Honda Civic Engine Bay Parts Diagram Overview

When exploring the structure beneath the hood, it’s essential to familiarize yourself with the arrangement of crucial elements. This section provides an overview of how various systems are organized and function together in a well-designed vehicle setup.

Efficient placement of mechanical components ensures optimal performance and accessibility during maintenance. Recognizing the positions of these elements can assist in diagnosing potential issues and performing routine upkeep.

Identifying the layout also allows for a better understanding of how each part contributes to the overall function, providing insights into the synergy between various technical elements.

Honda Civic Engine Bay Overview

The compartment beneath the front hood is a complex area housing essential mechanical components. This section is designed to provide easy access for maintenance and repairs, ensuring optimal functionality. Various systems within this area contribute to the vehicle’s overall performance, power delivery, and stability.

Below is a breakdown of the major groups of elements located within this section:

- Cooling system: Maintains the temperature of critical mechanical elements to prevent overheating.

- Air intake: Ensures efficient airflow for the combustion process.

- Electrical wiring: Powers the systems responsible for starting and managing different functionalities.

- Fluid reservoirs: Hold essential liquids like coolant and brake fluid for smooth operation.

- Fuel system: Delivers gasoline or diesel efficiently to support movement.

Common Components in the Engine Bay

In this section, we will explore several critical elements located under the hood of most vehicles. These components work together to ensure the smooth operation and performance of the car, playing key roles in its overall functionality. Understanding the purpose of each part can help with both maintenance and troubleshooting, enhancing the longevity and efficiency of the automobile.

Key features found here include fluid reservoirs, air intake systems, and cooling mechanisms. Each of these elements contributes to essential processes, such as managing temperature and ensuring proper airflow. By familiarizing yourself with these components, you can gain a deeper insight into how different systems collaborate to keep everything running efficiently.

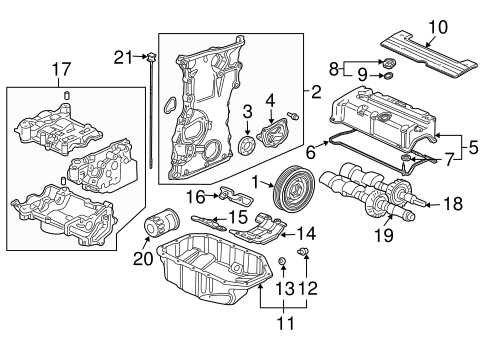

Identifying Critical Engine Parts

Understanding the key components under the hood is essential for maintaining and troubleshooting your vehicle. By familiarizing yourself with these fundamental elements, you can better assess the performance and health of your car. This knowledge will also help you address any issues that may arise during routine inspections or unexpected repairs.

| Component | Function |

|---|---|

| Crankshaft | Converts linear motion from the pistons into rotational movement, driving the wheels. |

| Pistons | Move up and down in the cylinders, generating power for the vehicle’s movement. |

| Alternator | Generates electricity to recharge the battery and power electrical systems. |

| Radiator | Regulates temperature by cooling the coolant that flows through the system. |

| Timing Belt | Synchronizes the movement of the camshaft and crankshaft to ensure proper valve timing. |

Honda Civic Cooling System Diagram

The cooling system is essential for maintaining optimal temperature control in the vehicle. It ensures that heat is efficiently transferred away from the power source to prevent overheating and maintain smooth operation. This system includes several interconnected components that work together to regulate temperature and prevent damage to various parts of the vehicle.

- Radiator – A key component that helps disperse heat into the surrounding air.

- Thermostat – Controls the flow of coolant based on the current temperature.

- Water Pump – Circulates coolant throughout the system to ensure consistent temperature control.

- Coolant Reservoir – Stores excess coolant and helps maintain the proper fluid levels.

- Cooling Fans – Assist in pulling air through the radiator to aid heat dissipation, especially when the vehicle is stationary.

Each of these elements is vital to ensuring that the system functions properly, working together to manage the temperature and protect the vehicle’s components fr

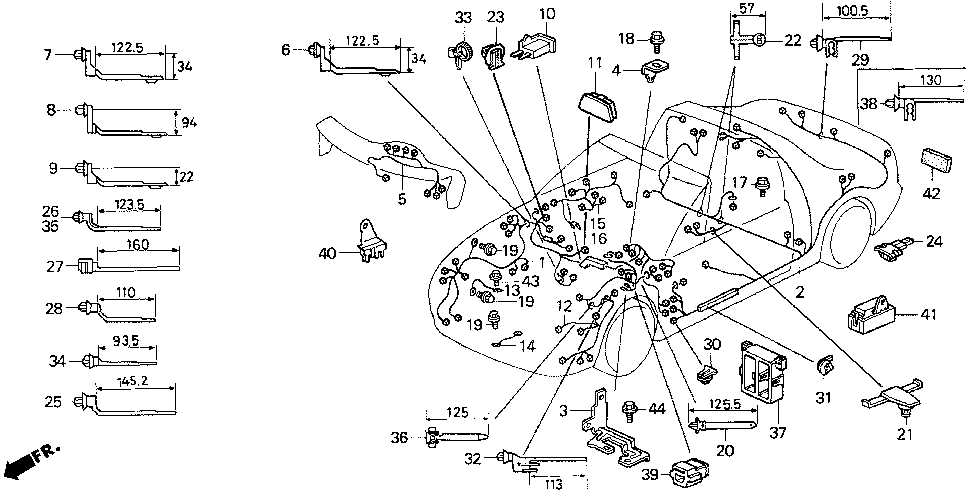

Key Sensors and Their Locations

Modern vehicles are equipped with various crucial sensors that monitor and adjust different operational aspects to ensure optimal performance. These sensors work together to provide real-time data to the onboard system, helping maintain efficiency and safety.

Primary Monitoring Devices

- Airflow Sensor: Located near the air intake, this component measures the amount of air entering the system, allowing precise adjustments for fuel efficiency.

- Oxygen Sensor: Positioned within the exhaust system, it detects oxygen levels in the gases, providing data to balance fuel mixtures.

- Temperature Sensor: Found in various systems, it monitors heat levels to prevent overheating and ensure smooth functioning.

Additional Sensor Locations

- Throttle Position Sensor: Located on the throttle body, it monitors the position of the throttle to manage power output.

- Knock Sensor: Positioned on the cylinder block, this device detects unusual vibrations or knocks, helping prevent potential damage.

Understanding the Exhaust Manifold Setup

The exhaust manifold is a crucial component that facilitates the expulsion of gases produced during the combustion process. Its primary role is to collect exhaust fumes from multiple cylinders and channel them into a single outlet, effectively managing emissions and ensuring optimal performance.

This setup is essential for maintaining engine efficiency and reducing harmful pollutants. The design and materials used in the construction of the manifold can significantly impact the overall performance of the vehicle.

| Component | Function | Material |

|---|---|---|

| Manifold Flange | Connects to the cylinder head | Cast Iron or Steel |

| Collector | Joins exhaust from multiple cylinders | Stainless Steel |

| Heat Shield | Reduces heat transfer | Aluminum or Steel |

Understanding this assembly can aid in troubleshooting and enhance knowledge regarding the overall functioning of the vehicle. Proper maintenance of the exhaust system is vital for performance and longevity.

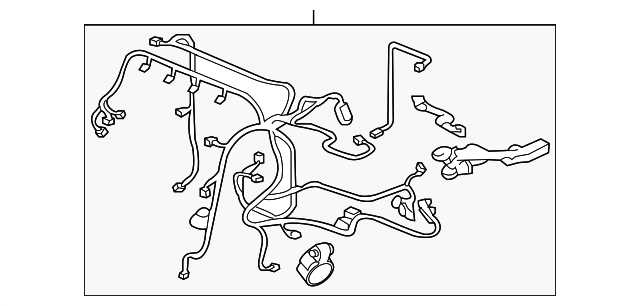

Electrical Connections in the Engine Compartment

Within the compartment housing the power unit, various electrical linkages play a crucial role in ensuring the smooth operation of the vehicle’s systems. These connections are essential for transmitting power and signals between different components, enabling everything from ignition to various sensors. Proper maintenance and understanding of these connections are vital for optimal performance and reliability.

Types of Electrical Connections

There are several types of electrical linkages found in the compartment that serve different functions. These include connectors for power distribution, grounding points, and signal wires that relay information to the control units. Each connection must be secure and free from corrosion to prevent electrical failures and ensure the efficient functioning of the vehicle.

Maintenance of Electrical Linkages

Regular inspection and maintenance of the electrical connections are crucial for preventing potential issues. Checking for signs of wear, fraying wires, and loose connectors can help identify problems before they escalate. Keeping these connections clean and properly secured will enhance the longevity and performance of the entire system.

Air Intake Path and Related Parts

The air intake system plays a crucial role in ensuring that the combustion process operates efficiently within the vehicle’s propulsion system. This system is designed to channel fresh air into the combustion chamber, where it mixes with fuel for optimal performance. Understanding the various components involved can help enhance the overall functionality and responsiveness of the vehicle.

Key Components of the Intake System

Several key elements contribute to the efficiency of the air intake system. The air filter is responsible for trapping contaminants, allowing only clean air to enter the engine’s interior. Following this, the intake manifold directs the airflow evenly across the cylinders, promoting balanced combustion. Additionally, sensors within the system monitor air pressure and temperature, ensuring that the optimal air-fuel mixture is achieved during operation.

Maintenance Considerations

Regular upkeep of the air intake assembly is essential for sustaining peak performance. Periodically checking and replacing the air filter helps prevent obstructions that could hinder airflow. Furthermore, inspecting hoses and connections for any signs of wear or damage can help maintain an unobstructed intake path, ultimately supporting efficient operation and longevity of the propulsion system.

Fuel System Layout in Honda Civic

The fuel delivery mechanism is crucial for ensuring optimal performance in a vehicle. It comprises various components that work in harmony to supply the engine with the necessary fuel for combustion. Understanding the layout of this system helps in diagnosing issues and maintaining the vehicle effectively.

Key Components of the Fuel Delivery System

- Fuel Tank: Stores the fuel until it is needed for combustion.

- Fuel Pump: Delivers fuel from the tank to the engine.

- Fuel Filter: Removes impurities from the fuel before it reaches the engine.

- Fuel Injectors: Atomize the fuel for efficient mixing with air.

- Fuel Lines: Transport fuel between the tank, pump, and engine.

Functionality and Importance

The effective operation of the fuel delivery mechanism is vital for the vehicle’s efficiency and reliability. Regular maintenance, including checking filters and fuel lines, ensures that the fuel system remains clean and unobstructed, allowing for optimal engine performance.

Overview of the Transmission Components

The transmission system is crucial for the efficient functioning of a vehicle, enabling the transfer of power from the motor to the wheels. Understanding the various elements involved in this system is essential for proper maintenance and troubleshooting. This section provides an insight into the main components, their functions, and how they interact to ensure smooth operation.

Main Elements of the Transmission System

The transmission comprises several key components that work together to facilitate gear changes and power distribution. Each part plays a specific role, contributing to the overall performance of the system.

| Component | Function |

|---|---|

| Clutch | Engages and disengages the connection between the motor and transmission, allowing for smooth gear shifts. |

| Gearbox | Houses the gears and allows the driver to change the vehicle’s speed and torque. |

| Driveshaft | Transmits power from the transmission to the wheels, enabling movement. |

| Torque Converter | Converts the rotational power from the motor into hydraulic energy to facilitate smooth acceleration. |

| Transmission Fluid | Lubricates the components, helping to reduce friction and maintain optimal operating temperatures. |

Importance of Regular Maintenance

Regular inspection and maintenance of the transmission components are vital for ensuring long-term performance and reliability. Addressing minor issues promptly can prevent costly repairs and enhance the overall driving experience.

Best Practices for Engine Bay Maintenance

Proper upkeep of your vehicle’s internal components is crucial for longevity and performance. Regular maintenance can prevent issues and enhance the overall reliability of your automobile. Implementing effective practices will ensure that critical systems operate smoothly, ultimately contributing to a safer driving experience.

Here are some essential tips to maintain your vehicle’s internal systems:

- Regular Cleaning: Remove dirt and debris that accumulate over time. A clean environment prevents corrosion and allows for easier inspections.

- Fluid Checks: Regularly inspect and top up fluids such as coolant, oil, and brake fluid. This helps in maintaining optimal performance and avoiding leaks.

- Inspect Hoses and Belts: Look for any signs of wear, cracks, or fraying. Replacing damaged components promptly can prevent larger issues.

- Battery Care: Keep terminals clean and ensure a secure connection. Check for corrosion and test the battery’s charge periodically.

- Monitor Temperature: Keep an eye on the temperature gauge to avoid overheating, which can lead to serious damage.

By following these best practices, you can maintain the vital systems of your vehicle effectively, ensuring it remains in peak condition for years to come.