Complete Guide to John Deere Z425 Deck Parts Diagram

In the realm of outdoor maintenance machinery, comprehending the various components is essential for optimal performance. This section aims to explore the intricacies of a specific model, focusing on its structure and the relationships between its elements.

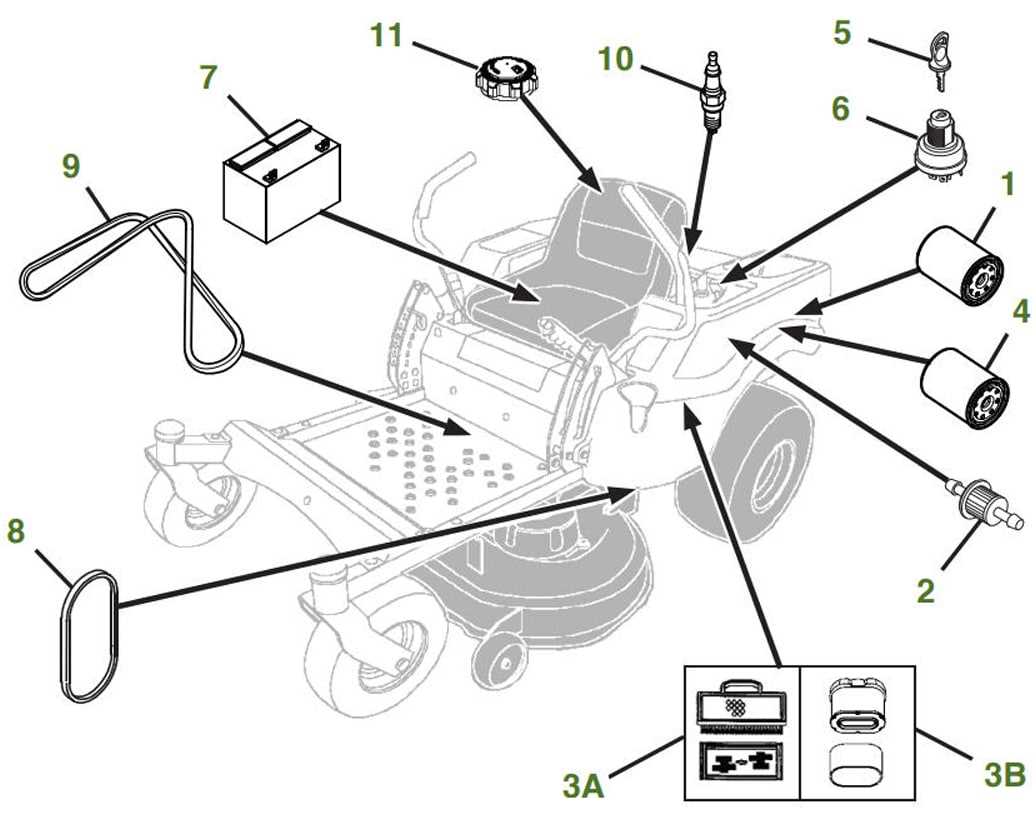

Visual aids play a crucial role in enhancing our understanding of how machinery functions. By examining a detailed representation of the components, users can identify essential features and gain insight into the assembly process.

As we delve deeper into this topic, we will uncover the ultimate significance of each element, ensuring that users can navigate their maintenance tasks with confidence and efficiency.

Understanding the John Deere Z425

This section explores a popular model known for its efficiency and durability in landscaping and lawn care. Users appreciate its reliability and performance, making it a preferred choice for both residential and commercial tasks. Familiarity with its components and functionality can enhance maintenance and usability.

Key Features

This model boasts a range of features designed to optimize user experience and ensure effective operation. Key aspects include robust construction, user-friendly controls, and efficient engine performance.

Maintenance Considerations

| Component | Function |

|---|---|

| Engine | Provides power for operation |

| Transmission | Facilitates movement and speed control |

| Wheels | Ensures stability and maneuverability |

Key Features of the Z425 Model

This model stands out in its category due to a combination of innovative engineering and user-friendly design. It offers exceptional performance for various landscaping tasks, making it a top choice for both homeowners and professionals.

Robust Power System: The engine provides reliable power, ensuring smooth operation even in challenging conditions. This strength allows users to tackle tough jobs with ease.

Efficient Cutting Mechanism: Equipped with advanced cutting technology, this model ensures a clean and precise cut. The adjustable height settings allow for customization based on lawn type and user preference.

Ergonomic Design: Comfort is a key consideration in its design, featuring an adjustable seat and intuitive controls that reduce fatigue during extended use. This enhances the overall user experience, making it more enjoyable.

Durable Construction: Built with high-quality materials, this model is designed to withstand the rigors of regular use. Its robust frame contributes to longevity and reliability, minimizing maintenance needs.

Easy Maneuverability: The compact design and responsive steering system facilitate navigation in tight spaces, allowing users to cover large areas efficiently while maintaining precision.

These features collectively enhance the functionality and appeal of this mower, making it a valuable asset for any lawn care endeavor.

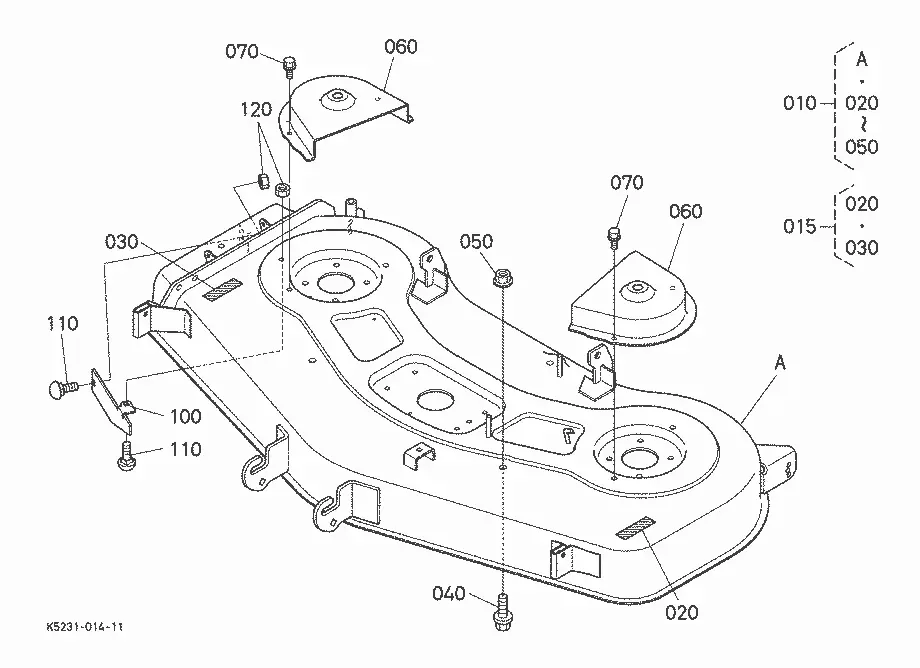

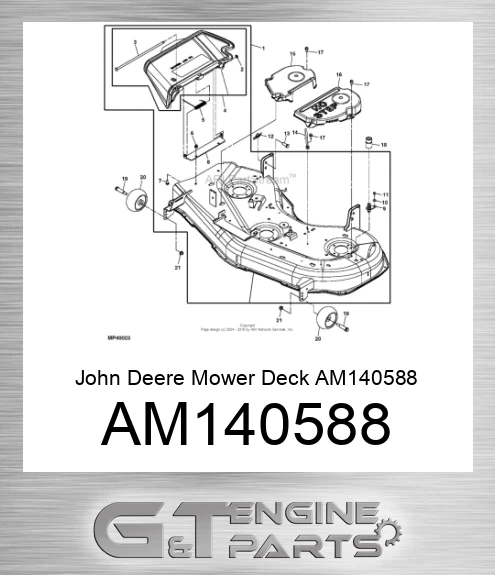

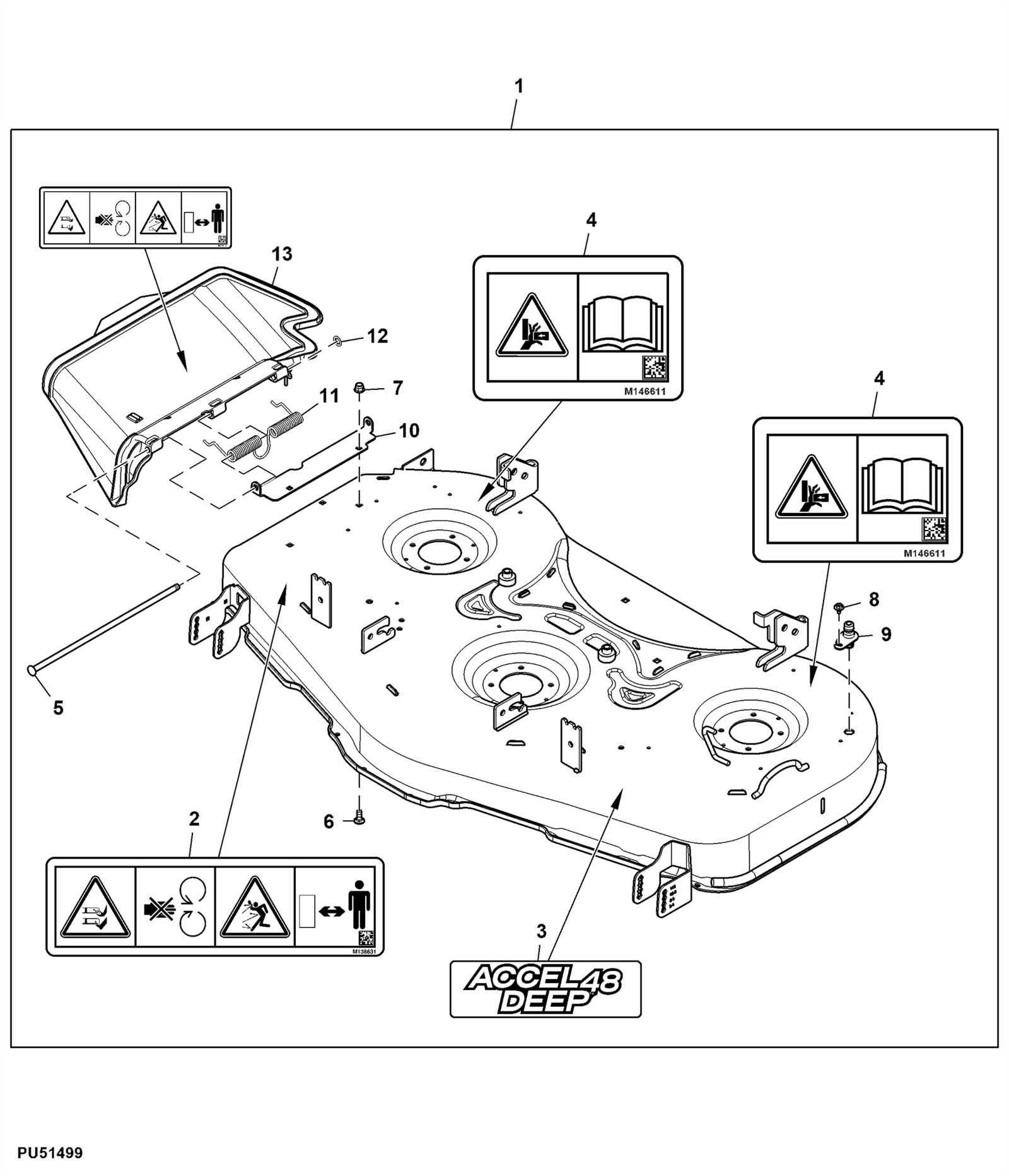

Importance of Deck Parts Diagram

Understanding the layout and components of a mower’s cutting assembly is essential for effective maintenance and repair. A comprehensive visual representation of these elements not only simplifies the identification of individual pieces but also enhances the overall efficiency of servicing tasks. This clarity can prevent unnecessary errors and streamline the repair process, ultimately saving time and resources.

Moreover, having access to an accurate schematic fosters a deeper understanding of how each component interacts within the system. This knowledge is crucial for troubleshooting and can significantly improve performance and longevity. Whether for a novice user or a seasoned technician, a well-organized visual reference is invaluable in ensuring all necessary elements are accounted for during inspections or replacements.

Additionally, such illustrations can serve as an educational tool, providing insights into the operational mechanics of the mower. By visualizing the relationship between different components, users can make informed decisions about upgrades or modifications, further enhancing their mowing experience. Ultimately, a clear visual guide is not just a resource; it is a critical asset for effective maintenance practices.

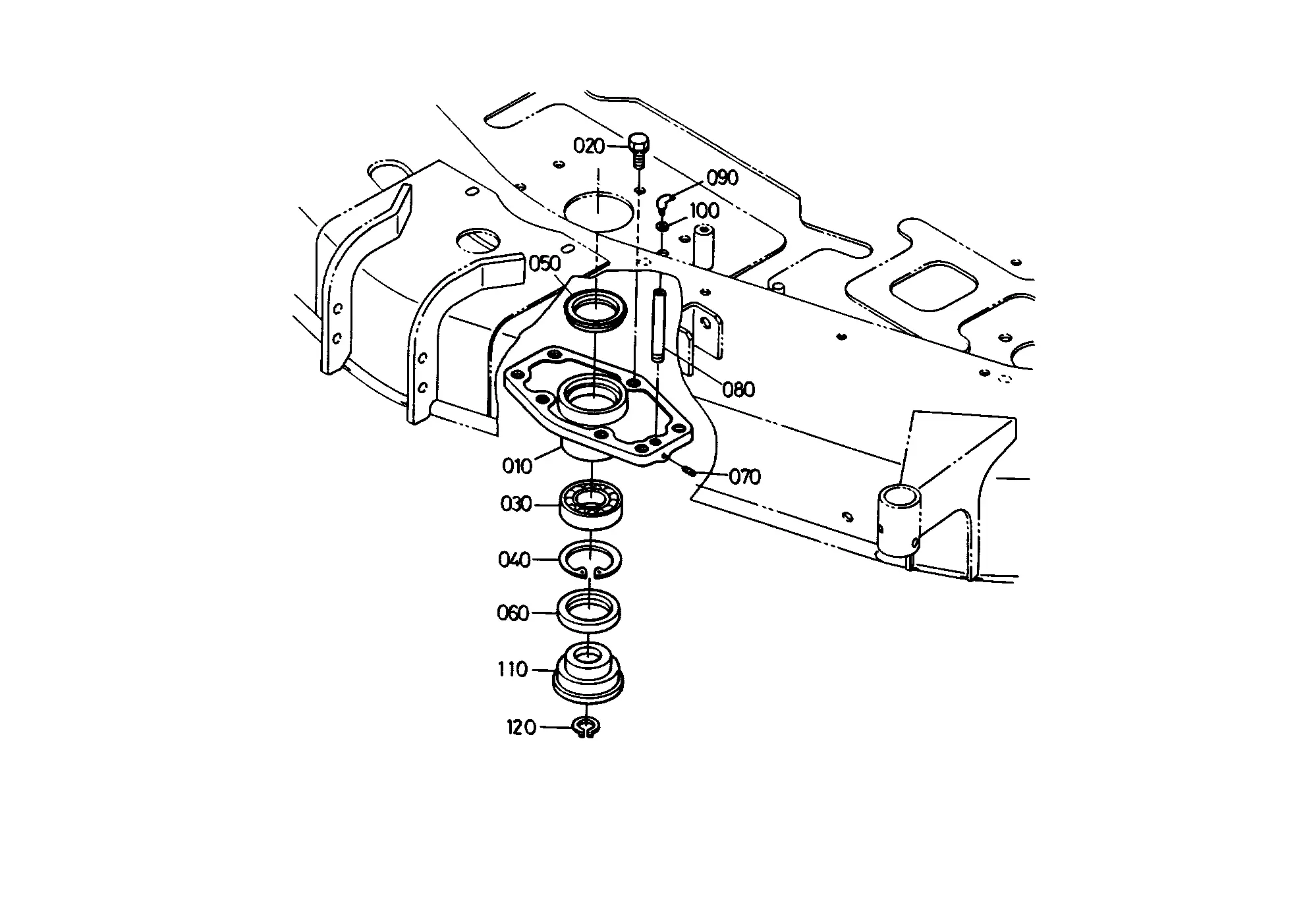

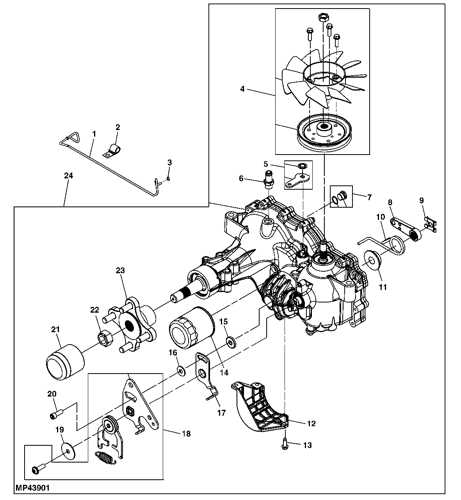

Common Deck Components Explained

This section provides an overview of essential components that contribute to the functionality and efficiency of a mowing platform. Understanding these elements can enhance maintenance practices and improve overall performance.

- Blades: The primary cutting elements responsible for achieving a clean and precise cut. Regular sharpening is crucial for optimal performance.

- Spindles: These house the bearings and support the blades, ensuring smooth rotation during operation.

- Housings: Enclosures that protect internal components and help direct grass clippings for an even discharge.

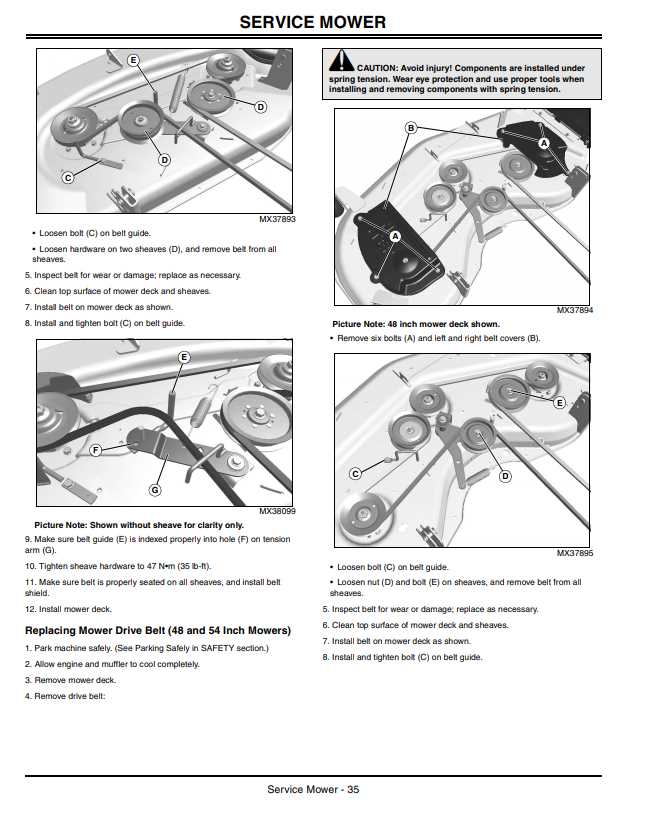

- Belts: Drive belts transmit power from the engine to the blades, crucial for their operation.

- Anti-scalp wheels: These prevent the cutting unit from scalping the ground, particularly on uneven surfaces.

Each of these components plays a significant role in the overall function, and understanding their characteristics can lead to better upkeep and longevity of the equipment.

Identifying Parts with Diagrams

Understanding the components of machinery can often be daunting, but visual aids play a crucial role in simplifying this process. Utilizing detailed illustrations helps enthusiasts and professionals alike to recognize and locate specific elements, streamlining maintenance and repairs. These visual representations serve as a roadmap, guiding users through the intricacies of assembly and function.

By examining diagrams, one can quickly pinpoint the various segments and their respective roles. This not only enhances knowledge but also fosters confidence when handling equipment. Below is a simple representation of common elements that may be found in such illustrations:

| Component | Description |

|---|---|

| Housing | Protective shell that encases internal mechanisms. |

| Blade | Cutting edge that performs the primary function of the equipment. |

| Drive Belt | Transmits power from the engine to the cutting mechanism. |

| Spindle | Supports and allows the rotation of the blade. |

| Mounting Bracket | Secures components in place for stability and safety. |

Using these illustrations effectively can drastically improve efficiency in understanding and maintaining various machinery. By referring to well-crafted visuals, operators can ensure they are fully aware of the assembly and functionality of each segment, leading to enhanced performance and longevity of the equipment.

Maintenance Tips for Z425 Deck

Proper upkeep of your mower’s cutting mechanism is essential for optimal performance and longevity. Regular care not only enhances efficiency but also ensures safety during operation. Here are some practical suggestions to maintain your equipment effectively.

Regular Cleaning

Keeping the cutting area free from debris is crucial. Grass clippings and dirt can accumulate, affecting performance and cutting quality. Follow these steps:

- Inspect the area after each use.

- Use a brush or scraper to remove built-up material.

- Rinse with water occasionally, ensuring all components are dry afterward.

Blade Maintenance

Sharp blades are key to achieving a clean cut. Dull blades can damage the grass and lead to uneven results. Consider the following:

- Check blades regularly for wear and damage.

- Sharpen blades at least once per season or more often if used frequently.

- Replace blades if they are excessively worn or nicked.

By adhering to these maintenance practices, you can ensure your mower operates smoothly and efficiently, providing the best results for your lawn care needs.

Common Issues and Solutions

Maintaining outdoor equipment is essential for ensuring optimal performance and longevity. Over time, users may encounter various challenges that can hinder operation. Understanding these issues and knowing how to address them can save both time and resources.

Below are some frequent problems along with effective solutions:

-

Uneven Cutting:

This issue often arises from improper blade height or dull blades.

- Check and adjust the cutting height settings.

- Inspect and sharpen or replace the blades as needed.

-

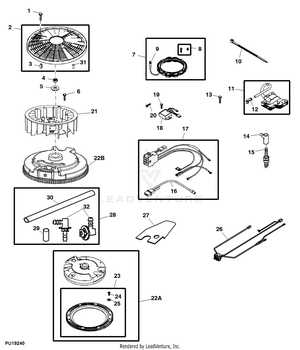

Engine Starting Difficulties:

Starting problems may stem from fuel issues or electrical components.

- Ensure the fuel is fresh and the lines are clear.

- Examine the battery and connections for corrosion.

-

Excessive Vibration:

Vibrations can indicate imbalanced components or loose fasteners.

- Inspect blades for any damage or imbalance.

- Tighten any loose bolts or screws.

-

Clogged Discharge Chute:

A blocked chute can disrupt grass flow and performance.

- Regularly clear debris from the chute.

- Ensure the cutting area is free of thick grass or obstacles.

By identifying these common issues and implementing the suggested solutions, users can maintain their equipment in peak condition and enhance its efficiency.

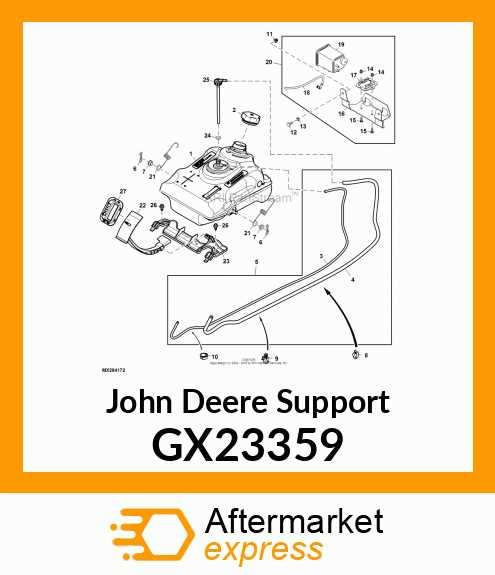

Where to Find Replacement Parts

Locating suitable components for lawn care equipment can be a straightforward task if you know where to look. Various sources provide access to essential items, ensuring your machinery operates efficiently and effectively.

One of the most reliable options is authorized retailers, which offer original components designed specifically for your model. These establishments often maintain a comprehensive inventory and can assist with identifying the correct replacements.

Online marketplaces also present a vast selection, allowing you to compare prices and find items from different suppliers. Websites dedicated to gardening tools and machinery frequently feature detailed descriptions and user reviews, helping you make informed choices.

Another valuable resource is local repair shops, where experienced technicians can provide guidance on suitable replacements and may even have parts available for immediate purchase. Additionally, forums and online communities focused on lawn maintenance often share tips and recommendations for sourcing quality components.

Finally, consider second-hand options such as auctions or classified ads, which can offer significant savings. Just ensure that you verify the condition and compatibility of the components before making a purchase.

Compatibility with Other Models

This section explores the potential for interchangeability among various machinery offerings from the same brand. Understanding these connections can enhance maintenance efficiency and allow for easier access to components across different models.

Interchangeable Components

Many parts designed for one model may also function seamlessly in others, promoting versatility. This compatibility can significantly reduce downtime during repairs and facilitate quicker access to necessary items.

Considerations for Compatibility

While many items may be interchangeable, it is essential to verify specifications to ensure proper fit and function. Consulting the manufacturer’s documentation or seeking expert advice can provide clarity on compatibility and help avoid costly errors.

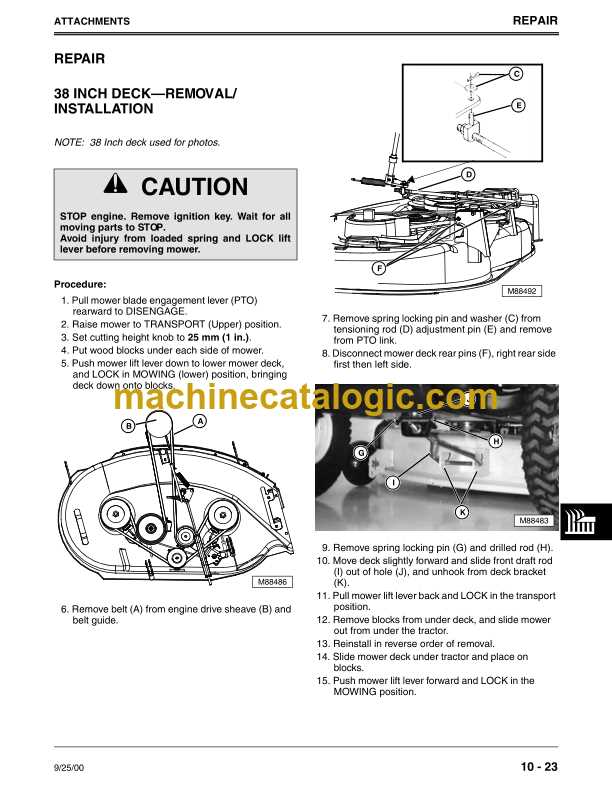

DIY Repairs: A Step-by-Step Guide

Engaging in maintenance tasks on your outdoor equipment can be both rewarding and cost-effective. This guide aims to empower you with the knowledge needed to tackle common repair challenges effectively. By following these steps, you can enhance the performance and longevity of your machinery without the need for professional help.

Understanding Your Equipment

Before starting any repair work, it is essential to familiarize yourself with the machinery’s components. Gather relevant manuals or resources that detail its structure and functionality. Identify the specific areas that require attention, whether it’s issues with the cutting mechanism or motor performance. Having a clear understanding of the layout will make the repair process smoother and more efficient.

Step-by-Step Repair Process

Once you have a comprehensive overview, proceed with the following steps:

- Gather Tools: Ensure you have all necessary tools, such as wrenches, screwdrivers, and safety gear.

- Disassemble Components: Carefully remove parts that need inspection or replacement. Take notes or photos to remember their arrangement.

- Inspect for Damage: Look for wear and tear, rust, or other issues that may affect functionality.

- Replace or Repair: Depending on your findings, either replace the faulty parts or make necessary adjustments.

- Reassemble: Put everything back together in the reverse order of disassembly, ensuring all connections are secure.

- Test: Once reassembled, run the equipment to verify that repairs have been successful.

By following this guide, you can confidently perform repairs, ensuring your outdoor machinery operates smoothly and efficiently.

Tools Needed for Deck Maintenance

Proper upkeep of your mowing platform requires specific implements to ensure optimal performance and longevity. Utilizing the right tools not only simplifies the maintenance process but also enhances the effectiveness of your efforts.

Essential Tools

- Wrench Set

- Screwdriver Set

- Socket Set

- Grease Gun

- Wire Brush

- Cleaning Cloths

Additional Equipment

- Safety Goggles

- Work Gloves

- Pressure Washer

- Measuring Tape

- Oil Change Kit

User Experiences and Reviews

This section delves into the insights and opinions shared by users regarding their experiences with various components and maintenance practices. By examining real-life feedback, potential buyers can gain valuable perspectives that help inform their decisions.

| User | Experience | Rating |

|---|---|---|

| Mark S. | Reliable performance with easy maintenance. | 4.5/5 |

| Linda T. | Impressive durability, but some parts are pricey. | 4/5 |

| James R. | Excellent cut quality, though a bit noisy. | 4/5 |

| Sarah K. | Great for large lawns, very efficient. | 5/5 |