Essential Components of the Craftsman 25cc Weed Eater

Maintaining your grass trimmer in excellent working condition requires a basic understanding of its key elements. This knowledge not only helps in regular upkeep but also assists in identifying and resolving any issues that may arise over time. By familiarizing yourself with the essential mechanisms, you can ensure a longer lifespan for the tool and improve its performance.

In this section, we will explore the main components that keep the device functioning smoothly. These elements are vital to the overall efficiency of the tool, allowing it to cut through tough grass and vegetation with ease. With proper maintenance and care, each part can significantly enhance the tool’s reliability and precision.

Additionally, understanding how to troubleshoot and replace specific elements is crucial. Whether you’re looking to upgrade or repair, knowing the structure of the tool will simplify the process, ensuring you can make necessary adjustments effectively.

Craftsman 25cc Weed Eater Overview

This versatile outdoor tool is designed to handle a variety of yard maintenance tasks efficiently. With a focus on power and ease of use, it offers homeowners a reliable solution for keeping their lawns and gardens in top shape.

Key Features

- Lightweight design for improved maneuverability

- Powerful engine for tackling dense grass and weeds

- Easy-start system for hassle-free operation

- Adjustable cutting options for precision work

Common Applications

It can be utilized in different types of yard work, from trimming lawn edges to clearing thick vegetation. Its adaptability makes it an essential tool for keeping outdoor spaces neat and well-maintained.

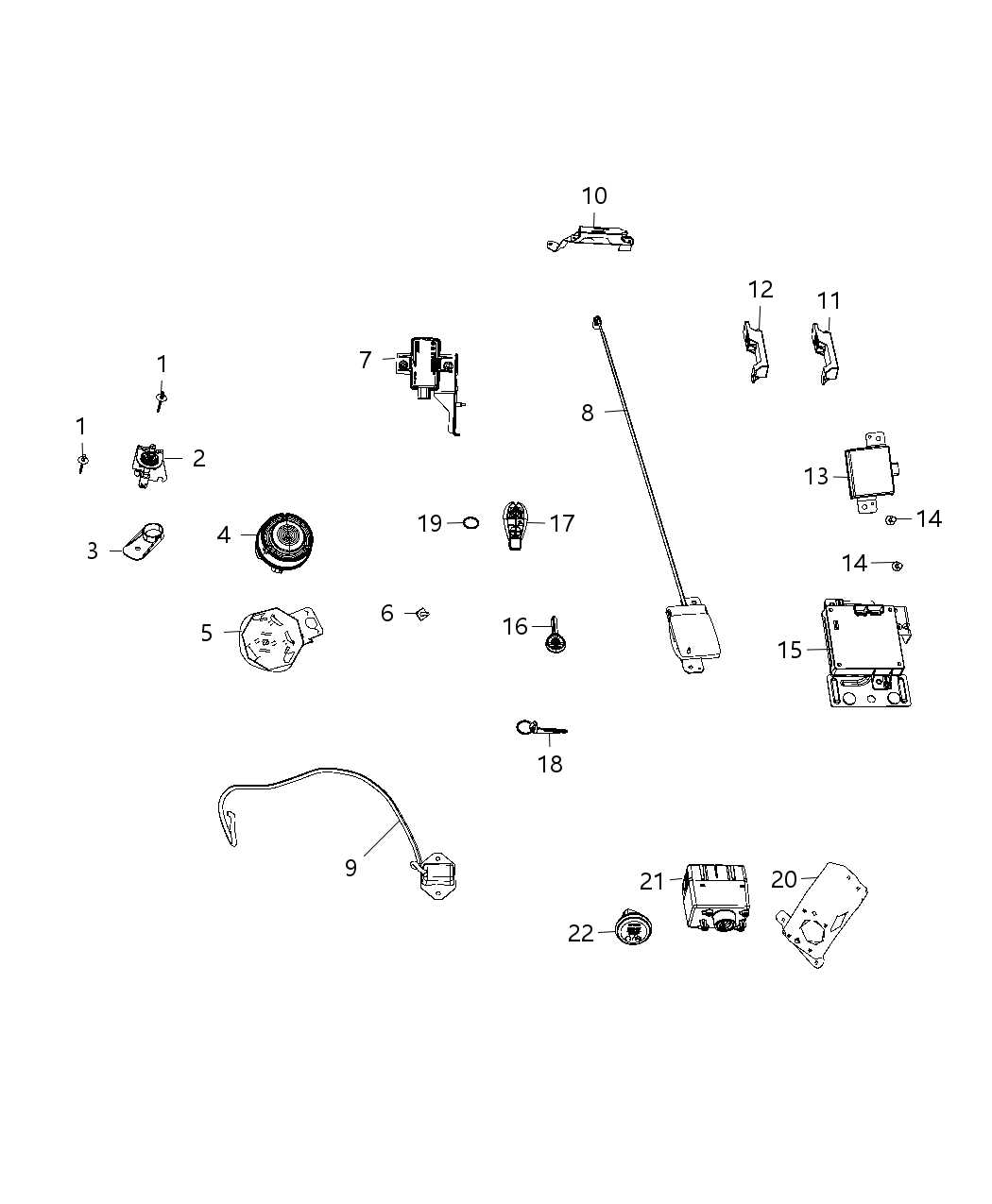

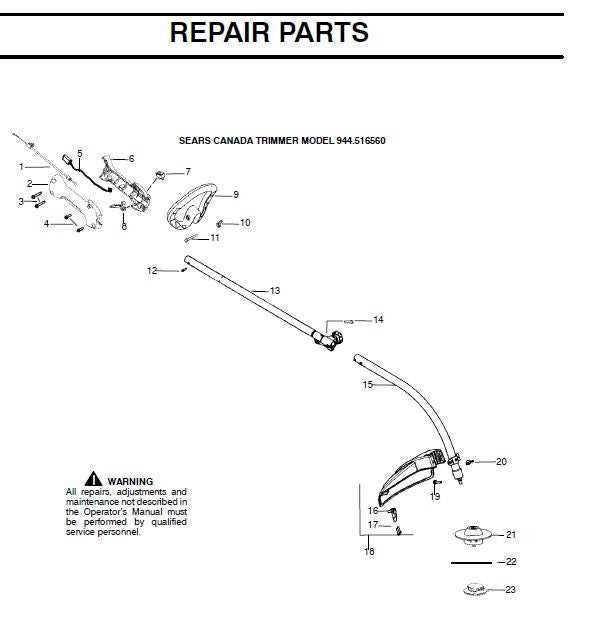

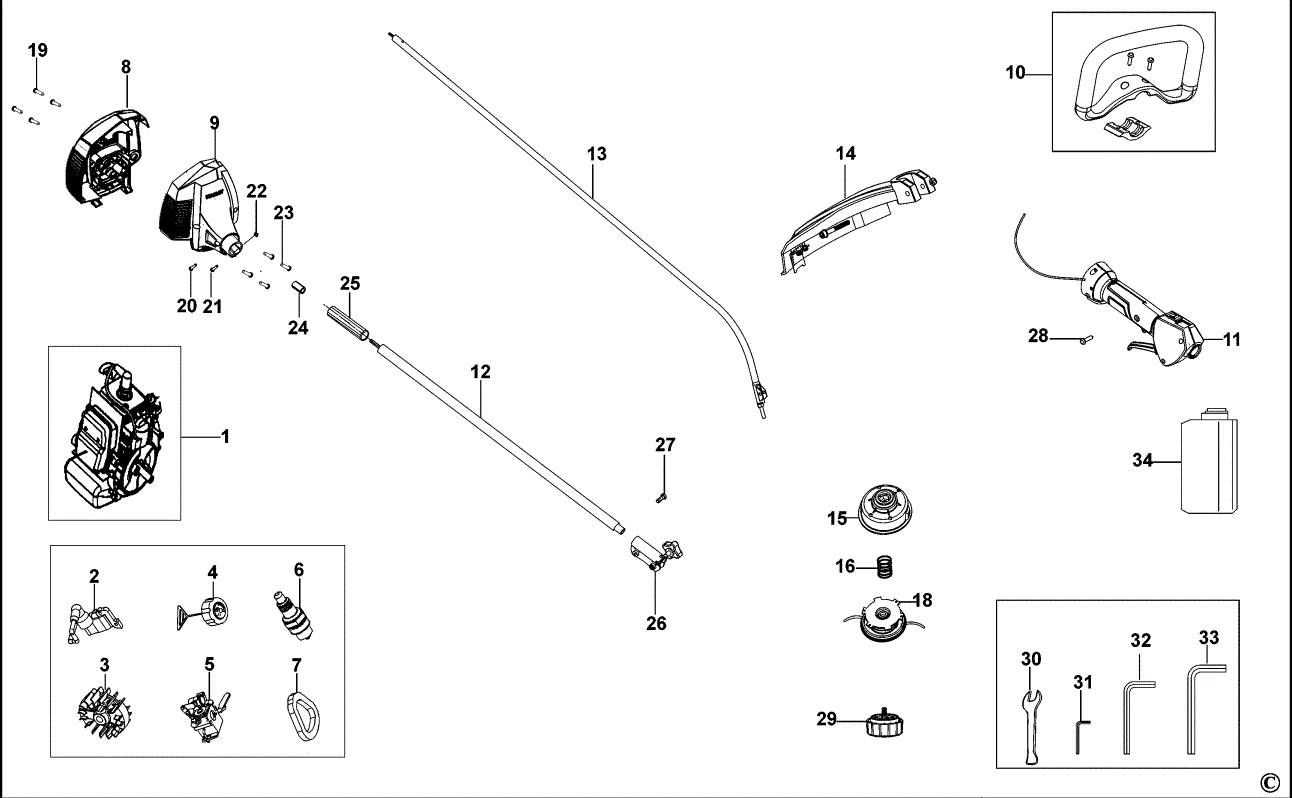

Main Components of the Craftsman 25cc Weed Eater

The operation of this outdoor tool relies on a variety of essential elements working together to deliver efficient performance. Each component plays a vital role in ensuring smooth and effective trimming of vegetation in various environments. Understanding these elements will help in maintaining and troubleshooting the device over time.

Engine Unit: The heart of the device, responsible for providing the power required to rotate the cutting mechanism. It converts fuel into mechanical energy, driving the cutting system with precision.

Cutting Head: This section holds the line or blade and is the point of contact with vegetation. It spins at high speed, enabling effective trimming or edging based on the selected attachment.

Shaft Assembly: A crucial connection between the power source and the cutting mechanism. This long, cylindrical part transfers the energy from the engine to the head while allowing for comfortable handling.

Handle and Controls: Designed to provide a secure grip and easy access to the operational switches. These parts ensure the user has full control over the tool’s speed and function, enhancing safety and precision during use.

Fuel Tank: This storage container holds the gasoline mix needed for the tool to run. Its capacity ensures a balanced duration of operation before needing a refill.

Common Issues with Weed Trimming Equipment Components

Regular use of grass-cutting tools can lead to various problems over time, especially if the equipment is not properly maintained. Many users encounter challenges related to different mechanical and functional aspects, which can significantly impact performance. It’s essential to be aware of these typical issues and how to address them effectively to keep the equipment running smoothly.

Engine Malfunctions

One of the most frequent problems involves engine failures or difficulty starting. This can happen due to a variety of reasons, such as fuel line blockages, dirty air filters, or spark plug issues. Ensuring regular checks and cleaning can prevent many of these common malfunctions.

Line Feeding Troubles

Another issue often faced is the improper feeding of the cutting line. This can occur when the spool is tangled or when the line gets stuck, causing frustration during use. Regular maintenance and correct installation of the spool are crucial to avoiding this issue.

Replacing the Cutting Head Assembly

Over time, the cutting head may wear out or become damaged, requiring replacement to ensure efficient performance. Understanding how to safely and correctly install a new cutting head is essential for maintaining your tool’s functionality.

Step 1: Remove the old cutting head

Before starting, ensure the tool is turned off and disconnected from any power source. Hold the shaft steady while unscrewing the cutting head by rotating it counterclockwise. You may need to use a wrench or similar tool to help loosen it if it’s too tight.

Step 2: Install the new cutting head

Once the old head is removed, align the new cutting head with the shaft. Twist it clockwise to secure it in place. Make sure it’s firmly attached, but avoid over-tightening. Check that the head spins freely before using the equipment again.

Regularly inspecting and replacing the cutting head when needed ensures that your equipment remains in top working condition.

Understanding the Fuel System in a Weed Trimmer

The fuel system plays a crucial role in ensuring the smooth operation of any handheld grass trimming tool. It consists of various components that work together to deliver the correct fuel mixture to the engine, enabling efficient and reliable performance. To maintain optimal functionality, it’s important to understand how these elements interact and how regular upkeep can prevent issues related to fuel delivery.

- Fuel Tank: The container where gasoline or a fuel mix is stored before being sent to the engine.

- Fuel Lines: Tubes that transport fuel from the tank to the carburetor, ensuring a steady flow for engine combustion.

- Carburetor: Responsible for mixing air and fuel in the correct proportion to allow proper combustion in the engine.

- Fuel Filter: A small component that removes debris and impurities from the fuel, protecting the engine from potential damage.

- Primer Bulb: A pump that helps draw fuel into the carburetor before starting the engine, making it easier to start the tool.

Regular inspection and maintenance of these components are essential for ensuring

How to Maintain the Trimmer Line

Maintaining the cutting line of your trimmer is essential for optimal performance and longevity. Proper care ensures that the tool operates efficiently, providing a clean and precise cut while minimizing wear and tear on the equipment.

Here are some tips to help you keep the trimmer line in excellent condition:

- Regular Inspection: Frequently check the line for signs of wear or damage. Replace it promptly if you notice fraying or breakage.

- Proper Line Length: Ensure the cutting line is the correct length for your trimmer model. An appropriate length enhances cutting efficiency and reduces strain on the motor.

- Use Quality Line: Choose high-quality line that suits your trimming needs. Different materials and thicknesses are designed for various tasks, such as edging or heavy-duty trimming.

- Store Correctly: When not in use, store your trimmer in a dry and cool place to prevent the line from becoming brittle due to heat or moisture.

- Feed Line Properly: Ensure that the line is fed correctly through the spool. Improper feeding can lead to tangles and inefficient cutting.

By following these guidelines, you can ensure that your cutting line remains effective and your trimming tasks are completed smoothly and efficiently.

Key Features of the Carburetor Assembly

The carburetor assembly plays a crucial role in the performance of small engines by mixing air and fuel in the correct ratio. This vital component ensures efficient combustion, which in turn contributes to the overall power and efficiency of the machine. Understanding its key features can help users maintain and optimize their equipment.

Efficient Fuel Mixture

One of the primary functions of the carburetor is to create an optimal fuel-air mixture. This is achieved through:

- Adjustable jets that control fuel flow

- Venturi design that enhances air intake

- Mixture screws for fine-tuning the ratio

Durability and Maintenance

The assembly is designed with longevity in mind, featuring components that withstand wear and tear. Key aspects include:

- Corrosion-resistant materials

- Easy access for cleaning and adjustments

- Sealed gaskets to prevent leaks

Cleaning and Maintaining the Air Filter

The air filter is a crucial component of any outdoor power tool, as it helps ensure optimal engine performance by preventing dust and debris from entering the combustion chamber. Regular maintenance of this part is essential for keeping your equipment running smoothly and efficiently.

To begin the cleaning process, first, ensure that the tool is turned off and disconnected from any power source. Carefully remove the air filter cover, which is typically secured by screws or clips. Once the cover is removed, gently take out the air filter itself. Inspect the filter for any signs of damage or excessive wear, and replace it if necessary.

Next, clean the filter using compressed air or a soft brush to remove dirt and particles. If the filter is heavily soiled, it may be beneficial to wash it in warm, soapy water. After cleaning, allow it to dry completely before reinstallation. When the filter is dry, place it back into the housing, ensuring a snug fit, and reattach the cover securely. This routine maintenance will prolong the life of your equipment and enhance its overall performance.

Choosing the Right Spark Plug for Craftsman 25cc

Selecting the appropriate ignition component is essential for the efficient operation of your outdoor power equipment. The spark plug plays a critical role in ensuring optimal performance by providing the necessary spark to ignite the fuel-air mixture. Understanding the specific requirements for your model will help maintain reliability and extend its lifespan.

Factors to Consider

When choosing an ignition component, it is important to consider factors such as heat range, electrode gap, and material type. The heat range determines how quickly the spark plug can dissipate heat, which affects engine performance. A proper electrode gap ensures efficient combustion and smooth operation. Additionally, selecting the right material, such as copper or platinum, can influence durability and longevity.

Consulting Manufacturer Specifications

Always refer to the manufacturer’s specifications for your equipment model. These guidelines will provide crucial information regarding the recommended ignition component type and settings. Following these recommendations will ensure that you select a compatible and effective component for your engine, helping to optimize performance and prevent potential issues.

Proper Lubrication for Engine Longevity

Maintaining the optimal performance of a motor requires diligent care, particularly in the area of lubrication. Properly lubricating engine components not only reduces friction but also minimizes wear and tear, ultimately extending the lifespan of the equipment. A well-lubricated engine operates more efficiently, leading to improved functionality and reliability during use.

Choosing the Right Lubricant

When selecting a lubricant, it is crucial to consider the specific requirements of the engine. Different engines may require various types of oils, ranging from synthetic to mineral-based options. Always refer to the manufacturer’s recommendations to ensure compatibility, as using the wrong lubricant can lead to severe damage.

Regular Maintenance and Application

Consistent maintenance is key to sustaining optimal lubrication. Regularly check the oil levels and apply lubricant as needed, ensuring that all moving parts are adequately coated. This proactive approach helps prevent overheating and reduces the risk of engine failure, ensuring that your motor remains in peak condition for a long time.

Upgrading the Handle and Shaft for Comfort

Enhancing the grip and extension of outdoor equipment can significantly improve the user experience. By focusing on the ergonomics of the handle and shaft, individuals can achieve a more comfortable and efficient operation. This upgrade can reduce fatigue during extended use and provide better control over the tool.

Consider replacing the existing handle with a model that offers better cushioning and grip. A padded handle not only reduces strain on the hands but also helps in maintaining a firm hold, especially in challenging conditions. Additionally, opting for an adjustable shaft can cater to different user heights, ensuring a comfortable stance while working.

When selecting these components, it’s essential to choose high-quality materials that withstand wear and tear. Investing in durable upgrades can enhance performance and prolong the lifespan of the equipment. Ultimately, the right modifications can transform the way tools feel and function, making outdoor tasks more enjoyable.