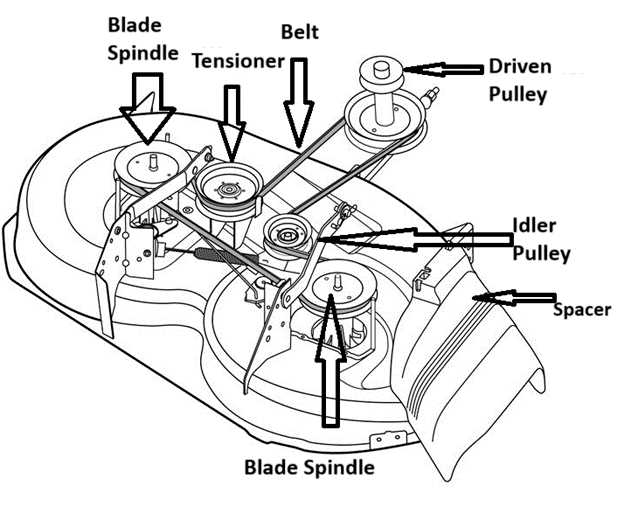

Parts Diagram for Husqvarna 42 Inch Mower Deck

When it comes to maintaining a pristine outdoor space, having a reliable cutting apparatus is essential. Knowing the different elements that comprise your machine can significantly enhance its performance and longevity. By familiarizing yourself with the essential features, you can ensure your device operates efficiently and meets your landscaping needs.

In this section, we will explore the various components associated with your cutting equipment. By gaining insights into each part’s function and arrangement, you can better manage repairs, replacements, and maintenance. This understanding will empower you to make informed decisions regarding the upkeep of your apparatus, ensuring it remains in top condition throughout its lifespan.

By examining the configuration of these elements, you can identify the right tools and techniques to optimize your equipment’s functionality. Whether you are looking to troubleshoot issues or simply enhance your understanding, a clear overview of the layout will provide valuable information for every user.

This section will delve into the various elements that constitute a typical cutting apparatus used for lawn maintenance. Understanding these components is essential for effective upkeep and troubleshooting. Each element plays a vital role in ensuring optimal performance, and recognizing their functions can greatly enhance the user experience.

Key Elements of the Cutting Mechanism

Exploring the fundamental components that make up the cutting mechanism, including the blades and their arrangement. Each blade’s design contributes to the efficiency of the cutting process, impacting both the quality of the cut and the speed of operation.

Understanding the Frame and Support Structures

The framework that houses the cutting apparatus is crucial for stability and durability. This section will highlight how various supports and reinforcements contribute to the overall strength of the assembly, ensuring it withstands the rigors of outdoor use.

Other sections will cover the following topics:

- Drive System Components – Detailing the elements responsible for propelling the cutting apparatus.

- Adjustment Mechanisms – Exploring how to modify cutting height and angle.

- Safety Features – Highlighting essential elements designed to protect users during operation.

- Maintenance Guidelines – Offering tips on how to care for and extend the lifespan of the apparatus.

- Common Issues and Solutions – Identifying typical problems users may encounter and their remedies.

- Tools Required for Repairs – Listing necessary tools for effective maintenance and repairs.

- Assembly Instructions – Providing guidance on how to assemble or disassemble components safely.

- Compatibility Information – Offering insights on which components are interchangeable or compatible with other models.

- Upgrades and Modifications – Discussing potential enhancements to improve performance.

- Frequently Asked Questions – Addressing common inquiries related to the operation and maintenance of the equipment.

Essential Parts of Mower Deck

Understanding the fundamental components of a cutting platform is crucial for maintaining its efficiency and performance. Each element plays a significant role in ensuring smooth operation and optimal results when tending to your lawn. Familiarity with these components not only aids in effective maintenance but also enhances the longevity of your equipment.

| Component | Function |

|---|---|

| Blade | Responsible for cutting the grass to the desired height. |

| Spindle | Holds the blade in place and allows it to rotate efficiently. |

| Housing | Encases the rotating blade, providing safety and support. |

| Wheel | Facilitates movement across different terrains, aiding in maneuverability. |

| Lift Lever | Adjusts the height of the cutting component to suit various grass lengths. |

| Belts | Transmits power from the engine to the rotating blade and other components. |

How to Read the Diagram

Understanding a schematic representation of components is essential for effective maintenance and repairs. This visual guide serves as a blueprint, illustrating the various elements and their interconnections. By grasping how to interpret this information, users can enhance their proficiency in managing their equipment.

Start by familiarizing yourself with the layout of the illustration. The components are typically arranged logically, often reflecting their physical arrangement in the system. Pay attention to any labels or annotations, as these provide crucial details regarding each element’s function.

Next, identify the key symbols used within the illustration. Different shapes and lines often represent various types of components, such as fasteners, brackets, or belts. Understanding these symbols will help you quickly locate specific items. Additionally, color coding may be utilized to indicate different functions or categories, adding another layer of clarity to the schematic.

Finally, cross-reference the schematic with the user manual or maintenance guide. This supplementary information can provide context and further details, ensuring that you fully understand the relationships between components. By mastering the interpretation of this visual representation, you will be better equipped to carry out repairs and maintenance tasks efficiently.

Common Issues with Mower Decks

Maintaining a healthy cutting system is crucial for achieving an immaculate lawn. Various complications can arise during the operation, often resulting from wear and tear or environmental factors. Recognizing these challenges early can help ensure optimal performance and extend the lifespan of the equipment.

Uneven Cutting Performance

One of the most prevalent problems is uneven cutting, which can lead to a patchy appearance on the lawn. This issue may stem from dull blades, incorrect height settings, or imbalances in the structure. Regular inspections and adjustments can help mitigate this problem, ensuring that the blades are sharp and properly aligned.

Clogging and Debris Buildup

Another frequent issue is the accumulation of grass clippings and debris, which can obstruct the cutting mechanism. This can hinder efficiency and potentially damage components if left unaddressed. To prevent this, it’s advisable to clean the cutting area regularly and inspect for any blockages that could impede performance.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your equipment. Regular attention to various components can prevent wear and tear, ultimately extending the lifespan of your machine. Following a consistent maintenance schedule not only enhances performance but also minimizes the risk of costly repairs.

1. Regular Cleaning: Keeping the exterior and working parts clean is crucial. Dirt and debris can accumulate, leading to potential damage and decreased efficiency. Use a soft brush or cloth to remove any buildup after each use.

2. Check and Change Fluids: Regularly inspect fluid levels, including oil and fuel. Fresh fluids are vital for optimal operation. Replace any old or contaminated fluids according to the manufacturer’s guidelines.

3. Inspect Components: Regularly examine key elements for signs of wear. Look for frayed belts, worn blades, or loose connections. Addressing these issues promptly can prevent more severe damage in the future.

4. Store Properly: Ensure your equipment is stored in a dry, protected area when not in use. This helps prevent rust and other damage from exposure to the elements.

5. Follow Usage Guidelines: Always adhere to recommended operating procedures. This not only ensures safe use but also prevents undue stress on the machinery, fostering longevity.

Identifying Wear and Tear Signs

Recognizing the signs of deterioration in your outdoor equipment is essential for maintaining optimal performance. Early detection of issues can prevent more severe damage and extend the lifespan of your machine. By knowing what to look for, you can ensure a smooth and efficient operation during your maintenance tasks.

Common Indicators of Deterioration

- Uneven Cutting: If the equipment is leaving grass uncut or unevenly trimmed, it may indicate blade damage or misalignment.

- Excessive Vibration: Increased vibration during operation can suggest loose components or wear in moving parts.

- Unusual Noises: Grinding, squeaking, or rattling sounds often signify mechanical issues that need immediate attention.

- Rust and Corrosion: Visible rust on metal surfaces is a clear sign of neglect and can compromise the structural integrity of the equipment.

- Fluid Leaks: Any leaks from the machine may indicate seal or gasket failure, which requires prompt repair to prevent further damage.

Regular Inspection Tips

- Perform routine checks before each use, looking for any noticeable wear.

- Clean the equipment thoroughly to remove debris that can hide signs of damage.

- Refer to the manufacturer’s guidelines for specific maintenance intervals and inspection criteria.

- Keep a maintenance log to track any repairs or issues that arise over time.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right tools is essential for ensuring efficient and effective repairs. A well-equipped toolkit allows for quick troubleshooting and enhances the overall repair experience. Below is a list of essential instruments that can assist in carrying out various repair jobs.

Essential Instruments

- Socket Set: A variety of sizes will accommodate different fasteners.

- Wrench Set: Both adjustable and fixed types are useful for gripping and turning.

- Screwdrivers: A selection of flathead and Phillips-head tools is necessary for various screws.

- Pliers: Needle-nose and standard pliers can help in gripping and manipulating components.

- Torque Wrench: Ensures fasteners are tightened to the specified level.

- Utility Knife: Handy for cutting materials or removing debris.

Additional Tools

- Cleaning Brush: Essential for clearing dirt and debris from hard-to-reach areas.

- Safety Gear: Always wear gloves and goggles for protection during repairs.

- Flashlight: Useful for illuminating dark spaces and inspecting components.

Replacement Parts Overview

When it comes to maintaining outdoor equipment, understanding the essential components that may need to be replaced is crucial. These elements ensure optimal performance and longevity, contributing to the overall efficiency of the machine. Familiarizing oneself with the various components can help in identifying issues and facilitating timely replacements.

Essential Components

Key elements that often require replacement include blades, belts, and bearings. Each of these components plays a vital role in the functionality of the equipment. Regular inspection and timely replacement of these items can prevent more significant issues and ensure smooth operation.

Quality and Compatibility

It is important to select high-quality replacements that are compatible with your specific equipment model. Using parts that meet manufacturer specifications not only enhances performance but also extends the lifespan of your machine. Researching and sourcing reputable suppliers can make a significant difference in maintenance efforts.

Installation Procedures Explained

Understanding the steps involved in setting up your equipment is essential for achieving optimal performance. Proper assembly ensures that all components function harmoniously, contributing to the longevity and efficiency of your machine. This section outlines the necessary procedures for effective installation, emphasizing attention to detail and systematic organization.

Preparation Steps

Before beginning the installation, gather all required tools and components. A clean workspace is crucial, as it prevents any loss or damage to essential items. Additionally, reviewing the user manual can provide insights into specific requirements and techniques relevant to your model.

Assembly Process

Start by positioning the various components according to the layout provided in the manual. Ensure that all fittings are secure and aligned properly. During assembly, it is important to tighten screws and bolts adequately, as this prevents future operational issues. Regular checks during the process can help identify any misalignments or concerns before completing the setup. Once all elements are connected, conduct a thorough inspection to confirm that everything is installed correctly and ready for use.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. By following specific guidelines, individuals can create a safer working environment while handling equipment. This section outlines essential precautions that should be taken before and during repair activities.

Preparation Before Starting Repairs

- Wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear.

- Ensure the workspace is clean and well-lit to avoid hazards.

- Disconnect the power source to prevent accidental starts while working.

- Keep tools organized and within reach to minimize unnecessary movement.

During the Repair Process

- Handle sharp objects with care, using tools designed for safety.

- Take breaks to avoid fatigue, which can lead to mistakes.

- Maintain a clear area around the equipment to avoid tripping hazards.

- Follow manufacturer instructions and guidelines for specific tasks.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and components of lawn care equipment. Understanding these aspects can enhance the longevity and performance of your machinery, ensuring efficient operation throughout the mowing season.

| Question | Answer |

|---|---|

| What should I check before using my lawn care equipment? | Before use, inspect the blades for sharpness, ensure all components are securely attached, and check fluid levels to avoid operational issues. |

| How often do I need to replace the cutting blades? | It is advisable to replace the cutting blades at least once per season or more frequently if you notice signs of wear or dullness. |

| Can I perform maintenance on my own? | Yes, many maintenance tasks can be done at home, such as cleaning the exterior, lubricating moving parts, and changing filters. |

| Where can I find replacement components? | Replacement components are typically available at authorized retailers, online stores, or local repair shops specializing in garden machinery. |

| What is the best way to store my equipment during the off-season? | Clean the equipment thoroughly, remove any debris, and store it in a dry, sheltered place to protect it from the elements and prolong its lifespan. |

Expert Recommendations for Upgrades

Enhancing the efficiency and performance of your gardening equipment can significantly improve your overall experience. By selecting the right enhancements, you can optimize functionality and ensure longevity, making maintenance tasks easier and more enjoyable. Consider focusing on key areas where improvements can have the most impact.

1. Consider Engine Performance: Upgrading the engine components can provide a noticeable boost in power and efficiency. Look for high-performance air filters and exhaust systems that facilitate better airflow and increase output. Additionally, using premium fuel and maintaining regular oil changes will keep your machine running smoothly.

2. Improve Cutting Efficiency: Investing in high-quality blades can enhance cutting precision and reduce the amount of time spent on maintenance. Sharp, durable blades ensure a clean cut, promoting healthier growth for your lawn. Regularly replacing and sharpening blades can yield significant improvements in cutting quality.

3. Enhance User Comfort: Ergonomics play a crucial role in user satisfaction. Upgrading the seat to a more comfortable model or adding ergonomic grips can reduce fatigue during prolonged use. Consider adding adjustable features that allow customization for a better fit.

4. Explore Technological Upgrades: Incorporating smart technology can make your equipment more efficient. Look for options such as digital displays that provide performance metrics or GPS systems for improved navigation. These features can help you track usage and plan maintenance schedules effectively.

5. Accessory Options: Additional tools and attachments can expand the functionality of your equipment. Whether it’s a bagging system for better debris collection or a snow blade for winter use, these accessories can enhance versatility and increase the machine’s value.

Where to Find Parts Online

Locating the right components for your outdoor equipment has become increasingly convenient with the growth of online resources. Numerous websites specialize in offering a wide array of replacement items tailored to various models, ensuring you can maintain and repair your machinery effectively.

Manufacturer’s Website: The first place to consider is the official website of the equipment’s manufacturer. They often have a dedicated section for spare items, allowing you to browse and order directly from the source, ensuring authenticity and quality.

Online Retailers: Many online retailers provide a vast selection of items, often at competitive prices. Websites like Amazon, eBay, and specialized gardening equipment suppliers typically have user-friendly search functions that make it easy to find what you need.

Parts Catalogs: Various sites offer digital catalogs that display comprehensive listings of available items. These resources can help you identify specific components based on your equipment’s model, ensuring compatibility.

Forums and Community Groups: Engaging with online forums and social media groups dedicated to outdoor equipment can also yield valuable insights. Members often share recommendations on where to find quality components and may even have suggestions for reputable sellers.