | Responsible for transferring power from the energy source to the wheels, allowing for smooth acceleration and gear changes. |

| Driveshaft | Connects the transmission to the differential, transmitting rotational force to the wheels. |

| Differential | Distributes power to the wheels, allowing them to rotate at different speeds, especially while turning. |

| Axles | Supports the weight of the vehicle and connects the wheels, allowing them to rotate and drive the car forward. |

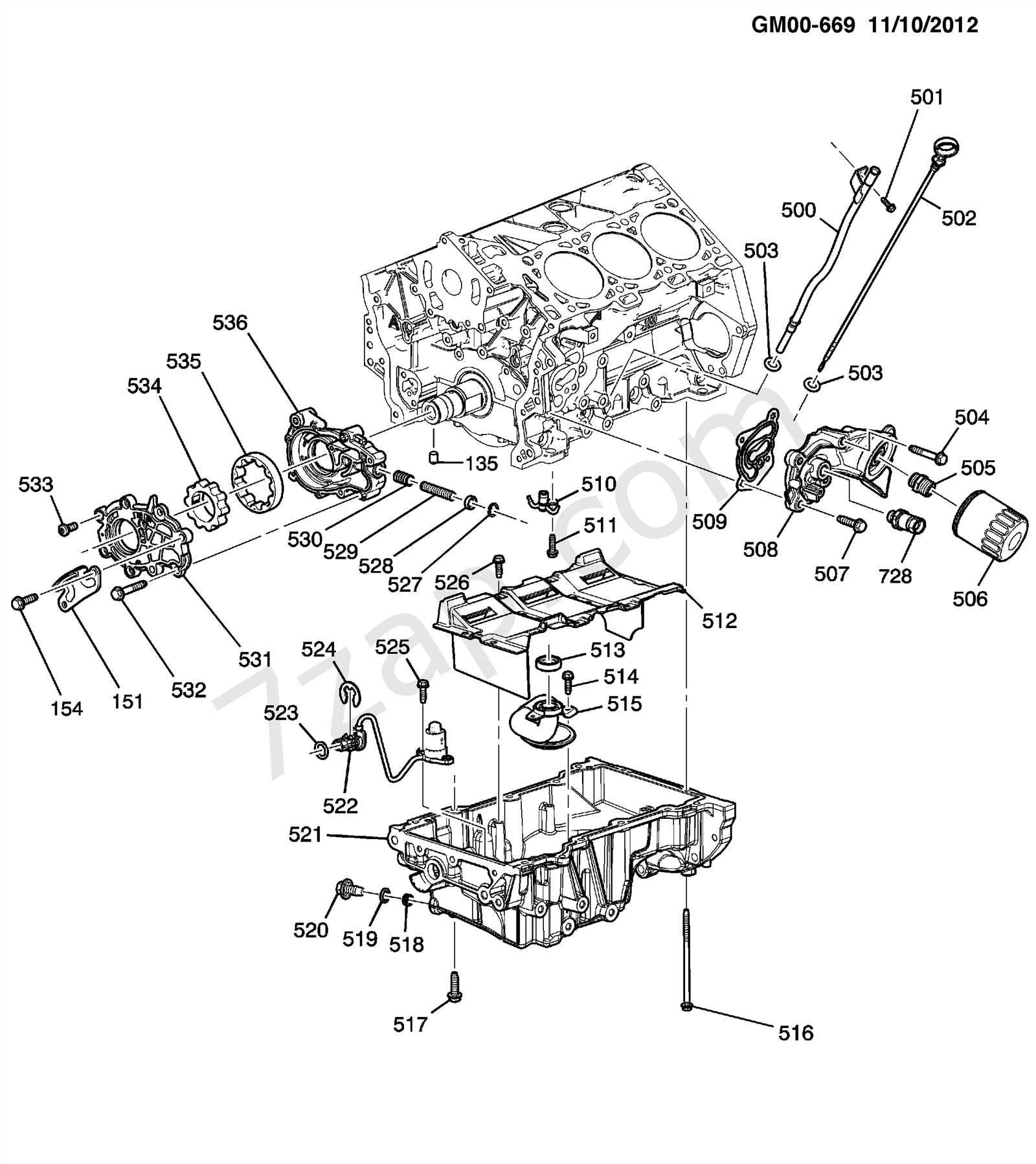

Understanding the Layout of the Cylinder Head

The structure at the top of the motor block plays a crucial role in regulating airflow and fuel distribution, ensuring optimal performance. Its intricate design involves various components working together to manage both the intake and exhaust processes. A clear understanding of this layout can assist in recognizing how each element contributes to the overall function.

- Valves: These are responsible for controlling the flow of air and fuel into the combustion chamber and directing exhaust gases out.

- Camshaft: Positioned to operate the valves, this part determines the timing and sequence of their opening and closing.

- Gaskets: These seals ensure a proper connection between the upper structure and the lower block, preventing leakage of gases or fluids.

- Cooling Passages: Channels are designed to allow coolant to flow through, helping regulate the temperature during operation.

In understanding these components, it becomes easier to appreciate the critical role this section of the motor plays in maintaining efficiency and longevity.

Fuel Injection System: Key Elements

The fuel delivery system plays a critical role in ensuring efficient combustion and overall vehicle performance. It is designed to precisely distribute the right amount of fuel into the combustion chambers, enhancing power output and reducing emissions. Understanding the main components involved can help identify potential issues and maintain optimal function over time.

Injectors

One of the most crucial components of the system is the injector. These devices are responsible for delivering a fine mist of fuel at the exact moment it is needed. The precision with which injectors operate directly impacts the combustion process, contributing to smoother operation and improved fuel efficiency.

Fuel Pressure Regulator

The pressure regulator ensures that the fuel is delivered at a consistent rate. By maintaining stable pressure within the system, it helps avoid fluctuations that could disrupt performance. This element is essential for balancing fuel delivery and ensuring the engine runs smoothly under various driving conditions.

Regular maintenance of these components is crucial for keeping the system in top shape. Identifying signs of wear early can prevent more significant issues from developing, extending the longevity of your vehicle’s overall performance.

Ignition System Parts and Their Functions

The ignition system is a crucial component in any vehicle, responsible for initiating the process that powers the vehicle. It relies on several interconnected elements to work seamlessly, ensuring efficient and reliable operation. Understanding the function of each element can help in maintaining and troubleshooting issues that may arise.

Spark plugs play a key role by creating the spark that ignites the fuel mixture, ensuring combustion at the right moment. Without properly functioning spark plugs, the ignition system would fail to start the engine.

Ignition coils amplify the electrical current from the battery, transforming it into the high voltage needed to create the spark. These coils are essential for ensuring the energy is strong enough to fire the spark plugs.

The distributor is responsible for directing the current to the correct spark plug at the correct time, ensuring the combustion occurs in the right sequence. In some modern systems, this role is performed electronically without a physical distributor.

Finally, the ignition switch serves as the control point, allowing the driver to activate the system and start the vehicle. When turned on, it sends a signal to the other components to begin their functions, bringing the vehicle to life.

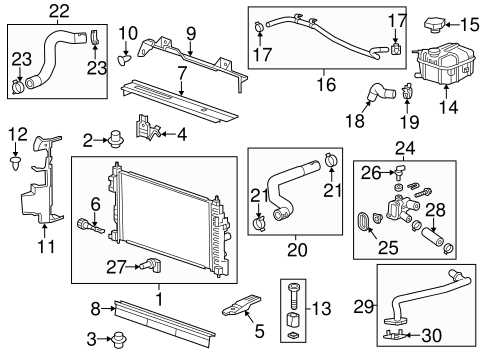

Cooling System Configuration and Components

The thermal regulation setup in modern vehicles plays a critical role in maintaining optimal operational temperatures. This system is designed to prevent overheating, ensuring smooth performance of the vehicle’s power source. By directing coolant through various parts, heat is absorbed and dissipated efficiently, promoting the longevity and reliability of key mechanical components.

The primary elements of this configuration include the radiator, thermostat, water pump, and cooling fans. Each component works in tandem to control the flow of coolant, responding to temperature fluctuations. The radiator acts as a heat exchanger, while the water pump circulates the coolant. The thermostat regulates the coolant’s temperature, ensuring it stays within a safe range. Cooling fans assist in reducing the temperature during peak heat conditions, ensuring the system functions properly even under load.

Proper maintenance of this system is crucial for preventing overheating and damage to internal components. Regular checks and timely replacements of parts like hoses, the radiator cap, and coolant ensure optimal function, allowing for reliable operation in various driving conditions.

Exhaust System Overview in Chevy Malibu

The exhaust system plays a crucial role in managing the gases produced during the combustion process. It ensures that harmful emissions are safely diverted away from the vehicle, contributing to both environmental protection and engine performance. This system is comprised of several key components working together to optimize efficiency and reduce noise.

By carefully routing the exhaust gases through a series of pipes and filters, the system helps maintain proper airflow, preventing the engine from being damaged due to excessive pressure buildup. It also aids in controlling the temperature of the exhaust gases, which is essential for preventing overheating.

| Component | Description |

|---|---|

| Exhaust Manifold | Collects exhaust gases from the engine cylinders and directs them into the exhaust pipe. |

| Catalytic Converter | Reduces harmful emissions by converting toxic gases into less harmful substances. |

| Oxygen Sensor | Monitors the oxygen level in the exhaust gases to optimize the fuel-to-air ratio. |

| Exhaust Pipe | Transports exhaust gases from the engine to the rear of the vehicle. |

| Muffler | Reduces the noise produced by the exhaust gases as they exit the system. |

| Resonator | Further reduces noise and fine-tunes the sound of the exhaust system. |

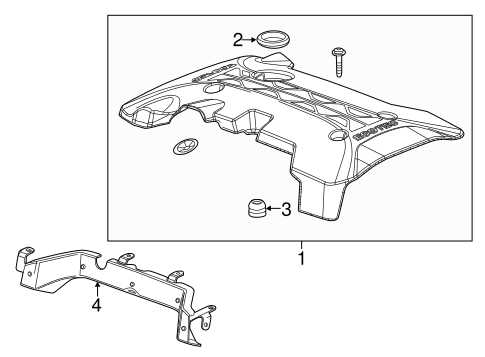

Air Intake System and Its Role in Performance

The air intake system plays a critical role in ensuring optimal performance by managing the flow of air into a vehicle’s combustion chamber. It is responsible for delivering a steady and clean supply of air to maximize the efficiency of the combustion process. A well-designed system enhances engine responsiveness and power, while maintaining proper fuel-to-air ratios.

This system includes various components such as filters, ducts, and sensors, each contributing to the overall effectiveness. By regulating air temperature and filtering out impurities, it helps the engine run smoothly, reducing wear and improving longevity. In performance applications, upgrades to the intake system can provide a noticeable increase in horsepower and torque, offering enhanced acceleration and fuel efficiency.

The balance between air quality, temperature, and flow rate is crucial for maintaining engine efficiency. A properly functioning air intake system supports both low-end torque and high-end performance, making it an essential element in the overall operation and tuning of a vehicle.

Transmission and Engine Connection Components

The smooth interaction between the powertrain and the gearbox relies on a series of components designed to ensure both systems work in harmony. These connection elements facilitate the transfer of mechanical power and enable efficient performance. Proper alignment and function of these parts are essential for optimal operation, preventing wear and ensuring longevity.

Key Components Involved

Various components play a critical role in linking the transmission to the power unit, each designed to manage different aspects of the connection, such as rotational force and power distribution. These elements include connectors, mounts, and supporting structures that maintain stability and reduce vibration during operation.

| Component | Description |

|---|---|

| Flywheel | The flywheel helps maintain rotational inertia, aiding in smooth power transfer and reducing vibrations. |

| Torque Converter | This component acts as a fluid coupling, transmitting torque between the engine and transmission while allowing for varying rotational speeds. |

| Clutch | The clutch enables engagement and disengagement between the engine and transmission, allowing for smooth gear shifts. |

| Mounting Brackets | These support and stabilize the connection, preventing misalignment and excessive movement between the two components. |

Importance of Proper Maintenance

Regular maintenance of these components is vital to ensure the reliability of the overall system. Neglecting to inspect or replace worn-out parts can result in poor performance, overheating, or even failure of the connection, leading to costly repairs.

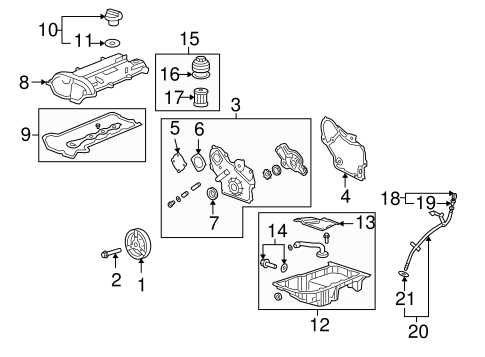

Lubrication System: Essential Engine Parts

The lubrication mechanism in a vehicle is crucial for the smooth operation of various mechanical components. This system ensures that the moving elements are well-oiled, reducing friction and wear. Proper lubrication enhances performance, extends the lifespan of components, and prevents overheating. The system includes several key components working in harmony to maintain optimal function and longevity of the entire system.

| Component | Description |

|---|---|

| Oil Pump | Circulates oil throughout the system, ensuring all parts receive adequate lubrication. |

| Oil Filter | Removes contaminants from the oil, ensuring that only clean oil is pumped into the system. |

| Oil Cooler | Helps maintain the oil at a stable temperature by dissipating excess heat. |

| Oil Reservoir | Stores oil for the lubrication process and serves as a source for replenishment when needed. |

| Lubrication Lines | Conduits that carry oil from the reservoir to various components, ensuring all moving parts are coated. |

Electrical Components in the Engine Compartment

The electrical systems within a vehicle’s front compartment play a crucial role in its overall functionality. These components ensure smooth operation by powering various systems that are vital for the vehicle’s performance. From providing energy to the ignition system to managing other critical functions, these elements are designed to be highly reliable and durable.

Among the key elements are the battery, alternator, and fuse box, each serving a unique function. The battery provides the initial power to start the vehicle, while the alternator ensures a constant supply of electricity once the engine is running. The fuse box protects the electrical circuits from overloads, ensuring safety and preventing damage to sensitive systems.

Additionally, the wiring harnesses distribute power throughout the compartment, connecting various components and facilitating communication between them. Sensors, relays, and connectors also form part of the electrical network, enabling the vehicle’s control modules to monitor and adjust operations as needed.