Comprehensive Guide to 2004 Honda Civic Engine Parts Diagram

Exploring the intricate structures of a vehicle’s mechanics provides valuable insights into its operation and maintenance. A comprehensive representation of the various components involved reveals how each element contributes to the overall functionality of the machine. By examining these configurations, enthusiasts and technicians alike can enhance their understanding of automotive systems.

Visualizing the arrangement of these elements allows for better troubleshooting and repairs, making it easier to identify potential issues. Whether one is a seasoned mechanic or a curious car owner, having access to detailed representations can significantly improve the ability to maintain and service the vehicle effectively.

In addition to aiding in repairs, a thorough grasp of the individual components fosters appreciation for the engineering behind modern automobiles. Each unit is designed to work harmoniously within a complex framework, showcasing the innovation and precision involved in automotive design.

This section aims to provide a comprehensive understanding of the internal mechanisms that contribute to a vehicle’s performance. By exploring various components, readers can gain insights into how these elements work together to ensure efficient operation and reliability. The importance of recognizing these components lies in their roles in maintenance and troubleshooting, which can enhance the overall driving experience.

Key Components of the Internal Mechanism

- Fuel Delivery System

- Ignition Assembly

- Cooling Mechanism

- Lubrication System

- Exhaust Management

Functions of Each Element

- Fuel Delivery System: Responsible for supplying the necessary fuel for combustion.

- Ignition Assembly: Initiates the combustion process to power the vehicle.

- Cooling Mechanism: Regulates the temperature to prevent overheating during operation.

- Lubrication System: Ensures all moving parts are well-lubricated for smooth operation.

- Exhaust Management: Directs exhaust gases away from the engine and reduces emissions.

Key Components of Engine System

The heart of any automotive machine is a complex assembly of essential elements that work in harmony to convert fuel into motion. Understanding the primary components within this assembly is crucial for diagnosing issues and maintaining optimal performance. Each segment plays a specific role, contributing to the overall functionality and efficiency of the system.

Fundamental Elements

Among the vital components are those responsible for air intake, fuel injection, and exhaust management. These elements ensure that the correct mixture of air and fuel reaches the combustion chamber while effectively expelling waste gases. Their coordination is essential for the smooth operation of the entire system.

Functional Overview

The efficiency and performance of the system depend on various interconnected units, including those that regulate temperature and manage electrical output. A breakdown in any of these units can lead to diminished power and increased emissions, highlighting the importance of regular inspection and maintenance.

| Component | Function |

|---|---|

| Intake Manifold | Distributes air to the cylinders |

| Fuel Injector | Delivers fuel into the combustion chamber |

| Exhaust Manifold | Collects and directs exhaust gases |

| Thermostat | Regulates engine temperature |

| Alternator | Charges the battery and powers electrical systems |

Functionality of Engine Parts

The various components within a power unit play crucial roles in the overall performance and efficiency of the vehicle. Each element is designed to fulfill specific functions, contributing to the smooth operation of the entire system. Understanding the roles of these components helps in diagnosing issues and optimizing performance.

Core Components

At the heart of the mechanism, certain key elements facilitate the conversion of fuel into energy. These components work in harmony to ensure proper combustion, which is vital for generating the necessary power. Their arrangement and functionality are essential for maintaining optimal performance and longevity.

Auxiliary Elements

Alongside the primary components, additional elements support the system’s overall efficiency. These auxiliary features aid in regulating temperature, managing airflow, and enhancing overall functionality. Their importance cannot be understated, as they directly impact the reliability and responsiveness of the entire setup.

Common Issues in Engine Components

Understanding typical problems associated with various components of a motor is crucial for maintaining optimal performance and longevity. These challenges can arise from factors such as wear and tear, improper installation, or environmental conditions. Addressing these issues early can prevent more significant complications and costly repairs.

One prevalent concern involves overheating, which can damage vital components and lead to significant failures. Insufficient coolant levels, malfunctioning thermostats, or blocked cooling passages often contribute to this issue. Regular monitoring and maintenance of the cooling system can mitigate such risks.

Another common issue is oil leaks, which can result from degraded gaskets or seals. Leaks not only lead to reduced lubrication but can also create hazardous conditions. It is essential to inspect and replace any worn-out components to ensure proper sealing and prevent fluid loss.

Moreover, unusual noises may indicate underlying problems, such as worn bearings or misaligned components. Identifying and addressing these sounds promptly can help avoid severe damage. Regular inspections and servicing can enhance the reliability and efficiency of the system.

Maintenance Tips for Engine Health

Ensuring optimal performance and longevity of your vehicle’s power unit requires regular care and attention. A proactive approach to upkeep can significantly enhance efficiency and reduce the risk of breakdowns. By following key maintenance practices, owners can safeguard their machinery against wear and tear, ultimately promoting a smoother driving experience.

Regular Oil Changes

Routine replacement of lubricating fluid is crucial for minimizing friction and preventing overheating. Using high-quality lubricant tailored to the specifications of your machinery will support smooth operation and prolong the lifespan of internal components. Adhering to a schedule for oil changes will help maintain cleanliness and efficiency.

Cooling System Care

Maintaining the cooling apparatus is essential for regulating operating temperatures. Regularly checking coolant levels and ensuring the system is free from leaks will help prevent overheating. Flushing the cooling system as recommended can also remove any accumulated debris, ensuring effective heat dissipation.

Replacement Parts for Honda Civic

When it comes to maintaining a vehicle, ensuring the quality and functionality of individual components is essential. This section highlights various options available for replacing critical elements, helping to sustain optimal performance and longevity. Choosing the right substitutes can enhance efficiency and driving experience.

Types of Replacement Components

There are several categories of substitutes that drivers can consider. These include mechanical elements, such as the transmission, brakes, and suspension, which are crucial for the overall operation of the automobile. Additionally, electrical units like starters, alternators, and sensors play a significant role in the vehicle’s functionality. Selecting high-quality options for these components is vital for ensuring reliability.

Quality Considerations

When searching for replacements, it’s important to focus on durability and compatibility. Opting for reputable brands or original manufacturers can significantly reduce the risk of premature failure. Moreover, considering aftermarket alternatives can provide cost-effective solutions without compromising on performance. Evaluating warranties and customer reviews can also guide informed purchasing decisions.

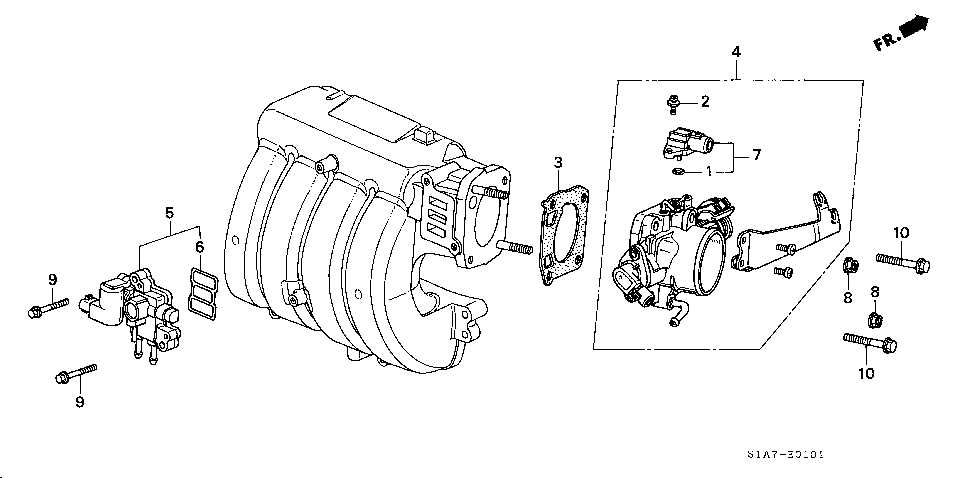

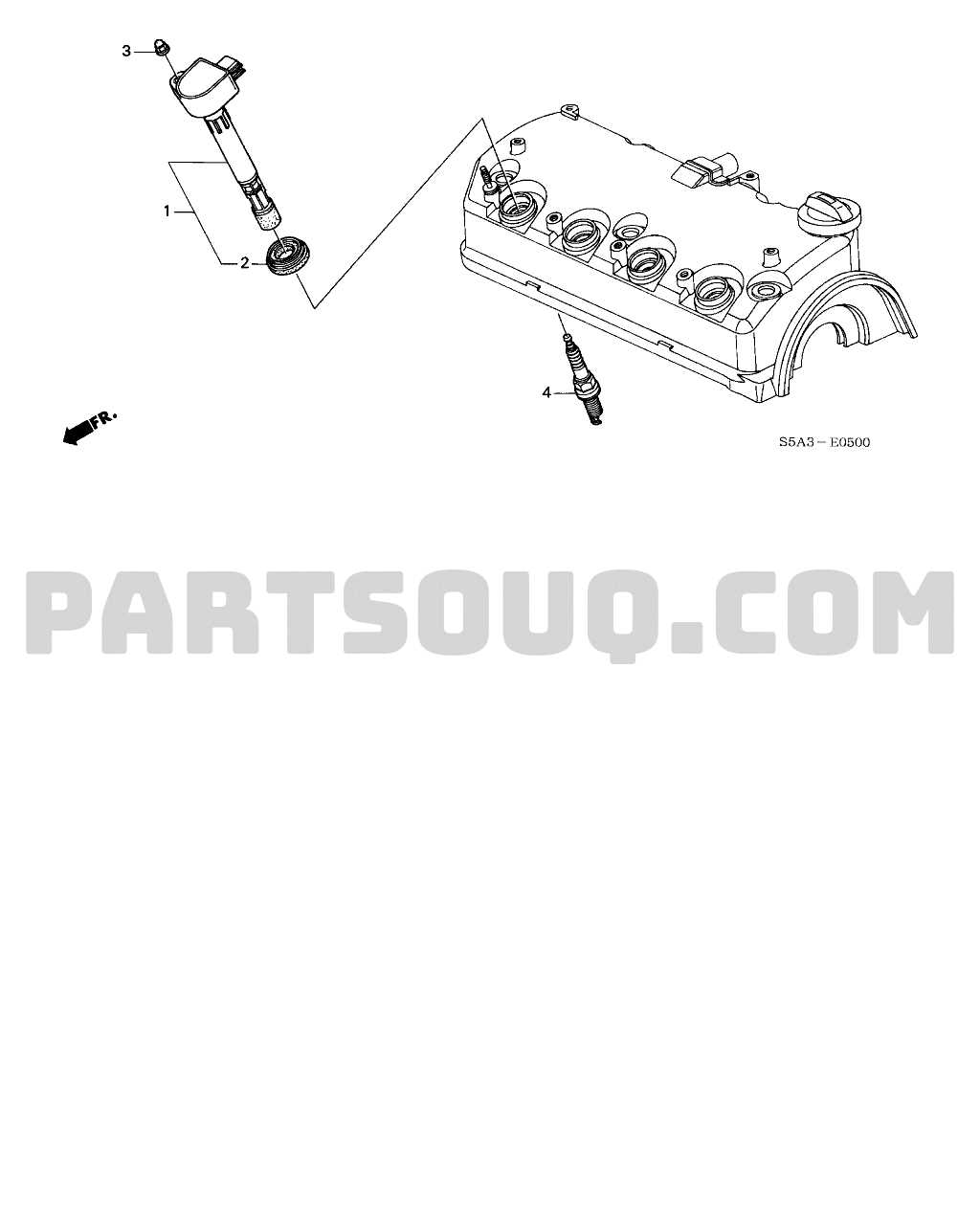

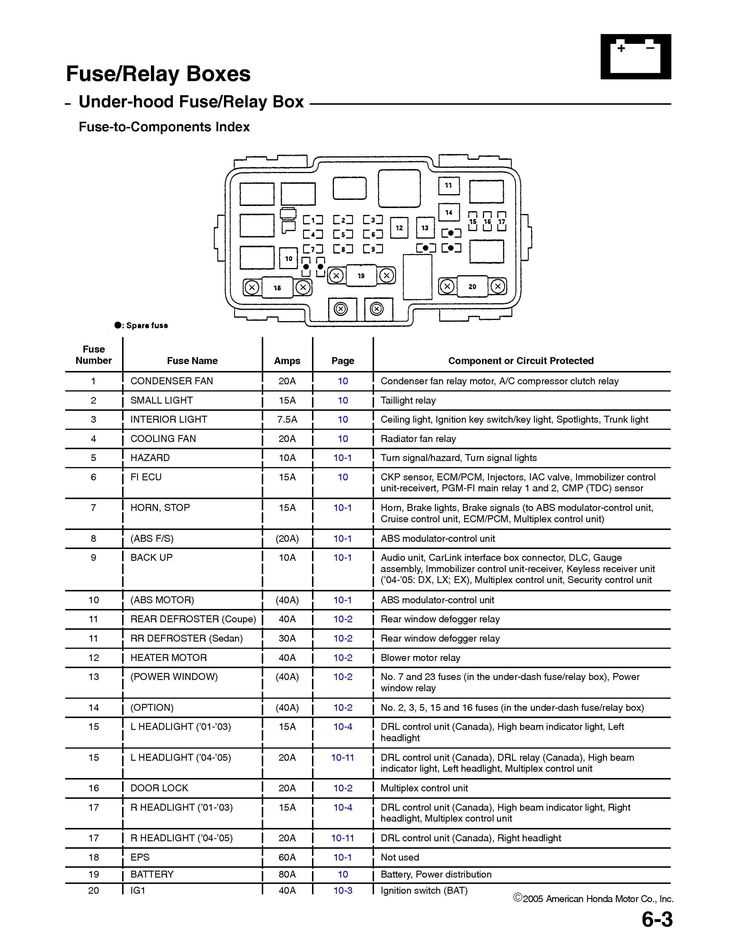

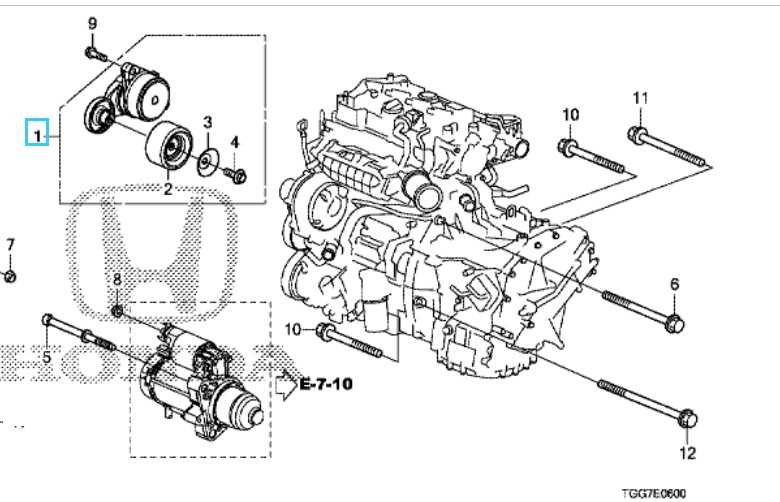

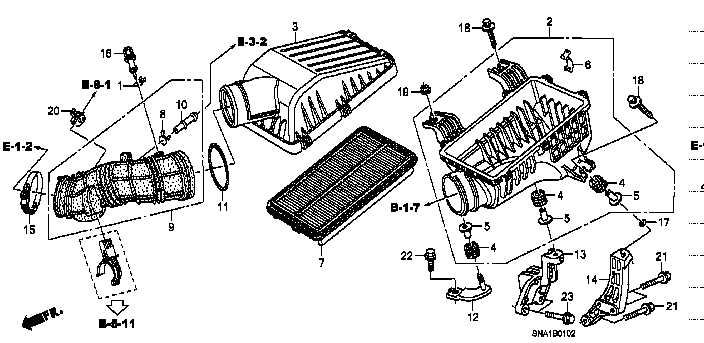

Understanding Engine Diagrams

Visual representations of mechanical systems play a crucial role in comprehending how components interact and function together. These illustrations provide valuable insights into the layout and relationships of various elements within a complex assembly, enabling individuals to grasp intricate concepts with ease.

Such diagrams typically include:

- Identification of key elements and their locations

- Connections between different components

- Flow paths for fluids and air

- Operational sequences for various functions

By analyzing these visual guides, one can enhance their understanding of the mechanics involved and troubleshoot potential issues more effectively. Each symbol and line carries significance, offering a simplified view of what might otherwise seem overwhelming.

To effectively utilize these illustrations, consider the following tips:

- Familiarize yourself with the symbols used to represent various components.

- Study the relationships between different parts to understand how they interact.

- Refer to the visual representation while performing maintenance or repairs to ensure accuracy.

- Keep a record of common issues and their locations for future reference.

In summary, mastering the interpretation of these visual tools can significantly improve both practical skills and theoretical knowledge in the realm of mechanical systems.

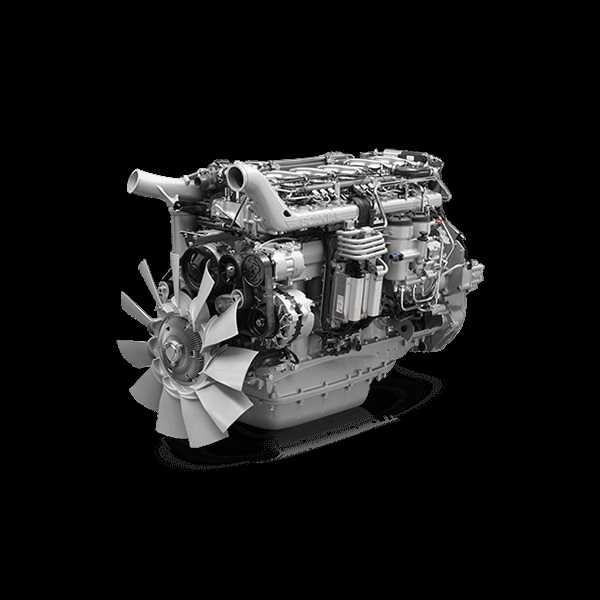

Visual Representation of Engine Layout

This section provides an insightful depiction of the arrangement and configuration of crucial components within a vehicle’s propulsion system. Understanding how these elements interact is essential for diagnosing issues and enhancing overall performance.

Diagrammatic illustrations can greatly aid in visualizing the spatial relationships among various components, such as the combustion assembly, fuel delivery systems, and exhaust configurations. By examining these representations, one can gain clarity on how power is generated and transmitted throughout the vehicle.

Moreover, comprehending the layout assists in identifying potential areas for upgrades or modifications, ensuring that any alterations align seamlessly with the existing framework. This knowledge fosters a deeper appreciation for the intricacies involved in the mechanics of mobility.

Importance of Genuine Parts

Utilizing authentic components is crucial for maintaining the longevity and performance of any vehicle. These elements are specifically designed to fit and function seamlessly within the overall assembly, ensuring optimal operation. When genuine components are employed, the risk of malfunctions decreases significantly, leading to a more reliable driving experience.

Benefits of Authentic Components

- Quality Assurance: Authentic components undergo rigorous testing to meet high standards of performance and safety.

- Perfect Fit: Genuine components are designed to match the specifications of the vehicle, promoting efficient functioning.

- Warranty Protection: Using authentic components often helps retain manufacturer warranties, protecting your investment.

- Increased Resale Value: Vehicles maintained with genuine components tend to have higher resale values due to their reliability and performance history.

Risks of Non-Genuine Components

- Compromised Safety: Non-genuine components may not meet safety standards, posing risks to the driver and passengers.

- Poor Performance: Imitation parts can lead to decreased efficiency and functionality, causing more issues over time.

- Higher Long-Term Costs: While non-genuine parts may appear cheaper initially, they can lead to costly repairs and replacements.

Comparing OEM and Aftermarket Options

When considering replacement components for a vehicle, two primary categories emerge: original equipment manufacturer (OEM) and aftermarket alternatives. Each option has its distinct characteristics, benefits, and drawbacks that can significantly influence the choice for vehicle maintenance and upgrades.

OEM components are made by the vehicle’s manufacturer, ensuring a perfect fit and compatibility with existing systems. These parts often come with warranties and are designed to meet the exact specifications set forth by the manufacturer, which can provide peace of mind regarding performance and reliability. However, this assurance often comes at a higher cost.

In contrast, aftermarket components are produced by third-party companies, offering a broader range of choices and often at more competitive prices. While many aftermarket options can match or even exceed the quality of OEM parts, it is crucial to research the reputation of the manufacturers and the materials used. The variety available in the aftermarket sector allows for customization and modifications, appealing to those looking to enhance performance or aesthetics.

Ultimately, the decision between OEM and aftermarket options hinges on personal preferences, budget constraints, and the specific needs of the vehicle. Evaluating these factors can lead to an informed choice that balances quality and cost-effectiveness.