Comprehensive Guide to John Deere 54 HC Mower Deck Parts Diagram

When it comes to maintaining a pristine landscape, the functionality of your equipment is crucial. A comprehensive understanding of the various elements that make up your lawn care machinery can greatly enhance its performance and longevity. By familiarizing yourself with each component, you can ensure that your device operates smoothly and efficiently.

In this section, we will delve into the intricate layout and design of essential elements related to a specific model of lawn care apparatus. Recognizing how each segment interacts with others is vital for troubleshooting and performing necessary maintenance. Moreover, an in-depth look at these components will empower users to make informed decisions regarding repairs or replacements.

Whether you are a seasoned professional or a novice, having access to a clear representation of these elements will simplify the process of upkeep. We aim to provide valuable insights that will aid you in optimizing the functionality of your machinery, ensuring that your outdoor space remains well-kept throughout the seasons.

Understanding John Deere 54 HC Mower Deck

This section explores the intricate components and functionality of a specific cutting apparatus designed for grass maintenance. It provides insight into the essential elements that contribute to efficient performance and optimal results. Understanding these features can enhance the user experience and maintenance of the equipment.

Key Components and Their Functions

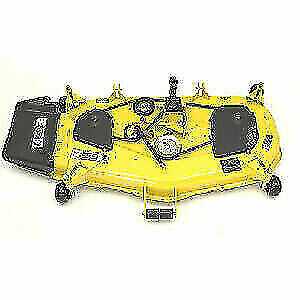

Every cutting apparatus consists of various segments that work in unison. The primary feature involves rotating blades that ensure a clean and precise cut. Additionally, the housing structure supports these blades, providing durability and stability during operation. Recognizing how each part contributes to the overall efficiency can aid in better management and care.

Maintenance Tips for Longevity

To prolong the lifespan of the equipment, regular upkeep is crucial. This includes inspecting the blades for sharpness and wear, checking the housing for any signs of damage, and ensuring all fasteners are secure. Routine cleaning after use helps prevent grass build-up and corrosion, ensuring optimal functionality. Adhering to maintenance schedules can significantly enhance performance and reliability.

Key Components of Mower Deck

The efficiency and performance of a cutting system rely heavily on its essential elements. Understanding these components is crucial for maintenance and optimal operation. Each part plays a specific role, contributing to the overall functionality and effectiveness of the machine.

| Component | Function |

|---|---|

| Blades | Responsible for cutting grass to the desired height. |

| Spindles | Support the blades and allow them to rotate smoothly. |

| Shell | Protects internal components while providing structural integrity. |

| Belt | Transfers power from the engine to the rotating blades. |

| Anti-scalp Wheels | Prevent the cutting unit from digging into the ground on uneven terrain. |

| Adjustable Hangers | Allow for height adjustments of the cutting assembly for different grass lengths. |

Importance of Proper Maintenance

Maintaining equipment in optimal condition is crucial for ensuring longevity and efficient performance. Regular upkeep not only enhances the reliability of machinery but also minimizes the risk of unexpected failures. By adhering to a structured maintenance routine, users can significantly reduce the chances of costly repairs and downtime.

Regular inspections play a vital role in identifying potential issues before they escalate. Detecting wear and tear early allows for timely interventions, which can extend the lifespan of the equipment. Moreover, cleaning and lubricating components regularly helps prevent rust and corrosion, preserving functionality and performance.

Additionally, keeping machinery well-maintained contributes to safety. Properly functioning equipment reduces the likelihood of accidents, protecting both the operator and the environment. Ultimately, investing time and resources in maintenance yields substantial benefits, fostering a reliable and efficient operational workflow.

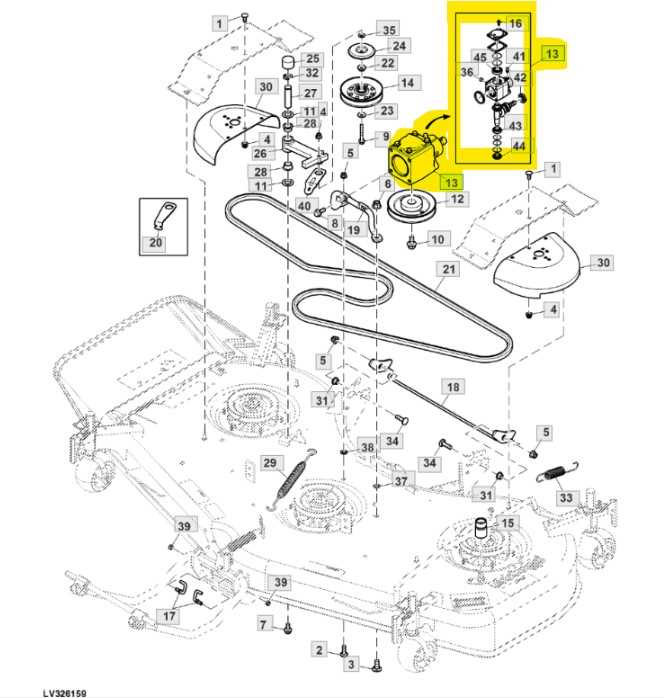

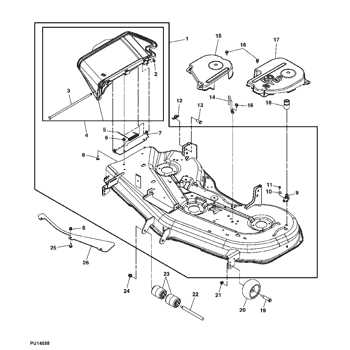

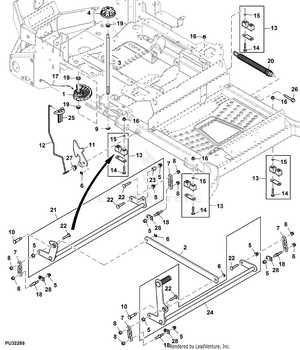

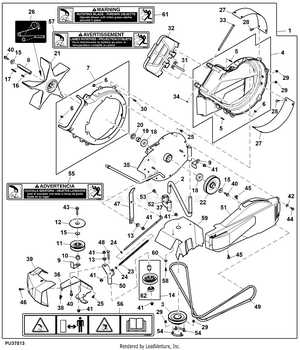

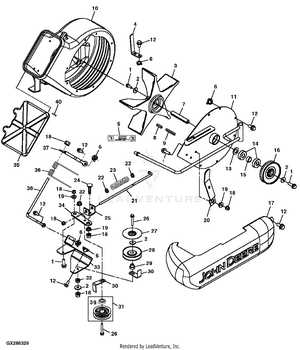

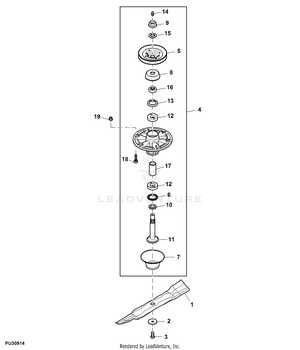

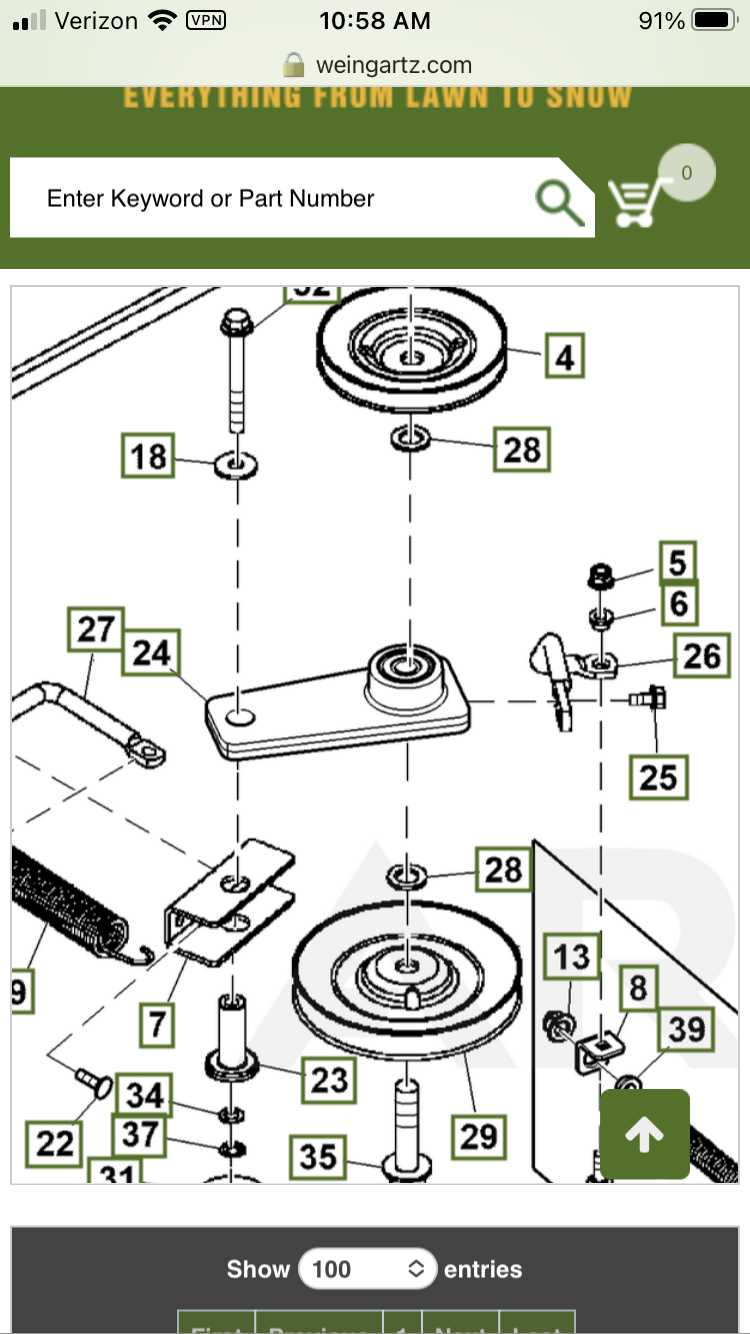

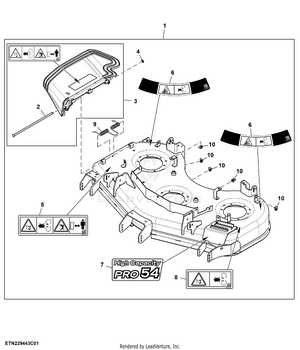

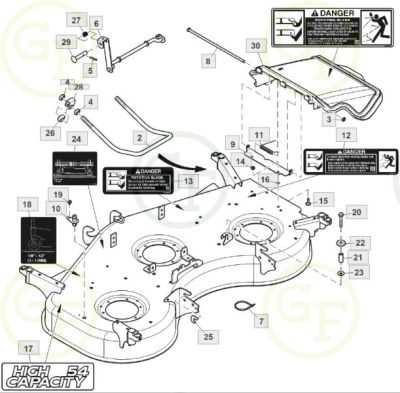

How to Identify Parts by Diagram

Understanding the components of your equipment can significantly enhance your maintenance capabilities. Visual representations provide a clear overview, making it easier to locate and recognize individual elements. This method not only simplifies the identification process but also aids in ensuring that replacements are accurate and compatible.

Step 1: Begin by examining the overall illustration. Take note of the layout and how various sections are organized. This will help you familiarize yourself with the general structure and relationship between different components.

Step 2: Focus on specific areas of interest. Zoom in on the relevant segments to get a closer look at each item. This detailed view allows for better recognition of shapes, sizes, and attachments.

Step 3: Cross-reference with a list of labels or numbers associated with each part. This ensures that you accurately match the visual with the corresponding component names, reducing the chance of errors when sourcing replacements.

Step 4: If necessary, consult additional resources or manuals that provide further clarification on assembly and function. This will deepen your understanding and confidence when handling individual items.

By following these steps, you can effectively utilize visual aids to navigate through the various elements of your equipment, making maintenance and repairs more efficient.

Common Issues with Mowing Equipment

Understanding the typical problems that can arise with cutting apparatus is crucial for maintaining optimal performance. Regular maintenance and awareness can help users address these concerns before they escalate into significant complications.

Frequent Problems

- Uneven Cutting: Often caused by dull blades or uneven wheel alignment, this issue results in an inconsistent lawn appearance.

- Clogging: Grass clippings and debris can build up, especially in humid conditions, hindering efficiency and requiring frequent cleaning.

- Noise and Vibration: Excessive sound or shaking may indicate loose components or worn parts, necessitating immediate attention.

Preventive Measures

- Regularly inspect and sharpen cutting edges to ensure a clean cut.

- Clear away debris after each use to prevent buildup.

- Check for tightness of all connections and components to minimize vibration.

By being aware of these common issues and implementing preventive measures, users can enhance the longevity and effectiveness of their equipment.

Where to Buy Replacement Parts

Finding quality components for your equipment can enhance its longevity and performance. Whether you’re in need of new items due to wear and tear or upgrades, several reliable sources are available to help you obtain what you require.

- Authorized Dealers: These retailers often carry genuine components and can provide expert advice on installation and compatibility.

- Online Marketplaces: Websites like Amazon, eBay, and specialized online retailers offer a vast selection. Ensure to check reviews and ratings to gauge reliability.

- Local Hardware Stores: Many community stores stock commonly used items and can order specific components if needed.

- Manufacturer’s Website: The official site frequently features an online shop or a list of recommended suppliers, ensuring you get authentic products.

Before purchasing, verify the specifications to guarantee compatibility with your model. Additionally, consider looking for warranty options, as this can provide extra peace of mind with your investment.

Step-by-Step Repair Instructions

This section provides a detailed guide to assist you in effectively addressing common issues with your equipment. Following a systematic approach ensures that each step is completed thoroughly, resulting in optimal performance and longevity.

1. Preparation: Begin by gathering all necessary tools and components. Having everything on hand will streamline the repair process and minimize downtime.

2. Safety First: Ensure that the machine is powered off and disconnected from any power source. Wear appropriate safety gear to protect yourself during the repair.

3. Inspection: Carefully examine the area in question for visible wear or damage. Identifying issues early can prevent more extensive repairs later.

4. Disassembly: Follow the specific instructions to disassemble the affected components. Keep track of all screws and fasteners, as they will be needed for reassembly.

5. Replacement: Install new components where necessary. Ensure that each piece fits correctly and is secured properly to maintain functionality.

6. Reassembly: Reverse the disassembly steps, ensuring that all parts are aligned correctly. Double-check that no pieces are left out.

7. Testing: Once reassembled, test the equipment to confirm that it operates as intended. Monitor for any unusual noises or behaviors.

8. Final Check: After successful testing, perform a final inspection to ensure everything is secure and in proper working order.

Tools Needed for Mower Deck Service

Proper maintenance of your cutting equipment requires a selection of essential tools. Having the right instruments at your disposal not only facilitates the process but also ensures that each component functions optimally. Understanding which tools are necessary can significantly enhance the efficiency of your servicing tasks.

Basic Hand Tools

Start with a set of wrenches and screwdrivers. These are crucial for loosening and tightening fasteners. A socket set can also be beneficial for accessing hard-to-reach bolts. Additionally, keep pliers handy for gripping and manipulating various parts during the service.

Specialized Equipment

For more complex tasks, consider investing in a torque wrench to ensure that bolts are tightened to the manufacturer’s specifications. A spark plug socket can also be invaluable when replacing ignition components. Finally, having a cleaning brush and lubricants on hand will help maintain the overall condition of your machinery.

Adjusting Mower Deck Height

Properly setting the cutting height of your equipment is crucial for achieving an even and healthy lawn. This process not only enhances the appearance of your yard but also promotes grass health by preventing scalping and ensuring optimal growth. Knowing how to adjust the height allows you to adapt to various conditions and types of terrain.

Tools Required

To successfully modify the cutting height, you’ll need a few basic tools. Having the right equipment on hand will make the process smoother and more efficient.

| Tool | Purpose |

|---|---|

| Wrench | To loosen and tighten adjustment bolts |

| Measuring Tape | To measure the height accurately |

| Level | To ensure even adjustments across the entire width |

Steps for Adjustment

Follow these steps to achieve the desired cutting height:

- Ensure the equipment is on a flat, level surface.

- Loosen the adjustment bolts with a wrench.

- Set the height by raising or lowering the cutting mechanism.

- Use a measuring tape to confirm the desired height is achieved.

- Tighten the bolts securely to lock in the setting.

Regularly checking and adjusting the cutting height is essential for maintaining a beautiful lawn and ensuring the longevity of your equipment.

Safety Precautions During Repairs

When undertaking maintenance on any machinery, ensuring safety is paramount. Proper precautions not only protect the individual performing the repairs but also safeguard the equipment from potential damage. Awareness of the risks involved and adherence to safety guidelines can greatly reduce the likelihood of accidents.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes safety glasses to shield your eyes from debris, gloves to protect your hands from sharp objects, and steel-toed boots to prevent foot injuries. Additionally, a dust mask may be advisable if working with materials that generate fine particles.

Workspace Safety

Maintaining a clean and organized workspace is crucial. Ensure that tools are properly stored when not in use and that the area is free of clutter. Adequate lighting should be provided to enhance visibility. Before starting any repair work, make sure to disconnect power sources to prevent unintended activation of the machinery.

Upgrading Your Mower Deck

Enhancing the performance of your cutting equipment can significantly impact your landscaping tasks. By integrating modern components or improving existing features, you can achieve a more efficient and effective mowing experience. This section will explore various options for elevating your machinery’s capabilities, ensuring a smoother operation and better results.

One of the primary considerations for improvement is the selection of high-quality components. Opting for durable materials can extend the lifespan of your equipment, reduce maintenance needs, and enhance cutting precision. Additionally, investing in upgraded blades can lead to cleaner cuts and improved grass health.

Another aspect to consider is the adjustment of your machine’s settings. Fine-tuning the height and angle of the cutting mechanism can optimize performance based on the specific terrain and grass type. Moreover, regular maintenance checks can prevent potential issues and ensure that all parts function harmoniously.

Lastly, exploring innovative attachments or accessories can further enhance the versatility of your equipment. From mulching kits to grass catchers, these additions can transform your tool into a multi-functional asset, allowing you to tackle various gardening challenges with ease.

Frequently Asked Questions About Parts

This section aims to address common inquiries related to components and their maintenance. Understanding the various elements involved can significantly enhance the performance and longevity of your equipment.

What are the most essential components to consider for maintenance? Regular checks on vital elements such as blades, belts, and bearings can prevent unexpected issues and ensure smooth operation.

How often should I replace worn-out elements? It is advisable to inspect these items frequently and replace them based on wear indicators or manufacturer recommendations to maintain optimal functionality.

Where can I find reliable replacement components? Authorized dealers and trusted online retailers often provide genuine items that meet the required specifications, ensuring compatibility and quality.

What should I do if I’m unsure about a specific element? Consulting the user manual or reaching out to a professional can help clarify any uncertainties regarding identification or replacement.

Can I use aftermarket options instead of original components? While aftermarket options may offer cost savings, it is crucial to ensure they meet quality standards to avoid compromising performance.