Engine Parts Diagram for 2012 Honda Civic

The inner workings of any modern automobile consist of numerous components working in harmony to ensure optimal performance. Each system plays a vital role in powering the vehicle, from energy generation to controlling movement. These elements are interconnected in ways that might not be immediately apparent, but their cooperation is crucial for smooth operation.

In this section, we will explore the various crucial components that make up the heart of a car’s operation. By delving into how each piece functions and interacts with others, you will gain a deeper understanding of what goes on under the hood. Whether you’re a car enthusiast or just looking to enhance your knowledge, learning about these systems is essential for anyone who wants to understand the full scope of automotive mechanics.

Key systems and their connections drive the overall performance. Each part must function efficiently, and their design ensures a perfect balance between power output, fuel efficiency, and durability. We will highlight how these elements are structured and explain their roles in achieving the vehicle’s goals.

Understanding the layout and function of each piece allows for better maintenance and troubleshooting, contributing to the longevity of the vehicle. Keep reading as we break down these intricate systems and uncover their purpose in the broader scope of vehicle functionality.

Understanding the Engine Components

Internal combustion systems rely on a variety of elements working together to produce motion and power. Each component plays a crucial role in converting fuel into the energy needed for operation. By understanding these elements, you gain insight into how they function in harmony to achieve efficient performance.

Core elements such as the combustion chamber, piston assembly, and fuel delivery system serve as the foundation of any mechanical system designed for mobility. These mechanisms rely on precision to ensure that each part moves seamlessly within the overall structure. The strength and durability of individual units can greatly impact the overall system’s efficiency.

Other components, including the cooling and lubrication systems, help maintain optimal working conditions by managing heat and minimizing friction. The timing mechanisms ensure that each movement occurs at the precise moment, promoting smooth operation. Understanding how all these elements interact is key to maintaining system longevity and achieving top-tier performance.

Overview of Honda Civic Powertrain

The powertrain of a vehicle plays a crucial role in its overall performance, combining various components that work together to deliver power to the wheels. This system includes everything from the internal combustion mechanism to the transmission and drive components, all of which are designed to provide an efficient and smooth driving experience. The harmony between these elements ensures that the vehicle can perform optimally across various driving conditions.

The system typically consists of a combination of mechanical and electronic components that help manage power distribution, fuel efficiency, and acceleration. From the central propulsion unit to the associated gearbox and drivetrain, each part is fine-tuned to provide both reliability and driving comfort. The interaction between these components also influences fuel consumption and the vehicle’s responsiveness to driver input.

The powertrain layout is engineered with a focus on durability and low maintenance. With advancements in design, many modern systems aim to reduce weight while enhancing fuel efficiency. Whether in urban traffic or on highways, the integration of these components ensures a responsive, safe, and smooth driving experience.

Essential Internal Components of the Power System

The internal workings of any high-performance machinery rely heavily on key elements that ensure smooth and efficient operation. These components function in harmony to convert energy into motion, and each part plays a critical role in maintaining optimal performance. Understanding the various elements within this complex system helps to identify how power is generated, transferred, and managed within the structure.

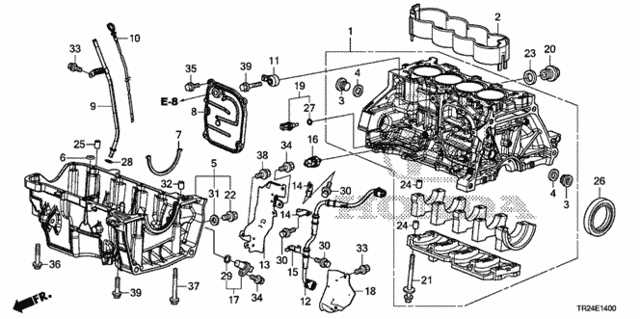

Pistons and Cylinders

The pistons are integral in generating force by moving up and down within their designated chambers. This motion is crucial for compressing air and fuel to create an explosion that drives the system. The cylinders, which house the pistons, are precisely designed to maintain the required space for the pistons’ movement, ensuring a tight fit that optimizes energy efficiency.

Crankshaft and Camshaft

The crankshaft converts the linear motion of the pistons into rotational force, which is essential for powering the vehicle. Positioned parallel to the crankshaft, the camshaft regulates the timing of valve openings and closings, coordinating the flow of gases into and out of the combustion chamber. These two components work in unison to maximize the efficiency of the system.

Role of the Cylinder Block and Pistons

The foundation of any internal combustion system relies on two critical components: the core structure that houses the moving elements and the individual pieces responsible for converting pressure into mechanical force. These elements work in tandem to facilitate the complex processes that power the system. Together, they provide the necessary environment for compression, ignition, and exhaust, ensuring smooth operation and efficiency.

The core structure of this system serves as the framework, containing the spaces where vital actions take place. The moving components within these spaces generate power by harnessing the energy produced during combustion. Each element is precisely engineered to withstand immense forces and heat while maintaining the integrity of the overall mechanism.

| Component | Function |

|---|---|

| Cylinder Block | Serves as the main housing for the moving elements and provides the structural support for the entire assembly. |

| Pistons | Convert the pressure created during combustion into mechanical force, driving the crankshaft and generating power. |

Exploring the Timing Mechanism

The timing system is a crucial component responsible for the precise coordination of various mechanical elements within a power unit. This intricate setup ensures that key operations, such as the intake and exhaust valve actions, occur at the right moments, contributing to optimal performance and fuel efficiency.

Understanding the Key Components

At the heart of the timing mechanism are several components, including the camshaft, crankshaft, and timing belt or chain. The camshaft controls the opening and closing of the valves, while the crankshaft regulates the movement of the pistons. Together, these elements work in harmony, governed by a series of gears or belts, to maintain the accurate synchronization required for efficient operation.

Importance of Precision

Any misalignment or failure in the timing mechanism can lead to severe mechanical issues, affecting both performance and longevity. Precise timing ensures smooth combustion cycles, reducing fuel waste and minimizing emissions. Regular maintenance and timely replacement of components like the timing belt or chain are essential for maintaining the system’s integrity and avoiding costly repairs.

Functions of the Crankshaft and Bearings

The crankshaft is a crucial component in any mechanical system that converts rotary motion into linear force. It plays a significant role in the smooth operation of the system by transmitting energy generated from various mechanical processes. Along with it, the bearings provide vital support and reduce friction, ensuring that the movement remains fluid and efficient throughout the operation.

The crankshaft is responsible for converting the linear force from the pistons into rotational motion, which powers various systems. It does this through a series of precisely positioned rods and journals that facilitate the continuous motion. The crankshaft must withstand significant forces while maintaining structural integrity, which is essential for the overall reliability of the system.

Bearings support the crankshaft and reduce the friction generated as it rotates. These components allow the crankshaft to spin smoothly within its housing, minimizing wear and tear. They are designed to handle high pressures and ensure that the crankshaft remains aligned correctly, thus optimizing the performance and lifespan of the entire mechanism.

Connecting Rods and Their Importance

Connecting rods are crucial components in any mechanical system that involves rotational motion. They play a significant role in translating linear force from pistons to rotational motion, ensuring the smooth operation of various mechanisms. Their ability to withstand high stress and transmit power efficiently makes them vital to the overall performance and longevity of the system.

Function and Design

The primary function of a connecting rod is to convert the linear force generated by the movement of pistons into rotational force that drives the crankshaft. This process is essential for the continuous motion of the system. The design of the connecting rod is influenced by factors such as material strength, weight, and the ability to endure high temperatures and pressures.

Materials and Durability

Connecting rods are typically made from high-strength materials like forged steel or aluminum alloys, which allow them to withstand the intense forces exerted during operation. The durability of these rods is vital, as any failure could result in catastrophic damage to other components in the system. Regular maintenance and proper lubrication help extend their lifespan and ensure optimal performance.

- Made from strong, lightweight materials

- Resistant to wear and high temperatures

- Critical to the efficiency and reliability of mechanical systems

Valves and the Combustion Chamber

The interaction between the internal components responsible for fuel intake and exhaust plays a crucial role in the performance of any vehicle. These elements work together within a confined space to optimize power generation and energy efficiency. The structure that houses this process is vital for maintaining smooth operation and high performance.

Valves serve as gateways, allowing the correct flow of air-fuel mixture and exhaust gases in and out of the chamber. These precision-controlled parts open and close at specific intervals to ensure that combustion occurs efficiently. A misaligned valve can lead to poor fuel efficiency and power loss.

The combustion chamber is where the magic happens. It is where the fuel ignites, producing the energy necessary to move the vehicle. The size, shape, and material of this chamber impact the engine’s effectiveness, with each design tailored to enhance compression and combustion rates.

Cooling System in the Engine Design

The cooling mechanism within a power unit is essential for maintaining optimal temperature levels during operation. It plays a critical role in preventing overheating by regulating the heat generated through various processes. This system ensures that the internal components function efficiently and are protected from thermal damage.

The cooling structure typically comprises several interconnected elements that work together to disperse heat effectively. These components include liquid-based circulatory systems, heat exchangers, and strategically placed ducts to promote air flow. Below is an overview of the key elements in this system:

| Component | Function |

|---|---|

| Radiator | Acts as a heat exchanger, releasing absorbed heat to the surrounding air. |

| Water Pump | Circulates coolant fluid throughout the system to maintain consistent temperature. |

| Thermostat | Regulates coolant temperature by controlling flow within the system. |

| Cooling Fans | Assist in reducing the temperature by forcing air through the radiator. |

| Hoses | Transfer coolant between various parts of the system, ensuring fluid flow. |

Effective heat management within a power unit is crucial for performance and longevity, making the cooling system an indispensable feature in the overall design.

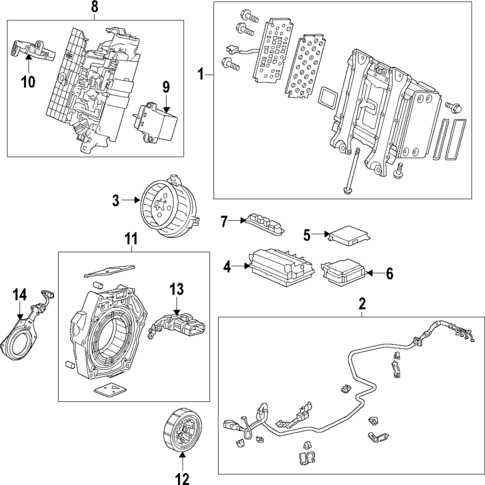

Engine Sensors and Their Role

The modern power unit relies heavily on a series of sensors to monitor and regulate various functions. These devices provide critical data that ensures the smooth operation and efficiency of the system, making it possible to fine-tune performance and minimize wear. By constantly collecting and relaying information, these sensors contribute to optimizing fuel consumption, emission control, and overall system health.

The sensors are designed to track a range of factors, such as temperature, pressure, air quality, and fuel levels. They send this data to the central processing unit, which adjusts various components accordingly to maintain optimal performance. Their accuracy and responsiveness are essential for ensuring that all aspects of the system work in harmony, preventing damage and ensuring longevity.

| Sensor | Function |

|---|---|

| Temperature Sensor | Monitors the temperature of key components to prevent overheating. |

| Pressure Sensor | Measures the pressure within the system to ensure proper fluid circulation. |

| Oxygen Sensor | Detects the level of oxygen in the exhaust gases, aiding in emission control. |

| Mass Airflow Sensor | Measures the amount of air entering the system, ensuring optimal air-fuel mixture. |

| Throttle Position Sensor | Tracks the throttle’s position, allowing precise control of airflow. |

How the Exhaust System Works

The exhaust system plays a vital role in directing harmful gases away from the internal combustion process. It ensures that toxic emissions are filtered and safely released into the atmosphere while improving overall vehicle efficiency.

Here’s how the components work together:

- Exhaust Manifold: Captures exhaust gases from the engine and funnels them into the system.

- Catalytic Converter: Reduces harmful pollutants by converting toxic gases like carbon monoxide and nitrogen oxides into less harmful substances.

- Oxygen Sensors: Monitor the air-fuel mixture and help the engine’s computer optimize combustion.

- Muffler: Reduces noise produced by exhaust gases as they exit the system.

- Exhaust Pipes: Transport gases from one part of the system to another until they exit through the tailpipe.

By working in harmony, these components minimize emissions and optimize engine performance, contributing to cleaner air and quieter operation.