Understanding John Deere 425 Mower Deck Parts Diagram

When maintaining your cutting equipment, understanding its essential elements can greatly enhance its longevity and performance. Whether you’re fine-tuning or troubleshooting, having

Key Components of the Mower Deck

The effective performance of a cutting system relies heavily on the arrangement and function of its essential elements. Understanding these components can help ensure proper maintenance and longevity, contributing to a smoother operation in any landscaping task.

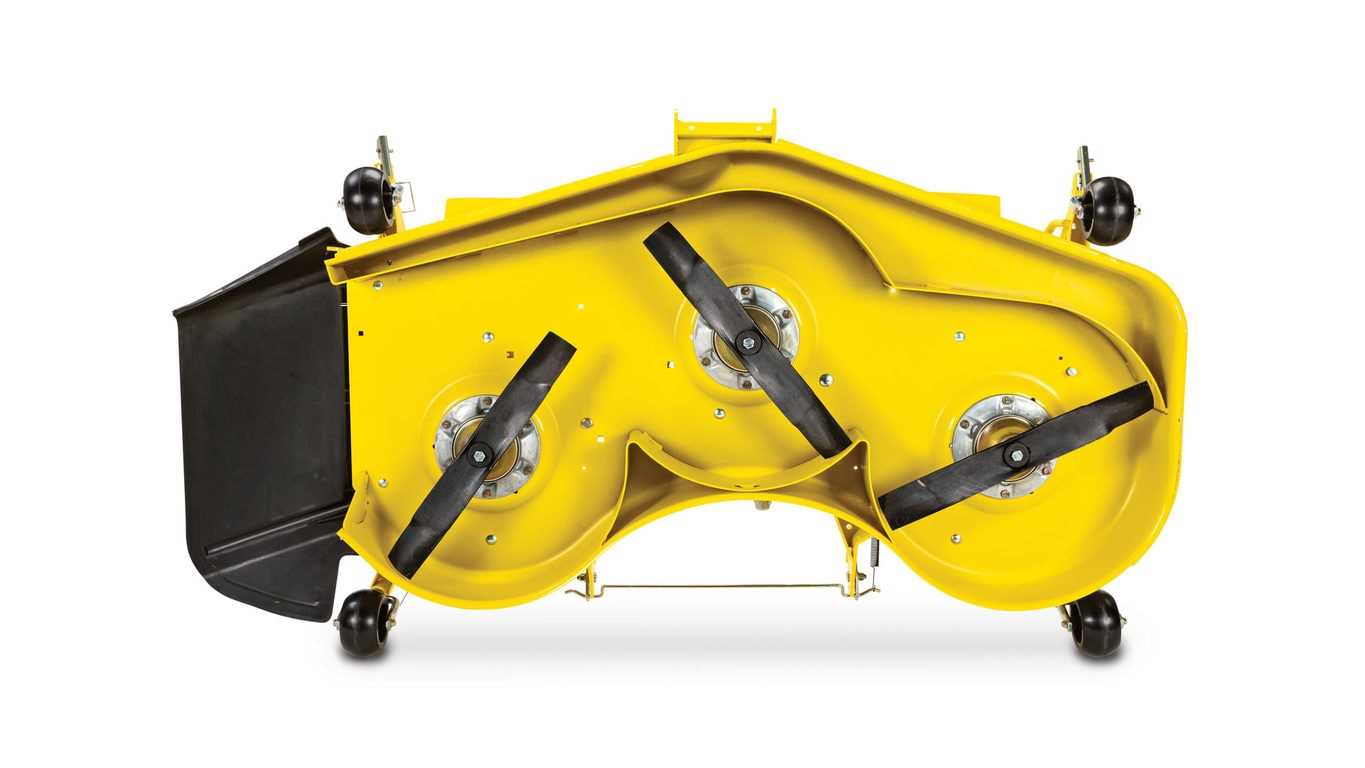

Cutting Blades

One of the most vital parts, the blades are responsible for the precise trimming of grass. They come in various designs depending on the terrain and the desired cutting style. Keeping them sharp ensures cleaner cuts and less strain on the engine.

- High-lift blades: Ideal for creating a clean, even cut by producing a strong airflow.

- Understanding the Blade Mechanism

The cutting component is crucial for ensuring efficient grass trimming, and understanding how it operates can help in maintaining optimal performance. This system is designed to deliver clean cuts while minimizing wear and tear.

Key Components of the Blade System

- Cutting Edge: The sharp side responsible for slicing through vegetation efficiently.

- Spindle Assembly: Supports and rotates the blades, enabling smooth and consistent movement.

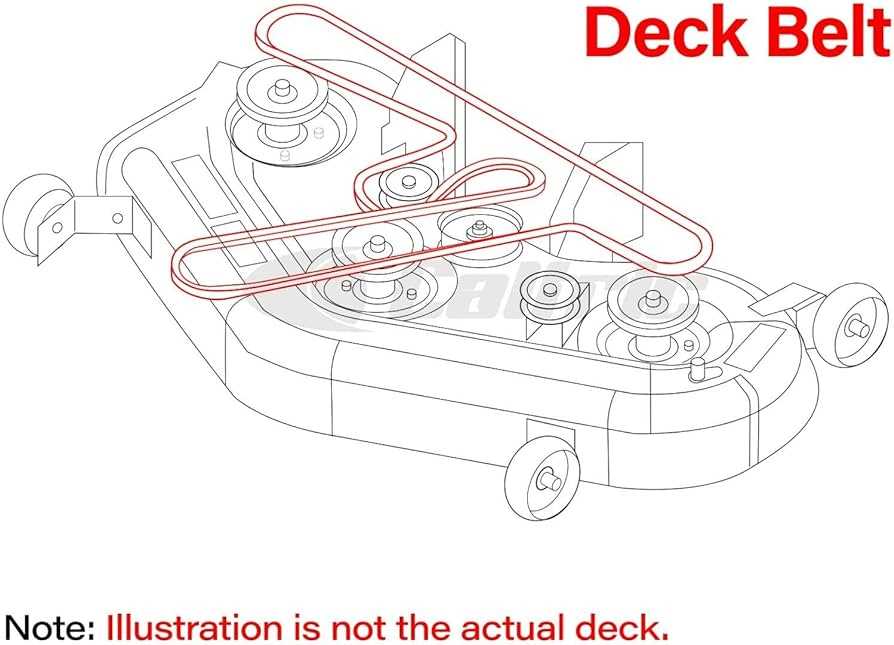

- Belt System: Transfers power from the motor to the blades, ensuring they move at the correct speed.

How the Mechanism Works

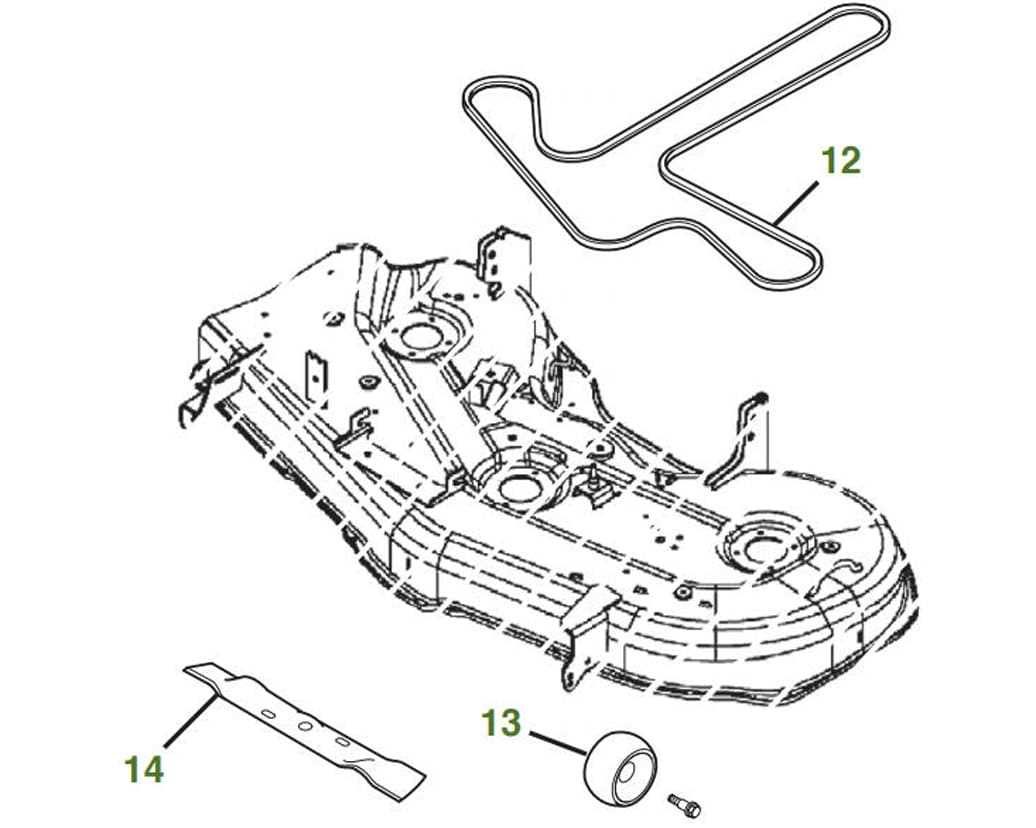

How the Belt System Works

The belt system is essential for the efficient transfer of power within mechanical setups. It plays a crucial role in synchronizing the rotation of various components, allowing the machine to function smoothly. The alignment and tension of the belt are key to ensuring that energy is properly distributed to all necessary parts.

Power Transmission and Tensioning

The belt functions by connecting pulleys, transferring rotational force from the engine to other components. Proper tension is required to prevent slippage, which can lead to reduced efficiency or even damage to the machinery. Regular maintenance, such as checking for wear or adjusting the tension, ensures long-lasting performance.

Alignment and Maintenance

Ensuring that

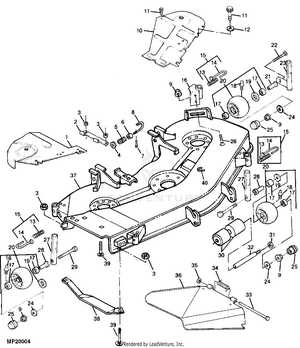

Identifying the Spindle Assembly

The spindle assembly is an essential component that supports the rotation and stability of the cutting blades. It ensures smooth operation by connecting various mechanical parts, allowing the blades to rotate effectively and cut grass efficiently. The proper functioning of this assembly directly influences the overall performance

Role of Pulleys in Deck Function

Pulleys play a crucial part in ensuring the proper performance of cutting systems. By transferring power efficiently between components, they enable smooth blade movement and optimal tension management. The placement and design of these mechanical wheels significantly impact the overall operation of the system, maintaining a consistent and balanced performance.

Maintenance Tips for Gearbox Operation

Proper upkeep of the gearbox is essential for ensuring optimal performance and longevity of equipment. Regular maintenance not only enhances efficiency but also minimizes the risk of costly repairs. Implementing a consistent maintenance routine will lead to smoother operation and a more reliable machine.

Regular Inspections

Conduct frequent examinations of the gearbox to identify any signs of wear or damage. Look for oil leaks, unusual noises, and any irregular movements during operation. Early detection of potential issues can prevent more severe complications down the line.

Lubrication Practices

Ensure that the gearbox is adequately lubricated at all times. Use high-quality lubricant recommended by the manufacturer and adhere to the specified intervals for reapplication. Proper lubrication reduces friction, prolongs component life, and contributes to smoother operation.

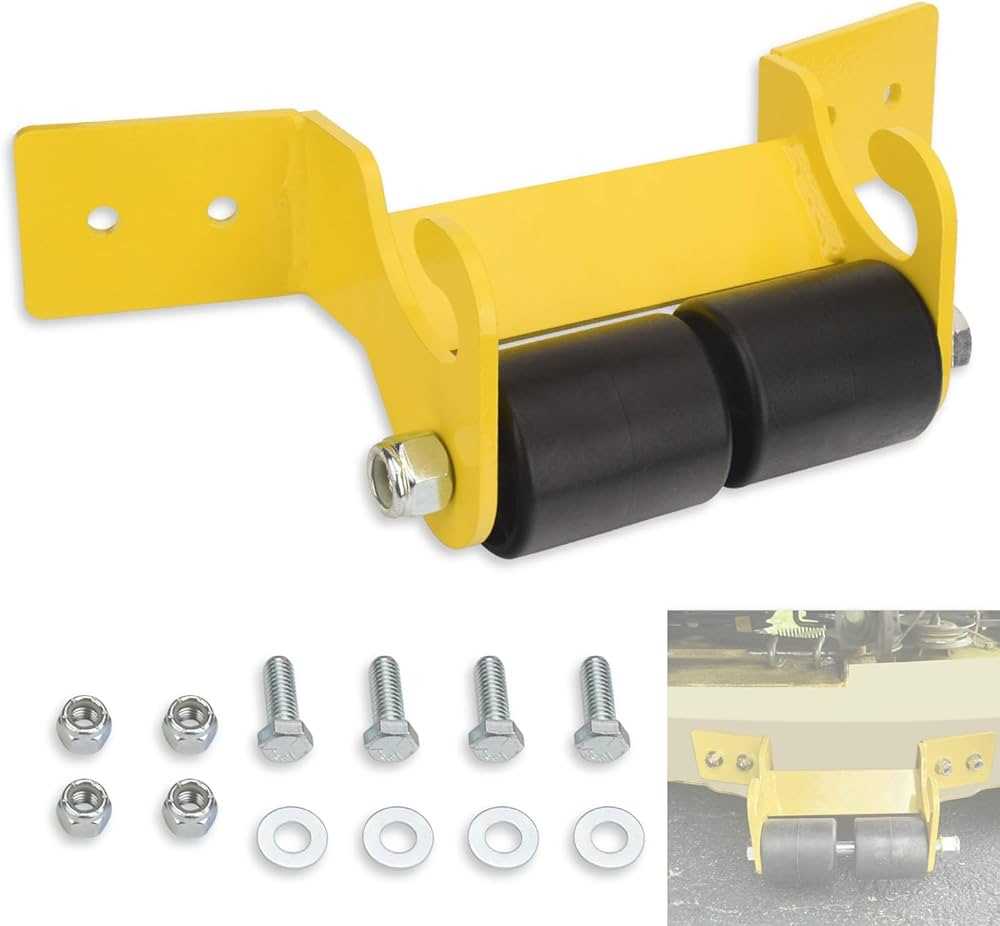

Proper Care for Mower Wheels

Maintaining the functionality of the wheels is essential for optimal performance and longevity of your cutting equipment. Regular attention to these components not only enhances efficiency but also ensures a smooth operation, reducing wear and tear over time. Implementing a consistent maintenance routine will contribute to reliable functionality and safety during use.

Regular Inspections

Frequent checks are crucial to identify any signs of damage or wear. Inspect the rubber for cracks, bulges, or uneven wear patterns. Ensure that the attachment points are secure and that no bolts are loose. Addressing minor issues promptly can prevent costly repairs in the future.

Cleaning and Lubrication

Keeping the wheels clean is vital for their performance. Remove any debris or grass clippings that may accumulate, as these can cause corrosion and hinder functionality. Additionally, applying appropriate lubricants to bearings and pivot points will ensure smooth rotation and reduce friction, promoting longer-lasting components.

Inspecting the Tensioner and Its Parts

Regular examination of the tensioning mechanism is crucial for ensuring optimal performance and longevity of your equipment. This component plays a vital role in maintaining proper belt tightness, which directly affects cutting efficiency. Understanding how to assess this assembly can help identify wear and prevent potential failures.

Components of the Tensioning Mechanism

The tensioning assembly consists of several key elements, each contributing to its functionality. These include:

- Tensioner Arm: This lever applies pressure to the belt, ensuring it remains taut during operation.

- Spring: A vital component that provides the necessary force to the arm, keeping the belt at the correct tension.

- Pulley: This circular part allows smooth movement of the belt, reducing friction and wear.

Steps for Effective Inspection

To ensure the tensioner is functioning properly, follow these steps:

- Visual Check: Inspect for signs of wear or damage on the tensioning arm, spring, and pulley.

- Spring Assessment: Ensure the spring is intact and not losing tension; a weak spring can lead to belt slippage.

- Belt Alignment: Verify that the belt runs smoothly along the pulley without any obstructions.

By performing these inspections regularly, you can maintain the efficiency of your equipment and avoid costly repairs.

Guide to Deck Leveling Procedures

Achieving the optimal height for cutting equipment is essential for effective grass management. Proper alignment ensures a consistent cut and enhances the longevity of the apparatus. This section outlines fundamental steps to effectively adjust the elevation of your cutting unit, allowing for improved performance and a well-manicured lawn.

Understanding the Importance of Leveling

Correctly positioning the cutting unit is crucial for uniformity in grass length and prevents scalping. An uneven setup can lead to patchy growth, requiring additional maintenance and reducing overall efficiency. Thus, regular checks and adjustments are recommended to maintain peak operational standards.

Step-by-Step Leveling Process

Follow these instructions to level your cutting equipment:

- Gather Necessary Tools: Ensure you have a measuring tool, appropriate wrenches, and a flat surface for accurate adjustments.

- Inspect Current Level: Place the unit on a level surface and measure the height from the ground to the cutting edge at various points to identify discrepancies.

- Adjust Height: Utilize the adjustment mechanisms to raise or lower specific corners of the cutting unit until all measured points are at the desired elevation.

- Recheck Levels: After adjustments, measure again to confirm uniformity and make further adjustments if necessary.

- Final Inspection: Conduct a test cut in your intended area to verify performance and make any minor tweaks as needed.

By following these procedures, you can ensure that your cutting unit operates at its best, promoting a healthy and attractive lawn.

Replacing Worn-Out Parts Efficiently

Maintaining optimal performance of your equipment requires timely replacement of worn components. Identifying and addressing these issues not only enhances functionality but also prolongs the life of your machine. This section outlines effective strategies for ensuring smooth replacements.

To successfully replace worn elements, follow these key steps:

- Assessment: Regularly inspect your equipment for signs of wear, such as unusual noises or reduced efficiency.

- Documentation: Keep a detailed record of all components that need replacement, including their specifications and part numbers.

- Quality Selection: Choose high-quality replacements that match or exceed original specifications to ensure reliability.

- Systematic Replacement: Replace components systematically, focusing on one area at a time to prevent confusion.

- Proper Tools: Utilize the correct tools for each replacement task to avoid damage and ensure efficiency.

By adhering to these guidelines, you can effectively manage replacements and maintain the peak performance of your machinery.

Enhancing Mower Performance Through Adjustments

Proper modifications can significantly enhance the efficiency and longevity of cutting equipment. By focusing on key areas of adjustment, users can optimize performance, ensuring that their machinery operates at its best. Regular evaluation and fine-tuning of various components lead to improved results and a more satisfying experience during operation.

Blade Height and Angle Adjustments

One of the most crucial aspects of maintaining optimal functionality is the proper setting of the blade height and angle. Adjusting these parameters can result in a cleaner cut and healthier turf. It’s essential to consult the manufacturer’s guidelines to find the recommended settings based on the specific type of grass and terrain.

Engine and Drive System Tuning

Fine-tuning the engine and drive system can greatly impact overall performance. Regular maintenance of filters, spark plugs, and belts ensures that power is efficiently transmitted. Additionally, checking the fuel system for any blockages or leaks will enhance responsiveness and reduce operational issues. Adopting these practices contributes to a reliable and effective machine.