Comprehensive Guide to John Deere Mower Deck Parts Diagram

When it comes to maintaining a pristine landscape, having a comprehensive grasp of the essential machinery is vital. The intricate systems within these tools play a crucial role in ensuring effective performance and longevity. Familiarizing oneself with these elements not only enhances operational efficiency but also aids in timely repairs and replacements.

Within the realm of lawn care, various sections of the machinery work in harmony to achieve the desired results. Each component serves a specific function, contributing to the overall effectiveness of the equipment. Gaining insight into these individual elements allows users to troubleshoot issues and optimize their maintenance routines.

In this discussion, we will explore the intricate layout and relationship of various components within these vital machines. By delving into their design and function, one can develop a more profound understanding that ultimately leads to better upkeep and a flourishing outdoor environment.

Understanding John Deere Mower Decks

This section delves into the intricate components and functions of lawn care equipment designed for efficient grass management. A thorough grasp of these elements is essential for optimal performance and longevity of your equipment.

Key Components

The core structure comprises various elements that contribute to effective grass cutting and collection. Understanding these components allows users to recognize the importance of regular maintenance and timely replacements, ensuring that the machinery operates smoothly.

Maintenance Tips

Regular upkeep is vital to extend the life of your equipment. This includes checking the sharpness of blades, ensuring proper alignment, and cleaning debris buildup. Neglecting these tasks can lead to decreased efficiency and potential damage.

Investing time in understanding the nuances of your equipment not only enhances performance but also promotes a well-maintained lawn, making it a valuable asset for any homeowner.

Components of a Mower Deck

The assembly of a cutting platform consists of various elements that work in harmony to ensure efficient operation. Understanding these components is crucial for proper maintenance and functionality. Each part plays a specific role in the overall performance, contributing to a seamless experience while managing grassy areas.

Key Elements

Among the primary elements, the cutting blades are essential for achieving a clean and precise cut. They rotate at high speeds, effectively trimming the grass to the desired height. Additionally, the housing provides structural integrity and protection for internal mechanisms. Wheels and casters support maneuverability, allowing for easy navigation across different terrains.

Support Structures

Support brackets and frames are critical for stability, ensuring that all components are securely in place during operation. The belt system is vital for transferring power from the engine to the blades, enabling them to rotate efficiently. Regular inspection of these structures can prevent malfunctions and enhance the longevity of the equipment.

Importance of Regular Maintenance

Consistent upkeep is essential for the longevity and performance of any mechanical equipment. By ensuring that components are regularly checked and serviced, owners can avoid costly repairs and enhance the efficiency of their machinery. This proactive approach not only saves time and money but also promotes safety during operation.

Benefits of Preventive Care

Routine maintenance offers numerous advantages. It helps identify potential issues before they escalate into major problems. Additionally, keeping all mechanisms in optimal condition improves overall functionality and can lead to better fuel efficiency. Regular checks also contribute to the safety of the operator and those nearby, minimizing the risk of accidents due to equipment failure.

Maximizing Lifespan

Investing time in maintenance practices significantly extends the life of machinery. Components that are properly cared for are less likely to wear out prematurely. By adhering to a maintenance schedule, users can ensure that their equipment operates smoothly for many seasons to come, providing reliable service throughout its lifespan.

Common Issues with Mowing Equipment

Maintaining a lawn care machine is crucial for optimal performance and longevity. Various challenges can arise during operation, impacting efficiency and results. Understanding these common issues can help users troubleshoot and maintain their equipment effectively.

- Uneven Cutting: This often results from dull blades, improper height settings, or uneven tire pressure.

- Clumping of Grass: Clumping can occur due to wet grass, clogged components, or insufficient blade speed.

- Vibrations: Excessive vibrations may indicate loose parts, misaligned components, or unbalanced blades.

- Engine Performance: Issues like stalling, difficulty starting, or reduced power can stem from fuel problems, air filter blockages, or spark plug wear.

- Overheating: Machines can overheat due to insufficient oil, debris accumulation, or blocked air vents.

Addressing these problems promptly not only enhances performance but also prolongs the life of the equipment.

How to Identify Parts by Diagram

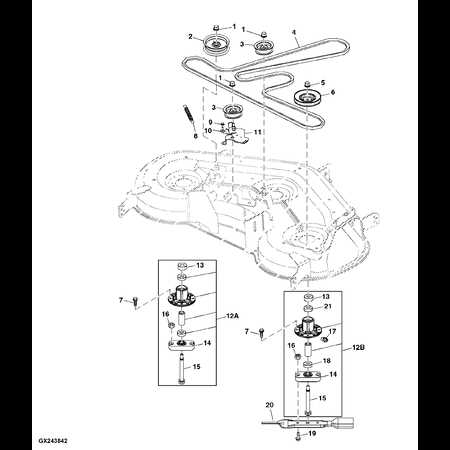

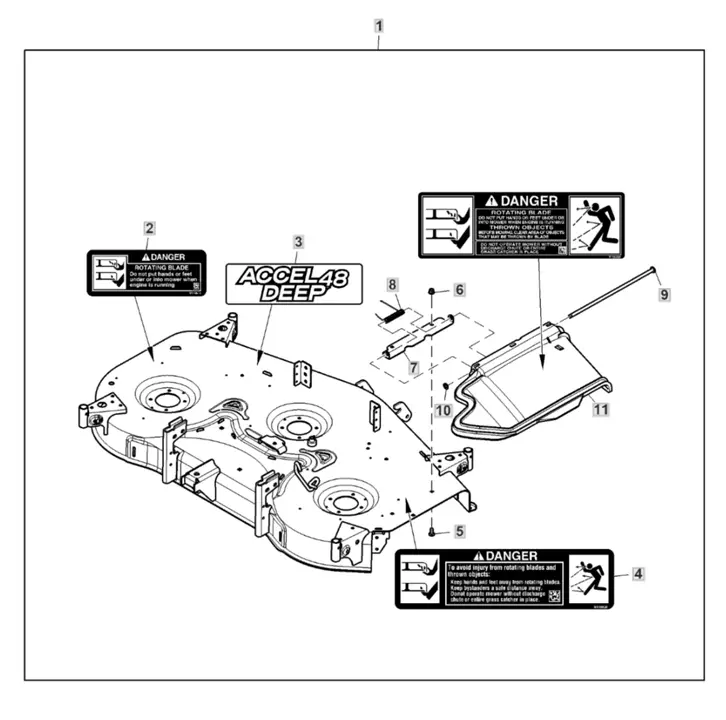

Understanding the layout of components is essential for effective maintenance and repair. A visual representation serves as a valuable guide, enabling users to pinpoint specific elements with ease. By familiarizing yourself with these illustrations, you can streamline the process of identification and replacement, ultimately enhancing the efficiency of your equipment.

Begin by examining the overall structure, noting the arrangement and connections between various components. Look for labels or numbers that correspond to each section; these will provide crucial information for locating and ordering replacements. Pay attention to the size and shape of each item, as this can aid in distinguishing similar-looking elements.

Referencing the legend accompanying the illustration can significantly assist in understanding what each symbol or number represents. Often, the legend will provide additional details, such as part specifications or compatibility notes, which are essential for ensuring the correct fit.

Finally, consulting additional resources like user manuals or online forums can enhance your knowledge. Engaging with a community of fellow enthusiasts can provide insights and tips that may not be readily available in diagrams alone. By leveraging these strategies, you can effectively navigate the complexities of component identification.

Steps for Proper Installation

Achieving a seamless assembly requires careful attention to detail and adherence to specific procedures. Proper installation ensures that all components function efficiently and safely, ultimately enhancing the overall performance of your equipment. Follow these guidelines to ensure a successful setup.

Preparation

Before starting the assembly, gather all necessary tools and components. Review the manual to familiarize yourself with each element’s role. Ensure your workspace is clean and organized to avoid losing small parts.

Installation Process

Begin by positioning the main unit on a stable surface. Align the components as indicated in your reference material, paying close attention to any specific orientations. Secure each part using the appropriate fasteners, tightening them firmly but not overtightening to prevent damage. Double-check connections to confirm everything is fitted correctly, and conduct a final inspection to ensure all elements are securely attached.

Finally, perform a test run to confirm everything operates smoothly. Address any unusual noises or movements immediately, as they may indicate improper installation.

Tools Needed for Repairs

Proper maintenance and repairs require specific implements to ensure efficiency and safety. Having the right tools on hand can make a significant difference in the ease and effectiveness of the work being performed. This section outlines the essential tools that will facilitate successful repairs and maintenance tasks.

Essential Hand Tools

First and foremost, a reliable set of hand tools is crucial. This includes items such as wrenches, screwdrivers, and pliers. These instruments allow for precise adjustments and secure fittings. Additionally, having a socket set can expedite the process of loosening or tightening various components.

Power Tools and Equipment

Incorporating power tools can further enhance efficiency. An electric drill is invaluable for making quick work of screws and fasteners, while a cutting tool can assist in modifying or removing materials with ease. Furthermore, having a compressor on hand can be beneficial for certain tasks that require air pressure for operation.

Safety Tips During Maintenance

Ensuring safety while performing upkeep on outdoor equipment is crucial for both personal protection and the longevity of the machinery. Adhering to specific guidelines can prevent accidents and enhance efficiency during the maintenance process.

Preparation Before Maintenance

- Read the manufacturer’s manual thoroughly to understand safety recommendations and maintenance protocols.

- Wear appropriate personal protective equipment, including gloves, safety glasses, and sturdy footwear.

- Ensure the work area is clear of obstacles and well-lit to reduce the risk of trips and falls.

During Maintenance

- Always disconnect the power source before beginning any repair or adjustment.

- Keep hands and tools away from moving parts to prevent injuries.

- Use tools that are in good condition and suitable for the task at hand.

- Maintain a clean workspace to avoid hazards from oil spills or debris.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing high-quality components is essential for ensuring optimal performance. Various avenues exist for acquiring these essential items, each offering unique advantages to suit different needs and preferences.

Online Retailers

One of the most convenient methods is to explore online platforms. Numerous retailers specialize in equipment components, providing a vast selection with detailed descriptions. Comparing prices and checking user reviews can help you make informed choices.

Local Dealers and Repair Shops

Another excellent option is to visit local dealers or repair shops. They often carry a range of products and can offer personalized advice. Supporting local businesses not only contributes to your community but also may result in quicker access to necessary items.

Benefits of OEM vs. Aftermarket Parts

The choice between original equipment manufacturer (OEM) components and those produced by third-party suppliers can significantly impact the performance and longevity of your machinery. Understanding the advantages of each option helps users make informed decisions that align with their needs and preferences.

OEM components are designed specifically for certain machines, ensuring perfect compatibility and optimal performance. These parts typically undergo rigorous testing and quality control, leading to enhanced reliability and extended lifespan. Additionally, utilizing OEM parts may help maintain the manufacturer’s warranty, providing peace of mind for users.

On the other hand, aftermarket components often come with a lower price tag and a broader range of options. They can offer innovative designs and features that may not be available with original parts. This flexibility can be appealing to those looking for cost-effective solutions or specific enhancements for their equipment.

Ultimately, the choice between OEM and aftermarket components hinges on individual priorities, whether they be reliability, cost, or performance enhancements. Assessing these factors carefully ensures that users can make the best decision for their specific applications.

Tips for Troubleshooting Problems

Tackling issues with your outdoor machinery can be a straightforward process when approached methodically. Understanding common complications and knowing how to diagnose them can save time and ensure optimal performance.

Start by examining the power source. Ensure that the equipment is properly connected and that there are no issues with the electrical supply. A malfunctioning battery or a faulty connection can often lead to performance problems.

Next, inspect the operational components for any signs of wear or damage. Look for loose screws, cracked parts, or debris that may be obstructing movement. Cleaning and securing these areas can often resolve minor issues.

Another critical step is to refer to the manufacturer’s manual for guidance on routine maintenance and troubleshooting tips specific to your model. This can provide valuable insights into common problems and recommended solutions.

Finally, if problems persist, consider reaching out to a professional for assistance. Their expertise can help identify complex issues that may not be easily recognizable to the average user.