Comprehensive Guide to Craftsman C459 Parts Diagram

Exploring the intricacies of machinery can significantly enhance your maintenance skills and overall understanding of equipment functionality. A comprehensive overview of component organization serves as an invaluable resource for both novice and experienced users alike. This knowledge not only aids in repairs but also fosters a deeper appreciation for the craftsmanship behind each tool.

When delving into the specifics of mechanical assemblies, visual aids play a crucial role. They provide clarity in identifying individual elements and their interrelations, ensuring a smoother repair process. A well-structured representation of these components can illuminate the complexities involved in machinery design, making it easier to troubleshoot issues and perform upgrades.

For anyone looking to maximize efficiency in their toolkit, familiarizing oneself with the layout of these essential elements is key. By understanding how each piece contributes to the overall operation, you empower yourself to tackle repairs confidently and extend the lifespan of your equipment. This exploration into the world of tool mechanics opens doors to greater self-sufficiency and innovation.

Understanding Craftsman C459 Components

This section explores the essential elements of a specific tool, highlighting their roles and interactions. Recognizing these components is crucial for effective maintenance and optimal performance.

Key Elements

- Engine: Powers the tool and influences its efficiency.

- Frame: Provides structural support and stability.

- Blade: Determines the quality of cuts and overall functionality.

- Handle: Ensures comfort and control during operation.

Maintenance Tips

- Regularly inspect components for wear and tear.

- Keep the engine clean to enhance performance.

- Sharpen the blade frequently to ensure precise cuts.

- Check the frame for any signs of damage.

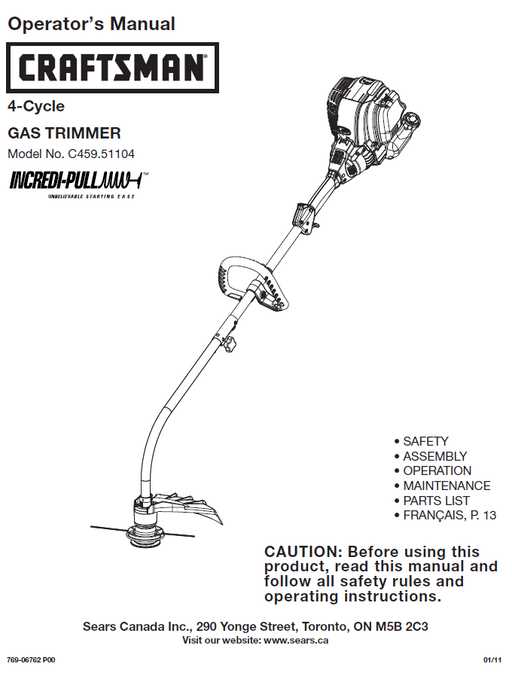

Overview of Craftsman C459 Model

This section provides a comprehensive insight into a specific model designed for efficiency and durability. The unit is engineered to meet various demands, showcasing a blend of functionality and user-friendly features. Its construction reflects a commitment to quality, making it a reliable choice for both casual users and professionals alike.

Key Characteristics: The device is built with robust materials, ensuring longevity and resilience under diverse conditions. Its design emphasizes ease of use, with intuitive controls that facilitate operation. Additionally, the model is equipped with innovative technology that enhances performance, making it suitable for a wide range of applications.

Overall, this model stands out in its category due to its impressive specifications and the reputation it has garnered among users. Understanding its components and functions can greatly assist in maximizing its potential for various tasks.

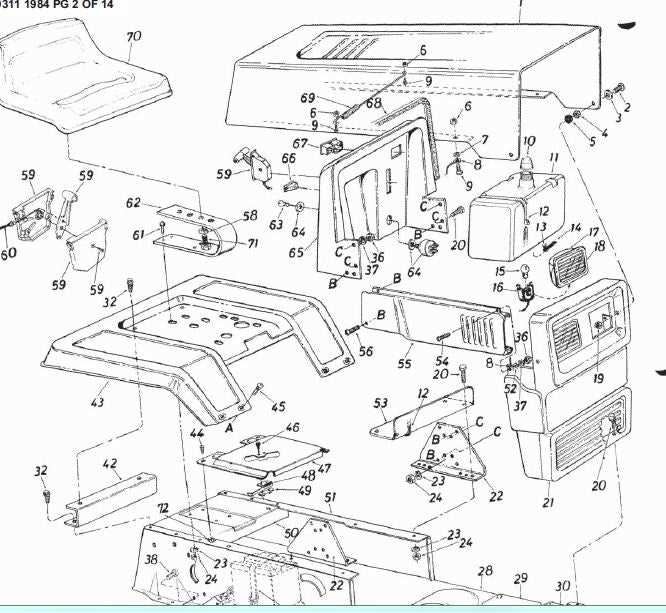

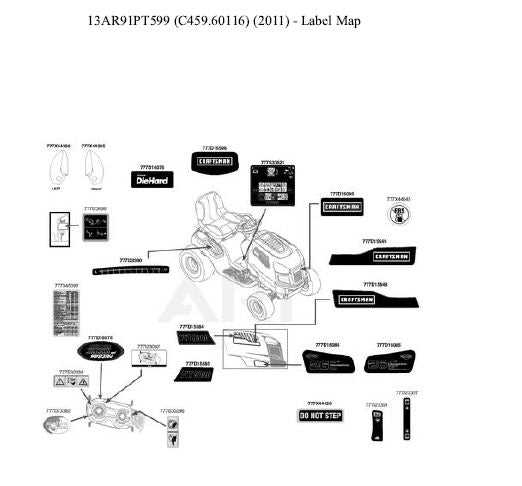

Importance of Parts Diagrams

Understanding the components of machinery is essential for effective maintenance and repair. Visual representations serve as invaluable tools that clarify the intricate relationships between various elements, enabling users to navigate assembly and disassembly with confidence.

Enhancing Efficiency

Visual aids significantly enhance the efficiency of repair tasks. By providing a clear overview, they help technicians identify specific elements quickly, reducing downtime and streamlining the repair process.

Aiding Troubleshooting

When problems arise, these illustrations become crucial for diagnosing issues. They allow users to pinpoint faults more accurately, facilitating targeted solutions that minimize unnecessary replacements and repairs.

Key Components of the C459

Understanding the essential elements of this equipment is crucial for optimal performance and maintenance. Each part plays a significant role in the overall functionality, ensuring that the machine operates smoothly and efficiently.

One of the primary features includes the motor, which powers the unit and influences its operational capacity. Additionally, the housing provides structural integrity, protecting internal mechanisms from external damage. The control system allows users to adjust settings for various tasks, enhancing versatility.

Furthermore, the cutting mechanism is vital for achieving precise results, while the safety features are designed to prevent accidents during use. Regular inspection of these critical components can prolong the life of the equipment and improve its effectiveness.

How to Read a Parts Diagram

Understanding a visual representation of components can greatly enhance your ability to assemble or repair equipment. These illustrations serve as essential guides, showcasing the relationship and positioning of various elements within a system. Grasping how to interpret these visuals can streamline the process of identifying and obtaining necessary components.

Familiarize Yourself with Symbols

Most visual representations use specific symbols to denote different elements. Take the time to learn what each icon represents, as this knowledge is crucial for deciphering the overall layout. Look for labels that indicate sizes, materials, or quantities to gain further insight into each component’s role.

Follow the Sequence

Typically, these illustrations will be organized in a logical flow, guiding you through the assembly process. Pay attention to the order in which components are presented; this can be vital for understanding how to effectively combine them. Referencing this sequence will ultimately lead to a more efficient repair or assembly experience.

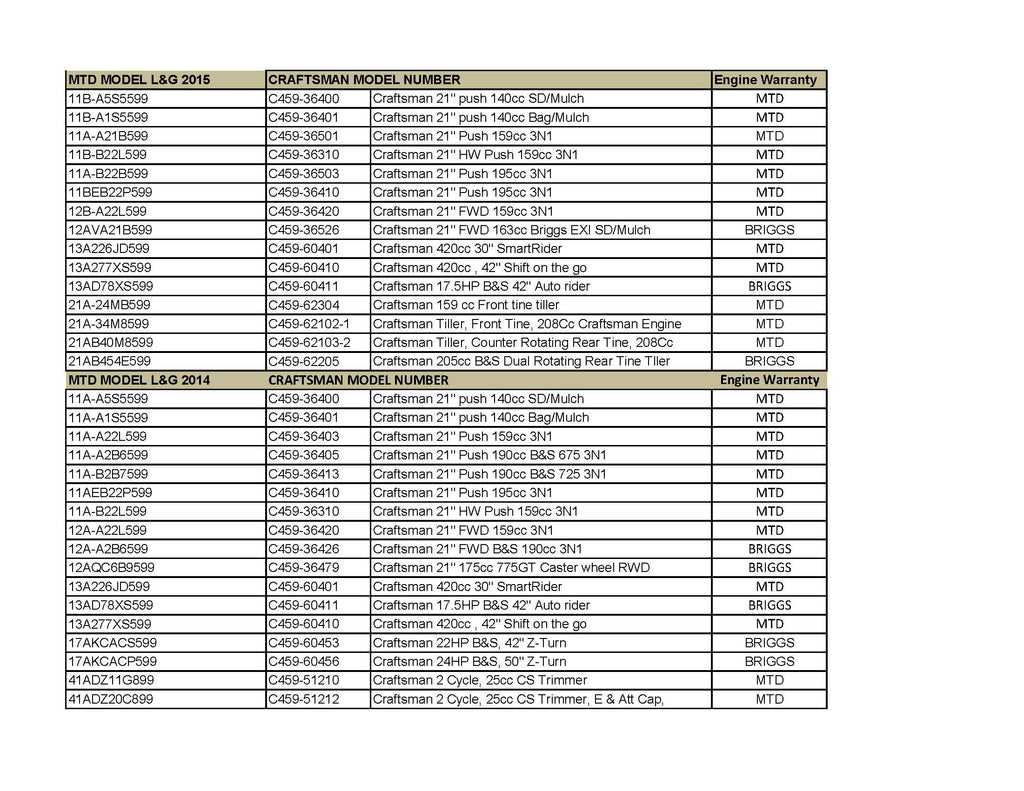

Identifying Replacement Parts

When maintaining or repairing machinery, recognizing the necessary components is crucial for ensuring optimal functionality. Identifying the correct elements can significantly enhance performance and extend the lifespan of your equipment. This process involves understanding the specific features and characteristics of the components that require replacement.

Steps to Identify Components

To effectively determine which parts need to be replaced, follow these steps:

- Examine the equipment thoroughly to pinpoint any damaged or worn-out elements.

- Refer to the manufacturer’s specifications for guidance on compatible components.

- Consult user manuals or online resources for additional information on the equipment’s construction.

Common Terminology

Familiarizing yourself with the terminology related to the machinery can simplify the identification process. Below is a table highlighting essential terms and their meanings:

| Term | Description |

|---|---|

| Assembly | A collection of parts that function together within the machine. |

| Component | A single part or piece that can be replaced or repaired independently. |

| Specification | A detailed description of the dimensions, materials, and functionalities of a part. |

| Compatibility | The ability of a component to work effectively with the existing system. |

By utilizing these strategies and understanding the relevant terminology, you can confidently identify and acquire the necessary replacements for your machinery, ensuring it operates at peak efficiency.

Common Issues with Craftsman C459

When working with power tools, users often encounter various challenges that can hinder performance and efficiency. Understanding these common issues can help in troubleshooting and ensuring a smoother experience. Whether it’s mechanical failures, electrical problems, or user-related mistakes, recognizing the signs early can save time and resources.

Mechanical Failures

One frequent issue involves components wearing out over time due to regular use. These mechanical failures can manifest as unusual noises or decreased efficiency during operation. Regular maintenance is essential to identify and address these concerns before they escalate. Checking for loose or damaged parts can often prevent larger problems.

Electrical Problems

Electrical malfunctions are another area of concern. Users may experience issues such as inconsistent power supply or complete shutdowns. This could be attributed to faulty wiring, worn-out connections, or even internal circuit problems. Ensuring that all electrical components are in good condition and free from debris can help maintain optimal functionality.

In conclusion, being aware of these common issues can significantly enhance the longevity and reliability of your tool. Regular inspections and proactive maintenance are key to avoiding unexpected breakdowns and ensuring seamless operation.

Where to Find Genuine Parts

Locating authentic components for your equipment is essential for maintaining performance and longevity. Ensuring that you use original elements guarantees compatibility and reliability, which ultimately saves you time and money in the long run.

Authorized Retailers

One of the most reliable sources for original components is authorized retailers. These establishments often have direct access to the manufacturer’s inventory and can provide:

- Genuine parts with warranties

- Expert advice on installation and maintenance

- Up-to-date information on new releases

Online Marketplaces

In addition to brick-and-mortar stores, various online platforms offer a wide selection of authentic elements. When shopping online, consider the following tips:

- Verify the seller’s reputation through reviews and ratings.

- Check if the products come with a guarantee of authenticity.

- Look for platforms that specialize in equipment components.

By utilizing these resources, you can ensure that you acquire the best quality parts for your needs, enhancing the performance and durability of your machinery.

Benefits of Using OEM Parts

Choosing original components for repairs and replacements ensures quality and compatibility with your equipment. These items are specifically designed to meet the exact specifications of the original manufacturer, providing numerous advantages that enhance performance and longevity.

Enhanced Reliability

Original components offer superior reliability compared to generic alternatives. They undergo rigorous testing and quality assurance processes, which minimizes the risk of failure and maximizes efficiency. This reliability translates into fewer breakdowns and a more consistent operational performance.

Optimal Performance

Using genuine components ensures that your equipment operates at its best. These parts are engineered to work seamlessly together, maintaining the integrity of the overall system. This compatibility helps to avoid issues that can arise from mismatched or inferior substitutes, ultimately prolonging the lifespan of your machinery.

Step-by-Step Repair Guide

This guide provides a clear process for repairing your equipment efficiently. By following these organized steps, you can ensure that you address common issues effectively and restore functionality.

- Gather Tools and Materials:

- Wrenches

- Screwdrivers

- Replacement components

- Cleaning supplies

- Identify the Problem:

Before starting the repair, determine the specific issue. Listen for unusual sounds, check for leaks, or assess performance inconsistencies.

- Disassemble Carefully:

Using the appropriate tools, gently take apart the unit. Keep track of all screws and parts by organizing them in a designated area.

- Inspect Components:

Examine each part for wear and damage. Look for cracks, corrosion, or other signs of deterioration that may need replacement.

- Replace Faulty Parts:

Install new or functional components as necessary. Ensure they fit correctly to avoid future issues.

- Reassemble the Unit:

Carefully put the equipment back together, reversing the disassembly steps. Ensure all screws and fittings are secure.

- Test Functionality:

Once reassembled, power on the equipment and monitor its performance. Check for any irregularities during operation.

- Perform Maintenance:

Regular upkeep will prolong the life of your equipment. Clean parts, lubricate moving components, and store properly when not in use.

By adhering to these steps, you can tackle repairs with confidence and maintain your equipment’s efficiency over time.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires consistent care and attention. By following a few essential maintenance practices, you can significantly extend the lifespan of your tools and machinery. Regular upkeep not only prevents unexpected breakdowns but also enhances efficiency, saving you time and money in the long run.

Here are some valuable tips to help you maintain your equipment effectively:

| Tip | Description |

|---|---|

| Regular Cleaning | Remove dust and debris after each use to prevent buildup that can affect performance. |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction and wear. |

| Inspection | Conduct routine checks for wear and tear, looking for any signs of damage that may require attention. |

| Proper Storage | Store tools in a dry, clean environment to avoid corrosion and degradation. |

| Follow Manufacturer Guidelines | Adhere to recommended maintenance schedules and procedures outlined in the user manual. |

By incorporating these practices into your routine, you can ensure that your equipment remains in excellent condition, ready to perform whenever you need it.

Resources for DIY Enthusiasts

Engaging in hands-on projects can be incredibly rewarding, offering both a creative outlet and the satisfaction of creating something unique. For those who enjoy crafting, having access to reliable materials, detailed guides, and community support is essential. This section explores various tools and resources that can enhance your DIY journey, making it easier to tackle any project with confidence.

Online Communities

Joining forums and social media groups dedicated to crafting can provide invaluable insights and inspiration. These platforms allow enthusiasts to share their experiences, troubleshoot issues, and showcase their work. Participating in discussions can lead to new friendships and collaborations, expanding your knowledge base while fostering a sense of belonging among fellow creators.

Instructional Resources

Access to high-quality tutorials, videos, and articles can significantly improve your skills. Numerous websites offer step-by-step guides tailored to various skill levels, ensuring that both novices and seasoned crafters find helpful content. Exploring these resources can ignite new ideas and techniques, empowering you to take on more complex projects.

Customer Support and Assistance

Access to reliable support services is essential for ensuring the longevity and performance of any equipment. Customers should feel confident in reaching out for help whenever they encounter issues or require guidance. Effective assistance not only addresses immediate concerns but also fosters a strong relationship between users and service providers.

Types of Support Available

- Phone Support: Direct communication with trained representatives who can provide immediate help.

- Email Assistance: A convenient way to get detailed responses and troubleshooting tips.

- Online Resources: Comprehensive guides and FAQs available on the official website for self-service.

- Live Chat: Instant messaging support for real-time problem resolution.

How to Access Support

- Visit the official support website for comprehensive resources.

- Utilize the contact number provided for immediate inquiries.

- Submit an email detailing your issue for in-depth assistance.

- Engage with live chat for quick questions and answers.

Utilizing these channels ensures that users can obtain the necessary support to maintain their equipment effectively and efficiently.