Comprehensive Guide to John Deere GT245 54 Mower Deck Parts Diagram

Maintaining a well-groomed outdoor space requires an efficient system that combines various mechanical elements. A thorough understanding of these components can significantly enhance performance and longevity. Each segment plays a crucial role in achieving optimal results, ensuring that the entire assembly operates seamlessly.

To facilitate the upkeep of such machinery, it is vital to have access to a comprehensive overview of its individual segments. This knowledge aids in proper maintenance, timely replacements, and troubleshooting issues that may arise during use. Familiarity with the arrangement and function of each part empowers users to maximize their equipment’s efficiency.

Furthermore, having a visual representation of the intricate relationships among these elements allows for easier identification of potential problems. By grasping how each section interacts within the whole system, operators can make informed decisions that enhance overall performance and reduce downtime.

Understanding the GT245 Mower Deck

This section aims to provide insights into the essential components and mechanisms that contribute to effective grass cutting and lawn maintenance. By exploring the construction and function of these elements, users can enhance their operational knowledge and maintenance routines.

Each element plays a vital role in ensuring a seamless experience while managing your outdoor space. Familiarity with these components will not only improve performance but also extend the longevity of the equipment.

| Component | Function |

|---|---|

| Blades | Designed for cutting grass efficiently, ensuring a clean finish. |

| Spindles | House the blades and provide rotational motion for cutting. |

| Belts | Transmit power from the engine to the cutting elements. |

| Frame | Supports all components and provides stability during operation. |

| Wheels | Facilitate mobility and help maintain the desired cutting height. |

By understanding these key elements, users can ensure optimal performance and address any potential issues that may arise during use. Regular maintenance and attention to detail can significantly improve the functionality and reliability of your equipment.

Key Features of the GT245 Model

The GT245 model stands out in the realm of outdoor equipment due to its robust design and impressive functionality. This machine is engineered to deliver efficiency and reliability, making it a favored choice among enthusiasts and homeowners alike. Its well-thought-out features contribute to an exceptional user experience, ensuring both performance and comfort during operation.

Powerful Engine: The unit is equipped with a high-performance engine that provides ample power for tackling various tasks. This strength allows users to navigate different terrains with ease, ensuring that even the toughest jobs are completed without hassle.

Efficient Cutting System: One of the most notable characteristics is its advanced cutting mechanism, which ensures a clean and precise cut. This feature not only enhances the aesthetics of the lawn but also promotes healthier grass growth by preventing uneven patches.

Durable Build: Constructed with high-quality materials, this model boasts durability and longevity. Its sturdy framework is designed to withstand the rigors of frequent use, providing peace of mind for owners who demand reliability.

User-Friendly Controls: The intuitive control layout simplifies operation, making it accessible for users of all experience levels. With easy-to-reach buttons and levers, managing the machine becomes a seamless process, allowing for a more enjoyable experience.

Comfort Features: Designed with the operator in mind, this model includes ergonomic seating and adjustable features to enhance comfort during extended use. This attention to detail ensures that users can work efficiently without sacrificing their well-being.

Importance of Maintenance

Proper upkeep of essential components in any landscaping machinery plays a crucial role in ensuring optimal performance and longevity. Regular attention to these elements not only enhances efficiency but also minimizes the risk of unexpected breakdowns and costly repairs.

Benefits of Regular Care

- Improved Efficiency: Well-maintained components operate more smoothly, resulting in better cutting performance and reduced fuel consumption.

- Extended Lifespan: Routine inspections and servicing can significantly prolong the life of machinery, saving money in the long run.

- Enhanced Safety: Regular checks help identify potential hazards, ensuring safer operation for the user and surrounding environment.

Key Maintenance Practices

- Cleaning: Regularly removing debris and buildup prevents rust and corrosion.

- Inspection: Frequent examination of components for wear and damage allows for timely repairs.

- Sharpening: Keeping blades sharp ensures clean cuts and promotes healthier grass growth.

- Lubrication: Applying the right lubricants reduces friction and wear, enhancing overall performance.

Incorporating these practices into a maintenance routine fosters a reliable and efficient machine, ultimately leading to a more satisfying experience for users and better results in lawn care tasks.

Common Issues with the GT245 Deck

Understanding the typical challenges faced by users of this particular cutting apparatus is essential for maintaining its performance. Over time, certain problems may arise that can affect efficiency and cutting quality. Recognizing these issues early can lead to effective solutions and prolong the lifespan of the equipment.

Frequent Problems Encountered

- Uneven Cutting: This often results from dull blades or improper leveling of the unit.

- Clumping of Grass: Accumulation can occur due to wet conditions or clogged discharge areas.

- Excessive Vibration: Loose components or worn-out parts may contribute to this issue.

- Stalling: Insufficient power or fuel issues can lead to the unit stopping unexpectedly.

Maintenance Tips

- Regularly sharpen blades to ensure clean cuts.

- Clear clippings and debris from the discharge area to prevent clogs.

- Inspect and tighten all bolts and screws to reduce vibrations.

- Check fuel levels and filter condition to avoid stalling.

By addressing these common concerns proactively, users can enhance the functionality and reliability of their cutting machinery.

Essential Tools for Repairs

Proper maintenance and repair require a set of essential tools that facilitate efficient work and ensure effective results. Having the right equipment on hand not only simplifies tasks but also enhances safety and prolongs the lifespan of your machinery. Here’s a breakdown of the crucial tools you’ll need for effective repairs.

Basic Hand Tools

- Wrenches: Various sizes for tightening and loosening bolts.

- Screwdrivers: Both flathead and Phillips for handling screws of different types.

- Pliers: Useful for gripping and bending materials.

- Socket Set: Provides versatility for various fasteners.

Specialized Equipment

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications.

- Grease Gun: Essential for lubricating moving parts.

- Multimeter: Helps diagnose electrical issues by measuring voltage, current, and resistance.

- Cutting Tools: Such as shears or saws for precision cutting of materials.

Investing in these tools will prepare you for various repair tasks, making your maintenance efforts more efficient and effective.

Parts List for GT245 Mower Deck

This section provides a comprehensive overview of the components essential for the functionality of your cutting apparatus. Understanding each element’s role can help in maintaining efficiency and ensuring longevity.

1. Cutting Blade: The primary element responsible for grass trimming, available in various lengths and materials to suit different needs.

2. Spindle Assembly: This crucial component houses the blade and allows for its rotation, facilitating a clean cut.

3. Belt: A vital transmission element that connects the engine to the spindle, ensuring power transfer during operation.

4. Pulley: These wheels aid in the movement of the belt, contributing to the overall functionality of the cutting mechanism.

5. Chassis: The frame that supports all components, providing stability and structure for the entire assembly.

6. Discharge Chute: This feature directs clippings away from the cutting area, enhancing visibility and preventing clogging.

7. Mounting Brackets: These connectors secure various parts to the frame, ensuring everything remains in place during operation.

8. Bolts and Nuts: Fasteners that hold components together, essential for maintaining the integrity of the assembly.

Having a clear understanding of these components will facilitate effective repairs and replacements, ultimately optimizing performance.

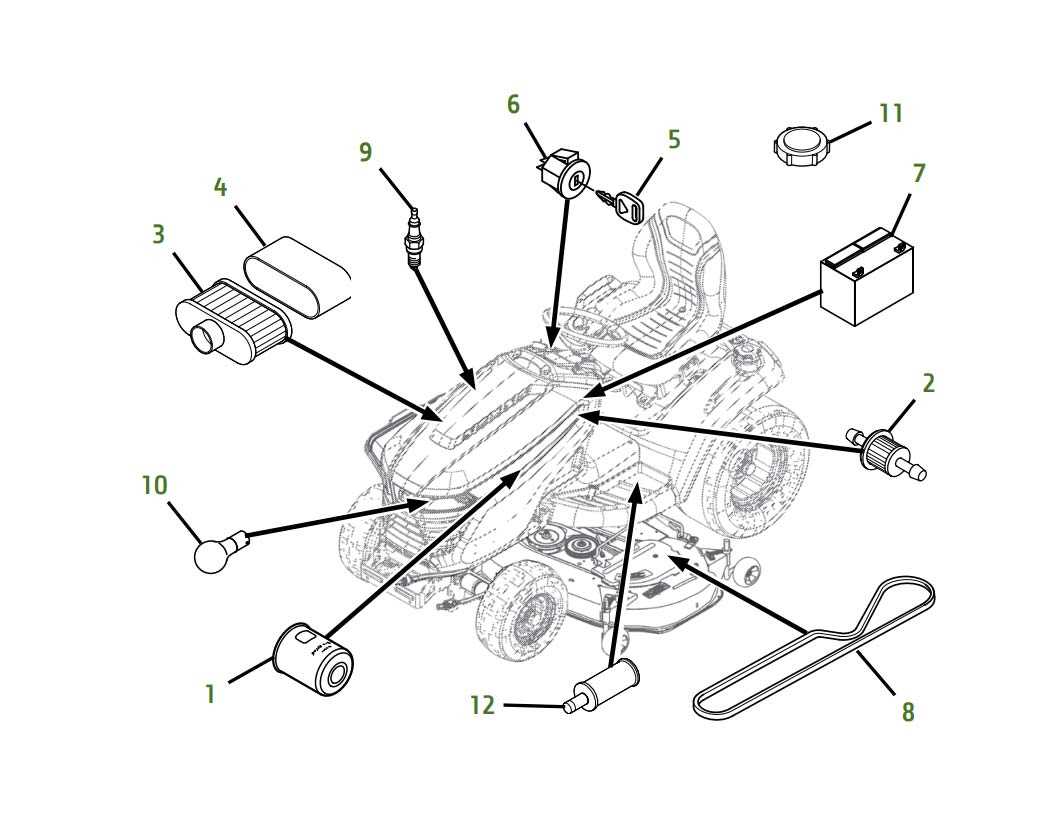

Visual Guide to Deck Components

This section provides a comprehensive overview of the various elements that make up the cutting mechanism of your equipment. Understanding these components is essential for maintenance, troubleshooting, and enhancing performance. Here, we will explore each part’s function and its significance in the overall operation.

Key Components Overview

Each segment plays a crucial role in ensuring efficiency and effectiveness. Familiarity with these components not only aids in identifying issues but also enhances your ability to perform routine checks and repairs.

| Component | Description | Function |

|---|---|---|

| Blade Assembly | Rotating sharp edges that cut grass. | Provides the primary cutting action. |

| Spindle | Housing for the blade assembly. | Supports and drives the blades. |

| Belt | Transfers power from the engine to the blades. | Ensures smooth operation of the cutting mechanism. |

| Guards | Protective barriers around the blades. | Enhances safety during operation. |

| Lift Linkage | System for raising and lowering the assembly. | Allows for height adjustments during use. |

Maintenance Tips

Regular inspection and maintenance of these components will prolong their lifespan and ensure optimal performance. Pay attention to wear and tear, particularly on the blade assembly and belt, as these are vital for effective operation. Keeping everything clean and lubricated is also crucial for preventing issues.

How to Replace Deck Parts

Replacing components of your lawn care equipment can enhance performance and ensure longevity. Proper maintenance not only keeps the machinery running smoothly but also improves the quality of your lawn care experience. Here’s a step-by-step guide to help you through the process of swapping out worn or damaged elements.

Tools Needed

- Socket wrench set

- Screwdriver set

- Pliers

- Safety gloves

- Replacement components

Replacement Steps

- Preparation: Disconnect the power source to prevent any accidental activation.

- Accessing Components: Tilt the machine to gain clear access to the area where components need replacement.

- Removing Old Components: Use the socket wrench to unfasten screws and bolts securing the old parts.

- Installing New Components: Align and secure the new parts, ensuring a snug fit.

- Final Check: Double-check all connections and fasteners before restoring power.

Following these guidelines will help ensure your equipment operates efficiently, providing you with reliable service for years to come.

Identifying Genuine John Deere Parts

Ensuring the longevity and efficiency of your equipment relies heavily on the components you choose. Recognizing authentic items is crucial for optimal performance and reliability. Here are key aspects to consider when distinguishing genuine products from alternatives.

- Brand Markings: Look for recognizable logos and trademarks that signify authenticity.

- Packaging Quality: Genuine items typically come in high-quality packaging with clear labeling.

- Part Numbers: Verify the part number against official resources to ensure compatibility.

- Authorized Dealers: Purchase from certified retailers to guarantee you’re getting original components.

Understanding these indicators can help you make informed decisions, ultimately leading to better maintenance and performance of your machinery.

Step-by-Step Repair Instructions

This section provides a comprehensive guide to effectively addressing common issues with your equipment. By following the outlined steps, you can ensure optimal performance and longevity. Each phase of the repair process is designed to simplify the task and minimize downtime.

Preparation and Safety Measures

Before commencing any repair work, it is essential to gather all necessary tools and materials. Ensure that the machine is turned off and disconnected from the power source to prevent accidents. Wear appropriate safety gear, including gloves and goggles, to protect yourself during the process.

Repair Process

Begin by examining the area for any visible damage or wear. Take note of any components that require replacement or adjustment. Carefully follow the sequence of steps outlined in the manual, ensuring to secure any loose parts and tighten fasteners as needed. After completing the repair, conduct a thorough inspection to verify that everything is functioning correctly before re-engaging power.

Tips for Enhancing Mower Performance

Maintaining optimal performance in your grass-cutting equipment is essential for achieving a pristine lawn. A few strategic adjustments and regular upkeep can significantly improve efficiency and extend the lifespan of your machine. Here are some practical suggestions to enhance its functionality and ensure it runs smoothly.

Regular Maintenance Checks

Frequent inspections can prevent minor issues from escalating into major problems. Cleaning the blades and ensuring they remain sharp is crucial, as dull edges can lead to uneven cuts and unnecessary strain on the engine. Additionally, check the air filter regularly; a clean filter promotes better airflow, enhancing combustion and overall power.

Optimize Operating Conditions

Utilizing the equipment in suitable conditions can greatly impact its performance. Avoid mowing during wet conditions to prevent clumping and uneven cutting. Adjusting the cutting height based on grass type and growth can also ensure a healthier lawn while minimizing wear on the machine. Lastly, using high-quality fuel will improve efficiency and reduce the likelihood of mechanical issues.

Where to Buy Replacement Parts

Finding the right components for your equipment is essential for maintaining its efficiency and performance. Whether you’re looking for specific elements or general accessories, knowing where to source these items can save you time and ensure you get quality replacements.

Online marketplaces are a convenient option, offering a vast selection from various sellers. Websites dedicated to outdoor machinery often have user-friendly interfaces, allowing you to search by model or type. Additionally, many manufacturers provide direct sales through their official platforms, ensuring authenticity.

Local retailers can also be a great resource. Visiting a store that specializes in gardening or agricultural tools may offer personalized assistance, helping you find the exact component you need. It’s advisable to call ahead to confirm stock availability.

Another option includes salvage yards or repair shops, which may have used or refurbished items at a lower cost. Networking with fellow enthusiasts in community forums can lead to recommendations for trustworthy sources.

Customer Reviews on GT245 Parts

This section highlights the feedback from users regarding various components of their machines. Insights shared by customers can significantly aid others in making informed decisions about replacements and enhancements. Reviews often encompass quality, durability, and overall performance, providing a well-rounded perspective.

Many users praise the reliability of certain components, noting their longevity even after extensive use. One reviewer mentioned how a specific replacement exceeded expectations, leading to improved functionality and efficiency. Positive experiences are often accompanied by suggestions for installation, helping newcomers navigate the process with ease.

Conversely, some customers express dissatisfaction, citing issues such as fitment problems or premature wear. These reviews serve as cautionary tales, prompting potential buyers to research thoroughly before making a purchase. Overall, customer feedback offers valuable insights that can guide others in selecting the right components for their equipment.