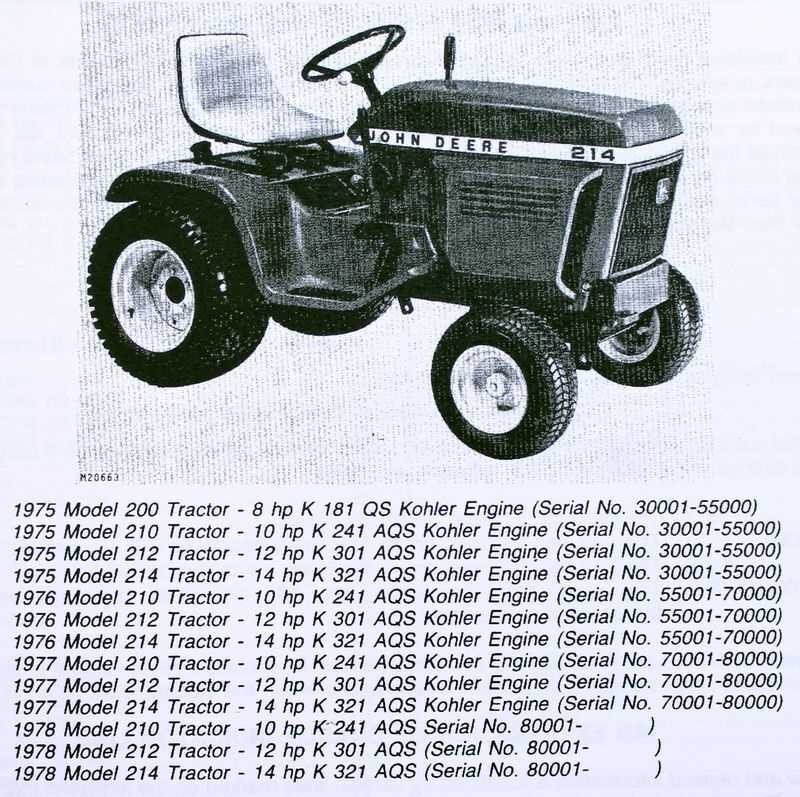

Understanding the John Deere 210 Mower Deck Parts Diagram

Understanding the intricate details of your lawn maintenance machinery is crucial for optimal performance and longevity. A well-functioning system not only enhances the overall efficiency but also ensures a beautiful landscape. Familiarizing yourself with the various elements involved in this machinery can save you time and effort in the long run.

In this section, we delve into the key components that contribute to the functionality of your grass-cutting apparatus. Each segment plays a pivotal role, and recognizing their arrangement can aid in troubleshooting and maintenance. Whether you’re a seasoned operator or a novice, grasping these essentials will empower you to make informed decisions regarding repairs and upgrades.

Equipped with the right knowledge, you can ensure that your equipment remains in peak condition. From understanding wear patterns to identifying replacement needs, this information will guide you through the intricacies of your machine’s design. Prepare to enhance your skills and elevate your lawn care experience.

Understanding John Deere 210 Mower Deck

This section explores the essential components and functionalities of a certain grass-cutting machine. Gaining insight into how these elements work together can enhance your maintenance experience and overall performance.

Key Components

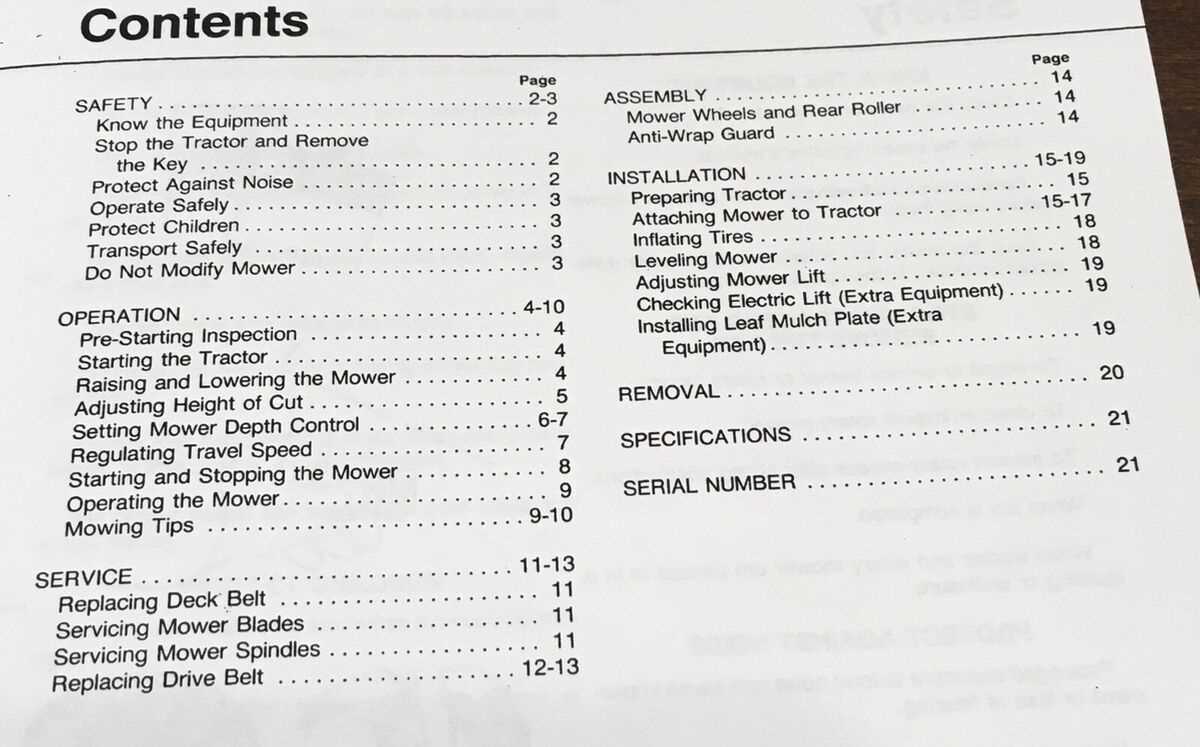

Familiarity with various elements is crucial for effective operation. These include the cutting blades, drive belts, and spindle assemblies, which collectively influence the efficiency and quality of the cutting process. Regular inspection and timely replacement of these components can prevent mechanical failures.

Maintenance Tips

Proper upkeep is vital for optimal performance. Keeping the blades sharp, ensuring belts are tensioned correctly, and regularly cleaning the area can extend the lifespan of your equipment. Adopting a routine maintenance schedule will help in preventing costly repairs.

Key Components of the Mower Deck

The efficiency of a cutting apparatus largely depends on its essential elements. Each component plays a vital role in achieving optimal performance and durability, ensuring that the equipment operates smoothly and effectively. Understanding these crucial parts can enhance maintenance practices and extend the lifespan of the machinery.

Blades and Spindles

At the heart of the cutting process are the blades, which deliver precision and uniformity. They are mounted on spindles, allowing for smooth rotation and effective grass trimming. Regular inspection and sharpening of these blades are essential for maintaining cutting performance.

Housings and Chassis

The housings provide protection and support to the inner components, ensuring stability during operation. The chassis, meanwhile, forms the structural framework, facilitating mobility and overall functionality. Together, these parts contribute significantly to the equipment’s resilience and efficiency.

Importance of Proper Maintenance

Regular upkeep of your equipment is crucial for ensuring its longevity and optimal performance. Neglecting maintenance can lead to decreased efficiency, costly repairs, and even complete failure. By adhering to a routine maintenance schedule, you can significantly enhance the reliability of your machinery.

Key reasons for maintaining your equipment include:

- Enhanced Performance: Well-maintained machines operate more efficiently, providing better results.

- Extended Lifespan: Regular care helps prevent wear and tear, allowing for a longer usable life.

- Safety: Proper checks reduce the risk of accidents caused by malfunctioning equipment.

- Cost Savings: Preventive measures can save money on repairs and replacement parts over time.

Incorporating a systematic maintenance routine not only safeguards your investment but also promotes productivity. Establishing clear guidelines for inspections, cleaning, and replacements is essential for maintaining functionality.

Consider the following maintenance practices:

- Regularly inspect components for wear and damage.

- Keep equipment clean to prevent build-up of dirt and debris.

- Lubricate moving parts as recommended to reduce friction.

- Replace any worn or damaged items promptly to avoid further issues.

By prioritizing proper maintenance, you ensure that your machinery remains in peak condition, ready to tackle any task with efficiency and reliability.

Common Issues with Mower Decks

Maintenance of cutting equipment can reveal a range of challenges that may affect performance and longevity. Understanding these frequent problems helps in proactive management and enhances efficiency during use.

1. Uneven Cutting

One prevalent issue is inconsistent trimming. This can result from several factors:

- Improper height adjustment

- Worn or damaged blades

- Inadequate tire pressure

2. Excessive Vibration

Another common concern is excessive shaking during operation. Possible causes include:

- Unbalanced blades

- Loose components

- Misalignment of the assembly

How to Identify Parts by Diagram

Understanding how to recognize components through visual representations can significantly enhance maintenance efficiency. These illustrations provide a structured view, allowing users to pinpoint each element effectively. Familiarity with the layout and labeling ensures accurate identification and replacement of essential items.

Utilizing Visual Aids

Visual aids serve as an invaluable resource in the identification process. Each segment is usually numbered or labeled, making it easier to correlate with the corresponding items in the inventory. Carefully analyzing these graphics can save time and reduce errors during repairs.

Steps for Effective Identification

To achieve the best results, start by familiarizing yourself with the entire illustration. Next, cross-reference each marked item with your physical components or replacement options. Taking notes on specific measurements or features can further streamline the identification process.

Replacing Worn-Out Components Effectively

Maintaining the efficiency of your equipment is crucial for optimal performance. Over time, certain elements may become damaged or deteriorated, impacting functionality. This section will explore how to identify and replace these components to ensure your machinery operates smoothly.

Identifying Worn Components

Recognizing when parts need replacement is key to maintenance. Look for the following signs:

- Unusual noises during operation

- Visible wear and tear on surfaces

- Decreased performance or efficiency

- Leaking fluids or other substances

Replacement Process

Once worn components are identified, follow these steps for effective replacement:

- Gather necessary tools and new components.

- Refer to your equipment manual for guidance on disassembly.

- Carefully remove the damaged parts, taking note of their arrangement.

- Install the new components, ensuring they are secured properly.

- Conduct a test run to verify that the replacements are functioning correctly.

By addressing worn components promptly and effectively, you can extend the life of your equipment and maintain its performance. Regular checks and timely replacements are key to a well-functioning system.

Tools Needed for Repairs

When tackling repairs on outdoor equipment, having the right tools is essential for efficient and effective maintenance. Proper instruments not only streamline the process but also ensure safety and precision in every task.

- Wrenches: Various sizes for loosening and tightening bolts.

- Screwdrivers: Flathead and Phillips for assembling or disassembling components.

- Pliers: For gripping and bending parts securely.

- Socket set: Ideal for reaching fasteners in tight spaces.

- Torque wrench: Ensures that bolts are tightened to manufacturer specifications.

- Grease gun: Essential for lubricating moving parts to enhance longevity.

- Utility knife: Useful for cutting and trimming various materials.

Investing in high-quality tools can significantly impact the repair process, leading to a more satisfactory outcome and extending the lifespan of the equipment.

Adjusting the Mower Deck Height

Maintaining the correct cutting height is essential for achieving a healthy and attractive lawn. Adjusting the height of the cutting equipment allows for flexibility in managing grass length based on seasonal needs and growth patterns. Proper adjustments can improve performance and extend the life of the machine.

Understanding Height Adjustment Mechanisms

Various mechanisms are utilized for adjusting cutting height. Familiarity with these can enhance your efficiency during maintenance. Common options include:

- Manual lever systems for quick adjustments

- Dial or knob controls for precise settings

- Mechanical lift systems that provide a wider range of motion

Steps to Adjust Cutting Height

Follow these steps to ensure the correct height for your cutting equipment:

- Park the machine on a level surface for accurate measurement.

- Locate the height adjustment mechanism, which is usually found near the wheels or on the chassis.

- Consult the user manual to identify the recommended height settings for your grass type.

- Use the appropriate tool or lever to adjust the height as needed.

- Test the new setting by making a few passes in the lawn.

Regularly checking and adjusting the height not only promotes healthy grass growth but also enhances the overall aesthetic of your outdoor space. Proper maintenance contributes to optimal machine performance and longevity.

Best Practices for Seasonal Storage

Properly preparing equipment for seasonal storage is essential for maintaining performance and longevity. Following a structured approach ensures that machinery remains in excellent condition, ready for use when the time comes. Here are some key steps to consider for effective storage.

Preparation Steps

- Clean Thoroughly: Remove dirt, grass, and debris to prevent corrosion and buildup.

- Inspect Components: Check for any wear and tear, addressing issues before storage.

- Drain Fluids: Empty fuel and oil to avoid degradation during the off-season.

- Protect from Pests: Use appropriate methods to deter rodents and insects.

Storage Environment

- Choose a Dry Location: Moisture can cause rust and deterioration.

- Control Temperature: Maintain a stable environment to prevent damage from extreme conditions.

- Use Covers: Invest in protective covers to shield against dust and environmental factors.

By following these practices, you can ensure that your equipment remains in optimal condition throughout its downtime, ready to perform effectively when needed again.

Ordering Genuine Replacement Parts

When it comes to maintaining your equipment, ensuring you have the right components is essential for optimal performance and longevity. Acquiring authentic replacements not only guarantees compatibility but also enhances overall efficiency.

Why Choose Genuine Components? Utilizing original replacements is critical for preserving the integrity of your machinery. These items are designed specifically for your model, ensuring a perfect fit and reliable operation.

Where to Find Authentic Parts The best sources for genuine components include authorized dealers and trusted retailers. Always verify the credibility of your supplier to avoid counterfeit products that could compromise performance.

Ordering Process Once you’ve identified the necessary components, follow the straightforward ordering process. Have your equipment model information handy to expedite the selection, and consider reaching out for assistance if you encounter any uncertainties.

Upgrades for Improved Performance

Enhancing the functionality of your cutting equipment can significantly elevate its efficiency and overall performance. Various modifications and accessories can transform your machine into a more effective tool, providing better results and a more enjoyable user experience.

First and foremost, consider upgrading the blades. High-quality or specialized blades can improve cutting precision and reduce the effort required during operation. Whether opting for mulching, side discharge, or bagging blades, the right choice can lead to a cleaner and more efficient cut.

Additionally, investing in advanced wheel and tire options can enhance traction and stability, especially in challenging terrain. This upgrade not only aids in maneuverability but also helps maintain a consistent cutting height.

Another beneficial enhancement is the installation of an aftermarket engine air filter. A superior filter can improve airflow, leading to better engine performance and fuel efficiency. This upgrade may result in a noticeable increase in power output, allowing for smoother operation.

Lastly, consider integrating a grass collection system if not already equipped. This addition can streamline cleanup and ensure a tidy finish to your mowing tasks, ultimately saving time and effort.

Finding Online Resources and Manuals

Accessing reliable online resources and manuals is essential for effective maintenance and troubleshooting of your equipment. The internet provides a wealth of information, including user guides, schematics, and community forums that can assist you in understanding your machinery better. Utilizing these resources can save time and ensure that you are using the right techniques and components.

Official Websites and Documentation

Many manufacturers host official websites that offer downloadable manuals and detailed documentation for their products. These resources typically include maintenance schedules, assembly instructions, and troubleshooting guides. Always start with the official site to ensure you receive the most accurate and updated information.

Community Forums and User Groups

Online forums and user groups are excellent places to connect with fellow enthusiasts and professionals. These platforms allow you to share experiences, seek advice, and find specific information that may not be readily available in official documentation. Engaging with a community can lead to valuable insights and practical tips that enhance your understanding and skills.