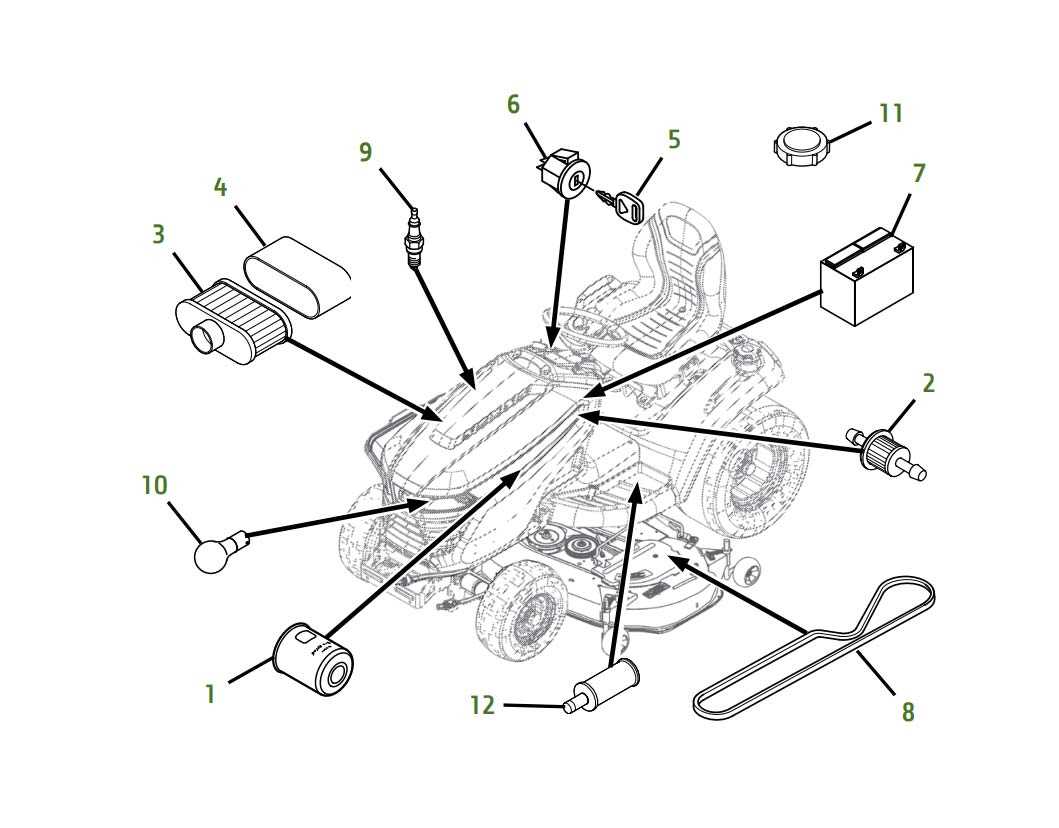

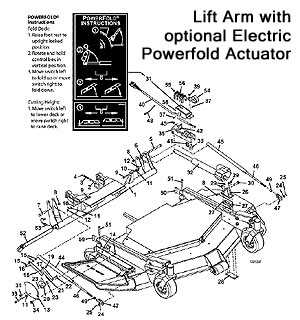

Mower Deck Parts Breakdown

When it comes to maintaining a well-kept lawn, one of the most crucial factors is ensuring that your machine operates efficiently. To achieve this, it’s essential to have a clear understanding of the various elements that make up the mechanism responsible for trimming the grass. Each component plays a vital role in delivering a smooth and even cut, making regular inspection and maintenance a priority.

In this section, we will explore the essential components that come together to form the cutting system. These elements are intricately connected, ensuring that the machine functions as intended. By identifying these crucial parts, you can ensure that your equipment performs optimally, leading to a healthier and more attractive lawn.

We will also touch on how these components interact with one another, allowing for precise adjustments and repairs. Proper knowledge of these key elements will not only extend the life of your equipment but also improve its

Mower Deck Components Overview

The various elements that make up a cutting platform are essential for its proper operation and performance. Each component plays a specific role in ensuring that the cutting process is smooth and efficient. Understanding the function of these elements helps in maintaining and optimizing the machine’s effectiveness over time.

Key structural elements are connected and work together to provide balance and precision during the cutting process. These parts are designed to handle different terrains and vegetation types, ensuring consistent results. Regular inspection and care of these elements will extend the life of the equipment and improve its performance.

Understanding the Structure of a Mower Deck

The mechanical foundation of grass-cutting equipment plays a crucial role in ensuring effective and smooth operation. Every element works in harmony to deliver precision in trimming, enabling the machine to function at its best. Grasping the internal layout is key to maintaining the longevity and efficiency of the entire system.

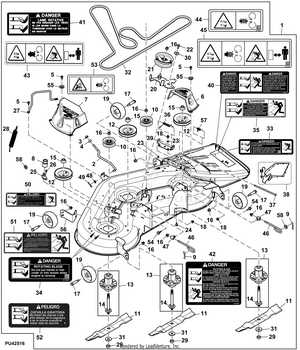

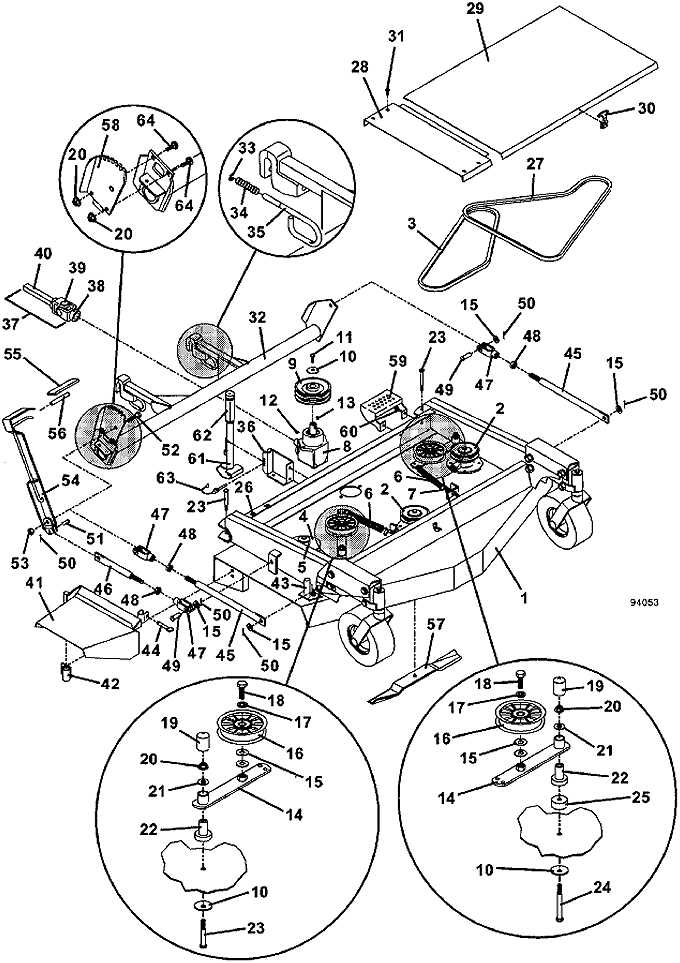

Blade Assembly forms the heart of the device, where sharp edges rotate to cut grass evenly. Proper maintenance of this area is essential to ensure consistent performance. Over time, wear and tear might reduce effectiveness, making regular inspection a necessity.

Support structures are just as important, providing stability during operation. These components keep everything aligned and prevent vibrations from affecting the quality of the cut. Ensuring these parts remain in good condition is crucial for overall

Key Parts of a Mower Deck Assembly

The mechanical foundation beneath cutting equipment consists of various essential components that work together to ensure smooth and efficient grass trimming. Understanding the primary elements of this assembly is crucial for maintaining functionality and extending the lifespan of the cutting machine. Below, we will explore the most important aspects of this structure and their roles in the operation.

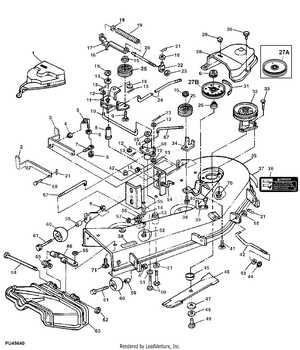

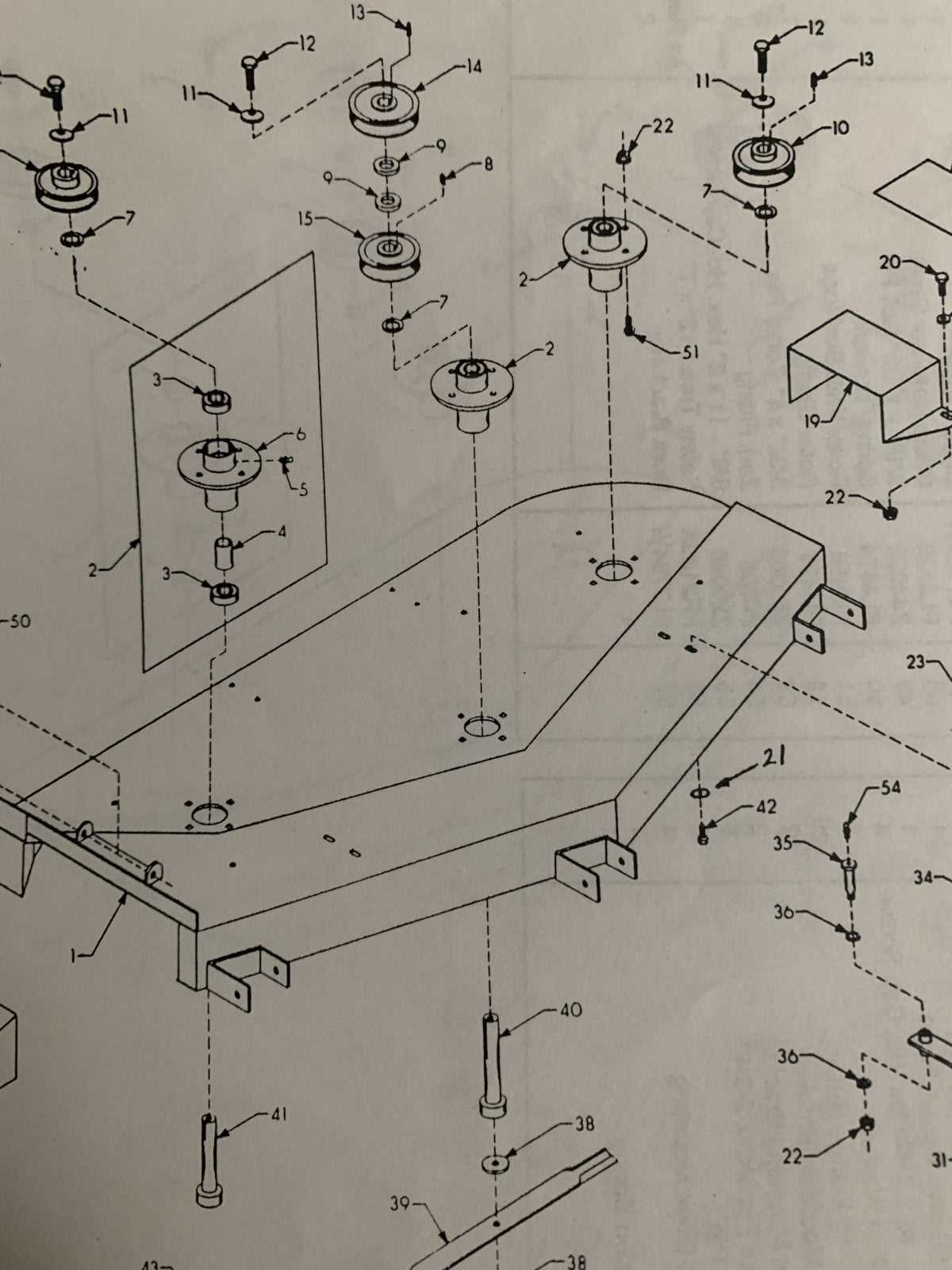

Structural Framework Components

The structural foundation holds the various mechanical systems together. It provides support for the cutting blades, housing the spindles and allowing for a stable attachment to the machinery. This frame also protects the internal mechanisms from external debris and wear.

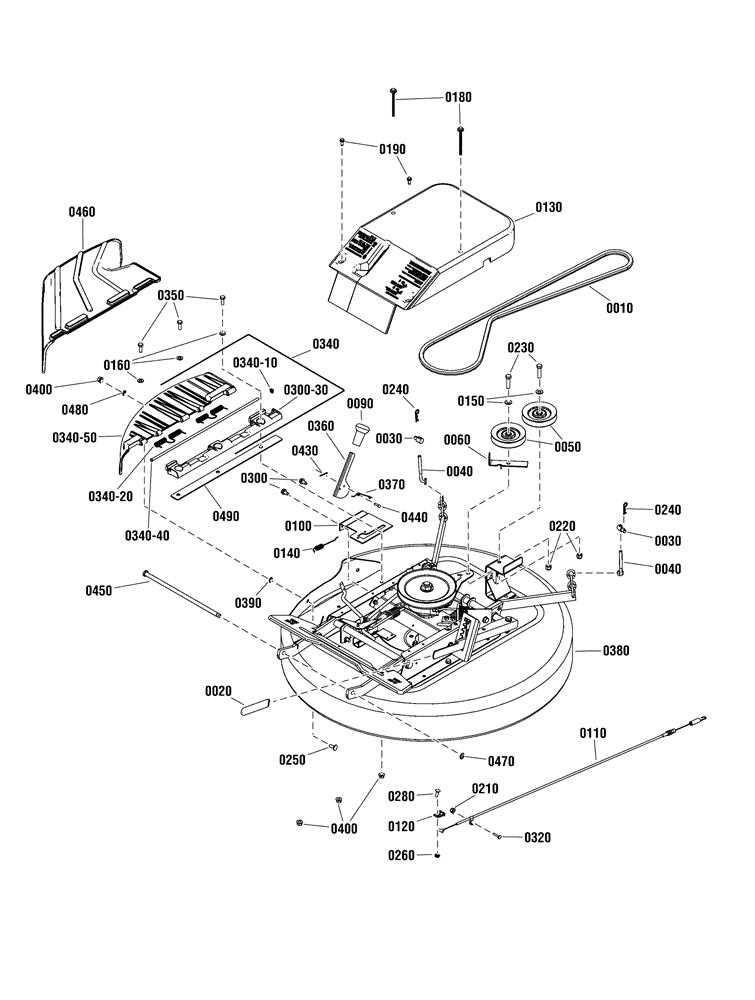

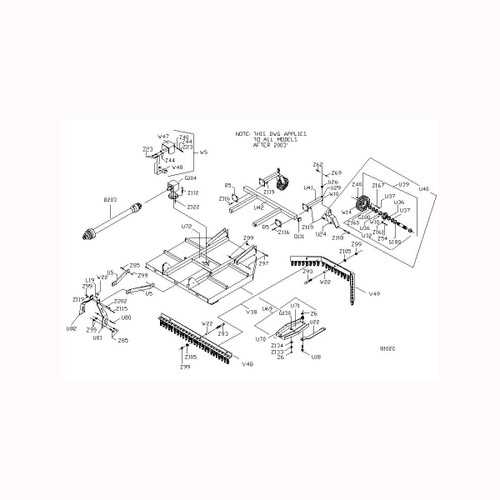

Rotational and Cutting Mechanism

At the core of this assembly are the rotating components that power the trimming blades. These elements include the spindles, belts, and pulleys that enable the blades to spin at high speeds, cutting through the grass. Regular maintenance of these parts is vital for optimal performance.

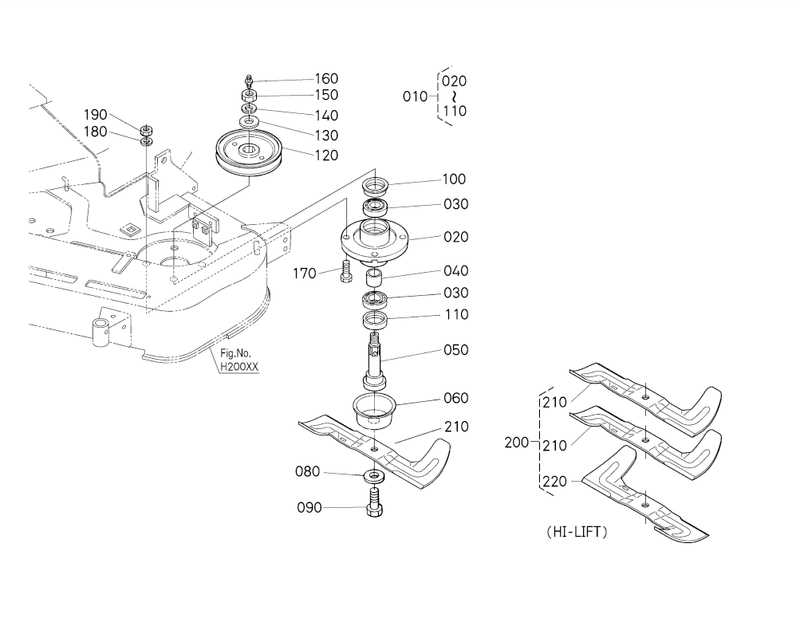

How Blades Work in a Mower Deck

The cutting components in a lawn machine play a vital role in trimming grass to an even length. They rotate at high speeds, creating a vacuum effect that lifts the blades of grass, making it easier to achieve a uniform cut. The way they function directly impacts the efficiency of the entire cutting system, ensuring a clean and consistent trim every time.

Rotation and Cutting Mechanism

The sharp edges of these rotating tools slice through grass efficiently as they spin. The faster the rotation, the more precise the cut. The design of these tools often includes angled surfaces that help to push the cut grass aside, preventing clumping and ensuring smooth operation.

Impact on Performance

The sharpness and balance of the cutting tools are essential for maintaining optimal performance. Dull or imbalanced tools can lead to uneven cutting, straining the engine and reducing overall effectiveness. Regular maintenance

Spindle Mechanism and Its Function

The spindle mechanism plays a vital role in the operation of cutting tools by facilitating the smooth rotation of blades. It serves as the central component that ensures efficient and precise movement, allowing for optimal performance during cutting processes. Understanding the function of this mechanism is essential for maintaining the longevity and effectiveness of the equipment.

| Component | Purpose | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Spindle Shaft | Transfers power from the engine to the blades. | ||||||||||||||||||||||

| Bearings | Allow for smooth and stable rotation of the spindle shaft. | ||||||||||||||||||||||

| Housing | Encases the spindle components, protecting them from external elements. | ||||||||||||||||||||||

| Importance of the Belt System

The belt mechanism plays a crucial role in the proper functioning of the cutting equipment. It ensures smooth operation by transmitting power from the engine to the various rotating components responsible for cutting grass. Without a well-functioning belt system, the efficiency of the entire system can significantly decrease, leading to performance issues and increased wear on other parts. Efficiency and Power TransferA well-maintained belt system ensures that power is evenly distributed, allowing the blades to operate with precision. It helps maintain a consistent cutting speed, ensuring uniform results across different terrains. When the belt system is compromised, it can lead to uneven cutting and put additional strain on the engine. Prevention of Wear and TearPulley System in a Lawn Mower Deck

The pulley assembly plays a crucial role in the efficient operation of a grass cutting unit. It functions as a mechanical link, transmitting power from the engine to the blades. This system ensures the blades rotate at the optimal speed, providing a clean and even cut. Without this essential component, the machine’s cutting performance would be significantly compromised. Components of the Pulley MechanismThe system consists of multiple pulleys, belts, and sometimes idler components. Each pulley serves as a connection point that guides the belt in the correct direction, ensuring proper tension and movement. The primary pulley, often linked to the engine, is responsible for initiating the motion. Other smaller pulleys help to adjust the speed and rotation direction of the blades. Importance of Maintenance

Regular inspection and maintenance of the pulley system are necessary to prevent issues like belt slippage or pulley misalignment. Over time, wear and tear can affect the efficiency of the system, leading to reduced cutting performance. Ensuring the pulleys and belts are properly lubricated and tensioned will extend the lifespan of the equipment and improve its overall functionality. Role of the Deck Shell in MowersThe shell structure of a grass cutting machine plays a crucial role in ensuring the smooth operation and longevity of the equipment. Its primary function is to house the essential components that interact directly with the ground, such as blades and the cutting mechanism. This element serves as a protective barrier, shielding the internal parts from external elements like debris and moisture, while also aiding in the efficient collection or discharge of grass clippings.

Common Issues with Mower Deck PartsMaintaining the key components of your cutting equipment is essential for smooth operation. However, over time, certain issues can arise that affect its performance. These problems often stem from wear and tear, incorrect adjustments, or lack of regular upkeep. Identifying and addressing these issues early can prevent further damage and ensure optimal performance.

By recognizing these common issues, you can take proactive steps to keep your machine functioning at its best. Maintenance Tips for Mower Deck ComponentsRegular upkeep of the essential elements responsible for cutting and trimming is vital to ensure efficient operation and prolong the lifespan of your equipment. Taking proper care of these critical components can prevent costly repairs and optimize performance during use. Cleaning and Debris RemovalOne of the most important aspects of maintenance is keeping the blades and surrounding areas free from grass, dirt, and other debris. This buildup can reduce the efficiency of the cutting mechanism and cause undue wear. Always clean these parts thoroughly after each use to maintain optimal functionality. Lubrication and AdjustmentProper lubrication is crucial for reducing friction and wear on moving elements. Ensure that all moving parts, including the spindles and bearings, are well-oiled. Additionally, regular adjustments to ensure the components are aligned and operating smoothly will prevent uneven cutting and damage over time. Replacing Worn Out Deck PartsOver time, certain components of your lawn care equipment may experience wear and tear, reducing its efficiency and performance. Replacing these worn-out elements ensures that your machine continues to operate smoothly and provides a cleaner, more even cut. Timely replacement also helps to prevent further damage to other parts, which could lead to more costly repairs in the future. Identifying Signs of Wear

When inspecting your equipment, there are common indicators that suggest specific components need replacing. These can include irregular cutting, uneven grass levels, or unusual vibrations during operation. Regular maintenance checks help catch these issues early before they become major problems. Choosing the Right Replacement ComponentsEnsure you select high-quality replacement components that are compatible with your machine’s model. Opting for original or recommended parts is crucial for maintaining peak performance. Compatibility is essential to ensure proper fit and function, so always double-check specifications before making a purchase.

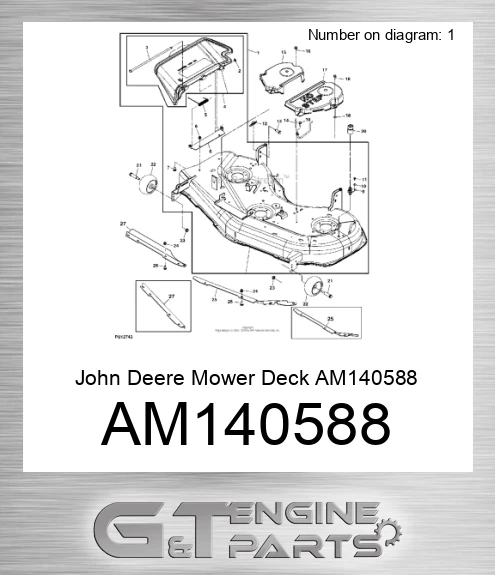

Choosing the Right Mower Deck Parts

When it comes to maintaining a lawn care machine, selecting the correct components is essential for optimal performance. Understanding the different elements that contribute to the overall functionality will ensure efficient operation and longevity of the equipment. Whether you are replacing worn-out pieces or upgrading for better efficiency, the right choices can make a significant difference. First, assess the condition of each component. Over time, wear and tear can affect various parts, from the cutting elements to the drive system. Identifying the areas that require attention allows for targeted replacement, avoiding unnecessary costs. Secondly, always choose quality materials that match the specifications of your machine. High-quality replacements will ensure smoother operation, reduce maintenance frequency, and enhance the overall lifespan of the machine. Lastly, consult your machine’s manual for compatibility. Different models may require distinct components, and using the wrong ones can lead to suboptimal performance or even damage. A thoughtful selection will ensure the machine operates at its peak potential. Upgrade Options for Mower Deck SystemsEnhancing the functionality of cutting mechanisms can significantly improve performance and efficiency. By considering a range of advanced components, users can achieve smoother operation, better durability, and a more precise cut. These upgrades are designed to optimize various aspects of the system, providing a higher level of control and longevity. One key option is the incorporation of reinforced blades. These are designed to withstand more rigorous use and deliver a cleaner, more consistent result. Additionally, upgrading to high-quality belts and pulleys can reduce wear and ensure a more reliable transmission of power. Another beneficial improvement is the installation of a mulch kit. This accessory shreds grass clippings into finer pieces, which not only improves the appearance of the lawn but also reduces the need for frequent clean-up. Furthermore, considering a quick-release system for the cutting assembly can save time during maintenance and allow for easier adjustments. |