Understanding the John Deere E140 Deck Parts Diagram

When maintaining a lawn care machine, having a clear visualization of its essential components is crucial. Knowing the arrangement and function of each segment can significantly enhance the efficiency of repairs and routine checks. This knowledge allows enthusiasts and professionals alike to tackle maintenance tasks with confidence.

Furthermore, recognizing the various elements that constitute the machine enables users to identify wear and potential issues before they escalate. By examining the intricate connections and interdependencies of these parts, operators can ensure optimal performance and longevity.

In this exploration, we will delve into the specifics of the layout, focusing on the ultimate components that contribute to the seamless operation of the machine. Whether you’re a novice or an experienced user, understanding these elements will empower you to keep your equipment in top shape.

Understanding the John Deere E140

This segment focuses on a specific model in the realm of lawn maintenance machinery, emphasizing its key features and functionality. Designed for efficiency, this equipment serves as an excellent choice for homeowners seeking reliable performance in yard care.

Key Features

- Powerful engine for robust performance

- Efficient cutting system ensuring a clean finish

- Ergonomic controls for user-friendly operation

- Durable construction for longevity

Benefits of Use

- Reduces time spent on lawn maintenance

- Enhances the aesthetic appeal of outdoor spaces

- Offers versatility for various terrain types

- Increases overall efficiency in yard care tasks

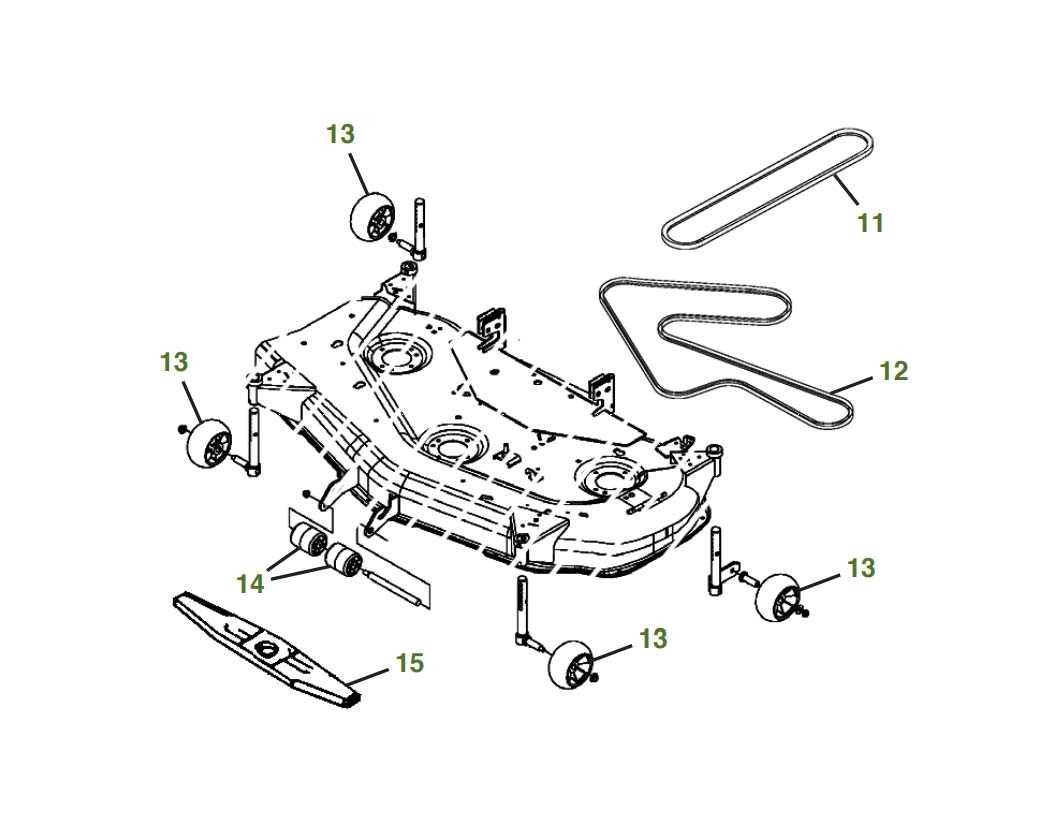

Overview of the E140 Deck Components

This section provides a detailed examination of the various elements that make up the cutting assembly of a specific lawn care machine. Understanding these components is essential for maintenance and optimal performance, ensuring a well-manicured lawn. Each part plays a crucial role in the overall functionality, contributing to efficient operation and longevity.

The following table outlines the main components, their functions, and typical specifications:

| Component | Function | Specifications |

|---|---|---|

| Blades | Cut grass at varying heights | 20 inches, steel construction |

| Spindles | Support and rotate the blades | Heavy-duty bearing, cast iron |

| Drive Belt | Transfers power from the engine | Heavy-duty, reinforced material |

| Housings | Enclose and protect the cutting assembly | Corrosion-resistant coating |

| Height Adjustment System | Allows for customizable cutting heights | Lever-operated, multiple settings |

Familiarity with these components enhances maintenance practices and helps in troubleshooting potential issues, leading to a smoother lawn care experience.

Importance of Regular Maintenance

Consistent upkeep is crucial for ensuring the longevity and efficiency of machinery. Regular checks and adjustments not only enhance performance but also prevent unexpected failures that can lead to costly repairs. Maintaining equipment in optimal condition is essential for reliable operation over time.

Benefits of Regular Upkeep

Engaging in routine maintenance offers numerous advantages. These include improved performance, enhanced safety, and prolonged lifespan of the machinery. By dedicating time to maintenance, users can avoid potential breakdowns and maintain high levels of productivity.

Key Maintenance Practices

Implementing specific practices can greatly enhance equipment health. These include checking fluid levels, inspecting components for wear, and cleaning filters. Regular attention to these areas can prevent larger issues from developing.

| Maintenance Activity | Frequency | Benefits |

|---|---|---|

| Fluid Checks | Monthly | Ensures optimal operation |

| Component Inspection | Quarterly | Identifies wear and tear early |

| Filter Cleaning | Biannually | Improves efficiency |

Common Issues with the E140 Deck

Regular maintenance is essential for optimal performance, but certain challenges can arise that affect functionality. Understanding these frequent concerns can aid in proactive measures to enhance longevity and efficiency.

| Issue | Description |

|---|---|

| Uneven Cutting | This may occur due to incorrect height settings or uneven wheel adjustments, leading to a less-than-ideal lawn appearance. |

| Clogging | Grass buildup can result in blockages, impacting the effectiveness of the cutting mechanism and requiring regular cleaning. |

| Vibration | Excessive shaking during operation might indicate worn-out components or misalignment, which can be detrimental to both the machine and user comfort. |

| Noise | Increased sound levels may suggest that maintenance is overdue, such as blade sharpening or lubrication, and should not be ignored. |

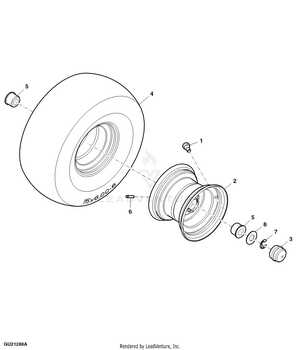

How to Identify Worn Parts

Recognizing signs of deterioration in essential components is crucial for maintaining optimal performance and safety. Regular inspection helps in detecting wear and tear early, preventing further damage and costly repairs.

Visual Inspection

Start by examining each component closely. Look for cracks, discoloration, and deformation. Regular cleaning can help reveal hidden issues.

Functional Testing

Perform tests to assess the functionality of each piece. Listen for unusual sounds and monitor for decreased efficiency during operation.

| Type of Component | Signs of Wear |

|---|---|

| Blades | Dull edges, nicks, or chips |

| Belts | Cracks, fraying, or stretching |

| Wheels | Uneven wear, flat spots |

| Filters | Discoloration or clogs |

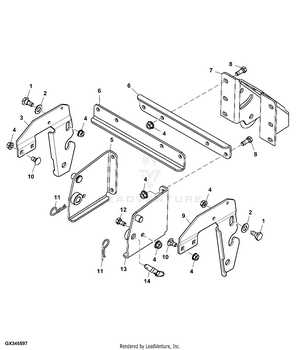

Steps for Deck Replacement

Replacing the cutting assembly of a lawn mower is a crucial task that ensures optimal performance and longevity. Proper execution of this procedure can lead to a smoother mowing experience and better results.

1. Preparation: Start by gathering all necessary tools and components. Ensure the machine is turned off and disconnected from any power source to prevent accidents.

2. Removal: Carefully detach the existing cutting assembly. This typically involves loosening bolts and removing any connected hardware. Take note of the arrangement for easier reinstallation.

3. Inspection: Examine the underlying components for wear or damage. Address any issues found during this assessment before proceeding with the new assembly.

4. Installation: Align the new cutting assembly with the frame and secure it in place using the appropriate hardware. Make sure everything is tightened to the manufacturer’s specifications.

5. Testing: Once installed, reconnect the power source and conduct a test run. Observe the mower’s performance to ensure everything operates smoothly and efficiently.

Tools Needed for Repairing the Deck

When undertaking maintenance or repair tasks, having the right tools is essential for efficiency and effectiveness. Proper instruments not only facilitate the process but also ensure that the job is completed to a high standard. Below is a comprehensive list of necessary equipment for handling repairs on the specific assembly in question.

Essential Tools

| Tool | Purpose |

|---|---|

| Socket Set | Used for loosening and tightening bolts and nuts. |

| Wrench Set | Provides leverage for turning fasteners in tight spaces. |

| Screwdrivers | Needed for various screws that may secure components. |

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

| Utility Knife | Handy for cutting through materials or packaging. |

| Cleaning Brush | Removes debris and buildup from surfaces. |

Safety Gear

In addition to standard tools, safety equipment is critical. Using gloves protects hands from sharp edges, while safety glasses shield eyes from debris. These measures enhance safety and comfort during repair work, ensuring a smooth process from start to finish.

Where to Find Replacement Parts

Locating the necessary components for your machinery can enhance its performance and longevity. Understanding where to source these items is essential for maintenance and repair.

Online Retailers

The internet offers a vast array of options for purchasing components. Here are some popular platforms:

- Specialized websites focused on machinery

- Major e-commerce platforms

- Manufacturer’s official site

Local Stores

Visiting physical shops can be beneficial as well. Consider the following:

- Hardware stores

- Garden supply centers

- Machinery dealers

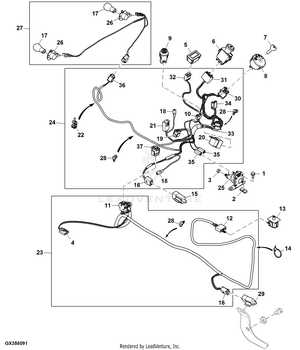

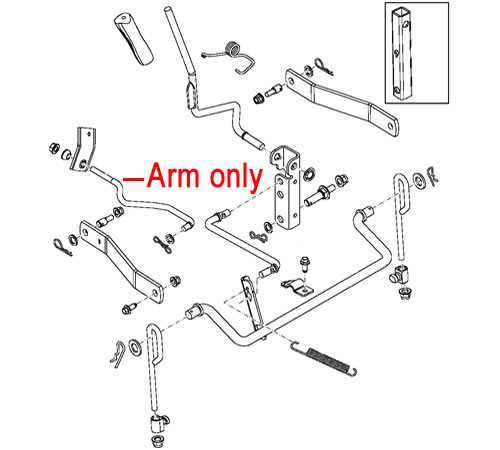

Visual Guide to Deck Assembly

This section provides a comprehensive overview of the assembly process for the mowing platform. Understanding the various components and their arrangement is crucial for efficient operation and maintenance. The guide aims to simplify the assembly, ensuring that every part is in its correct position for optimal performance.

Starting with the foundational structure, each segment is designed to fit seamlessly with others, promoting stability and ease of use. Familiarity with these components will enhance your ability to troubleshoot and perform necessary repairs. Visual representations highlight the configuration, allowing for quick identification and assembly.

Throughout this guide, you’ll find detailed descriptions of each element, along with tips for assembly that can save time and effort. By following the visual cues and instructions, you can ensure a successful setup, enhancing the overall functionality of your equipment.

Tips for Safe Operation

Ensuring safety while operating lawn maintenance equipment is crucial for both the user and the environment. By following established guidelines, individuals can minimize risks and enhance their overall experience. Here are some essential tips to consider.

- Always wear appropriate protective gear, including gloves, goggles, and sturdy footwear.

- Read the owner’s manual thoroughly before use to familiarize yourself with the machinery.

- Inspect the equipment regularly for any signs of wear or damage, addressing issues immediately.

Prioritizing a safe work environment is key. Consider the following practices:

- Ensure the area is clear of debris and obstacles before starting.

- Keep bystanders and pets at a safe distance while operating the machinery.

- Maintain a firm grip and a stable stance while in operation.

Lastly, remember to follow proper procedures for starting and stopping the equipment. This will contribute to a safer and more effective operation.

Resources for E140 Owners

For enthusiasts of this renowned lawn care machine, having access to quality materials and support is essential for optimal performance and maintenance. Whether you’re troubleshooting issues or seeking enhancements, various resources can make your experience more rewarding.

Online Communities

Engaging with fellow owners through online forums and social media groups can provide invaluable insights. These platforms often feature discussions about common challenges, recommendations for upgrades, and tips for effective upkeep.

Official Manuals and Guides

Accessing official documentation is crucial for understanding the intricacies of your machine. These manuals not only offer step-by-step maintenance instructions but also include safety guidelines and troubleshooting tips to ensure your equipment runs smoothly.