Kubota ZD1211 Deck Parts Diagram Overview

When it comes to maintaining your lawn care equipment, having a clear understanding of its individual elements is crucial. A comprehensive visual representation of these components can significantly enhance your ability to perform effective repairs and maintenance. By familiarizing yourself with each segment of your machine, you can ensure its longevity and optimal performance.

This section will guide you through the intricate layout of your mower’s components, offering insights into their specific functions and interconnections. Each piece plays a vital role in the overall operation, contributing to the efficiency and reliability of the entire system. A well-organized reference can serve as a valuable tool for both novice and experienced users.

Moreover, knowing the configuration of your equipment empowers you to tackle common issues independently. Whether you’re replacing a worn-out element or troubleshooting a malfunction, this knowledge equips you to make informed decisions and take action swiftly. Embracing this understanding leads to a more rewarding and productive experience with your lawn care machine.

This section serves as an introduction to the specific model of the lawn maintenance equipment. Understanding the essential features and functions will provide a solid foundation for delving deeper into its components and operations. This overview will highlight the key attributes and capabilities that make this equipment stand out in its category.

- General specifications

- Engine performance and features

- Operational efficiency

- Unique selling points

- Comparative advantages over similar models

- Maintenance recommendations

- User experience and feedback

- Common issues and troubleshooting tips

- Accessorizing options

- Future models and enhancements

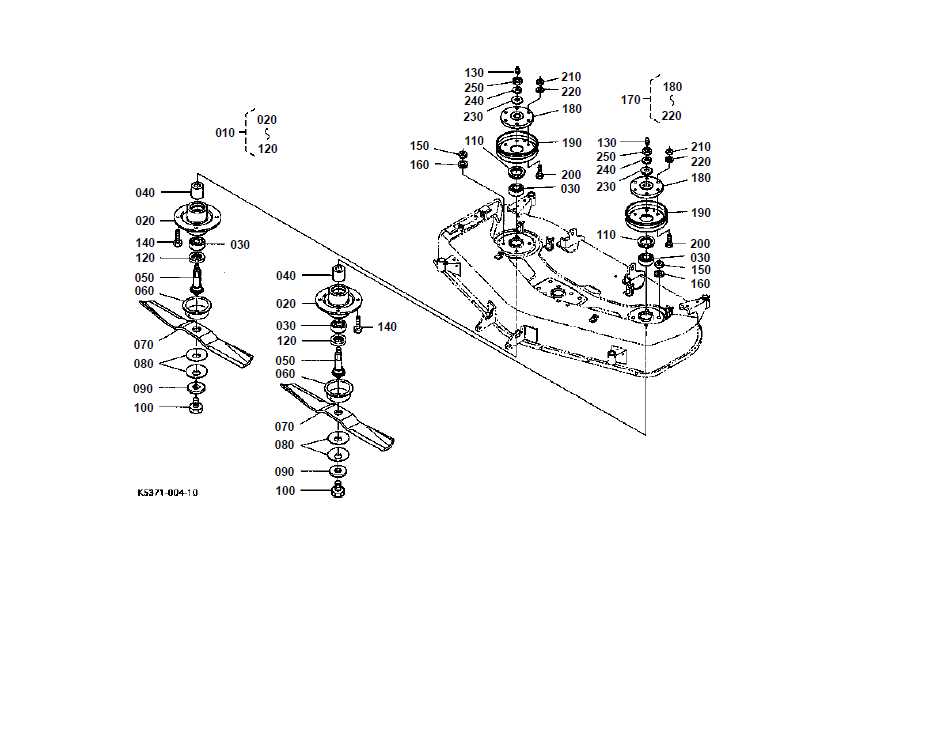

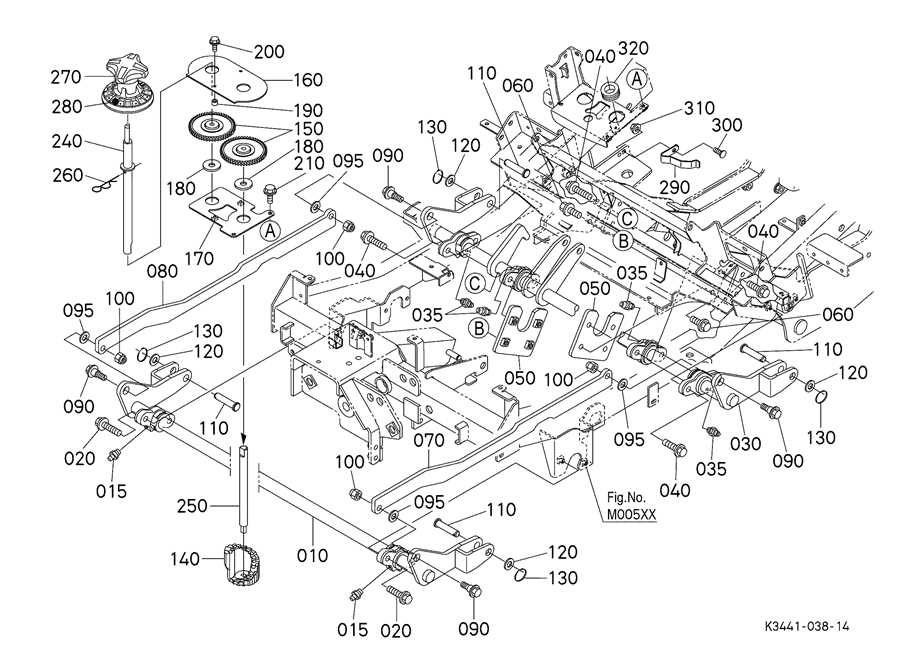

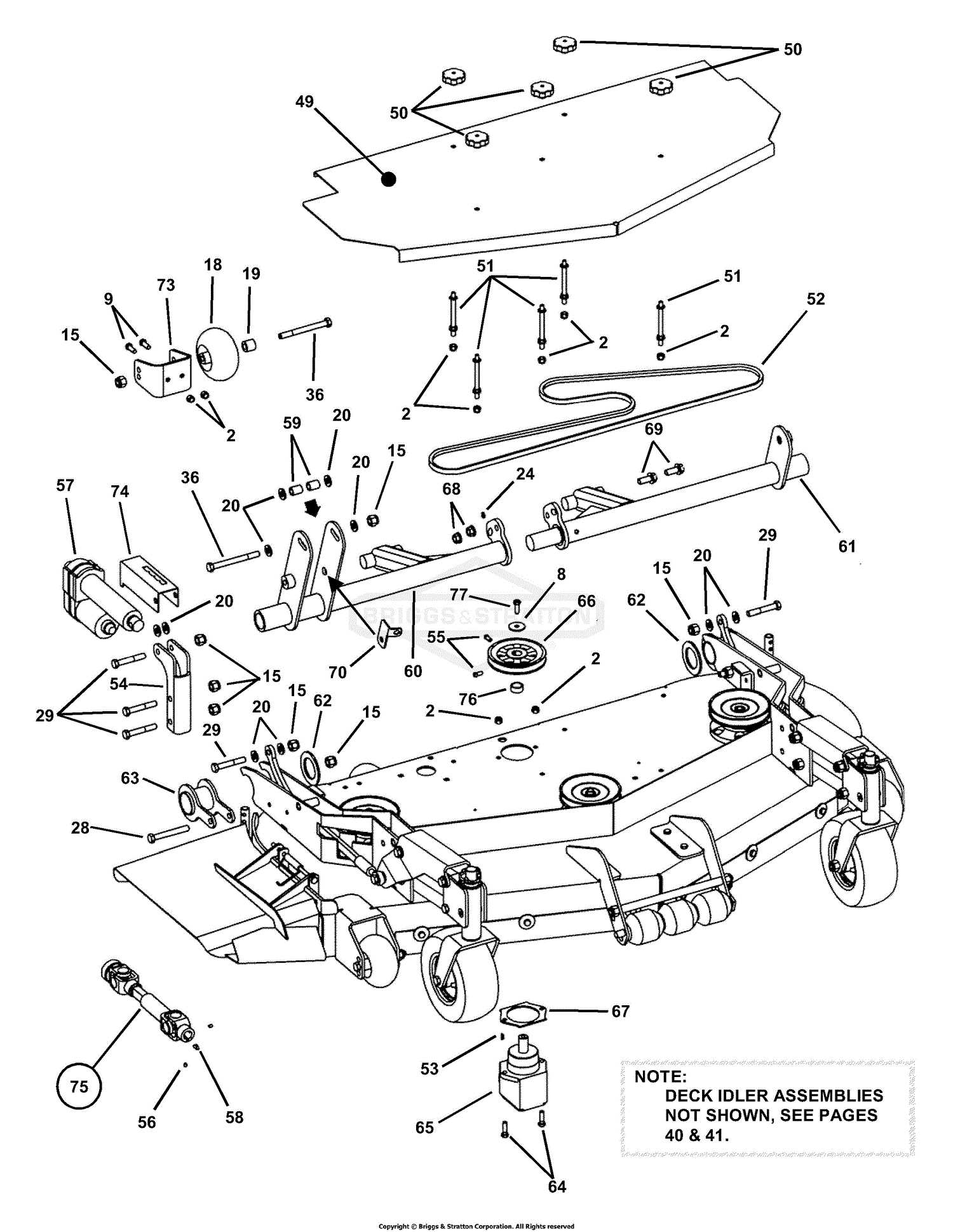

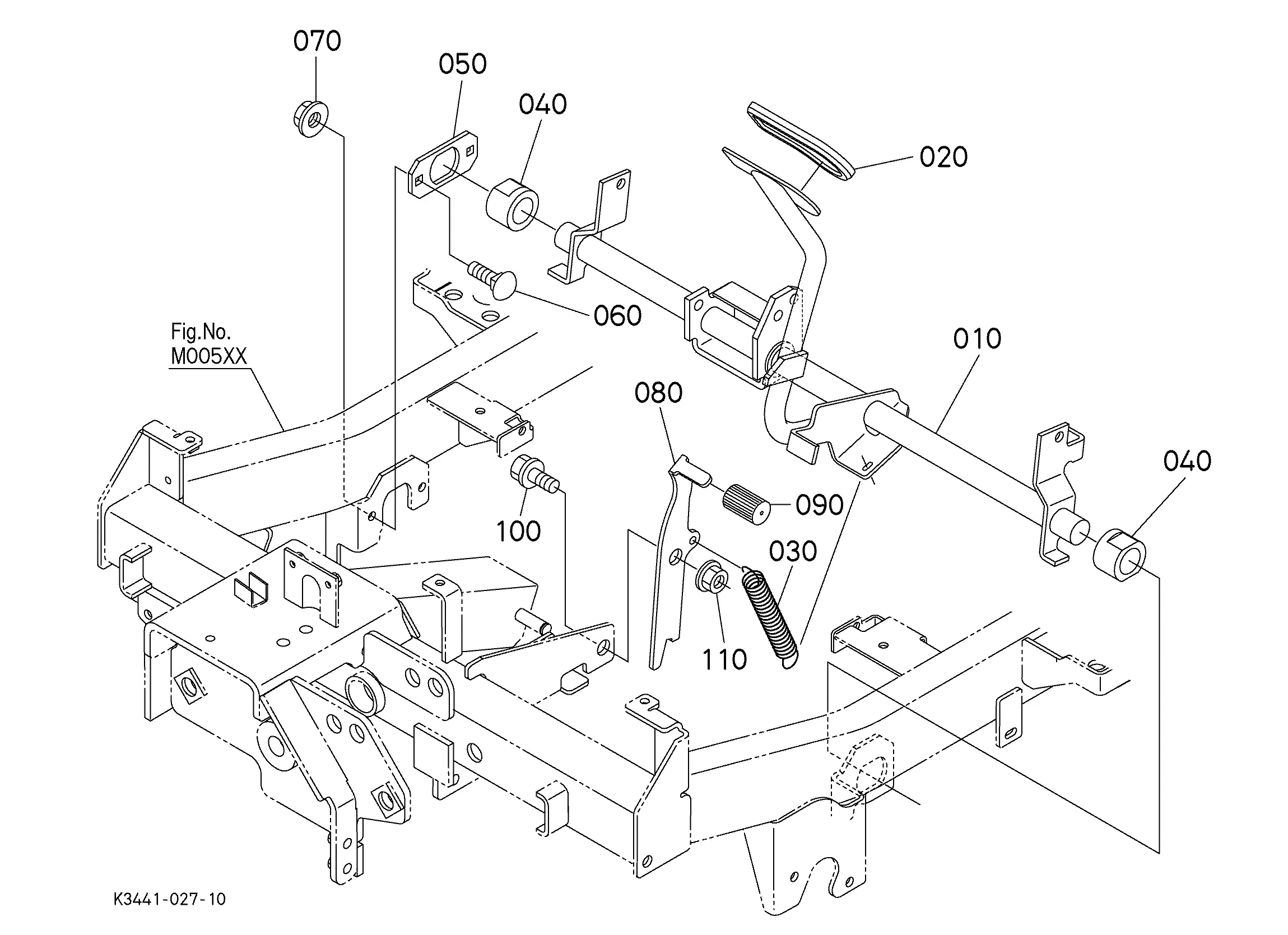

Understanding Deck Assembly Components

The assembly of a cutting mechanism in lawn maintenance equipment consists of various essential elements, each playing a crucial role in the overall functionality. A comprehensive understanding of these components is vital for ensuring optimal performance and maintenance of the machinery.

Key Components of the Assembly

- Cutter Blades: These sharp elements are responsible for trimming grass to the desired height.

- Spindle Housing: This component houses the spindle, which connects to the blades and enables rotation.

- Belt System: The belts transfer power from the engine to the blades, ensuring efficient operation.

- Chassis: The structural framework supports all other components and provides stability during operation.

- Adjustable Hangers: These allow for height adjustments of the cutting elements to suit different grass lengths.

Maintenance Considerations

- Regularly inspect the blades for wear and sharpness to maintain cutting efficiency.

- Ensure the spindle housing is free from debris to prevent overheating and damage.

- Check the belt tension periodically to avoid slippage and premature wear.

- Lubricate moving parts to reduce friction and extend the lifespan of components.

- Keep the chassis clean and free from grass clippings to prevent rust and deterioration.

Key Parts of the Mower Deck

Understanding the essential components of a cutting mechanism is crucial for effective maintenance and operation. Each element plays a significant role in ensuring optimal performance, contributing to a smooth and efficient mowing experience. Familiarizing oneself with these components can enhance longevity and reliability.

Cutting Blades

Cutting blades are the primary tools responsible for trimming grass. These sharp implements are designed to slice through vegetation cleanly and efficiently. Regular inspection and sharpening are vital to maintain their effectiveness and prevent damage to the lawn.

Spindles

Spindles serve as the rotating shafts that hold the blades in place. They facilitate smooth movement, allowing the blades to rotate at high speeds. Ensuring that spindles are well-lubricated and free from debris is essential for uninterrupted operation.

Importance of Proper Maintenance

Regular upkeep of machinery is essential for ensuring optimal performance and longevity. When equipment is maintained correctly, it functions more efficiently, reducing the risk of unexpected breakdowns and costly repairs. This proactive approach not only enhances reliability but also improves overall safety during operation.

Neglecting maintenance can lead to serious consequences. Components may wear down faster, resulting in decreased effectiveness and potential hazards. Additionally, regular inspection and servicing can help identify minor issues before they escalate into major problems, saving both time and resources.

Ultimately, investing in maintenance is an investment in the future. It fosters a culture of care and responsibility, ensuring that the machinery remains in peak condition for years to come. Proper maintenance is not just a task; it is a vital practice that safeguards the functionality and safety of any equipment.

Common Issues with Deck Parts

When operating any outdoor machinery, it is essential to be aware of potential challenges that may arise with the cutting mechanism. Understanding these common difficulties can enhance performance and longevity. This section addresses typical concerns that users may encounter, along with possible solutions.

Wear and Tear

One frequent issue is the natural degradation of components over time. Constant exposure to various conditions can lead to wear on blades and other elements, diminishing their effectiveness. Regular inspections can help identify these problems early, allowing for timely replacements to maintain optimal functionality.

Blockages

Another common challenge involves obstructions caused by debris, such as grass clippings and dirt. These can hinder movement and affect the overall efficiency of the system. Clearing these blockages regularly is crucial to ensure smooth operation and prevent potential damage to the machinery.

Tools Needed for Deck Repairs

When it comes to maintaining and fixing lawn equipment, having the right tools is essential for effective repairs. Ensuring that you are well-equipped can save you time and enhance the quality of your work. This section outlines the necessary implements for efficient restoration tasks.

- Wrenches: Various sizes are needed to remove and tighten bolts.

- Screwdrivers: A set of both flathead and Phillips screwdrivers will help in dealing with different fasteners.

- Socket Set: A complete socket set allows for quick and easy access to nuts and bolts in tight spaces.

- Pliers: These are useful for gripping and manipulating small components.

- Cutting Tools: A sharp utility knife or scissors is needed for cutting through belts or materials.

- Measuring Tools: A tape measure or calipers ensure accurate measurements during the repair process.

- Safety Gear: Always wear gloves and safety glasses to protect yourself while working.

By gathering these essential tools beforehand, you can streamline your repair process and achieve satisfactory results in maintaining your equipment.

Step-by-Step Assembly Guide

This section provides a comprehensive guide for assembling the equipment effectively. Following these instructions carefully will ensure a smooth and efficient setup, enhancing the overall functionality of the machine. It is essential to work methodically to prevent any mistakes that could lead to complications later on.

Gather Your Tools and Components

Before starting the assembly, collect all necessary tools and components. Ensure that you have everything within reach, including screws, bolts, and other hardware. Having the right tools at hand will facilitate a seamless construction process.

Follow the Assembly Steps

Begin the assembly process by carefully reading the instructions provided. Start with the base and gradually work your way up. Ensure that each component is securely fastened before moving on to the next part. Pay close attention to alignment and positioning, as this is crucial for the overall stability and performance of the equipment.

Safety Tips During Maintenance

Maintaining machinery is crucial for its longevity and performance, but it also involves certain risks. Prioritizing safety during these procedures can prevent accidents and injuries. Understanding the proper protocols ensures that maintenance tasks are conducted effectively and without harm.

Always wear appropriate personal protective equipment, such as gloves and safety glasses, to shield against potential hazards. Before beginning any work, ensure that the equipment is turned off and disconnected from any power source to eliminate the risk of accidental activation. Familiarize yourself with the machinery’s user manual to understand its components and recommended maintenance practices.

Maintain a clean and organized workspace to avoid trips and falls. Keep tools and materials in designated areas, and be mindful of where you place your hands and feet while working. If you’re using sharp or heavy tools, exercise caution and use them as intended to reduce the risk of injury.

When working with fluids, such as oils or fuels, follow proper handling guidelines to prevent spills and leaks. Dispose of any waste materials responsibly and in accordance with local regulations. Lastly, if you encounter any unfamiliar issues or feel uncertain about a procedure, don’t hesitate to seek assistance from a qualified professional.

Where to Find Replacement Parts

When it comes to maintaining and repairing your outdoor machinery, locating quality components is essential for ensuring optimal performance. There are several avenues to explore when seeking suitable alternatives to worn or damaged elements.

Here are some reliable sources to consider:

- Authorized Dealers: Visiting a certified distributor can provide access to genuine components tailored for your equipment.

- Online Retailers: Numerous e-commerce platforms offer a wide selection of alternatives, often featuring customer reviews to help you make informed decisions.

- Local Repair Shops: Engaging with nearby repair facilities can yield insights into the best components available in your area, along with expert installation services.

- Second-hand Markets: Exploring local classifieds or online marketplaces may uncover pre-owned options at a lower cost, though quality checks are crucial.

By considering these sources, you can ensure that your machinery remains in excellent working condition for years to come.

Comparative Analysis with Other Models

This section aims to explore the distinctions and similarities between various models within the same category, focusing on their design, functionality, and overall performance. By examining these factors, users can make informed decisions based on their specific needs and preferences.

When comparing different models, several key aspects should be considered:

- Design and Build Quality: Each model presents unique construction characteristics, influencing durability and ease of maintenance.

- Performance Metrics: Evaluating horsepower, cutting efficiency, and operational speed can help highlight strengths and weaknesses across different units.

- Operational Features: Features such as maneuverability, ease of use, and comfort during operation significantly affect user experience.

- Availability of Replacement Components: Access to spare parts can vary greatly, impacting long-term maintenance and serviceability.

- Price Point: Comparing initial costs alongside maintenance expenses is essential for understanding the total investment required for each model.

In summary, analyzing these factors allows potential buyers to appreciate the nuances between different models, ensuring they select the best option that aligns with their operational requirements.

Owner Reviews and Experiences

This section aims to gather insights and impressions from users regarding their experiences with their lawn care equipment. Feedback from owners can provide valuable information on performance, reliability, and ease of use, helping potential buyers make informed decisions.

Many users appreciate the durability of their machines, highlighting how they withstand various conditions while maintaining efficiency. Owners often report a significant improvement in their landscaping tasks, noting the smooth operation and power of their equipment.

Some reviews emphasize the importance of maintenance and how straightforward the upkeep process can be. Owners share their experiences with routine checks and the accessibility of components, making it easier to keep the machinery in optimal condition.

Additionally, users frequently comment on the user-friendly design and comfort features, which enhance the overall experience. Many find that these attributes reduce fatigue during prolonged use, allowing them to complete their tasks more efficiently.

Overall, the collective feedback from owners offers a comprehensive view of the product’s capabilities, guiding future customers in their purchasing choices.