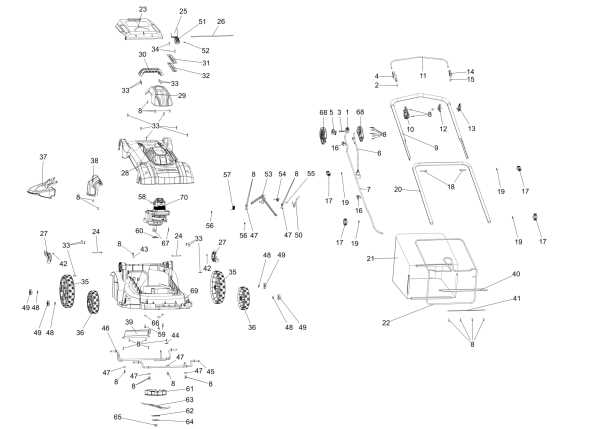

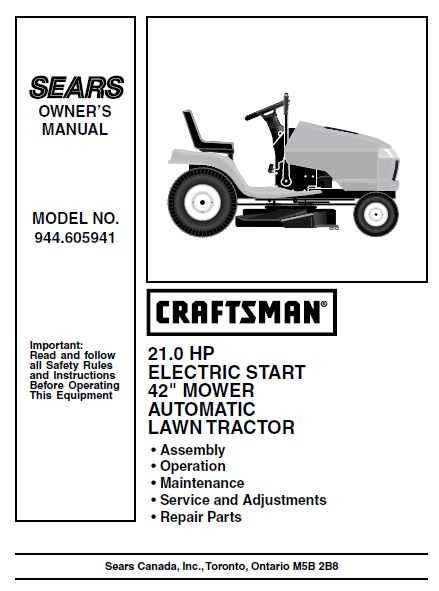

Craftsman Electric Lawn Mower Parts Diagram and Assembly Guide

Understanding the structure and inner workings of a mechanical device can significantly aid in its maintenance and repair. When all elements are laid out in a clear and concise manner, it becomes easier to identify each individual component and its function within the whole system. This knowledge not only enhances operational efficiency but also ensures longer lifespan through proper care.

In this section, we delve into the arrangement of various elements that make up a modern piece of machinery. The breakdown of its main elements allows users to gain insight into the intricate connections and roles of each component, facilitating troubleshooting and general upkeep.

By exploring this detailed layout, you will be equipped with the necessary understanding to manage any issues that arise, ensuring smooth operation and effective handling of this essential tool. With this guide, you can better navigate the complexities of the device’s structure and maintain it for optimal performance.

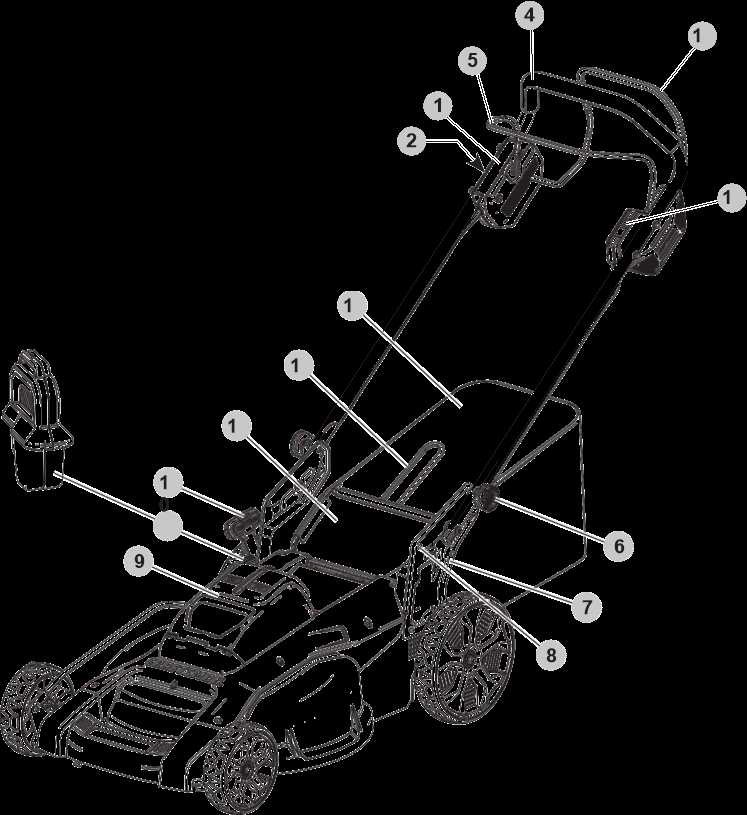

Craftsman Electric Lawn Mower Parts Overview

When maintaining any garden equipment, it’s essential to understand how the different elements work together to ensure optimal performance. This guide offers a comprehensive look into the components of a typical outdoor cutting machine, breaking down the main functional areas that contribute to its efficiency and longevity. Whether you’re looking to replace a piece or simply want to know more about its inner workings, having a clear picture of the device’s structure can be immensely helpful.

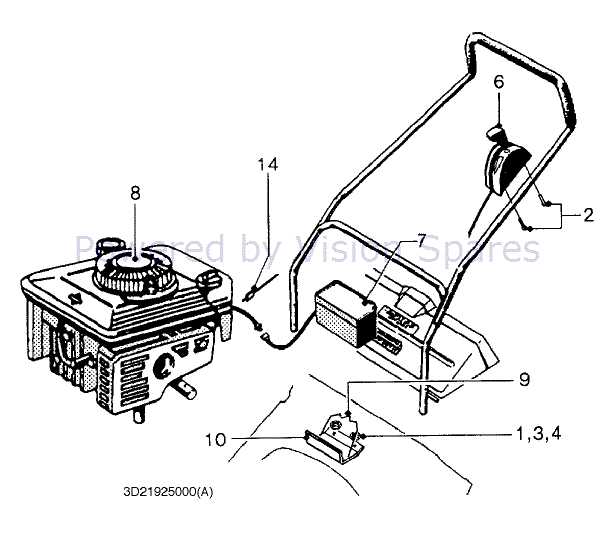

Key Mechanical Elements

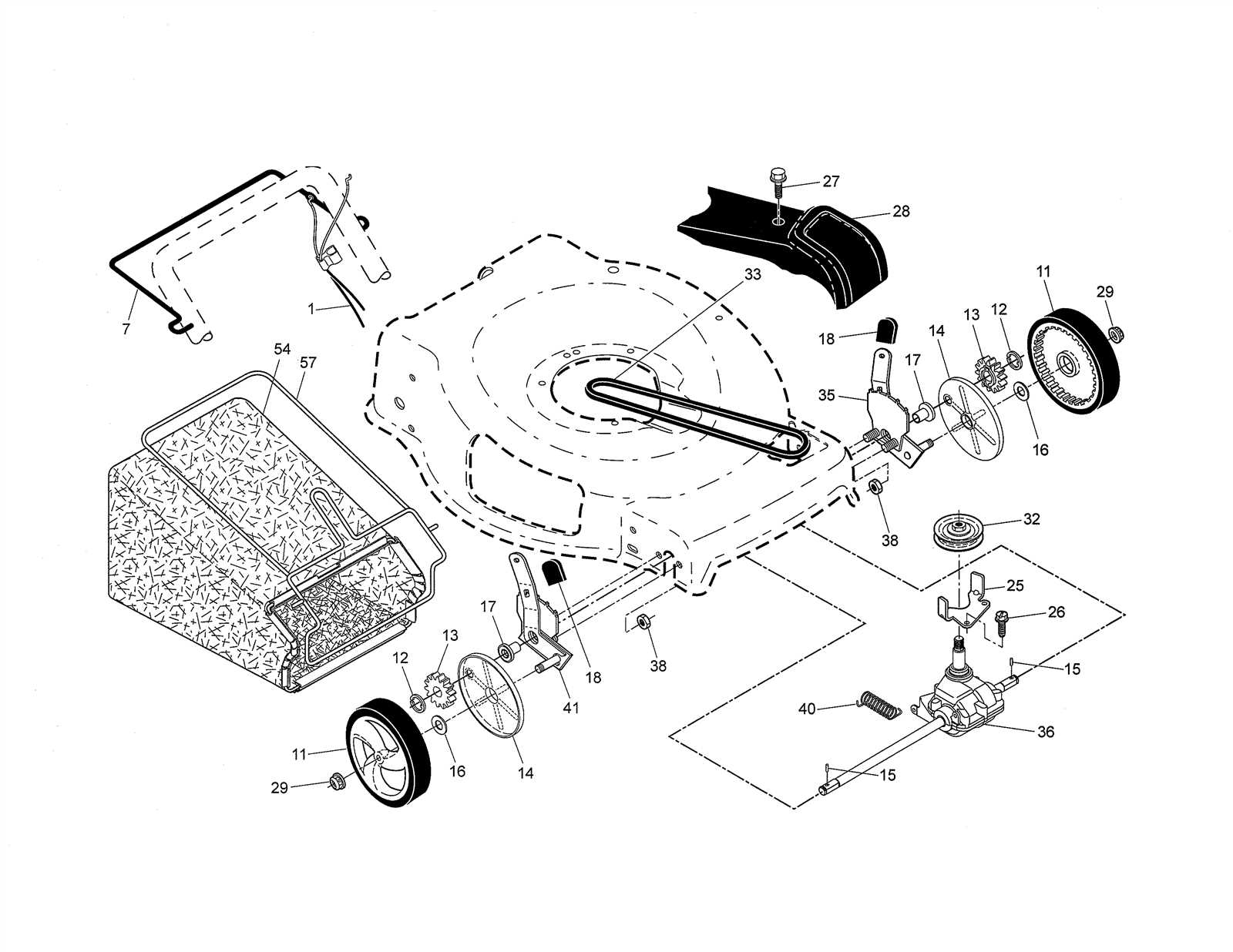

One of the most vital sections involves the drive and cutting mechanisms. These sections include rotating blades, wheels, and motor components. Each of these mechanical elements is designed to interact seamlessly, providing smooth operation and efficient grass trimming. Regular inspections of these areas will help to maintain consistent performance and avoid potential breakdowns during use.

Electrical and Control Systems

The control system typically includes the power switch, safety controls, and connection points to the power supply. Proper functioning of these systems ensures safe and efficient operation, as well as a reliable start-up process. Ensuring that electrical connections are intact and controls are responsive is key to preventing interruptions and maintaining the tool’s overall effectiveness.

Key Components of the Mower

The mechanical device consists of several essential elements that work together to ensure efficient cutting and operation. Understanding these main components can help users maintain and troubleshoot the equipment effectively.

| Component | Function | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cutting Blade | The sharp metal edge responsible for trimming the grass to the desired height. | |||||||||||

| Motor Assembly | Drives the blade rotation, providing the power necessary for smooth operation. | |||||||||||

| Control Panel | Contains the main switches and levers that allow the user to start, stop, and adjust settings. | |||||||||||

| Wheels | Support the movement of the equipment across various terrains, ensuring stability and mobility. | |||||||||||

| Deck | A protective housing that shields the user from debris and ensures proper airflow for cutting. |

| Component | Function | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power Source | Generates the necessary energy for the system. | |||||||||||

| Transmission Mechanism | Transfers the generated energy to drive the movement. | |||||||||||

| Cooling System |

| Material | Advantages | Considerations |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | May be more expensive |

| Plastic | Weather-resistant, easy to mold | Less durable than metal options |

| Treated Wood | Natural appearance, strong | Requires maintenance to prevent rot |

Understanding the characteristics of these materials will aid in making informed decisions that align with specific needs and environmental conditions. Ultimately, a well-constructed platform enhances functionality and extends the lifespan of the equipment.

Grass Bag and Collection System

The grass collection system is essential for maintaining a tidy and healthy outdoor area. This feature is designed to gather clippings and debris efficiently, ensuring that the area remains neat after trimming. Understanding its components and functionality can greatly enhance the overall mowing experience.

Typically, this system comprises several key elements:

- Collection Bag: A large receptacle that holds the cut grass, making disposal easy and convenient.

- Mounting Frame: The structure that secures the bag to the main unit, ensuring stability during operation.

- Chute: The pathway through which clippings are directed into the bag, often designed for optimal airflow.

- Release Mechanism: A feature that allows for quick detachment of the bag for emptying and cleaning.

To maintain the efficiency of the collection system, regular cleaning is crucial. Over time, clippings can accumulate in various parts, potentially leading to blockages. It is advisable to follow these maintenance tips:

- Empty the bag frequently to avoid overfilling, which can hinder performance.

- Inspect the chute for any debris and clear it regularly.

- Clean the bag with water and mild detergent to prevent mold and odors.

- Ensure all connections are secure to maintain effective operation.

By keeping the collection system in optimal condition, users can ensure a more efficient and enjoyable mowing experience, resulting in a well-kept outdoor space.

Corded vs Cordless Operation Differences

The choice between wired and wireless operation can significantly influence user experience and efficiency. Each type presents distinct advantages and drawbacks that cater to different needs and preferences. Understanding these differences can aid in making an informed decision tailored to specific tasks and environments.

Power Source and Mobility

Wired devices are often limited by the length of the cord, which can restrict movement and access to certain areas. However, they typically offer consistent power without the need for recharging. In contrast, wireless options provide greater freedom of movement, allowing users to navigate freely without being tethered. This mobility is particularly beneficial in expansive spaces or uneven terrain.

Maintenance and Convenience

Maintenance plays a crucial role in the choice between these two systems. Wired models generally require less upkeep, as they do not involve battery care. Conversely, cordless systems necessitate regular charging and battery replacement, which can be inconvenient. Yet, the convenience of not dealing with cords can outweigh these maintenance considerations for many users, especially in residential settings.

Ultimately, the decision hinges on the user’s specific needs, including the size of the area to be managed and personal preferences regarding mobility and maintenance.

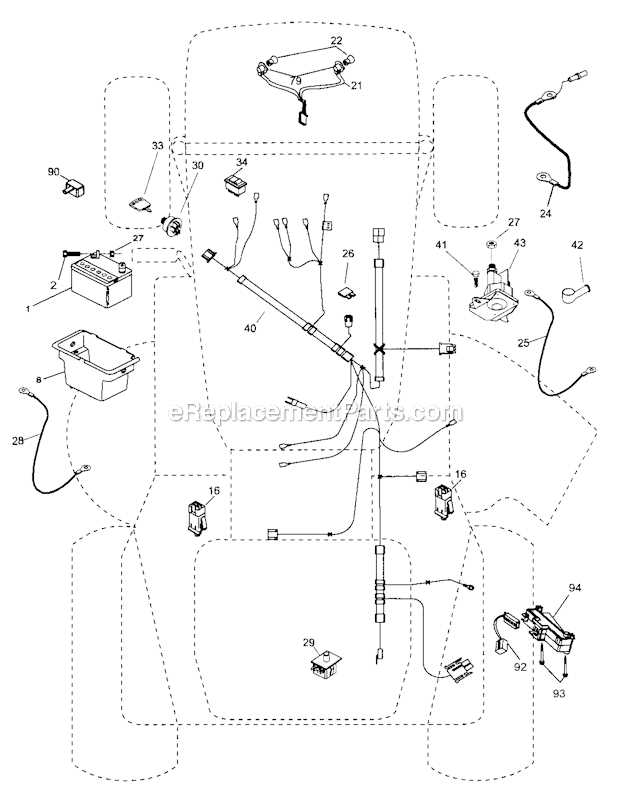

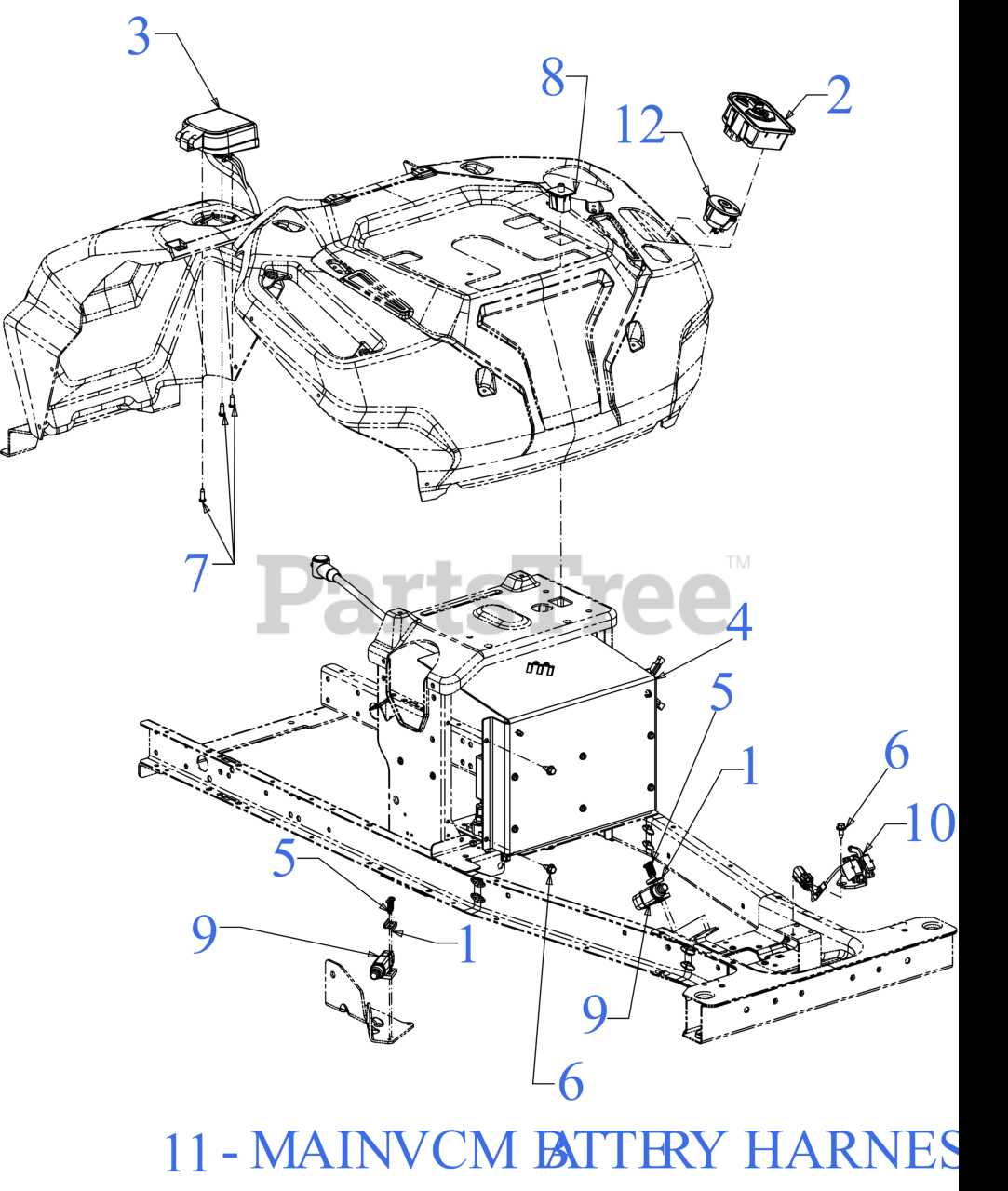

Electrical Connections and Wiring Diagram

This section focuses on the crucial aspects of electrical connections within the machine, ensuring proper functionality and safety during operation. Understanding the layout and interconnections can significantly aid in troubleshooting and maintenance tasks.

Proper wiring is essential for optimal performance. The following points highlight key components and their roles:

- Power Source: Provides the necessary energy for the device’s operation.

- Control Switch: Initiates and terminates operation, allowing for user control.

- Motor Connections: Links the power supply to the motor, facilitating movement.

- Safety Features: Incorporates fuses and circuit breakers to prevent overload.

The configuration of these connections can vary, so it’s crucial to refer to the specific wiring schematics for accurate setup. A systematic approach to understanding these elements can enhance safety and efficiency.

Here’s a general outline for checking connections:

- Inspect the power source for proper voltage.

- Verify the integrity of the control switch.

- Ensure motor terminals are securely connected.

- Check for any signs of wear or damage in wiring.

By following these guidelines, users can maintain the functionality and safety of their equipment, minimizing the risk of electrical issues.

Routine Part Replacement and Care

Regular maintenance and timely exchanges of essential components are crucial for ensuring optimal performance and longevity of your gardening equipment. Understanding when and how to replace specific elements can significantly enhance the efficiency and reliability of your device.

Inspection should be a routine task. Check various components for signs of wear, damage, or any abnormalities. This proactive approach helps identify potential issues before they escalate, allowing for immediate action and replacement as needed.

When it comes to replacement, it is vital to refer to the manufacturer’s guidelines to ascertain the recommended intervals for changing specific parts. For instance, blades should be sharpened or replaced regularly to ensure a clean cut, while belts and filters should be inspected frequently to maintain proper functionality.

Additionally, routine cleaning is essential. Removing debris and grass clippings from the exterior and undercarriage of the machine helps prevent rust and corrosion. This simple task can prolong the life of various components and enhance overall performance.

Finally, always use high-quality replacements that meet or exceed original specifications. This not only ensures compatibility but also helps maintain the overall integrity of the equipment. Proper care and attention to detail will lead to a smoother and more efficient gardening experience.