Understanding the Chrysler 300 Parts Diagram for Efficient Repairs

When it comes to vehicle maintenance and repair, having a comprehensive understanding of the various elements that comprise an automobile is crucial. Knowledge of how each component fits into the overall structure aids in diagnosing issues and performing effective repairs. This section aims to provide an insightful overview of the intricate network of mechanical and electrical systems that work together to ensure optimal performance.

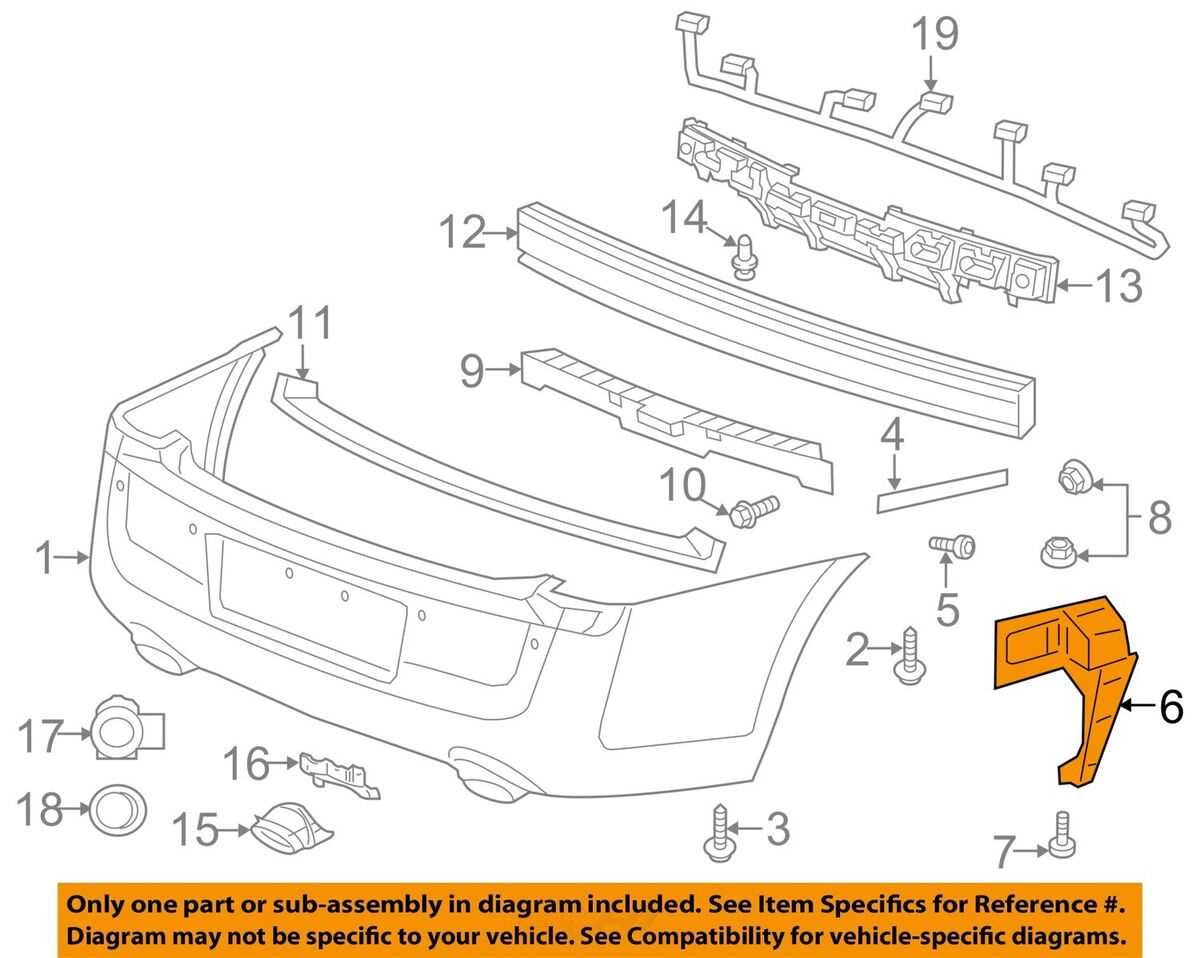

Visual representations of these components not only enhance understanding but also serve as valuable resources for both professionals and enthusiasts alike. By exploring the relationship between individual sections and their functions, one can gain a deeper appreciation for the engineering marvels that vehicles truly are. Such insights empower individuals to tackle repairs with confidence, whether they are replacing a faulty mechanism or upgrading specific systems.

In the following segments, readers will encounter detailed illustrations that simplify complex systems, making it easier to locate and identify essential elements. This approach not only demystifies the structure of automobiles but also promotes a hands-on learning experience, enabling users to engage more effectively with their vehicles.

Understanding Chrysler 300 Parts

Every vehicle is a complex assembly of components working in unison to deliver performance and comfort. Grasping the intricacies of these elements enhances the overall experience of ownership and maintenance. A comprehensive awareness of these various segments allows enthusiasts and owners alike to navigate repairs and modifications with confidence.

Key Components and Their Functions

The fundamental structure of an automobile includes several vital systems, such as the powertrain, suspension, and electrical framework. Each of these systems plays a crucial role in the vehicle’s operation. For instance, the engine and transmission form the powertrain, enabling propulsion, while the suspension system ensures stability and ride quality. Understanding how these elements interact can facilitate better decision-making regarding upgrades or repairs.

Importance of Quality and Compatibility

Choosing the right components is essential for optimal performance and longevity. High-quality replacements often lead to improved reliability and safety. Moreover, ensuring compatibility between different segments is critical; mismatched parts can result in inefficiencies or even damage. When selecting components, consider not just the price but also the manufacturer’s reputation and the materials used. Investing in quality pays off in the long run, reducing the need for frequent replacements.

Importance of Parts Diagrams

Understanding the layout and components of a vehicle is essential for effective maintenance and repair. Visual representations that outline the various elements play a crucial role in assisting technicians and enthusiasts alike. These illustrations not only aid in identifying individual components but also provide insights into how they interact within the overall system.

Enhanced Understanding

Detailed illustrations contribute significantly to a clearer comprehension of a vehicle’s structure. They enable individuals to recognize specific components, their functions, and their locations. This knowledge is vital for troubleshooting issues and executing repairs accurately, reducing the likelihood of errors during the process.

Efficient Repair Processes

When faced with a malfunction, having access to comprehensive visual guides can expedite the repair process. Technicians can quickly reference the needed elements, ensuring that replacements or adjustments are made precisely. This efficiency not only saves time but also minimizes costs associated with labor and unnecessary part replacements.

In conclusion, utilizing visual guides is indispensable for anyone involved in automotive maintenance. Their role in simplifying complex systems and enhancing operational efficiency cannot be overstated.

Common Chrysler 300 Components

Understanding the various elements of a vehicle is essential for maintenance and repair. Each automobile consists of numerous integral components, each serving a unique purpose that contributes to the overall functionality and performance. Familiarity with these elements can aid in troubleshooting issues and enhancing the driving experience.

Among the fundamental components are the engine, transmission, and suspension systems. The engine serves as the heart of the vehicle, generating the power necessary for movement. The transmission, responsible for transferring this power to the wheels, plays a crucial role in controlling speed and torque. Meanwhile, the suspension system ensures a smooth ride by absorbing shocks from uneven surfaces.

Other vital parts include the braking system, which is essential for safety, allowing the driver to slow down or stop the vehicle effectively. The electrical system powers various features, from the ignition to entertainment systems, playing a significant role in modern driving experiences. Additionally, the exhaust system helps manage emissions and noise, contributing to both environmental compliance and passenger comfort.

Moreover, understanding the interior components such as the dashboard, seating, and climate control enhances user comfort and accessibility. Each of these elements is designed with precision, ensuring a harmonious interaction between man and machine.

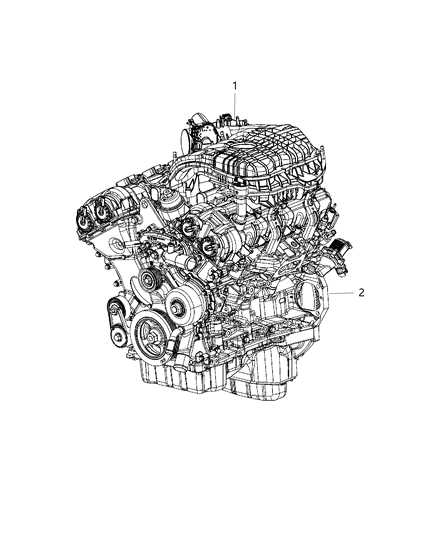

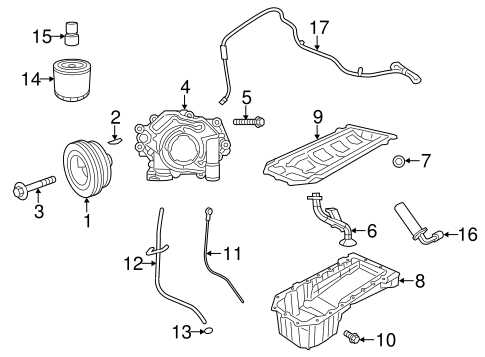

Engine Parts Overview

The intricate system of components that powers a vehicle plays a crucial role in its overall performance and efficiency. Understanding the various elements within this system is essential for maintenance and repair. This section provides insight into the key constituents that contribute to the engine’s functionality.

At the heart of this assembly is the cylinder block, which houses the cylinders where fuel combustion occurs. Adjacent to this is the cylinder head, responsible for sealing the top of the cylinders and containing essential components such as valves and spark plugs. Together, these elements create the necessary environment for the combustion process.

Another significant component is the crankshaft, which transforms the linear motion of the pistons into rotational motion, ultimately powering the vehicle’s drivetrain. The camshaft works in tandem with the crankshaft, controlling the timing of valve openings and closings, ensuring optimal airflow and performance.

Cooling is vital for engine longevity, making the water pump and radiator indispensable parts. They work together to dissipate excess heat generated during operation. Additionally, the oil pump circulates lubricant to reduce friction among moving parts, thereby enhancing durability.

Fuel delivery is managed by the fuel injectors, which precisely dispense the necessary amount of fuel into the combustion chambers. This is complemented by the intake and exhaust manifolds, which facilitate air entry and exhaust gas expulsion, contributing to efficient engine operation.

In summary, each element within the engine assembly serves a specific purpose, and their collaboration is vital for optimal performance and reliability. A thorough understanding of these components enables effective maintenance and ensures a smooth driving experience.

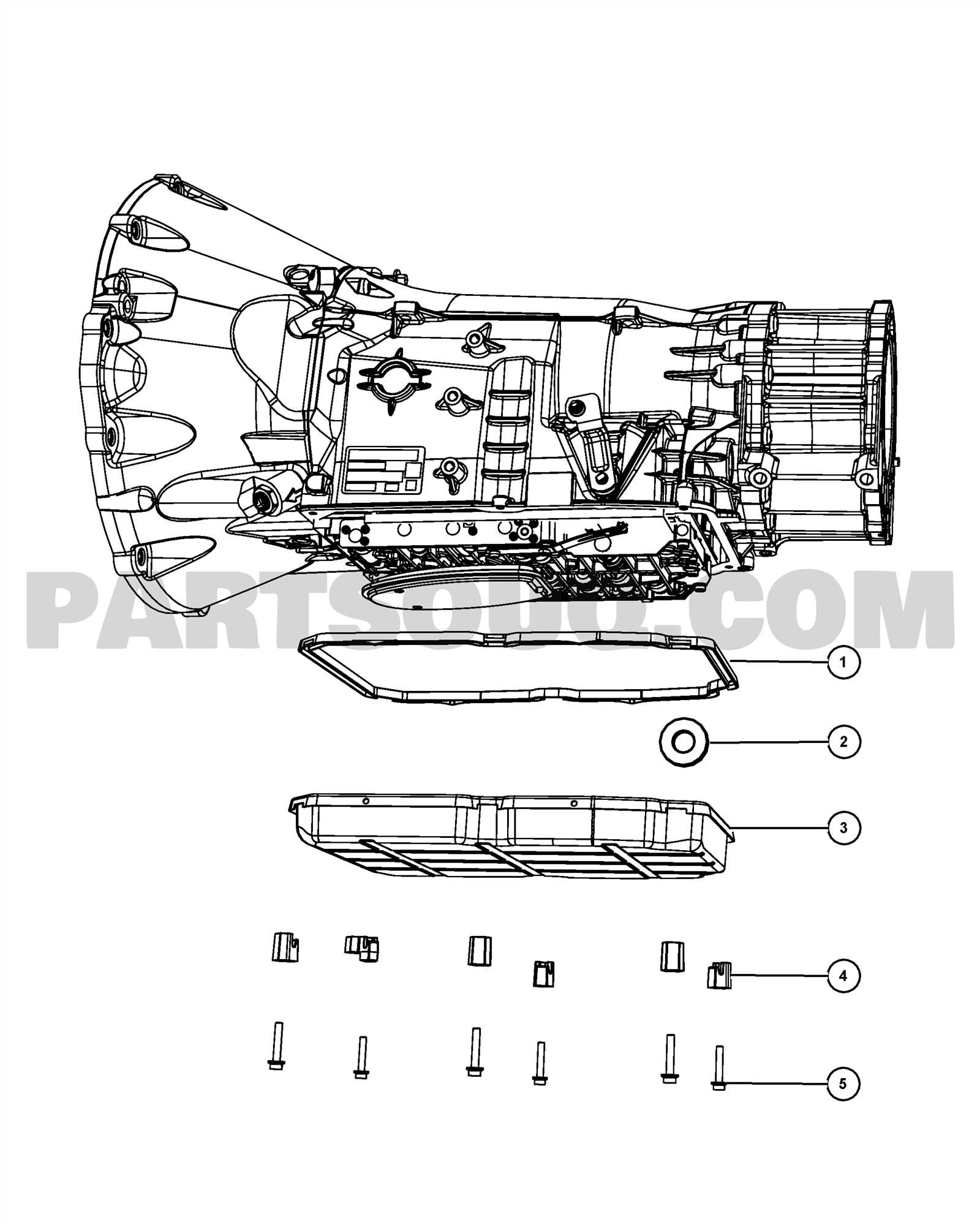

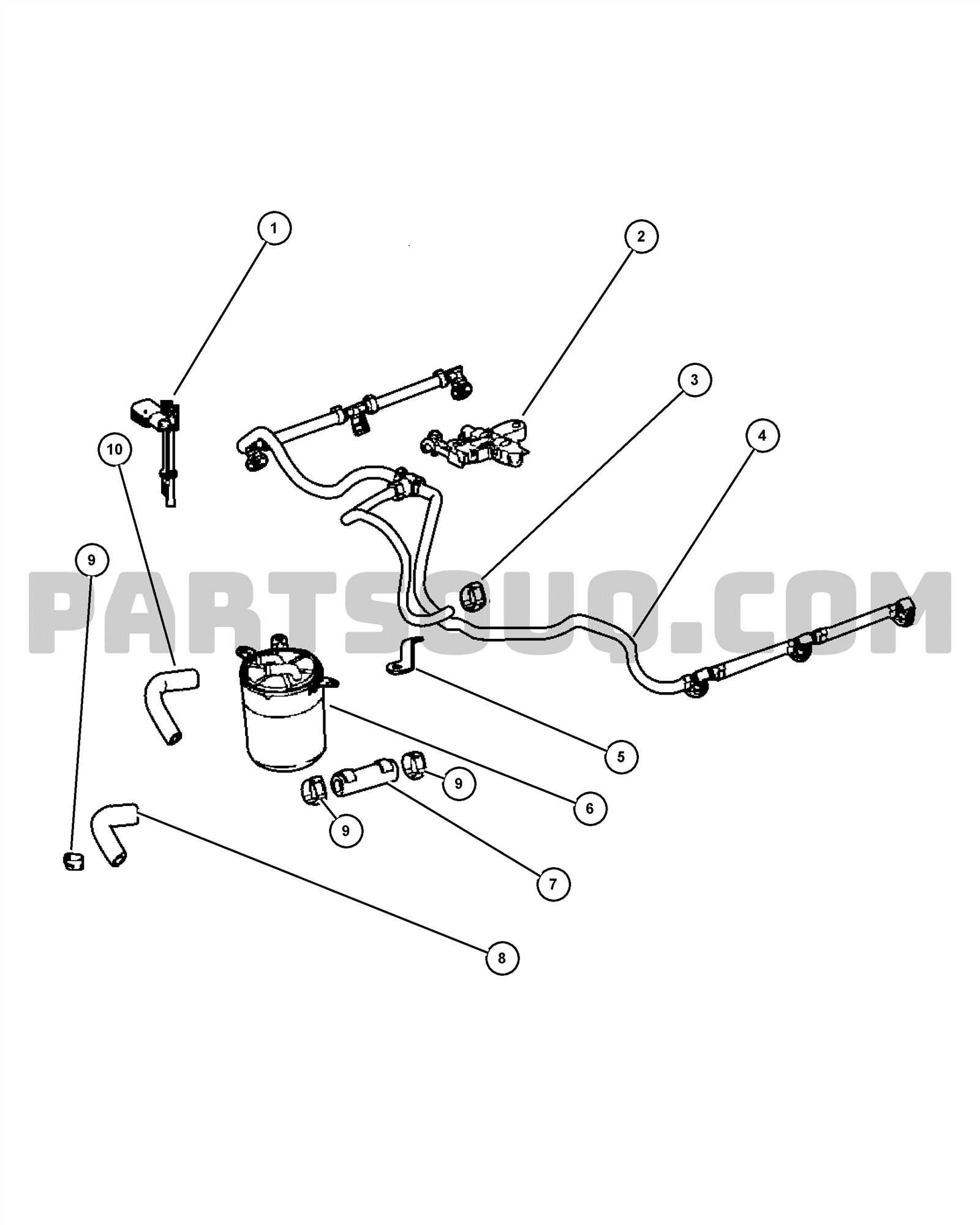

Transmission and Drivetrain Elements

The components responsible for transferring power from the engine to the wheels play a crucial role in a vehicle’s performance and efficiency. Understanding these elements is essential for maintenance, upgrades, or repairs, as they ensure smooth operation and optimal functionality.

Key components within the drivetrain system include:

- Transmission: This mechanism regulates the power output from the engine, allowing the vehicle to change speeds effectively.

- Driveshaft: A rotating shaft that transmits torque from the transmission to the differential, enabling wheel movement.

- Differential: This unit distributes power to the wheels, allowing them to rotate at different speeds, especially when turning.

- Axles: These rods connect the differential to the wheels, transmitting power while supporting the vehicle’s weight.

- Transfer Case: In all-wheel-drive systems, this component directs power to both front and rear axles, enhancing traction.

When examining these elements, consider the following:

- Regular inspections help identify wear and tear, ensuring longevity.

- Fluid levels should be maintained to prevent overheating and ensure proper lubrication.

- Any unusual noises during operation may indicate underlying issues requiring immediate attention.

Proper understanding and care of these systems contribute significantly to the overall performance and safety of the vehicle.

Chassis and Suspension Details

The framework and support systems of a vehicle play a crucial role in its overall performance and handling. Understanding these components helps in optimizing ride quality and ensuring safety on the road. This section explores the essential elements of the undercarriage and suspension system, highlighting their functions and configurations.

Key Components of the Chassis

- Frame: The main structure that supports all other parts of the vehicle, providing stability and strength.

- Subframe: A smaller framework that houses specific components, often including the engine and suspension elements.

- Body Mounts: Attachments that connect the body to the frame, allowing for flexibility while maintaining structural integrity.

Suspension System Overview

- Shock Absorbers: Devices designed to dampen the impact of road irregularities, improving comfort and control.

- Springs: Components that support the weight of the vehicle and absorb shocks, allowing for a smooth ride.

- Control Arms: Linkages that connect the suspension to the vehicle frame, enabling proper wheel movement.

Maintaining these crucial systems is essential for enhancing vehicle performance and ensuring driver and passenger safety. Regular inspections and timely replacements can prevent issues related to handling and ride quality.

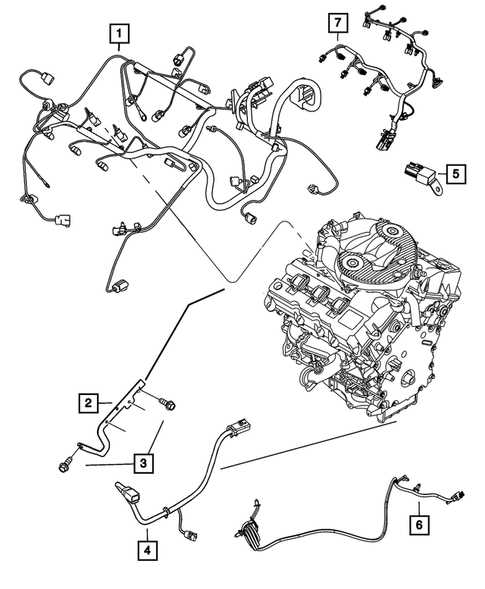

Electrical System Breakdown

The electrical system of a vehicle plays a crucial role in its overall functionality and performance. This complex network consists of various components that work together to ensure efficient operation. Understanding the intricacies of this system is essential for troubleshooting and maintenance.

Key components of the electrical system include:

- Batteries

- Alternators

- Starter motors

- Fuses

- Relays

- Wiring harnesses

Each of these elements contributes to the proper functioning of the vehicle. For example, batteries provide the necessary power to start the engine, while alternators recharge the battery during operation.

In addition to these core components, the electrical system also supports various accessories, such as:

- Lighting systems

- Infotainment systems

- Heating and cooling controls

- Power windows and locks

Proper maintenance and timely repairs of the electrical system are vital to prevent potential issues. Regular inspections can help identify wear and tear on wiring, connectors, and other components, ensuring the vehicle remains reliable and safe.

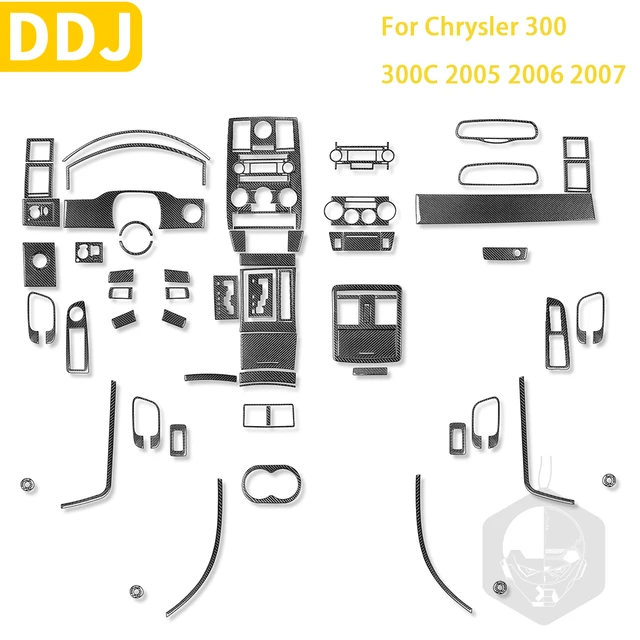

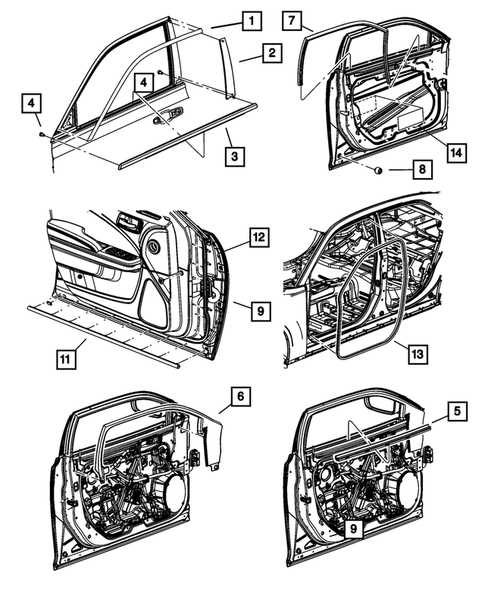

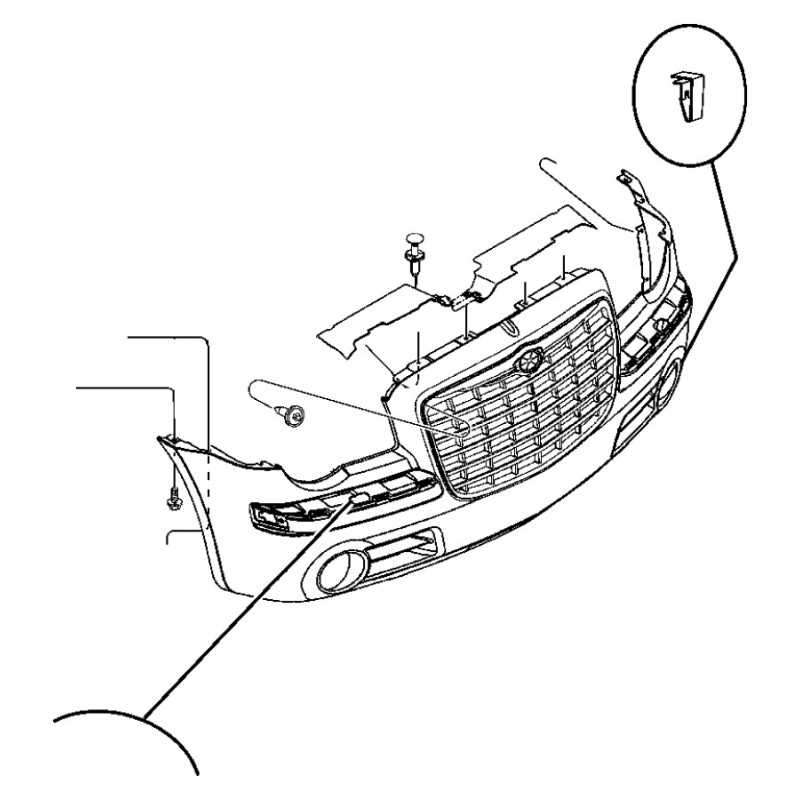

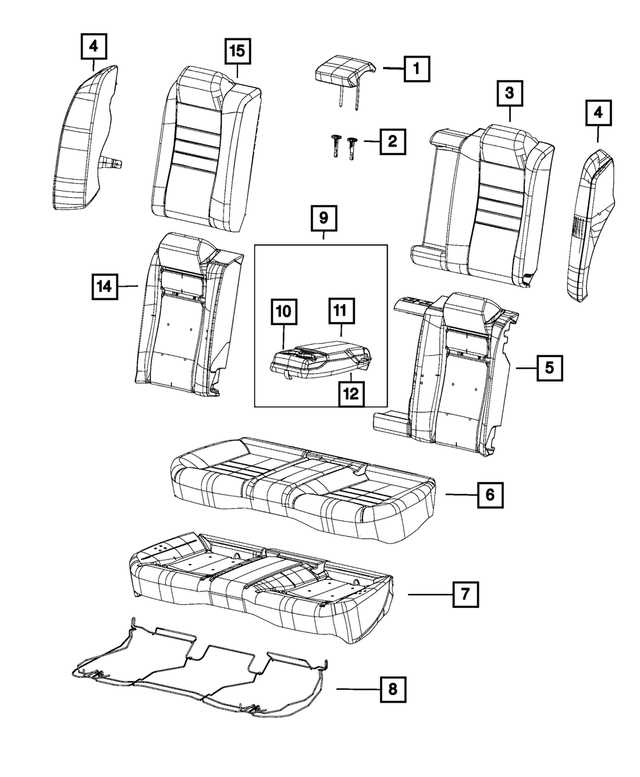

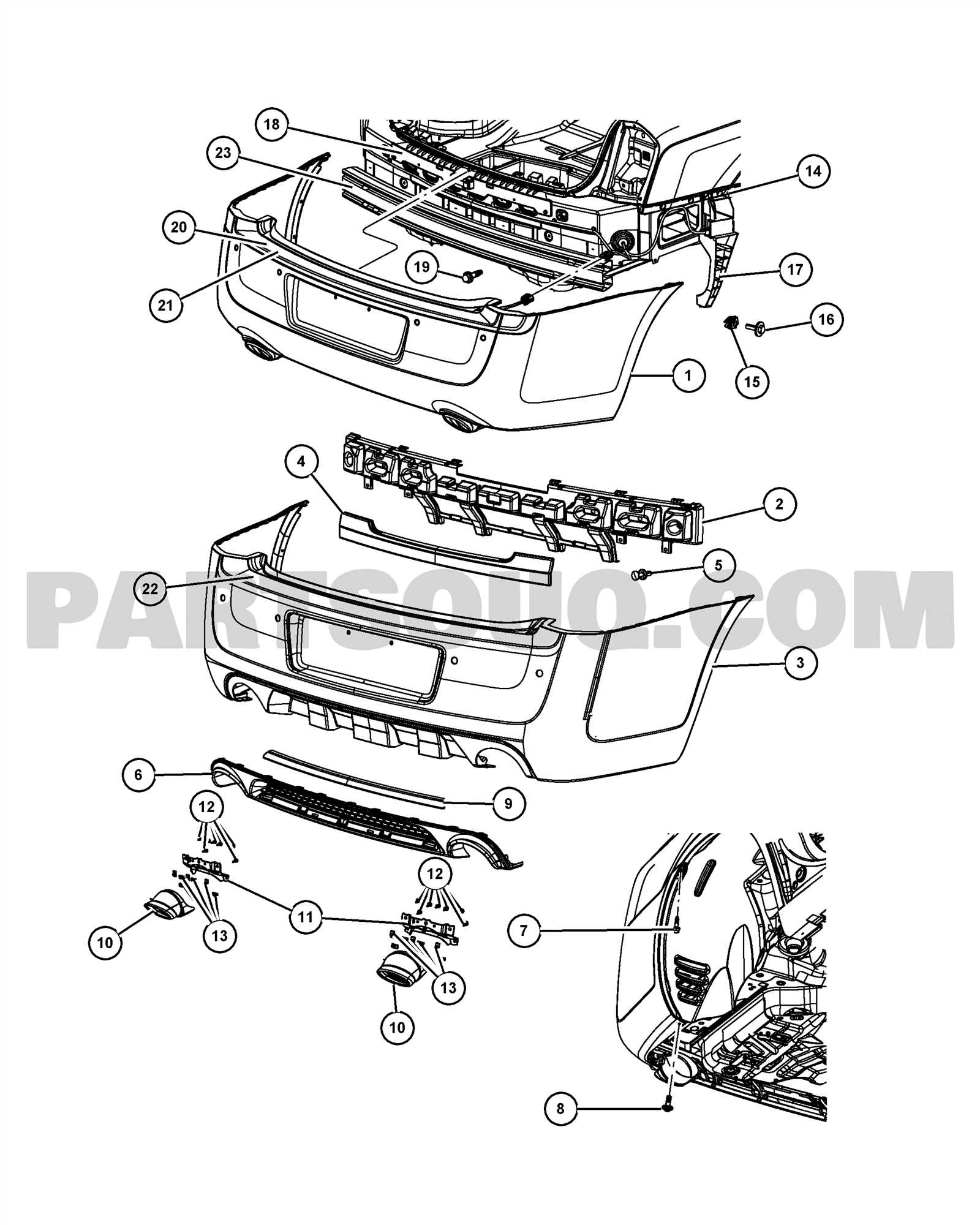

Interior and Exterior Features

The allure of modern vehicles lies not only in their performance but also in their meticulously designed elements that enhance comfort and style. The interior and exterior characteristics play a significant role in creating a cohesive driving experience, blending functionality with aesthetic appeal.

Within the cabin, numerous elements contribute to an inviting atmosphere:

- Luxurious seating materials that provide comfort and support.

- Intuitive layout of controls and displays for seamless interaction.

- Advanced infotainment systems offering connectivity and entertainment.

- Ambient lighting that sets the mood for any journey.

- Spacious compartments for storage, ensuring practicality for everyday use.

On the outside, the vehicle showcases a striking profile and design features that command attention:

- Sleek lines that enhance aerodynamics and visual appeal.

- Distinctive grille and headlight designs that contribute to its identity.

- Alloy wheels that add a sporty touch and improve performance.

- Robust paint options that protect against wear while providing a unique style.

- Smart use of chrome accents to elevate the overall elegance.

Together, these attributes reflect the commitment to excellence in engineering and design, ensuring an exceptional experience for drivers and passengers alike.

Maintenance and Replacement Insights

Proper upkeep and timely substitutions are crucial for the longevity and optimal performance of any vehicle. Understanding the intricate components and their functions not only aids in identifying potential issues but also streamlines the process of replacing worn-out elements. This section aims to provide valuable insights into the maintenance practices and the nuances of component replacement.

Key Maintenance Practices

Regular inspections and servicing are fundamental to ensure that every system operates efficiently. Engaging in routine checks can help detect minor problems before they escalate into significant concerns. Adhering to manufacturer recommendations regarding oil changes, filter replacements, and fluid top-ups is essential for maintaining vehicle health.

Replacement Considerations

When it comes to replacing any component, choosing high-quality alternatives is paramount. Inferior substitutes may lead to further complications and increased costs in the long run. It is advisable to consult detailed schematics or guides that outline each element’s specifications and placement within the assembly for a successful replacement process.

| Component | Maintenance Interval | Replacement Type |

|---|---|---|

| Oil Filter | Every 5,000 miles | Standard Replacement |

| Brake Pads | Every 30,000 miles | Complete Set Replacement |

| Battery | Every 3-5 years | Direct Replacement |

| Air Filter | Every 15,000 miles | Standard Replacement |

Aftermarket vs. OEM Parts

When it comes to vehicle repairs and enhancements, enthusiasts often face a choice between components manufactured by the original equipment manufacturer and those created by third-party companies. Each option presents its own set of advantages and disadvantages that can impact performance, durability, and cost. Understanding these differences is crucial for making informed decisions about vehicle maintenance and upgrades.

Original Equipment Manufacturer (OEM) Components

OEM components are produced by the same company that manufactured the original parts of the vehicle. They are designed to meet the specific standards and specifications set by the manufacturer, ensuring compatibility and quality.

- Guaranteed fit and functionality

- Typically backed by a warranty

- Ensures compliance with manufacturer standards

Aftermarket Components

Aftermarket components are produced by independent manufacturers and may offer alternatives to OEM options. These parts can vary widely in quality, price, and performance, providing consumers with a broader range of choices.

- Potential for lower costs

- Greater variety in performance and aesthetics

- Some products may exceed OEM specifications

Ultimately, the choice between OEM and aftermarket components depends on individual preferences, budget, and the specific requirements of the vehicle. Careful consideration of each option can lead to a satisfactory outcome for any automotive project.

Locating Reliable Diagrams Online

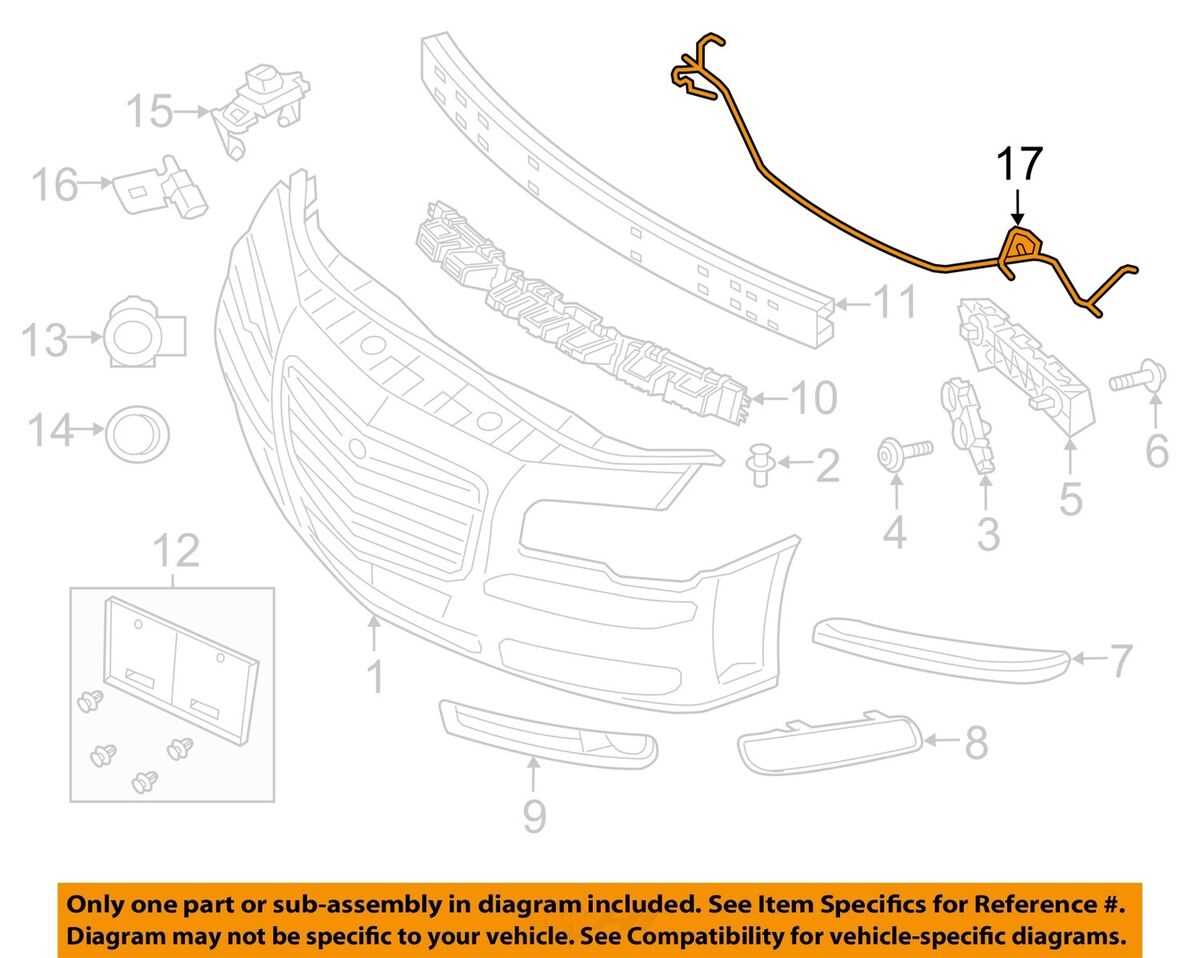

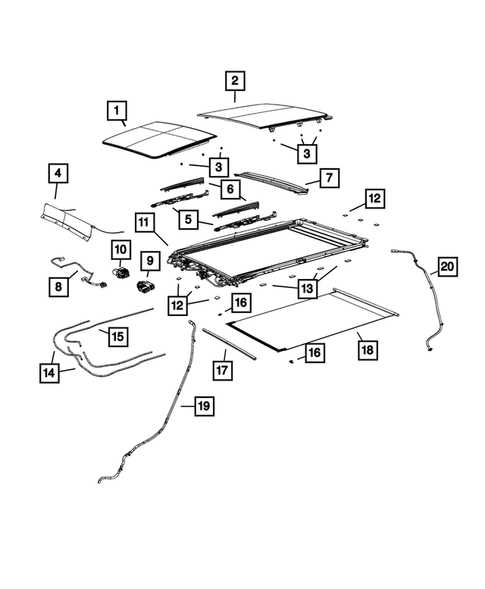

Finding trustworthy visual aids for automotive components can be a challenging task. With a plethora of resources available on the internet, it’s essential to identify reputable websites that offer accurate and detailed illustrations. Utilizing these resources can significantly enhance your understanding of vehicle mechanics and facilitate efficient repairs.

One effective method is to explore official manufacturer websites, which often provide comprehensive guides and visuals tailored to specific models. Additionally, reputable automotive forums and communities can be valuable sources of information, where experienced enthusiasts share insights and resources. Furthermore, online retailers that specialize in vehicle components frequently offer detailed schematics as part of their product listings, allowing users to view the parts in context.

Another option is to consult dedicated automotive repair manuals, which may be available in digital format. These manuals typically include an extensive array of visual references and detailed instructions, ensuring that users can easily locate and understand the necessary components. Always cross-reference information from multiple sources to verify accuracy, as this practice will help ensure that the visuals align with the actual parts of your vehicle.

Using Diagrams for Repairs

Visual representations play a crucial role in the maintenance and repair of vehicles. They serve as valuable tools that enhance understanding and facilitate the repair process by illustrating the various components and their relationships.

Utilizing these visuals can lead to a more efficient workflow. Here are some key benefits:

- Clarity: Diagrams simplify complex systems, making it easier to identify parts and their functions.

- Guidance: They provide step-by-step instructions, reducing the likelihood of errors during repairs.

- Time-Saving: Visual aids can expedite the troubleshooting process, allowing for quicker resolutions.

- Enhanced Learning: For novices, these illustrations serve as educational resources that promote better comprehension of automotive systems.

Incorporating diagrams into repair routines not only improves accuracy but also boosts confidence in tackling various tasks. By leveraging these tools, one can ensure that repairs are executed efficiently and effectively.

Tips for Part Identification

Identifying components within a vehicle can often be a challenging task, but certain strategies can simplify the process. Understanding the structure and function of each element is essential for accurate identification and replacement.

1. Utilize Reference Materials: Consult manuals or online resources that provide detailed information about the specific model. Visual aids can enhance your understanding of where each component is located and its role.

2. Take Clear Photos: When disassembling parts, capture images from various angles. This practice helps in remembering how everything fits together during reassembly.

3. Label Components: Use sticky notes or labels to mark parts as you remove them. This method keeps everything organized and reduces the risk of misplacing items.

4. Engage with Online Communities: Forums and social media groups dedicated to automotive enthusiasts can be invaluable. Sharing experiences and asking for advice from others who have tackled similar tasks can provide insights.

5. Familiarize with Common Terms: Understanding the terminology associated with automotive components will make it easier to communicate your needs when seeking assistance or ordering replacements.