Understanding the John Deere 455 60 Inch Mower Deck Parts Diagram

Exploring the intricacies of lawn care machinery can significantly enhance your maintenance routine. Familiarizing yourself with the various elements that contribute to optimal performance not only ensures longevity but also improves efficiency. Whether you are a seasoned landscaper or a homeowner, a solid grasp of these components is essential.

In this guide, we delve into the specifics of a popular model’s assembly. We will provide an insightful overview of its configuration, allowing users to identify and understand the essential features and functions. This knowledge empowers users to make informed decisions regarding repairs and upgrades.

By the end of this exploration, you will have a comprehensive understanding of how each section contributes to the overall functionality of the equipment. From essential maintenance tasks to potential modifications, being well-informed can elevate your experience and productivity.

Understanding John Deere 455 Mower

This section explores the intricacies of a specific model known for its efficiency and versatility in landscaping tasks. Equipped with advanced features, this machine offers reliability and ease of use, making it a preferred choice among enthusiasts and professionals alike.

Key Features

This model boasts a powerful engine, designed to handle various terrains effortlessly. Its cutting system ensures a precise finish, while the ergonomic design enhances user comfort during extended operations.

Maintenance and Care

Overview of the 60 Inch Deck

The 60-inch cutting platform is designed for efficiency and effectiveness in landscaping tasks. It enables users to achieve a clean and precise cut, enhancing the overall appearance of lawns and gardens.

Key Features

- Robust construction for durability.

- Wide cutting width for faster mowing.

- Adjustable height settings for various grass types.

- Optimized blade design for superior performance.

Benefits

- Improved productivity due to reduced mowing time.

- Enhanced grass health with clean cuts.

- Versatility in handling different terrains.

- Ease of maintenance and repairs.

Key Components of the Mower Deck

The efficient functioning of any cutting apparatus relies on several critical elements that work in harmony. Understanding these components can enhance performance, ensure longevity, and facilitate maintenance. Here are the essential parts that contribute to the overall operation of the cutting system.

- Blades: Sharp edges designed to slice through grass and vegetation, they are vital for achieving a clean cut.

- Spindles: These rotating shafts hold the blades and enable their movement, ensuring effective cutting action.

- Belt: A vital link that transmits power from the engine to the spindles, allowing for blade rotation.

- Chassis: The framework supports all components, providing stability and strength during operation.

- Rollers: Positioned at the rear or sides, they help maintain even contact with the ground, ensuring consistent cutting height.

- Guards: Protective covers that shield users from rotating blades and debris, enhancing safety during use.

Regular inspection and maintenance of these components are essential for optimal performance and to prevent potential issues. Understanding their function will aid users in making informed decisions regarding care and replacement.

Importance of Regular Maintenance

Consistent upkeep is essential for ensuring optimal performance and longevity of equipment. By adhering to a routine maintenance schedule, operators can prevent potential issues that may lead to costly repairs and downtime. This proactive approach not only enhances efficiency but also promotes safety during operation.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 50 hours | Improves engine performance |

| Filter Replacement | Every 100 hours | Ensures clean air and fuel flow |

| Blade Sharpening | Every season | Enhances cutting efficiency |

| Inspect Belts and Cables | Monthly | Prevents unexpected failures |

Common Issues and Troubleshooting

When operating outdoor equipment, various challenges can arise, impacting performance and efficiency. Understanding these common complications is essential for maintaining optimal functionality and prolonging the lifespan of your machinery.

Frequent Problems

One of the most typical issues includes irregular cutting performance, often caused by dull blades or uneven adjustments. Another common concern is engine difficulty starting, which may stem from fuel delivery issues or electrical faults. Recognizing these symptoms early can prevent further damage.

Troubleshooting Steps

To address cutting issues, first inspect the blades for wear and ensure they are properly aligned. For starting problems, check fuel levels, filters, and battery connections. Regular maintenance can significantly reduce these problems, ensuring that your equipment runs smoothly and efficiently.

Replacement Parts for Optimal Performance

Maintaining the efficiency and effectiveness of your outdoor equipment requires attention to specific components that ensure smooth operation. When these elements wear out or malfunction, replacing them with high-quality alternatives can significantly enhance performance. This section explores essential components necessary for keeping your machinery running at its best.

Understanding Component Quality

Investing in superior replacements is crucial for longevity and reliability. Genuine or high-grade aftermarket options often provide better durability and performance compared to generic alternatives. Ensuring that each replacement meets or exceeds the original specifications can lead to enhanced functionality and reduced downtime.

Key Components to Consider

Focus on vital components such as blades, belts, and bearings. Blades should be sharp and well-balanced for effective cutting. Belts must fit snugly and show no signs of wear to ensure power transmission without slippage. Additionally, bearings need to be lubricated and free of debris to maintain smooth movement and prevent overheating.

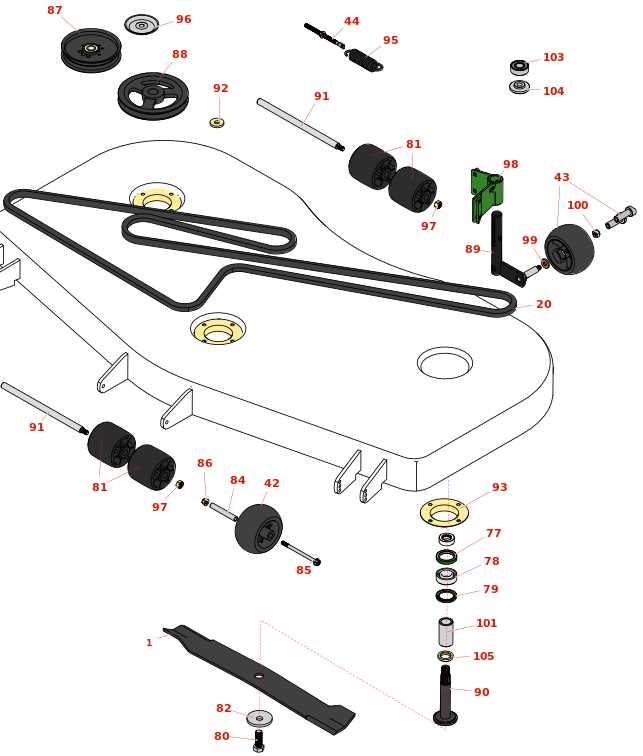

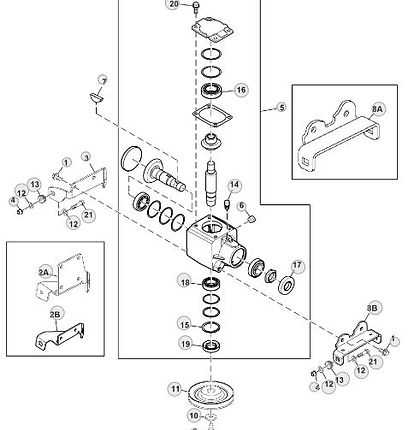

Identifying Parts Using Diagrams

Visual representations are essential tools for understanding the components of complex machinery. By utilizing detailed illustrations, users can easily locate and recognize individual elements, facilitating effective maintenance and repairs. This approach not only enhances familiarity with equipment but also streamlines troubleshooting processes.

Benefits of Using Visual Aids

Employing illustrations allows for quicker identification of specific components. Users can refer to a comprehensive guide that clearly outlines each part’s position and function. This method reduces the likelihood of errors during assembly or disassembly, ensuring that maintenance tasks are carried out with precision.

How to Interpret Illustrations

When examining a visual aid, it’s crucial to focus on the labels and numbering associated with each element. Understanding the layout will enable users to match components with their corresponding names, which is particularly helpful when ordering replacements. Taking time to study these visuals can significantly improve overall equipment knowledge and confidence in handling repairs.

Tools Needed for Repairs

When it comes to maintaining and fixing lawn equipment, having the right instruments is essential for efficiency and safety. Proper tools not only streamline the process but also ensure that the work is done correctly, preventing future issues.

Here is a list of essential tools to consider for your repair tasks:

- Wrenches: A variety of sizes will help you tighten or loosen bolts and nuts.

- Screwdrivers: Both flathead and Phillips types are necessary for various screws.

- Socket set: Ideal for reaching tight spaces and providing better leverage.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Torque wrench: Ensures that bolts are tightened to the correct specifications.

Additionally, you may find the following items helpful:

- Safety glasses: Protect your eyes from debris.

- Gloves: Provide grip and protect your hands during repairs.

- Cleaning supplies: Keep your tools and workspace tidy to prevent accidents.

- Flashlight: A bright light can help you see in dark or cramped areas.

Equipping yourself with these tools will greatly enhance your ability to carry out repairs effectively and safely.

Where to Buy Genuine Parts

Acquiring authentic components for your machinery is essential for ensuring optimal performance and longevity. The right source not only guarantees quality but also offers support and expertise in selecting the appropriate items for your needs.

Authorized Dealers

Visiting authorized retailers is often the most reliable way to obtain genuine components. These dealers maintain a comprehensive inventory and are knowledgeable about compatibility, helping you make informed choices.

Online Marketplaces

Reputable online platforms also provide access to authentic components, often at competitive prices. Look for sellers with positive reviews and strong return policies to ensure a satisfying purchasing experience. Always verify that the parts are genuine by checking product descriptions and certifications.

Comparing Aftermarket vs. OEM Parts

When it comes to equipment maintenance, choosing between original components and alternative options can significantly impact performance and longevity. Each choice carries its own set of benefits and drawbacks, influencing both cost and reliability. Understanding these differences is crucial for making an informed decision.

Benefits of OEM Components

Original components are designed specifically for certain machinery, ensuring a precise fit and adherence to quality standards set by the manufacturer. These elements often come with warranties that provide additional peace of mind, reinforcing their long-term value.

Advantages of Aftermarket Options

Alternative options frequently offer a more budget-friendly solution. They can be easier to find and provide a wider variety of choices. However, quality can vary significantly among different brands, making research essential to ensure compatibility and durability.

| Factor | OEM Components | Aftermarket Options |

|---|---|---|

| Quality | High, meets manufacturer standards | Varies by brand, requires research |

| Cost | Typically higher | Generally lower |

| Warranty | Often includes warranty | May or may not include warranty |

| Availability | Specific to manufacturer | Widely available from various suppliers |

Assembly Instructions for New Parts

When it comes to installing new components on your equipment, following a clear set of guidelines ensures a smooth and effective process. Proper assembly not only enhances performance but also extends the lifespan of your machinery. This section provides a comprehensive overview of the steps needed to correctly fit new elements into your unit.

Begin by gathering all necessary tools and components. Ensure that you have a clean and organized workspace to prevent any parts from getting lost. Before starting, review the installation manual specific to your model for detailed instructions and safety precautions.

Start the assembly by securely attaching the primary component to the frame, ensuring all connection points align perfectly. Use the recommended fasteners and tighten them to the specified torque settings to avoid any future issues. If applicable, install any secondary components in the correct order, referring to the diagram as a guide.

Once all pieces are in place, perform a thorough inspection to confirm that everything is secured and aligned. It’s crucial to test the functionality before putting the equipment back into operation. By following these steps, you will achieve optimal performance and reliability from your newly assembled components.

Tips for Extending Deck Lifespan

Maintaining the longevity of your cutting equipment is essential for optimal performance and efficiency. Implementing proper care routines and regular inspections can significantly enhance the durability of your machinery. By following a few key strategies, you can ensure that your gear remains in top condition for years to come.

First, always keep the underside free from grass clippings and debris. After each use, make it a habit to clean the surface thoroughly. This not only prevents corrosion but also promotes better airflow, improving cutting efficiency.

Second, check for wear and tear regularly. Inspect the blades and other components for any signs of damage or dullness. Timely sharpening or replacement of blades can lead to a cleaner cut and reduce strain on the engine.

Additionally, lubricating moving parts is crucial. Proper lubrication minimizes friction, helping to prevent overheating and extending the life of mechanical components. Make sure to use the recommended types of oils and greases for your equipment.

Lastly, store the equipment in a sheltered environment when not in use. Exposure to the elements can lead to rust and degradation. A dry, covered space will provide protection and maintain the integrity of the machine.

User Experiences and Testimonials

This section gathers valuable insights from users who have interacted with the equipment. Their experiences highlight both the strengths and challenges encountered during usage, offering a comprehensive perspective for potential buyers.

Positive Feedback

- Many users praise the reliability and efficiency, noting significant improvements in their lawn care routines.

- Customers appreciate the ease of operation, which reduces the time needed for maintenance tasks.

- The robust construction is frequently mentioned as a key factor in longevity and durability.

Challenges Encountered

- Some users report difficulty in sourcing specific components, leading to extended downtimes.

- A few have faced learning curves associated with the initial setup and adjustments.

- Maintenance requirements can be more demanding than anticipated, particularly for novices.