Complete Guide to John Deere 345 48C Mower Deck Parts Diagram

Maintaining your lawn care machinery is crucial for optimal performance and longevity. An intricate understanding of various elements involved in these tools enhances their functionality and ensures a smoother operation. Whether you are a professional or an enthusiast, familiarity with each segment is essential for effective upkeep.

Identifying individual components is key to troubleshooting and repairs. By examining how these pieces fit together, users can grasp the mechanics behind their operation. This knowledge enables seamless maintenance and helps avoid potential issues down the line.

In this section, we will delve into the essential components that make up a specific model of lawn care machinery. Grasping the layout and connections between parts not only aids in repairs but also enhances the ultimate performance of your equipment. Prepare to explore a comprehensive breakdown that will elevate your understanding and enhance your lawn care experience.

Understanding the John Deere 345 Mower

This section explores the intricate design and functionality of a specific model of outdoor machinery, focusing on its essential components and overall performance. Recognizing the various elements that contribute to its efficiency is crucial for optimal maintenance and operation.

The model is celebrated for its durability and reliability, making it a popular choice among enthusiasts and professionals alike. Comprehending the mechanics behind this equipment allows users to maximize its potential and ensure longevity.

To truly appreciate the engineering involved, one must delve into the assembly and function of each element. Understanding these features provides the ultimate insight into effective usage and troubleshooting strategies.

Key Features of the 48C Deck

The 48C attachment is designed to enhance the efficiency and performance of turf maintenance. This versatile tool incorporates several innovative characteristics that cater to both professional landscapers and homeowners. Its construction and features ensure a smooth cutting experience, making lawn care more manageable and effective.

Durability and Design

Constructed from high-quality materials, this implement is built to withstand the rigors of regular use. Its robust design contributes to longevity and reliability, minimizing the need for frequent repairs. The thoughtful engineering also promotes optimal air circulation, leading to a uniform cut every time.

Ease of Maintenance

Routine upkeep is straightforward, allowing users to focus on achieving a well-groomed lawn rather than spending time on maintenance. Key components are easily accessible, simplifying tasks such as blade replacement and cleaning. This user-friendly aspect ensures that operators can maintain peak performance with minimal effort.

| Feature | Description |

|---|---|

| Material | High-quality steel for enhanced durability |

| Cutting Width | Optimized for efficient lawn coverage |

| Blade Design | Specially engineered for precision cutting |

| Adjustment | Simple height adjustment for customized results |

| Compatibility | Designed to fit a variety of models |

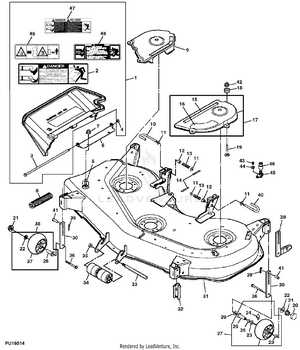

Parts Breakdown for Mower Deck

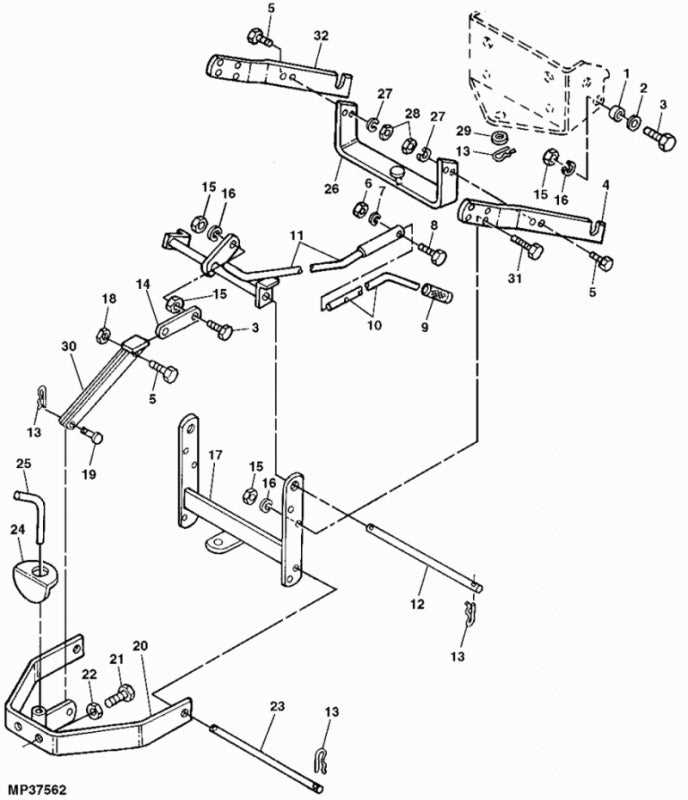

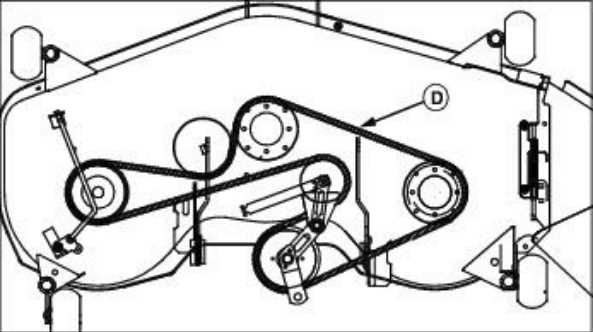

Understanding the components of a cutting apparatus is essential for efficient maintenance and operation. This section will provide an overview of the various elements that contribute to the functionality of the system, highlighting their roles and importance.

Each section of the assembly is designed to work in harmony, ensuring optimal performance. From the blades to the housing, each part plays a critical role in achieving a clean cut and effective operation.

Regular inspection and familiarity with these components can greatly enhance longevity and performance. Knowing what each element does will aid in troubleshooting and repairs, ensuring a seamless experience when using the equipment.

Common Maintenance Practices for Longevity

Ensuring the durability of equipment involves a series of essential upkeep tasks that enhance performance and extend its lifespan. Regular attention to various components can prevent premature wear and tear, ultimately saving time and resources.

Routine cleaning is vital to remove debris and contaminants that can cause corrosion and reduce efficiency. Additionally, inspecting and replacing worn parts promptly can prevent further damage and ensure smooth operation. Proper lubrication of moving elements minimizes friction, while checking fluid levels contributes to optimal functionality.

Storing machinery in a dry, sheltered environment protects it from harsh weather conditions that may lead to deterioration. Lastly, following the manufacturer’s guidelines for seasonal maintenance helps keep equipment in peak condition and ready for use whenever needed.

How to Replace Mower Blades

Maintaining sharp cutting implements is essential for achieving a clean and even finish on your lawn. Over time, these tools can become dull or damaged, affecting their performance. This guide will walk you through the straightforward process of replacing these essential components, ensuring your equipment remains in top condition for optimal results.

Tools and Materials Needed

Before starting the replacement process, gather the necessary tools and materials. You will need a socket wrench or a ratchet, safety gloves, a replacement blade, and a protective eyewear. Having these items on hand will streamline the procedure and enhance safety.

Step-by-Step Replacement Process

Begin by disconnecting the power source to ensure safety. Next, tilt the machine on its side or use a lift for easier access. Locate the fastening bolts that secure the cutting implements in place and remove them carefully. Once the old blade is detached, position the new one correctly and secure it with the bolts. Ensure everything is tightened properly before returning the unit to its upright position. Finally, reconnect the power and test the equipment to confirm that it operates smoothly.

Troubleshooting Common Mower Issues

Maintaining the functionality of your equipment is essential for achieving optimal performance. Various challenges may arise, leading to inefficiencies or operational failures. Identifying these common problems and their solutions can help ensure your machine runs smoothly.

Common Symptoms and Solutions

- Uneven Cutting: Check blade sharpness and height adjustment.

- Engine Won’t Start: Inspect the fuel supply and battery condition.

- Excessive Vibration: Look for loose components or damaged blades.

- Overheating: Ensure proper airflow and clean any debris from the cooling system.

Preventive Measures

- Regularly sharpen and replace blades.

- Change the oil and replace filters as needed.

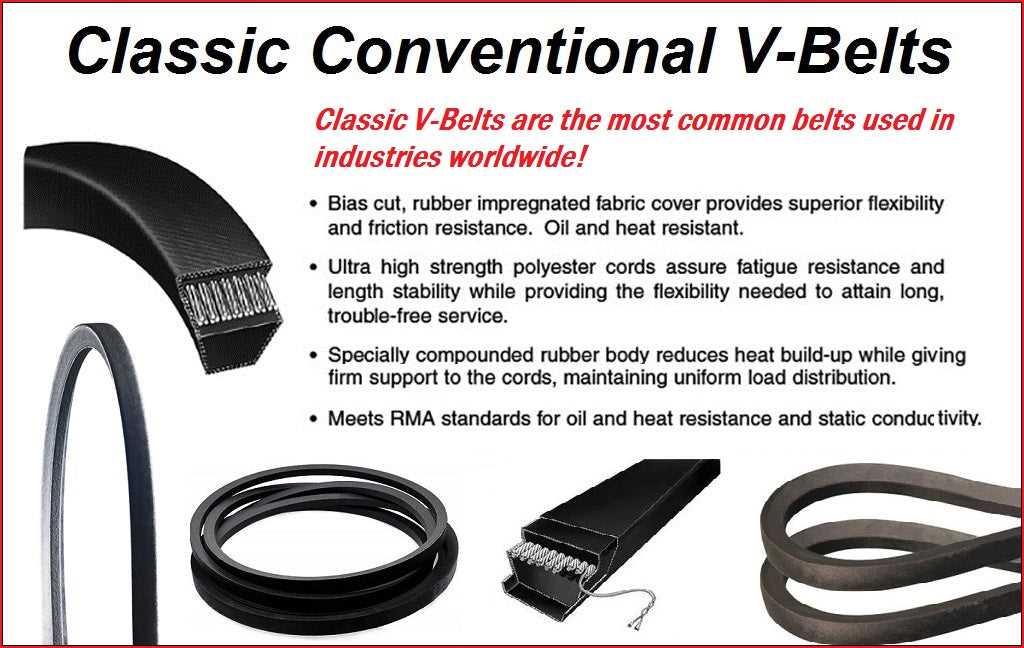

- Inspect belts for wear and replace them if frayed.

- Store the machine in a dry place to prevent rust.

Tools Needed for Deck Repairs

When it comes to maintaining and fixing your cutting apparatus, having the right tools at your disposal is essential for ensuring a smooth and efficient process. Proper equipment not only simplifies the task but also helps in achieving a professional finish. Below is a list of tools that are crucial for effective repairs and maintenance.

Essential Hand Tools

- Socket Wrench Set

- Adjustable Wrench

- Phillips and Flathead Screwdrivers

- Pliers (needle-nose and regular)

- Hammer

Specialized Equipment

- Torque Wrench

- Scraper or Putty Knife

- Wire Brush

- Safety Goggles

- Gloves

Having these tools readily available will make your maintenance tasks much easier and more efficient, ensuring your equipment remains in optimal condition for years to come.

Buying Genuine John Deere Parts

When it comes to maintaining outdoor machinery, opting for authentic components is crucial for optimal performance and longevity. These original items are designed to meet specific standards, ensuring compatibility and reliability. By choosing genuine products, users can significantly reduce the risk of malfunctions and enhance the overall functionality of their equipment.

Here are some key reasons to consider purchasing original components:

- Quality Assurance: Authentic items undergo rigorous testing to meet high standards, ensuring durability and efficiency.

- Perfect Fit: Designed specifically for your equipment, these components ensure seamless integration and operation.

- Long-Term Savings: Investing in quality reduces the need for frequent replacements and repairs, saving money over time.

- Manufacturer Support: Genuine components come with manufacturer warranties, providing peace of mind and assurance of service.

In addition to these benefits, using original items helps maintain the resale value of your machinery. Buyers are often more interested in well-maintained equipment that uses high-quality components, making it easier to sell when the time comes.

To ensure you are purchasing authentic items, consider the following tips:

- Purchase from authorized dealers or trusted retailers.

- Verify packaging and labels for authenticity markers.

- Consult the manufacturer’s website for recommended suppliers.

By prioritizing genuine components, you not only enhance the performance of your machinery but also invest in its future reliability and efficiency.

Benefits of Regular Mower Maintenance

Consistent upkeep of your landscaping equipment is essential for optimal performance and longevity. Regular checks and servicing ensure that machinery runs efficiently, preventing minor issues from escalating into costly repairs.

Enhanced Performance

Regular maintenance leads to improved functionality. Clean air filters, sharpened blades, and well-lubricated parts contribute to a smoother operation, allowing for more effective grass cutting.

Increased Longevity

By performing routine checks, you can significantly extend the life of your equipment. Timely interventions reduce wear and tear, ensuring that your investment serves you well for years to come.

Assembly Instructions for the Deck

This section provides essential guidance for assembling the cutting apparatus efficiently and effectively. Proper assembly ensures optimal performance and longevity of the equipment. Follow these instructions closely to achieve a seamless setup.

Required Tools

Before starting, gather the following tools to facilitate the assembly process:

| Tool | Description |

|---|---|

| Wrench Set | To tighten and secure bolts and nuts. |

| Screwdriver | For assembling smaller components. |

| Socket Set | To ensure a proper fit on various fasteners. |

| Torque Wrench | To apply the correct tension to bolts. |

Assembly Steps

Follow these steps to assemble the cutting unit:

- Begin by laying out all components to ensure nothing is missing.

- Attach the main frame to the support brackets using the appropriate fasteners.

- Securely fasten the pulleys and ensure they are aligned properly.

- Connect the cutting blades, ensuring each is positioned correctly for balanced operation.

- Finally, check all connections for tightness and stability before testing the assembly.