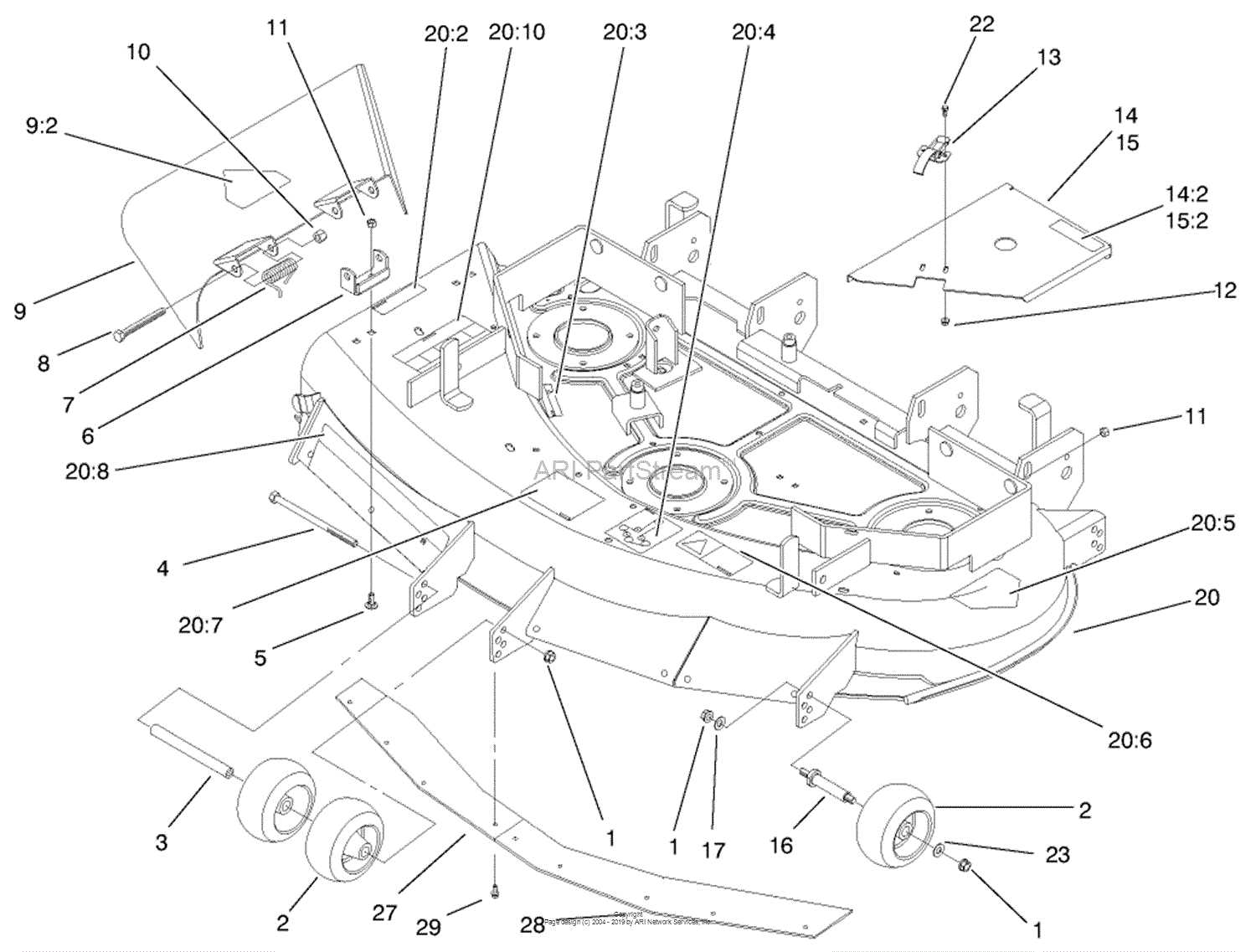

Piranha 44 Mulching Deck Parts Diagram Guide

When maintaining outdoor equipment, it’s essential to have a clear understanding of how various elements work together to ensure smooth operation. Whether you’re focusing on cutting systems or the intricate setup beneath, recognizing the key components can make servicing much easier and more efficient. This section explores the structural aspects and how each element functions as part of a whole.

We’ll take a closer look at the key features of the cutting mechanism, highlighting how different sections are interconnected. By understanding how individual components align and interact, you can ensure the optimal performance of your equipment, avoiding potential issues and ensuring longevity.

With a well-organized layout and proper knowledge of the mechanical setup, performing adjustments, repairs, or replacements becomes a more straightforward task. This guide will offer insights into the main elements that form the foundation of the cutting mechanism, helping you navigate through potential challenges.

Overview of Piranha 44 Mulching Deck

This system is designed for efficient handling of grass and other yard materials during routine lawn care. Built with a focus on performance and durability, it helps to manage vegetation by processing it in a way that enhances soil health. The structure optimizes the cutting process, allowing the operator to cover large areas effectively while ensuring that the clippings are evenly distributed across the surface.

One of the key features of this setup is its ability to maintain smooth operation even in demanding conditions. The construction supports a balanced and uniform result, making it a reliable choice for both residential and professional use. Its configuration ensures that the workload is minimized, reducing the need for frequent maintenance or adjustments.

Overall, this equipment combines user-friendly design with the ability to tackle various tasks, offering a practical solution for maintaining green spaces. The attention to detail in its engineering allows for seamless operation, providing both efficiency and ease of use for the operator.

Main Components of the Deck

Understanding the core elements of a grass-cutting platform is essential for efficient operation and maintenance. These structural and mechanical pieces work together to ensure a smooth and consistent trimming process. Below is an overview of the most important parts involved in the system.

- Blades: The cutting edges that trim the grass, typically shaped for maximum efficiency.

- Spindles: These connect the cutting edges to the system, allowing rotation and movement.

- Belts: A crucial component that transfers power from the motor to the cutting mechanism.

- Pulleys: Wheels that guide the belts and help maintain proper tension during operation.

- Housings: Protective coverings that shield internal components from debris and damage.

- Wheels: These support the entire assembly and enable smooth movement across uneven terrain.

Each of these components plays a vital

Blade Assembly and Functionality

The proper setup of cutting components is crucial for the efficiency and overall performance of lawn equipment. The system’s arrangement directly influences how effectively grass is trimmed and how well the machine operates in varying conditions. A well-balanced configuration ensures smooth movement and prevents unnecessary strain on the equipment.

Key Components in the Setup

The cutting mechanism typically consists of sharpened steel edges, secure mounting points, and stabilizers that work together to provide clean and even trimming. Proper alignment is essential, as any imbalance can lead to uneven cutting or damage to the surrounding hardware. The assembly process must prioritize precision, ensuring each element is firmly in place.

Importance of Regular Maintenance

Routine care is vital to maintain optimal performance. Sharpening the blades, inspecting for wear, and checking the tension in the mounting areas help extend the lifespan of the equipment. Regular attention to these details keeps the cutting mechanism operating at peak efficiency and prevents long-term issues.

Mulching Process Explained

The technique of finely shredding organic material to support lawn health is widely used in gardening and lawn care. This method involves transforming clippings into smaller fragments that can easily decompose and nourish the soil. The process plays a significant role in promoting a healthier, greener environment without the need for chemical fertilizers.

- Chopped fragments are left on the ground to break down naturally.

- Helps retain moisture in the soil, reducing the need for watering.

- Prevents weed growth by covering exposed soil.

- Recycles essential nutrients back into the ecosystem.

This natural approach encourages a sustainable lawn maintenance routine, benefiting both the environment and plant growth. By letting the fragments disintegrate, the soil structure improves, creating a rich, fertile base for future growth.

Deck Frame and Structural Parts

The structural framework forms the essential foundation, providing strength and durability to the overall design. It ensures proper alignment and support for other components, allowing the equipment to function efficiently under various conditions. Without a solid base, maintaining stability and balance would be impossible, especially when facing uneven terrain or demanding tasks.

Reinforcements and Supports

Key reinforcements within the frame help distribute the load evenly across the structure. These components are strategically placed to withstand both external forces and internal wear. Properly designed supports prevent deformation and extend the lifespan of the equipment by enhancing its ability to handle continuous use.

Connection Points and Fasteners

Strong connection points hold various sections together, ensuring a secure fit and preventing unnecessary movement. The choice of fasteners and their placement is critical for maintaining the integrity of the framework. Regular checks and maintenance of these elements are essential to ensure ongoing reliabil

Discharge Chute and Its Role

The discharge chute is a vital component in lawn maintenance machinery, serving a significant purpose in the efficient operation of cutting equipment. This feature plays a crucial role in managing the output of clippings, directing them away from the machine to ensure a clean and tidy finish on the lawn.

Functionality and Benefits

By channeling the cut grass and debris, the discharge chute helps prevent clogging and ensures smooth operation. An effective chute design not only enhances the performance of the equipment but also contributes to the overall health of the lawn. Properly directing the clippings can promote a more uniform distribution, allowing for better nutrient recycling back into the soil.

Maintenance Considerations

Regular upkeep of the discharge chute is essential for optimal performance. It is important to check for any blockages or wear that could impede functionality. Keeping this component in good condition not only ensures efficient clipping management but also prolongs the lifespan of the entire machine.

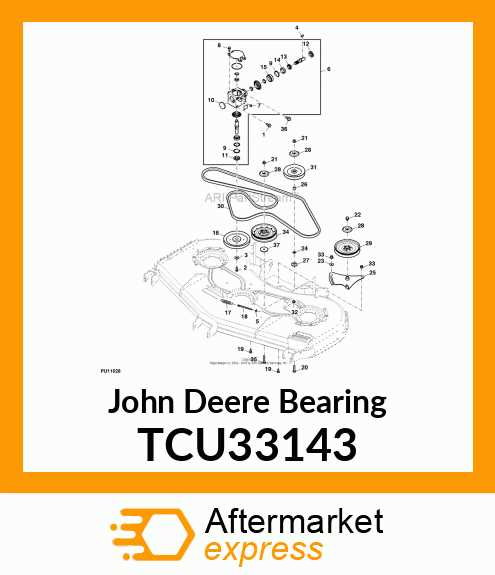

Spindle Housing and Bearings

The spindle housing and bearings play a crucial role in the overall functionality of lawn care equipment. This assembly is designed to support the rotating spindle, ensuring smooth and efficient operation. Proper maintenance and understanding of this component can significantly enhance the performance and longevity of the machinery.

Functionality of the Spindle Housing

The primary purpose of the spindle housing is to secure the spindle while allowing it to rotate freely. This structure is engineered to withstand various stresses during operation, providing stability and reducing vibrations. A well-designed housing ensures that the spindle operates without friction, contributing to optimal performance.

Importance of Bearings

Bearings are essential in minimizing friction between moving parts. They enable the spindle to rotate smoothly, reducing wear and tear over time. Regular inspection and timely replacement of bearings can prevent costly repairs and extend the life of the equipment. Utilizing high-quality bearings tailored for specific applications further enhances operational efficiency.

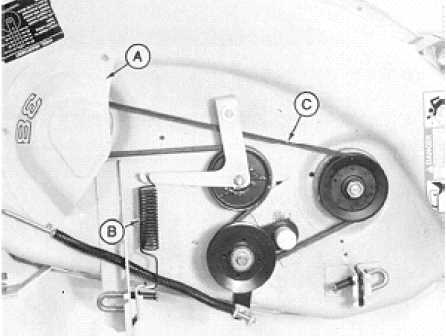

Belt System and Drive Mechanism

The efficiency of any cutting apparatus relies heavily on its transmission components. These systems play a crucial role in converting power from the engine to the cutting mechanisms, ensuring smooth operation and optimal performance. Understanding the intricacies of these systems can aid in troubleshooting and maintenance.

Key elements of the drive system include:

- Belt: Serves as the primary link between the engine and the cutting components, transferring rotational motion effectively.

- Pulleys: Facilitate the change in direction and speed of the power delivered from the engine to the blades.

- Idler Tensioner: Maintains the appropriate tension in the belt, preventing slippage and wear.

- Drive Shaft: Connects the engine to the cutting apparatus, allowing for efficient power transfer.

Regular inspection and maintenance of these components are essential for prolonging the lifespan of the equipment. Common issues may arise from wear and tear or misalignment, leading to decreased efficiency or mechanical failures. By addressing these concerns promptly, operators can ensure that the system remains functional and reliable.

Height Adjustment Controls

The ability to modify the cutting height of lawn equipment is crucial for achieving the desired lawn appearance and health. Proper adjustment mechanisms allow users to tailor the blade height to suit various grass types and conditions, ensuring optimal performance and results. These controls facilitate ease of use and enhance the overall efficiency of the machinery.

Types of Adjustment Mechanisms

There are several types of mechanisms designed for height adjustments, each providing different levels of precision and ease. Manual levers are commonly found on many models, allowing users to make quick changes by simply pulling or pushing the lever into the desired position. Alternatively, electronic systems offer a more sophisticated approach, enabling users to set specific heights with the touch of a button, providing consistency and convenience.

Maintenance of Adjustment Features

Regular maintenance of the adjustment controls is essential for their longevity and functionality. Users should routinely inspect these components for any signs of wear or damage, as this can affect the overall cutting performance. Keeping the adjustment mechanisms clean and lubricated will ensure smooth operation and accurate height settings.

Common Wear and Tear Parts

Every lawn maintenance equipment consists of components that are susceptible to deterioration over time. Regular use, exposure to various elements, and the demands of heavy-duty tasks contribute to the gradual decline of these vital elements. Recognizing these components is essential for maintaining optimal performance and prolonging the lifespan of the machinery.

Identifying Key Components

When assessing equipment for wear and tear, focus on the following critical areas:

- Blades: Regular cutting can cause them to dull or become damaged.

- Belts: Continuous operation can lead to fraying or breaking.

- Bearings: Over time, they may wear out, causing noise and inefficiency.

- Wheels: Frequent movement can lead to flat spots or other issues.

- Deck Housing: Exposure to weather can lead to rust or structural damage.

Maintenance Recommendations

To mitigate wear and ensure longevity, consider the following maintenance practices:

- Regularly inspect all components for signs of damage.

- Sharpen or replace blades as needed for efficient cutting.

- Check belts for signs of wear and replace them proactively.

- Lubricate bearings to maintain smooth operation.

- Store equipment in a dry place to prevent rust.

Replacement Options for Blades

When it comes to maintaining optimal performance of your lawn equipment, selecting the right cutting edges is essential. Whether you’re looking for enhanced durability or improved cutting efficiency, there are various alternatives available to suit different needs and preferences. Understanding the options can significantly influence the overall quality of your lawn care routine.

Types of Replacement Blades

Replacement cutting edges come in several varieties, each designed to fulfill specific functions. The choice of blade can affect cutting performance, grass health, and even the life span of your equipment. Here are a few common options:

| Blade Type | Features | Benefits |

|---|---|---|

| Standard Blades | Basic design, versatile | Good for general use, cost-effective |

| High-Lift Blades | Curved edges for better airflow | Improves grass discharge, reduces clumping |

| Mulching Blades | Specially designed for finer cutting | Reduces grass clippings, enhances nutrient recycling |

| Gator Blades | Hybrid design for versatility | Combines mulching and bagging functions |

Considerations for Selecting Blades

When choosing replacement blades, it is important to consider the specific requirements of your lawn care tasks. Factors such as the type of grass, the terrain, and your desired results should influence your decision. Furthermore, consulting the equipment’s manual can provide valuable insights into compatible blade options.

Maintenance Tips for Mulching Deck

Proper upkeep of your cutting mechanism is essential for optimal performance and longevity. Regular maintenance not only ensures that the device operates efficiently but also enhances the quality of the finish. Here are some key suggestions to keep your equipment in top shape.

Regular Cleaning

After each use, it is crucial to clean the underside of the cutting mechanism to remove any accumulated grass clippings and debris. This practice prevents rust and keeps the blades sharp. Use a brush or a putty knife to scrape off the buildup, ensuring that all surfaces are clear.

Blade Maintenance

Sharp blades are vital for an even cut. Regularly inspect the cutting edges for wear and damage. If dull, consider sharpening or replacing them as needed. Additionally, check for any nicks or dents that could affect performance, and ensure that the blades are securely fastened to avoid accidents during operation.

How to Troubleshoot Issues

Troubleshooting mechanical challenges can often seem daunting, but with a systematic approach, many problems can be identified and resolved efficiently. By following a series of logical steps, you can pinpoint the source of the issue and implement the necessary repairs or adjustments.

Here are some common steps to consider when diagnosing problems:

- Visual Inspection: Begin by closely examining the equipment for any visible signs of damage or wear. Look for cracks, rust, or loose components.

- Check Connections: Ensure that all connections are secure. This includes belts, cables, and any attachments that might have come loose during operation.

- Listen for Unusual Noises: While the machine is in use, pay attention to any strange sounds. These can often indicate where the malfunction lies.

If the problem persists after initial checks, consider the following:

- Consult the Manual: Refer to the operational guide for troubleshooting sections that may offer insights specific to your model.

- Test Components: Isolate and test individual components to determine if they are functioning correctly. This may involve using tools to measure performance.

- Seek Professional Help: If you’re unable to resolve the issue, it may be beneficial to contact a technician who specializes in this type of equipment for further assistance.

By adhering to these steps, you can effectively troubleshoot and resolve mechanical issues, ensuring your equipment remains in optimal working condition.