Comprehensive Chevy 350 Engine Parts Diagram Explained

In the realm of automotive engineering, the intricacies of a high-performance motor are fundamental to unlocking its full potential. Every piece within this mechanical marvel plays a crucial role, contributing to the overall functionality and efficiency of the unit. By delving into the various elements that comprise this powerhouse, enthusiasts can gain invaluable insights into maintenance, performance enhancements, and restoration techniques.

The configuration of a robust propulsion system is marked by a harmonious interplay of various components. Each section, from the intake to the exhaust, has been meticulously designed to optimize airflow and power delivery. Understanding how these parts interact can empower owners to make informed decisions about modifications and repairs, ensuring that their vehicle runs smoothly for years to come.

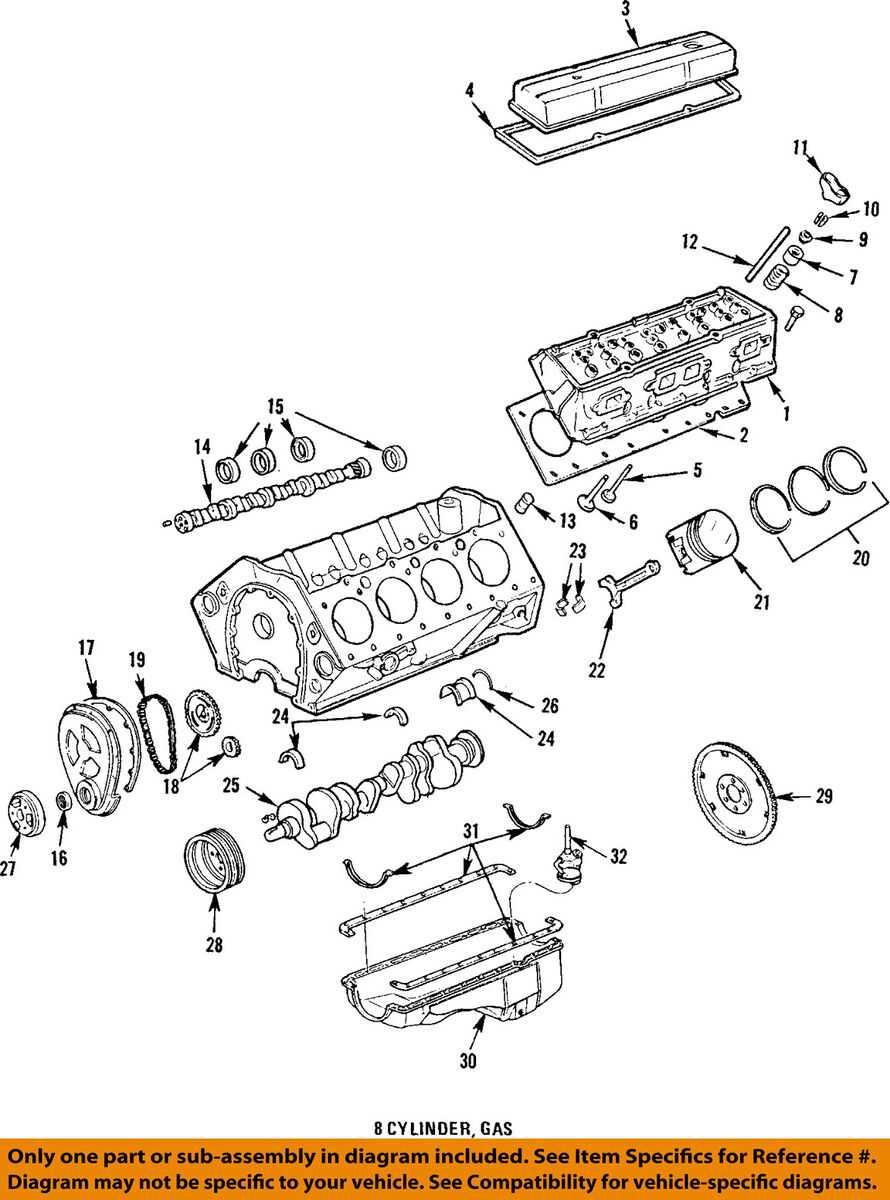

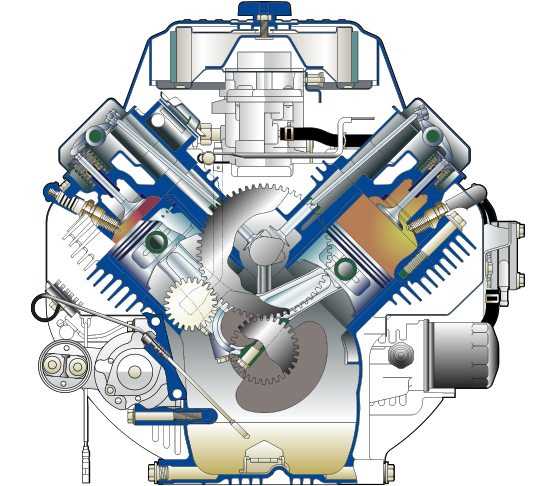

Furthermore, visual representations of these elements serve as a practical tool for both novice and seasoned mechanics alike. By studying these illustrations, one can easily identify the layout and function of each component, facilitating a deeper comprehension of the unit’s operation. Such knowledge not only enhances technical skills but also fosters a greater appreciation for the engineering excellence behind these machines.

Overview of Chevy 350 Engine

This section delves into the key features and characteristics of a widely recognized power unit known for its performance and versatility. Renowned among automotive enthusiasts, this assembly offers a balance of efficiency and power that appeals to a broad range of applications, from everyday vehicles to high-performance machines.

One of the standout aspects of this power source is its robust design, which allows for both longevity and adaptability. Over the years, it has garnered a reputation for being easily modified, making it a favorite among those who seek to enhance their vehicle’s capabilities.

Additionally, this unit is celebrated for its compatibility with numerous components, enabling enthusiasts to customize their setups according to specific preferences and requirements. This flexibility, combined with a solid performance track record, solidifies its position as a cornerstone in the automotive world.

Key Components of the Engine

The functionality of a power unit relies on several critical elements, each playing a vital role in its overall performance. Understanding these components helps in comprehending how the assembly operates and contributes to the vehicle’s efficiency and power delivery.

Essential Elements

Among the primary components are the following:

| Component | Function |

|---|---|

| Cylinder Block | Forms the main structure and houses cylinders for combustion. |

| Pistons | Move within the cylinders to compress air and fuel for ignition. |

| Crankshaft | Converts the linear motion of pistons into rotational motion. |

| Camshaft | Controls the timing of valve openings and closings. |

| Valves | Regulate the flow of air and fuel into the cylinders and exhaust out. |

Supporting Systems

In addition to the core components, several auxiliary systems enhance performance and efficiency:

| System | Purpose |

|---|---|

| Fuel System | Delivers the necessary fuel for combustion. |

| Ignition System | Ignites the fuel-air mixture to initiate the power stroke. |

| Cooling System | Maintains optimal operating temperature to prevent overheating. |

| Lubrication System | Reduces friction between moving parts to enhance longevity. |

Importance of Engine Diagrams

Visual representations of mechanical systems play a crucial role in understanding the intricacies of machinery. These illustrations provide clarity, enabling both enthusiasts and professionals to comprehend complex structures and their functions. By breaking down components into easily digestible formats, these visuals facilitate better maintenance, troubleshooting, and overall knowledge of mechanical assemblies.

Enhanced Understanding

Detailed visuals aid in grasping the relationships between various components. They illustrate how parts interact, which can significantly enhance learning and retention. This understanding is vital for effective repair and optimization, allowing individuals to identify issues quickly and implement solutions efficiently.

Streamlined Communication

Using visuals fosters clearer communication among team members and across different departments. When discussing repairs or modifications, having a shared reference minimizes misunderstandings and ensures everyone is aligned on the specifics. This collective understanding contributes to smoother operations and improved project outcomes.

Identifying Parts in the Diagram

Understanding the components within a schematic is crucial for both novices and experienced enthusiasts. Each section of the illustration provides insights into the functionality and arrangement of various elements, facilitating better maintenance and upgrades.

Key Components Overview

Begin by familiarizing yourself with the primary sections of the layout. Recognizing major groups, such as the fuel delivery system and ignition assembly, will enhance your comprehension of how these assemblies interact. Pay close attention to labels and numbers, as they offer vital information about each specific component.

Interpreting Symbols and Notations

Many illustrations use standardized symbols and annotations to represent various elements. Understanding these notations is essential for accurate identification. For instance, dashed lines may indicate a connection that is not rigid, while solid lines often represent direct attachments. Taking notes while studying these symbols can aid in retention and ensure a thorough grasp of the schematic.

Common Issues with Chevy 350

When dealing with a popular V8 powerhouse, several typical complications may arise, affecting its performance and longevity. Understanding these frequent concerns can help owners maintain optimal operation and avoid costly repairs.

Overheating is a widespread problem that can stem from various factors, such as a failing thermostat, clogged radiator, or worn-out water pump. If not addressed promptly, this can lead to severe damage, including warped cylinder heads.

Oil leaks are another common issue. They often occur due to deteriorated gaskets or seals, leading to diminished lubrication and increased wear on internal components. Regular inspections can help catch these leaks early.

Poor fuel efficiency can indicate problems with the fuel delivery system, including clogged injectors or a malfunctioning fuel pump. Addressing these issues can restore performance and save on fuel costs.

Knocking sounds may signify issues with the ignition timing or low-quality fuel. Ignoring these sounds can result in more significant engine damage, so it’s essential to investigate promptly.

Lastly, starting difficulties can arise from a variety of sources, including battery failure, starter problems, or ignition system malfunctions. Regular maintenance checks can prevent these frustrations and ensure reliable operation.

How to Read Engine Diagrams

Understanding mechanical illustrations is essential for anyone working with automotive machinery. These visuals provide a clear representation of the components and their relationships within a system. Learning to interpret these schematics can significantly enhance your ability to troubleshoot and maintain various machines.

Identifying Key Components

The first step in deciphering mechanical illustrations is to recognize the main elements involved. Typically, each piece is labeled, and familiarizing yourself with common terminology will facilitate easier comprehension. Pay attention to symbols and lines that indicate how components interact.

Understanding Connections and Flow

Connections between components are crucial for understanding how the system functions. Arrows often represent flow directions, whether it be for fluids or power transmission. Observing these connections allows for a clearer insight into operational processes.

| Symbol | Description |

|---|---|

| Circle | Represents a rotational component |

| Arrow | Indicates direction of flow or movement |

| Rectangle | Denotes a static part or casing |

| Dotted Line | Suggests an optional or alternate path |

Essential Tools for Maintenance

Regular upkeep of your vehicle is crucial for ensuring its longevity and optimal performance. Having the right instruments on hand not only simplifies the maintenance process but also enhances safety and efficiency. This section outlines the fundamental tools that every vehicle owner should consider for routine care and minor repairs.

Basic Hand Tools

Every maintenance kit should include a selection of basic hand tools. Wrenches and sockets in various sizes are essential for loosening and tightening bolts. Screwdrivers, both flathead and Phillips, are necessary for securing or removing screws. Pliers, especially adjustable and needle-nose varieties, provide added grip and manipulation for components in tight spaces.

Diagnostic Equipment

In addition to hand tools, having diagnostic equipment can greatly assist in identifying issues before they escalate. A multimeter is invaluable for electrical tests, while an OBD-II scanner allows for reading error codes from the vehicle’s computer system. These tools help pinpoint problems quickly, enabling timely and effective maintenance.

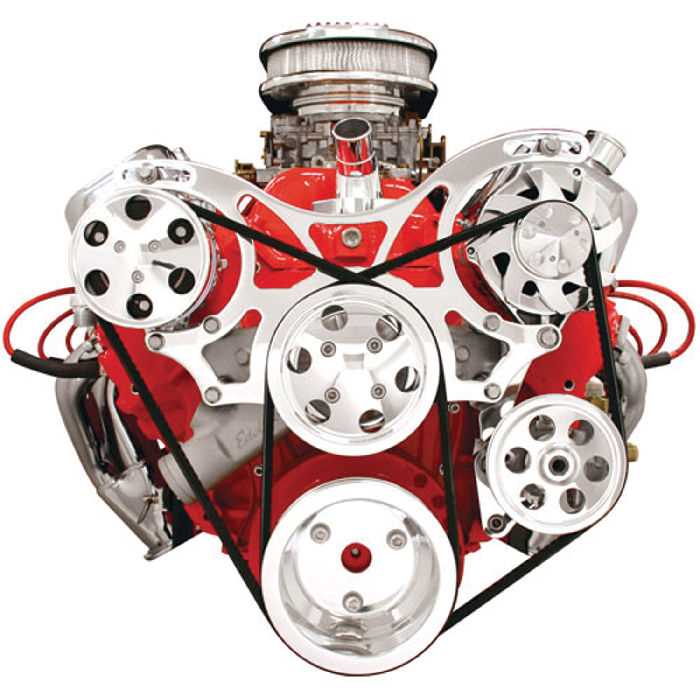

Aftermarket Parts vs. OEM Parts

When it comes to vehicle components, enthusiasts often find themselves debating the merits of different options available in the market. The choice between original manufacturer offerings and alternative solutions can significantly impact performance, durability, and cost-effectiveness. Each category presents distinct advantages and drawbacks that can influence a vehicle owner’s decision-making process.

Original Equipment Manufacturer (OEM) options are produced by the same company that made the original parts for the vehicle. This typically ensures a perfect fit and adherence to specific standards set during the vehicle’s production. Many drivers appreciate the reliability and warranty coverage that comes with these parts, as they are designed to meet the exact specifications of the manufacturer.

On the other hand, aftermarket alternatives provide a range of choices, often at a lower price point. These components can enhance performance or offer unique features not found in standard offerings. However, potential downsides include variability in quality and compatibility. Consumers may find themselves needing to do thorough research to ensure that the selected alternatives align with their expectations and needs.

Ultimately, the decision hinges on individual priorities–whether one values brand reliability and warranty or seeks cost savings and customization. Understanding these differences can help vehicle owners make informed choices that best suit their driving experience.

Popular Upgrades for Performance

Enhancing the capabilities of your vehicle’s power unit can significantly improve its overall performance. Various modifications can help achieve better acceleration, increased horsepower, and improved efficiency. Below are some popular options to consider when looking to boost performance.

- Cold Air Intake: Upgrading to a cold air intake system can enhance airflow, resulting in better combustion and increased power output.

- Performance Exhaust: A high-flow exhaust system reduces back pressure and allows for better exhaust flow, leading to improved engine efficiency.

- Upgraded Camshaft: Replacing the stock camshaft with a performance version can optimize valve timing, increasing power across the RPM range.

- ECU Tuning: Remapping the engine’s control unit can unlock hidden potential by optimizing fuel delivery and ignition timing.

- High-Performance Fuel Injectors: Installing larger or more efficient injectors can provide better fuel atomization, supporting increased power demands.

Each of these upgrades can contribute to a more responsive and powerful driving experience. When planning modifications, it’s important to consider compatibility and the desired outcome for your vehicle.

Maintenance Tips for Chevy 350

Proper upkeep is essential for optimal performance and longevity of your vehicle’s power unit. Regular maintenance not only enhances efficiency but also prevents costly repairs down the road. This section outlines key strategies to ensure your machinery runs smoothly and reliably.

Regular Checks and Fluid Changes

Consistent inspections and timely replacements of fluids are critical for the health of your system. Pay attention to oil, coolant, and transmission fluid levels to prevent overheating and wear. Following the manufacturer’s recommendations for fluid change intervals will keep your components in prime condition.

Inspection of Components

Frequent assessments of various components can identify potential issues before they escalate. Look out for signs of wear in belts, hoses, and filters. Addressing these problems early can save time and money while maintaining efficiency.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 3,000-5,000 miles |

| Coolant Level Check | Monthly |

| Air Filter Replacement | Every 12,000-15,000 miles |

| Fuel Filter Replacement | Every 20,000 miles |

Repairing Common Engine Problems

Addressing frequent mechanical issues is essential for maintaining optimal performance in vehicles. Understanding the root causes of these malfunctions can significantly reduce repair time and costs. This section will outline typical challenges and provide guidance on how to effectively resolve them.

Overheating Issues

One prevalent problem is excessive heat. Common culprits include a malfunctioning radiator, low coolant levels, or a faulty thermostat. To tackle this, first, check the coolant reservoir and fill it if necessary. Inspect the radiator for leaks or blockages, and replace the thermostat if it appears to be stuck. Regular maintenance of the cooling system can help prevent these complications.

Misfiring Cylinders

Another frequent issue is cylinder misfires, often caused by worn spark plugs or ignition coils. Symptoms may include rough idling and decreased power. To resolve this, start by examining the spark plugs for wear and replacing them if needed. Additionally, inspect the ignition coils for proper function and replace any that are malfunctioning. Keeping these components in good condition is vital for smooth operation.

Impact of Engine Parts on Performance

The efficiency and output of a power unit are heavily influenced by its various components. Each segment plays a critical role in determining how well the machine operates, affecting everything from acceleration to fuel economy. Understanding the intricate relationships between these components can lead to better performance and longevity of the unit.

- Intake System:

- Enhances airflow, improving combustion efficiency.

- Increases horsepower and torque by optimizing air-fuel mixture.

- Exhaust System:

- Facilitates the removal of gases, reducing back pressure.

- Contributes to better overall performance and sound quality.

- Fuel Delivery:

- Ensures precise fuel atomization for optimal combustion.

- Directly impacts fuel efficiency and power output.

- Ignition System:

- Controls the timing of spark, crucial for performance.

- Affects cold starts and throttle response.

- Cooling Mechanism:

- Maintains ideal operating temperatures to prevent overheating.

- Prolongs the life of the entire assembly.

In summary, the interplay of these various elements is fundamental to achieving superior functionality and responsiveness. Each component must work in harmony to maximize the potential of the power unit.

Finding Reliable Parts Suppliers

Locating trustworthy sources for components is crucial for any automotive enthusiast or professional. The quality and reliability of the materials used can significantly affect performance and longevity. Understanding where to find dependable suppliers ensures that you receive top-notch items suited to your needs.

Key Factors to Consider

When searching for reputable vendors, several elements should guide your decision-making process:

- Reputation in the industry

- Customer reviews and feedback

- Return policies and warranties

- Availability of technical support

Comparison of Popular Suppliers

| Supplier Name | Reputation Rating | Warranty Offered | Customer Support |

|---|---|---|---|

| Supplier A | 4.5/5 | 2 Years | Available |

| Supplier B | 4.0/5 | 1 Year | Email Support |

| Supplier C | 4.8/5 | Lifetime | Phone and Email |

By evaluating these criteria and comparing different providers, you can make informed choices that enhance your projects and maintain high standards in quality.