Understanding the Components of a Torque Converter Diagram

In the realm of automotive engineering, one of the pivotal elements that ensure smooth power transmission is a specific fluid-based mechanism. This intricate system is designed to facilitate the seamless transfer of energy from the engine to the drivetrain, allowing vehicles to accelerate and decelerate with ease. Understanding its internal structure and functionality can provide valuable insights into its operation and maintenance.

The effectiveness of this mechanism relies heavily on its individual components, each playing a crucial role in the overall performance. From the initial energy transfer to the final output to the wheels, these elements work in harmony to enhance efficiency and responsiveness. Familiarizing oneself with these integral pieces can aid in diagnosing issues and optimizing performance.

In this section, we will explore the various components that make up this fluid-based system, providing a clear visual representation of how each part interacts with one another. By breaking down these elements, we aim to offer a comprehensive understanding of their significance and interrelation within the larger assembly.

Understanding Torque Converters

This section explores the mechanics behind a vital component of automatic transmission systems. These devices play a crucial role in transferring power from the engine to the wheels, allowing for smooth acceleration and deceleration. By harnessing fluid dynamics, they create a seamless connection that enhances driving performance.

The operation of this mechanism involves a combination of various elements working together to optimize efficiency. Key features include the ability to multiply engine power and facilitate a gradual engagement with the drivetrain. Understanding these functionalities can provide insights into improving vehicle performance and addressing potential issues.

Ultimately, delving into the intricacies of this system reveals its significance in modern automotive engineering. Recognizing how each component contributes to overall functionality can enhance maintenance practices and inform choices when selecting or repairing transmission systems.

Basic Function of Torque Converters

The primary role of these devices is to facilitate smooth transitions between the engine and the transmission system, enhancing overall vehicle performance. By allowing for a seamless connection, they optimize the transfer of power while adapting to varying driving conditions.

| Component | Function |

|---|---|

| Impeller | Initiates fluid movement and increases pressure. |

| Turbine | Receives fluid from the impeller, converting energy into rotation. |

| Stator | Redirects fluid returning from the turbine, enhancing efficiency. |

These components work in harmony to ensure that the vehicle accelerates smoothly, allowing for optimal power delivery during various driving scenarios.

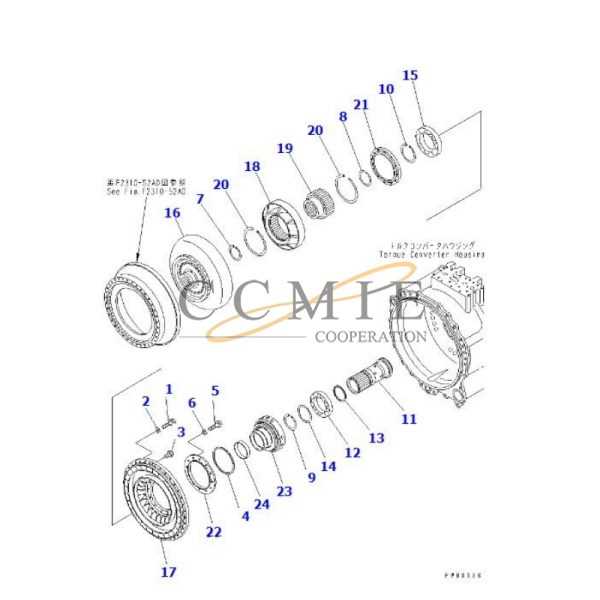

Key Components of Torque Converters

Understanding the essential elements of hydraulic couplings is crucial for grasping how they function efficiently in automotive applications. These components work together to facilitate the transfer of energy between the engine and the transmission, ensuring smooth acceleration and deceleration.

- Impeller: This is the primary element responsible for converting engine power into hydraulic energy. It spins and generates fluid flow, initiating the process of power transmission.

- Turbine: Positioned opposite the impeller, the turbine receives the fluid flow and transforms it back into mechanical energy, driving the transmission and propelling the vehicle forward.

- Stator: This component redirects the fluid returning from the turbine back to the impeller, enhancing efficiency. It ensures that energy loss is minimized during the energy transfer process.

- Transmission Fluid: The lifeblood of the system, this specialized fluid transmits power and helps to cool the components, ensuring optimal performance and longevity.

- Lock-Up Clutch: This mechanism engages at higher speeds to eliminate slippage between the engine and transmission, improving fuel efficiency and performance during highway driving.

lessCopy code

Each of these elements plays a vital role in ensuring the system operates smoothly, providing the necessary torque for effective vehicle movement.

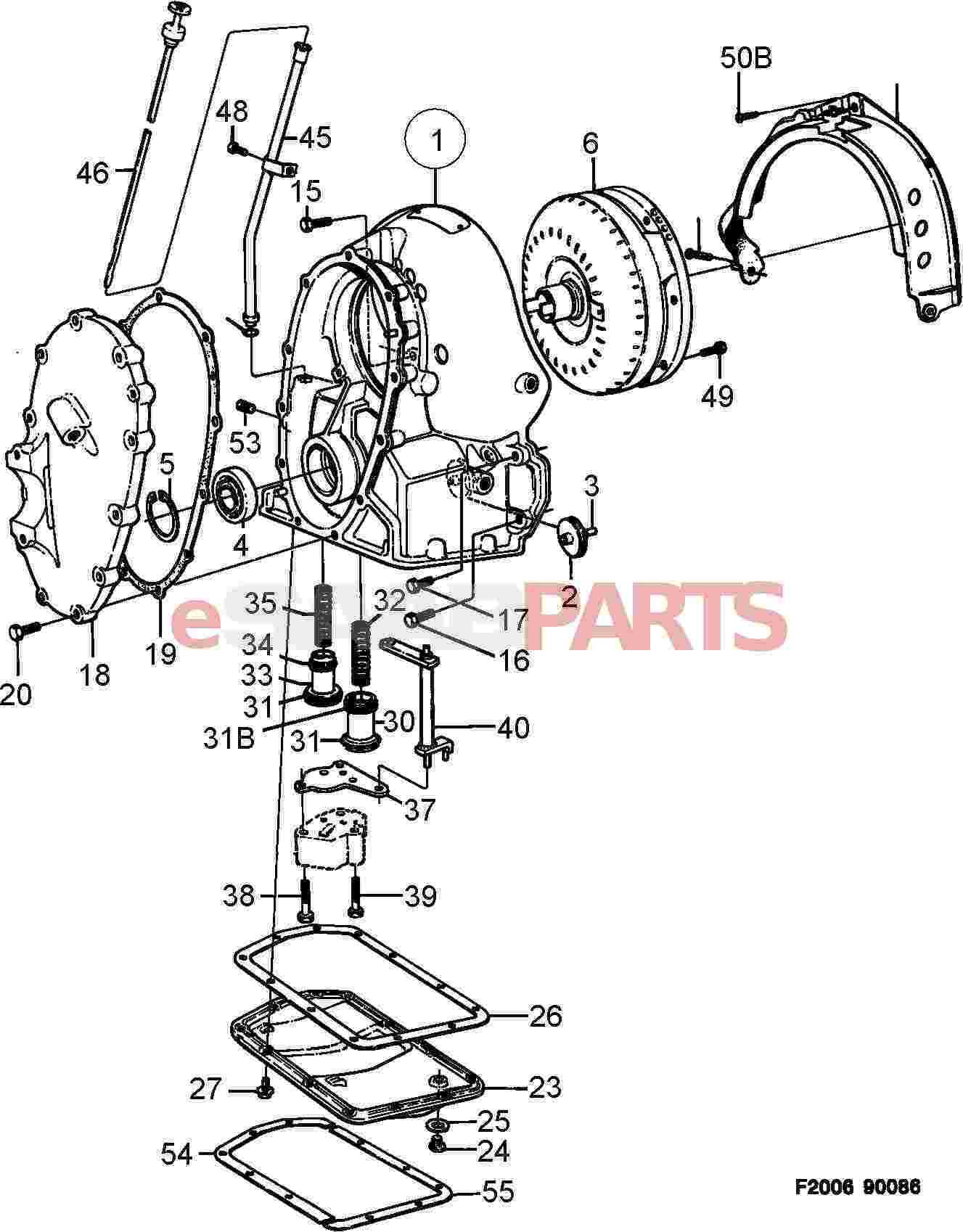

Torque Converter Parts Overview

This section explores the fundamental components that play a crucial role in the operation of a fluid coupling device, facilitating smooth power transfer between an engine and transmission. Understanding these elements is essential for grasping how efficiency and performance are achieved in automotive systems.

Key Components

At the heart of this mechanism are several key elements, including the turbine and stator, which work in tandem to enhance rotational force. The outer casing, or housing, envelops these critical parts, ensuring that fluid movement is optimized for maximum effectiveness.

Functionality and Importance

Each component contributes significantly to overall functionality. The interaction between the turbine and stator not only increases torque but also aids in minimizing energy loss. This synergy is vital for delivering the ultimate driving experience and enhancing vehicle performance.

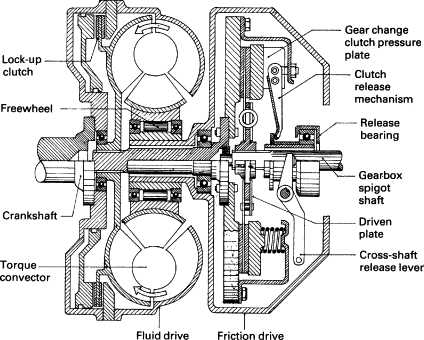

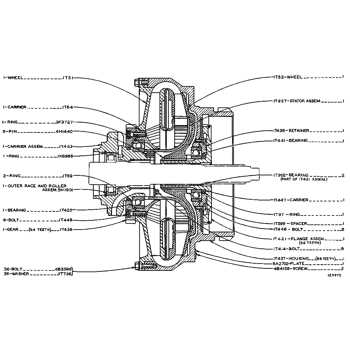

How Torque Converters Work

This mechanism plays a crucial role in the operation of automatic transmissions, facilitating the smooth transfer of power from the engine to the drivetrain. By utilizing hydraulic principles, it allows for an efficient transition between various speeds while maintaining optimal engine performance.

At its core, the system consists of a set of essential components that work in harmony. The fluid dynamics involved enable the transmission of energy, adapting to changing driving conditions and providing the ultimate driving experience. The elements involved include a pump, turbine, and stator, each contributing to the overall functionality.

When the engine operates, it drives the pump, creating fluid movement. This action generates a force that spins the turbine, ultimately transferring energy to the wheels. The stator redirects the fluid flow, enhancing efficiency and responsiveness. This intricate interplay allows for smooth acceleration and deceleration without the abrupt changes typical of manual systems.

In summary, this technology significantly enhances vehicle performance by ensuring that the engine’s power is effectively utilized, making for a more enjoyable and efficient driving experience.

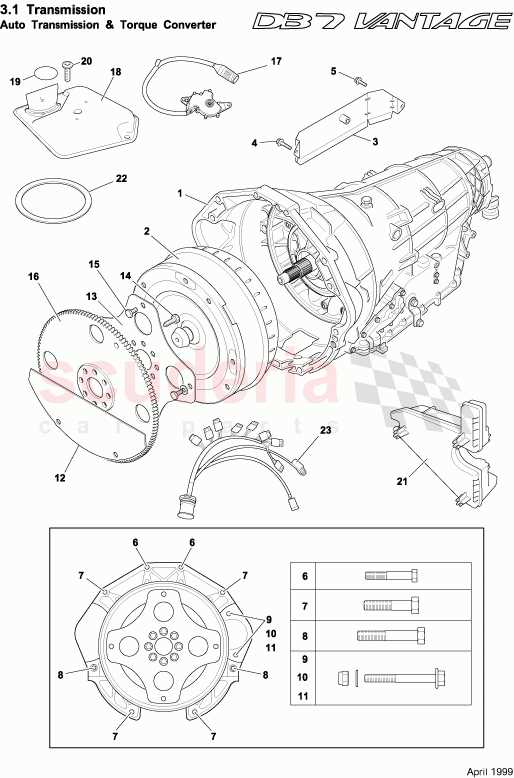

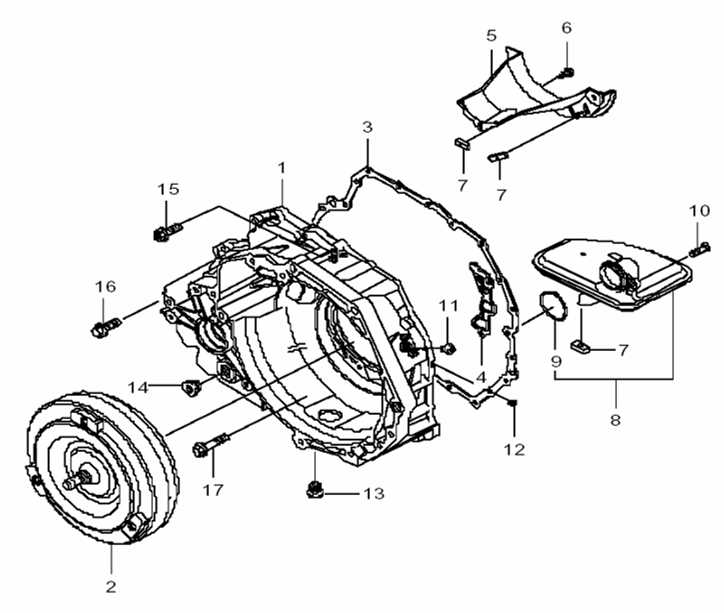

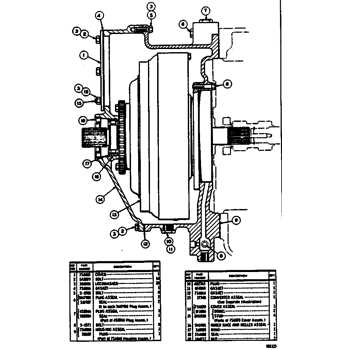

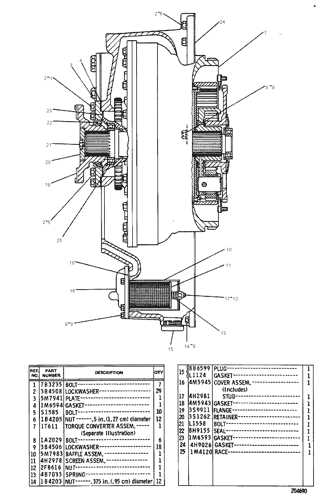

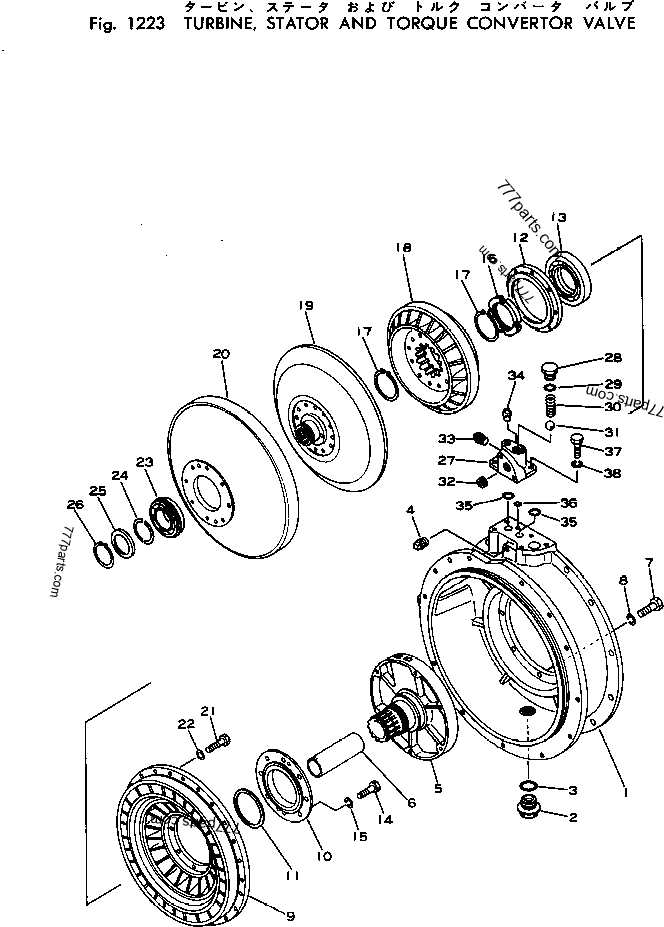

Visual Representation of Torque Converter Parts

This section aims to provide a clear illustration of the components that play a crucial role in the operation of a specific automotive mechanism. Understanding the layout and interrelation of these elements is essential for anyone interested in the functioning of vehicle drivetrains. A visual guide can greatly enhance comprehension, making it easier to grasp the complexities involved in this system.

Key Components Overview

Among the primary elements involved, one can identify the fluid coupling, which serves as a vital link between the engine and the transmission. This component is designed to facilitate the transfer of energy while allowing for smooth acceleration and deceleration. Additionally, the turbine, which transforms hydraulic energy into mechanical energy, plays a significant role in optimizing performance.

Interconnectivity of Elements

Each component is intricately connected, working harmoniously to ensure efficient power delivery. For example, the stator, positioned strategically within the assembly, aids in redirecting fluid flow to enhance efficiency. Understanding these connections helps to appreciate how each section contributes to the overall functionality, resulting in a seamless driving experience.

Common Issues with Torque Converters

Many drivers encounter various complications related to fluid coupling mechanisms, which can impact vehicle performance. Understanding these common problems can help in timely maintenance and avoidance of severe damage.

Frequent Problems

- Slipping: Loss of power transfer can lead to decreased acceleration.

- Overheating: Excessive heat can result from fluid breakdown, affecting efficiency.

- Noisy Operation: Unusual sounds often indicate internal wear or failure.

- Fluid Leaks: Visible leakage can point to seal or gasket issues.

Symptoms to Watch For

- Unresponsive acceleration despite pressing the gas pedal.

- Engine revs higher without a corresponding increase in speed.

- Shifting delays or harsh transitions between gears.

- Unusual vibrations while driving.

Maintenance Tips for Torque Converters

Ensuring optimal performance of your vehicle’s fluid coupling system is essential for a smooth driving experience. Regular upkeep can prevent wear and enhance the longevity of this critical component. Below are some key practices to maintain efficiency and reliability.

Regular Fluid Checks

Monitoring fluid levels is crucial. Ensure that the transmission fluid is clean and at the appropriate level, as contamination can lead to overheating and inefficient operation. Regularly changing the fluid can help maintain optimal performance.

Inspection of Components

Periodically inspecting associated elements such as seals and pumps can identify potential issues before they escalate. Look for signs of leaks or unusual noises that may indicate a problem, and address these promptly to avoid costly repairs.

Benefits of Torque Converter Upgrades

Enhancing the efficiency of automatic transmission systems offers numerous advantages that can significantly improve vehicle performance. Upgrading components leads to better power transfer, increased responsiveness, and an overall enhanced driving experience.

Key benefits of such enhancements include:

| Benefit | Description |

|---|---|

| Improved Performance | Upgrades allow for quicker acceleration and smoother shifts, maximizing engine output. |

| Enhanced Fuel Efficiency | By optimizing energy transfer, these upgrades can lead to better fuel consumption rates. |

| Increased Durability | Higher quality components often result in a longer lifespan and reduced wear and tear. |

| Customization Options | Drivers can tailor upgrades to suit their specific driving style and preferences. |

Comparing Torque Converters and Clutches

Understanding the differences between two essential components in vehicle transmission systems can greatly enhance knowledge of performance and efficiency. These mechanisms play critical roles in transmitting power from the engine to the wheels, yet they operate under different principles and purposes.

Functionality

One mechanism enables seamless engagement and disengagement of power, allowing for smoother acceleration without interruptions. In contrast, the other creates a direct mechanical connection, offering greater control during gear changes and improved response at high speeds.

Applications

While one is predominantly found in automatic transmissions, providing convenience and ease of use, the other is commonly utilized in manual systems, catering to drivers who prefer a more hands-on approach. Each has its advantages, depending on the driving style and vehicle type.

Torque Converter Technology Advancements

Recent innovations in fluid coupling systems have transformed performance, efficiency, and driving experiences. Engineers continuously explore new materials and designs to enhance durability and responsiveness, leading to a significant evolution in automotive technology.

Improved Efficiency

Advancements in electronic control systems allow for optimized fluid dynamics, resulting in enhanced power transfer. These improvements enable vehicles to achieve better fuel economy while maintaining peak performance under varying conditions.

Enhanced Durability

The introduction of advanced composites and metallurgy has increased the lifespan of these systems. Manufacturers now employ cutting-edge techniques to reduce wear and tear, ensuring reliability and reducing maintenance costs over time.

Choosing the Right Torque Converter

Selecting the appropriate mechanism for vehicle performance involves understanding various elements that influence efficiency and responsiveness. The right choice can significantly enhance driving experience and optimize power delivery.

Key Considerations

- Vehicle Type: Consider whether you drive a sports car, SUV, or sedan.

- Purpose: Identify if the focus is on towing, racing, or daily commuting.

- Engine Specifications: Match with engine size and horsepower for optimal synergy.

Performance Metrics

- Stall Speed: Higher stall speeds may be beneficial for racing applications.

- Efficiency Ratings: Look for mechanisms with high efficiency to reduce energy loss.

- Durability: Select a robust design to withstand specific driving conditions.