Craftsman Eager 1 Parts Diagram Overview

Understanding the internal structure of various tools can significantly enhance the ability to maintain, repair, or upgrade them. Knowing how different elements fit together ensures that any disassembly or reassembly is done efficiently, minimizing potential issues down the line.

When working with mechanical systems, it’s essential to recognize the relationships between various sections and mechanisms. A well-documented layout offers clarity, helping users address potential malfunctions while also extending the equipment’s lifespan.

Accurate breakdowns of elements make it easier to identify replacement needs, track wear, and ensure smooth performance. Whether you’re dealing with gears, bolts, or housing components, having a clear picture of how everything aligns is invaluable for any repair enthusiast.

By using detailed layouts, both novices and experienced individuals can confidently navigate even the most complex mechanical setups. These layouts serve as a guide to ensure no part is left out or misplaced, streamlining the process of restoring the equipment to optimal working condition.

Craftsman Eager 1 Parts Diagram Overview

This section offers a structured insight into the essential components of a well-known lawn maintenance tool. Understanding how different elements fit together ensures smoother repairs and upkeep, enhancing performance over time.

- Engine Components: These drive the core functionality, providing the necessary power to keep everything running efficiently.

- Cutting Mechanism: A sharp, rotating blade section designed to trim grass evenly across various surfaces.

- Drive Assembly: Transfers force to the wheels, making it easier to move the tool across lawns without additional effort.

- Control Features: Includes levers and switches that allow users to manage speed, height, and cutting modes.

- Frame and Chassis: The base structure holding everything together, providing stability and durability.

Familiarity with these sections helps users perform maintenance tasks, identify worn-out components, and ensure seamless operation throughout the seasons.

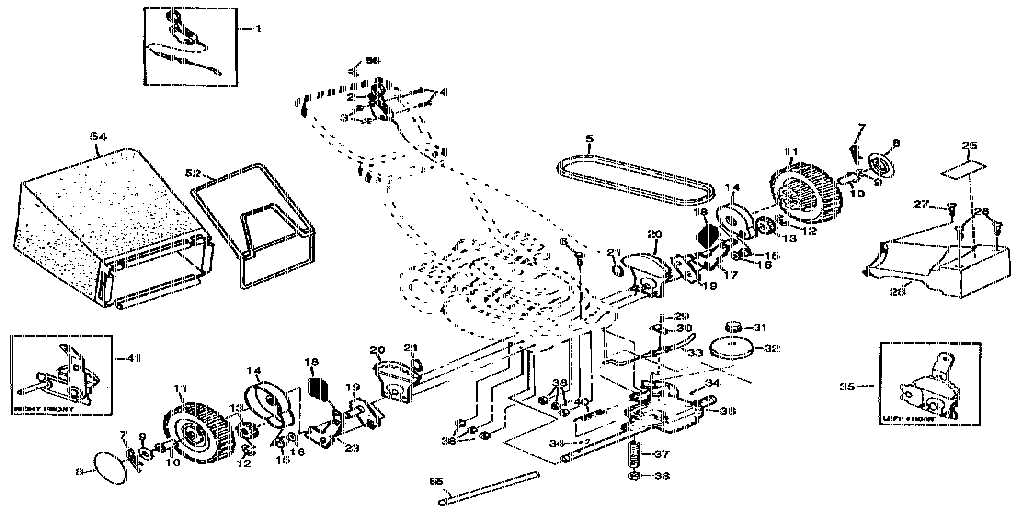

Understanding Engine Components Layout

The arrangement of internal engine elements plays a crucial role in ensuring smooth operation and performance. Each component is strategically positioned to optimize power transfer, fuel efficiency, and cooling. Grasping how these elements are organized provides insight into the machine’s overall functionality and helps identify potential maintenance areas.

Key Structural Elements and Their Purpose

At the core of the layout are moving parts like cylinders, pistons, and crankshafts, which work in harmony to generate motion. Surrounding these are stationary components that support the process, including the cooling system and intake sections. Proper alignment of these elements minimizes friction and ensures the engine runs reliably over time.

Importance of Placement and Interaction

Many of the engine’s critical elements are interconnected. For example, the exhaust and intake valves must synchronize with the pistons to achieve smooth combustion cycles. Even a slight misalignment between these elements can lead to inefficiencies or mechanical issues, underscoring the importance of understanding their precise arrangement.

Exploring the Fuel System Structure

The internal configuration responsible for powering small engines involves several key elements working together to deliver energy efficiently. Understanding this structure helps identify how fuel moves through various pathways, ensuring consistent operation and smooth performance.

Fuel intake is the first stage, where the system draws gasoline from the storage tank. The design ensures that only the required amount of fuel is pulled, preventing waste. From here, it flows toward the essential filtering components.

A proper filtration process removes impurities before the liquid reaches the combustion chamber. This step is critical for prolonging the engine’s life and reducing unexpected failures. The cleaned fuel is then routed to the next section for precise mixing.

The blend of air and fuel is managed through carefully adjusted mechanisms, which maintain the correct balance for ignition. This ensures smooth combustion and minimizes emissions. Finally, the system completes its cycle by redirecting unused fuel back to the reservoir for reuse.

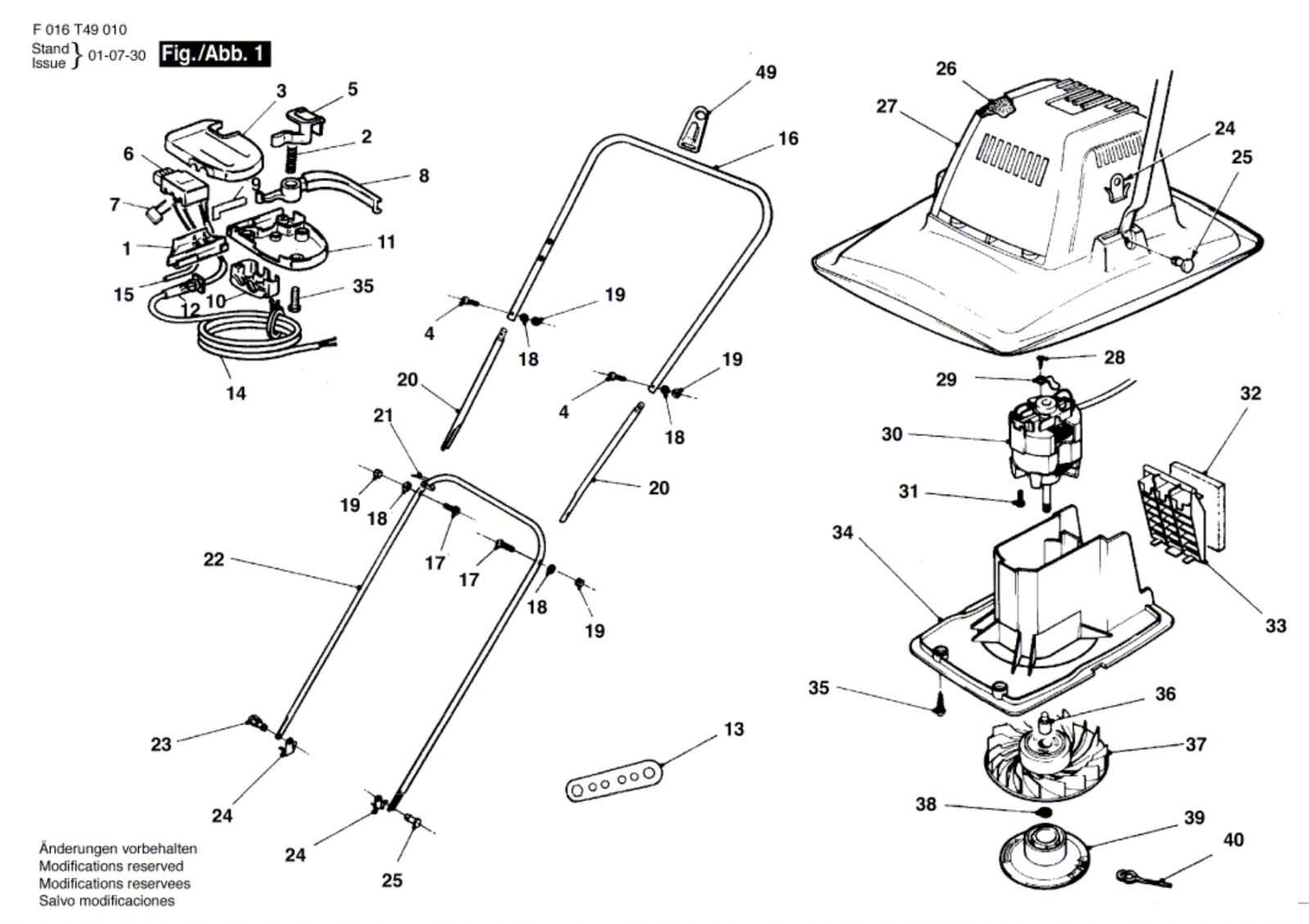

Details of the Starter Mechanism

The starting system plays a crucial role in ensuring the smooth ignition of the equipment, allowing users to get it up and running effortlessly. This section provides an overview of how different components interact to initiate operation, focusing on key elements involved in the process.

- Starter Rope: The pull cord triggers the initial rotation needed to engage the system.

- Recoil Spring: This spring ensures the rope rewinds automatically after each pull, readying it for the next start.

- Pawl Assembly: These small levers lock into place during the pull, transmitting energy to the internal mechanism.

- Flywheel Engagement: The flywheel is vital for building momentum, ensuring a consistent and reliable start.

Maintaining these components properly ensures the longevity of the system and minimizes potential delays during future operations. Regular inspection of the starter rope and recoil spring, along with occasional lubrication of internal parts, can prevent unexpected issues.

How the Ignition Assembly Works

The ignition system plays a crucial role in initiating the engine’s operation. It ensures that the engine starts by delivering the necessary spark at the right moment. This process requires several components working in harmony to create the energy needed for combustion.

The system relies on mechanical movement and electrical signals. When the user triggers the start mechanism, a current flows through key elements, setting off a chain reaction. As these components engage, they produce a spark that ignites the fuel-air mixture inside the engine, bringing it to life.

Maintaining proper alignment between the ignition components is essential for smooth and efficient operation. If any part fails or becomes misaligned, it can result in delayed starts or complete failure to ignite. Understanding the basic principles of this system can help in diagnosing potential issues and ensuring reliable performance.

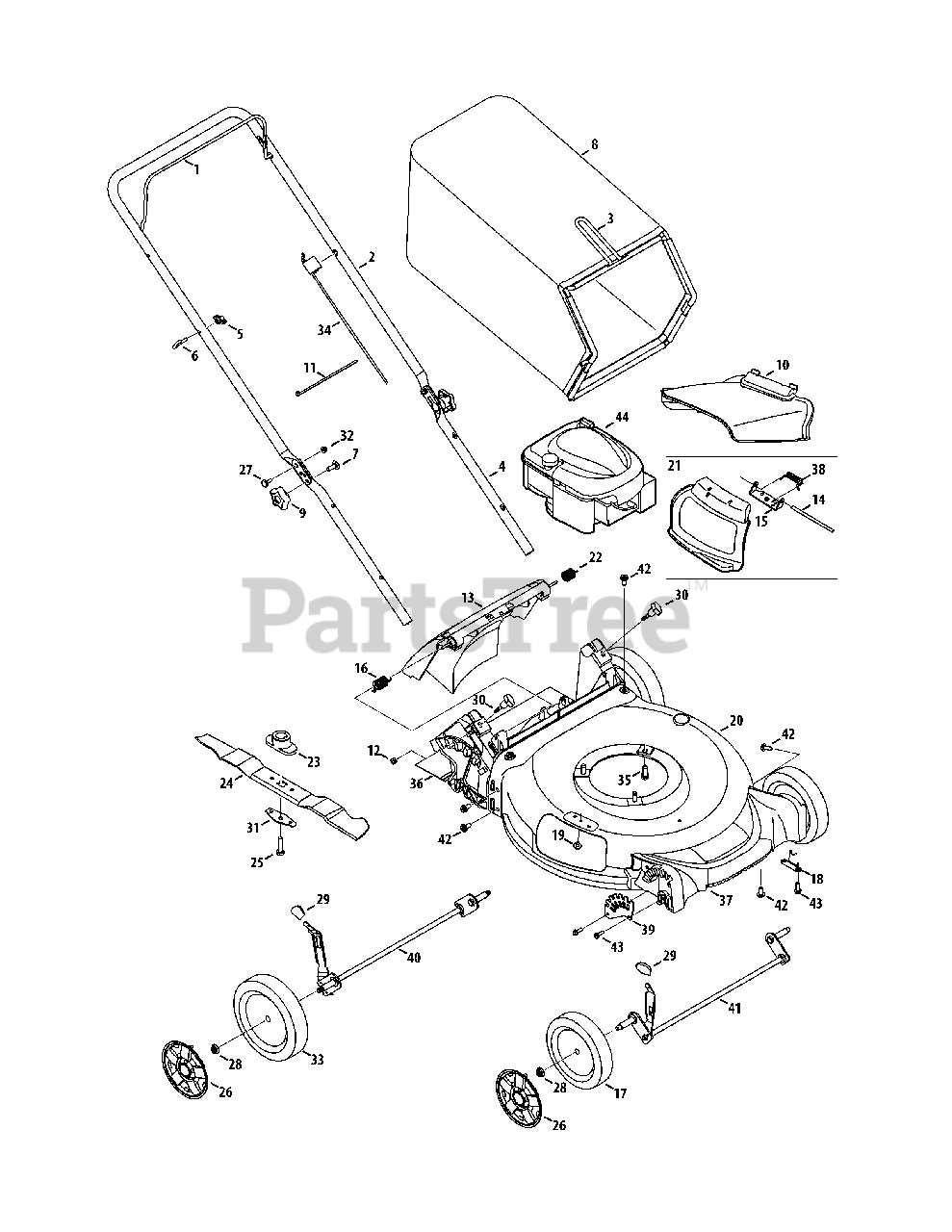

Analyzing the Blade and Deck Arrangement

This section focuses on understanding the layout and positioning of the cutting elements and the associated framework that supports them. A well-organized assembly plays a crucial role in ensuring optimal performance and efficiency in operation. By examining the configuration, one can gain insights into how each component contributes to the overall functionality.

Importance of Proper Alignment

Correct alignment of the cutting edges with the supporting structure is essential for effective operation. Misalignment can lead to uneven cutting, increased wear, and potential damage to the equipment. Ensuring that all elements are positioned accurately helps maintain consistent results and prolongs the lifespan of the device.

Maintenance Considerations

Regular inspection of the assembly is necessary to identify any signs of wear or misplacement. Keeping the components clean and properly adjusted enhances their performance. Regular maintenance routines should focus on checking the connections and ensuring that everything is securely fastened to prevent operational issues.

Air Filter Placement and Functions

The positioning of air filtration systems plays a crucial role in ensuring optimal performance and longevity of various equipment. Properly placed filters are essential for maintaining a clean environment and enhancing efficiency. Understanding their location and purpose can significantly impact overall functionality.

Air filters are typically installed in designated compartments, strategically designed to capture contaminants and prevent them from entering sensitive areas. This setup not only protects internal components but also promotes cleaner airflow, contributing to improved performance and reliability.

| Function | Description |

|---|---|

| Contaminant Removal | Filters trap dirt, dust, and other particles, preventing them from damaging internal mechanisms. |

| Airflow Improvement | Ensures unobstructed airflow, which is vital for efficient operation and performance. |

| Maintenance Indicator | Visible signs of wear or clogging can indicate when the filter needs to be replaced, aiding in upkeep. |

Carburetor System Breakdown

The carburetor plays a crucial role in the functioning of internal combustion engines, regulating the mixture of air and fuel. This essential component ensures optimal performance by efficiently delivering the right ratio to support combustion. Understanding the components and their interactions within this system can enhance maintenance and troubleshooting efforts.

Key Components of the Carburetor

A typical carburetor consists of several key elements, including the float chamber, jets, and throttle plate. Each part has a specific function, contributing to the overall efficiency of the engine. The float chamber maintains a steady fuel level, while jets control the amount of fuel entering the airstream. The throttle plate, meanwhile, adjusts airflow based on the driver’s demands, affecting power and speed.

Common Issues and Solutions

Various issues can arise within the carburetor system, leading to performance problems. Clogged jets, for example, can disrupt the fuel flow, resulting in engine stalling or poor acceleration. Regular cleaning and inspection are essential to prevent such issues. Additionally, ensuring proper adjustments of the throttle plate can help maintain optimal engine p

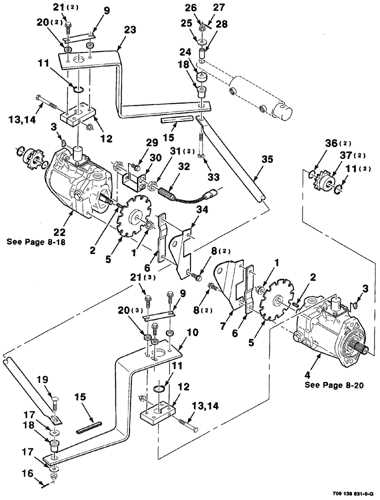

Transmission Setup and Drive Belt Path

This section focuses on the arrangement of the gear system and the routing of the driving belt, essential for ensuring smooth operation. Understanding these elements is crucial for maintaining optimal performance and extending the lifespan of your equipment.

When setting up the transmission, consider the following aspects:

- Alignment: Ensure that all components are properly aligned to prevent wear and tear.

- Torque Specifications: Adhere to the recommended torque values during assembly for secure connections.

- Lubrication: Apply appropriate lubrication to moving parts to reduce friction and enhance efficiency.

The drive belt path plays a significant role in the overall functionality. Here are some key points to keep in mind:

- Belt Routing: Follow the specified routing to ensure the belt operates effectively without slipping.

- Tension Adjustment: Regularly check and adjust the tension of the belt to avoid excessive slack or tightness.

- Inspection: Frequently inspect the belt for signs of wear or damage, replacing it as needed to maintain performance.

By paying close attention to the transmission setup and the routing of the drive belt, you can achieve reliable operation and prevent potential issues in the future.

Troubleshooting the Electrical Circuit

Understanding and resolving issues within an electrical framework is crucial for ensuring optimal performance. By systematically examining components and connections, you can identify potential faults that may disrupt functionality. This process not only enhances the reliability of your equipment but also improves safety during operation.

Common Issues and Solutions

- Power Loss: Verify that all connections are secure and that the power source is functioning correctly.

- Intermittent Operation: Inspect for loose wires or corroded terminals that may cause unreliable connectivity.

- Overheating Components: Check for adequate ventilation and ensure that no components are overloaded beyond their rated capacity.

Step-by-Step Diagnostic Process

- Begin by disconnecting power to avoid any hazards.

- Visually inspect all connections and wiring for signs of wear or damage.

- Utilize a multimeter to test voltage levels at various points within the circuit.

- Replace any faulty components identified during testing.

- Reconnect the power and observe the system to confirm that the issues have been resolved.

Replacement Options for Common Parts

When it comes to maintaining equipment, finding suitable alternatives for frequently used components is essential. Understanding the various choices available can help extend the lifespan of your tools and enhance their performance.

Here are some popular alternatives that can be considered:

- High-quality aftermarket components: These often provide similar or improved performance compared to original components, making them a great choice for replacements.

- Generic options: Many manufacturers offer universal pieces that fit a range of models, offering flexibility and affordability.

- OEM alternatives: Original Equipment Manufacturer components can be sourced, ensuring compatibility and reliability.

Additionally, consider the following factors when selecting replacements:

- Compatibility with your specific model to ensure proper fit and function.

- Quality and durability to avoid frequent replacements and enhance reliability.

- Cost-effectiveness to maintain budget while ensuring good performance.

By exploring these options, you can effectively manage maintenance needs and keep your equipment running smoothly.

Maintenance Tips for Long-Term Use

Ensuring longevity in your tools requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of your equipment. Here are some essential strategies to keep in mind.

- Regular Cleaning: Remove dust, debris, and any residues after each use to prevent buildup that can hinder functionality.

- Inspect Components: Routinely check for any signs of wear or damage, and replace any faulty elements promptly.

- Lubrication: Apply the appropriate lubricants to moving parts to reduce friction and enhance operation.

- Store Properly: Keep tools in a dry, cool environment to avoid rust and corrosion, ensuring they are stored in a protective case or toolbox.

- Follow Manufacturer Guidelines: Always refer to the guidelines provided for specific maintenance requirements tailored to your equipment.

By implementing these practices, you can maintain optimal performance and enjoy your tools for years to come.

Where to Find Authentic Parts

When it comes to acquiring genuine components for your tools, ensuring quality and compatibility is crucial. Sourcing from reliable suppliers can make all the difference in performance and longevity. Here are some recommendations on how to locate these essential elements.

Authorized Retailers

One of the most reliable avenues is through authorized retailers. These establishments are sanctioned by manufacturers to sell genuine items, providing assurance of authenticity. Shopping at these locations can often yield the latest innovations and updated versions of necessary components.

Online Marketplaces

The internet offers a wealth of options for purchasing high-quality components. Well-established online marketplaces frequently feature sellers that offer genuine items with verified reviews. Make sure to check the seller’s ratings and read customer feedback to ensure a satisfactory transaction.