D130 John Deere Parts Diagram Overview

Understanding the intricate workings of lawn machinery is essential for any enthusiast or professional. This section provides an overview of essential elements that contribute to the efficiency and functionality of these machines. Whether you’re maintaining your garden or engaging in larger landscaping projects, knowing these components can significantly enhance your experience.

By examining the various sections and pieces that make up a typical model, users can grasp how each part plays a crucial role in the overall performance. This knowledge empowers operators to identify potential issues, streamline repairs, and ensure optimal operation. An in-depth exploration into these mechanical aspects is ultimately rewarding.

With a focus on clarity, this guide aims to demystify the complexities of lawn equipment. Each segment will be presented in a straightforward manner, highlighting key components and their interrelationships. Prepare to delve into a wealth of information that will support both novice and experienced users alike.

D130 John Deere Parts Overview

This section provides a comprehensive look at the essential components and accessories for a popular lawn care machine. Understanding these elements is crucial for maintenance, repair, and optimal performance.

Key Components

- Engine Assembly

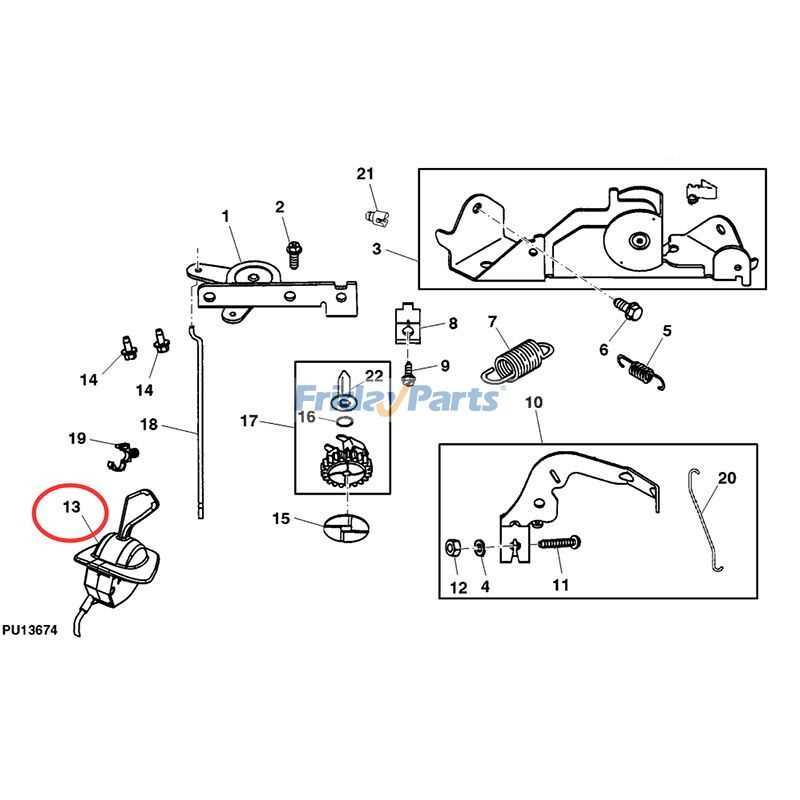

- Transmission System

- Cutting Deck

- Wheel and Tire Sets

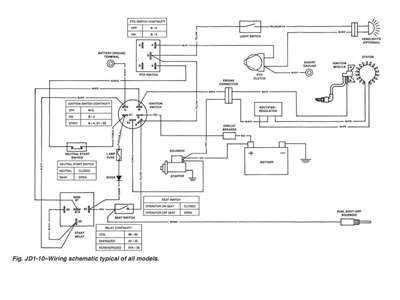

- Electrical System

Maintenance Accessories

- Oil Filters

- Air Filters

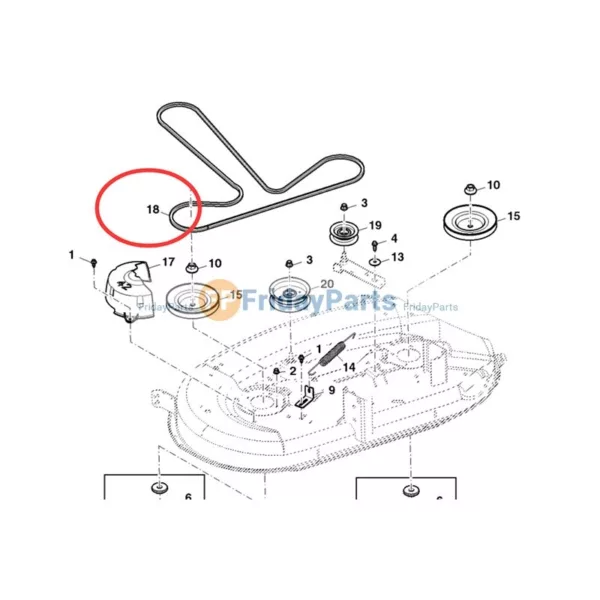

- Belts and Blades

- Battery Replacements

- Fuel System Components

Understanding the D130 Model

This section delves into a specific lawn care machine designed for efficiency and reliability. It provides insights into its components, functionality, and overall importance in maintaining outdoor spaces. The model is recognized for its user-friendly features and robust performance, making it a popular choice among homeowners and landscaping professionals alike.

Key Features

The machine is equipped with various innovative elements that enhance its usability. From its powerful engine to ergonomic controls, each feature is thoughtfully designed to ensure optimal performance. The cutting mechanism is particularly noteworthy, offering adjustable heights and precise trimming capabilities. These characteristics allow users to achieve a well-manicured lawn with minimal effort.

Maintenance and Care

Key Components of D130 Mower

This section explores the essential elements of a popular lawn care machine, highlighting their roles in ensuring optimal performance and efficiency. Understanding these components can help users appreciate their functionality and maintain the equipment effectively.

Engine

The heart of the mower, the engine, powers the entire system. Its robust design allows for reliable operation, delivering the necessary torque for cutting grass efficiently. Regular maintenance of this unit is crucial for longevity and peak performance.

Cutting Deck

The cutting deck is where the magic happens. Equipped with sharp blades, it provides a clean and precise cut. The deck’s height adjustment feature allows users to customize their mowing experience, adapting to various grass types and conditions.

How to Access Parts Diagram

Finding detailed illustrations of components for your equipment can significantly enhance your maintenance and repair processes. Here’s a guide to help you locate these valuable resources effectively.

- Visit the official manufacturer’s website.

- Navigate to the support or service section.

- Look for a category dedicated to your model or series.

- Utilize the search function by entering your equipment’s model number.

- Access the relevant documentation or visual guides available for download.

Alternatively, consider these options:

- Consult local dealers or authorized service centers for printed resources.

- Join online forums or communities dedicated to equipment enthusiasts.

- Explore third-party websites that specialize in technical references.

Identifying Common Replacement Parts

Understanding the essential components of your machinery can significantly enhance maintenance efforts and prolong lifespan. Familiarizing yourself with frequently replaced elements ensures efficient repairs and optimal performance.

- Belts: Essential for transferring power, these often wear out over time.

- Blades: Key for cutting performance, they require regular checks for sharpness and damage.

- Filters: Crucial for maintaining fluid cleanliness, regular replacement is vital for efficiency.

- Battery: Powers the entire system; checking connections and condition is necessary.

- Tires: Affect traction and stability; inspect for wear and pressure regularly.

Recognizing these components can aid in timely replacements and ensure your equipment operates smoothly.

Tools Required for Repairs

When undertaking maintenance and repair tasks, having the right tools is essential for efficiency and effectiveness. The appropriate equipment not only facilitates smoother operations but also ensures that the job is completed safely and to a high standard.

Basic Hand Tools

For most repair jobs, a set of basic hand tools is necessary. This includes wrenches, screwdrivers, and pliers. These items are vital for loosening or tightening various components, making adjustments, and performing basic troubleshooting.

Specialized Equipment

In addition to standard tools, specific repairs may require specialized equipment. Diagnostic tools, torque wrenches, and jacks are examples of instruments that can help delve deeper into complex issues. Having these tools on hand can lead to more accurate repairs and enhance the overall longevity of the machinery.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires consistent care and attention. Implementing regular maintenance practices not only extends the lifespan but also enhances efficiency, saving time and costs in the long run.

1. Regular Cleaning: Keep surfaces free of dirt and debris. This prevents buildup that can lead to wear and tear over time.

2. Fluid Checks: Regularly inspect and change fluids, including oil and coolant. Proper lubrication is essential for smooth operation.

3. Tire Maintenance: Check tire pressure and tread regularly. Maintaining the correct pressure ensures better traction and fuel efficiency.

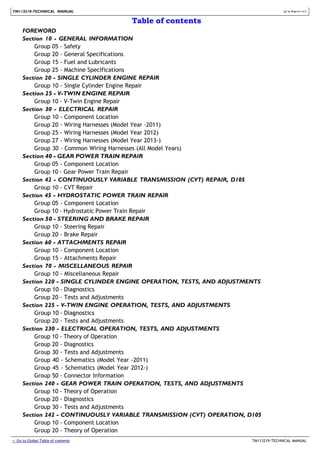

4. Component Inspections: Periodically examine critical components for signs of wear. Early detection of issues can prevent more significant problems.

5. Follow the Manual: Adhere to the manufacturer’s guidelines for maintenance schedules. These recommendations are tailored for optimal performance.

By integrating these practices into your routine, you can ultimately achieve a reliable and efficient machine that serves you well for years to come.

Where to Purchase Genuine Parts

Finding authentic components for your equipment is essential for maintaining optimal performance and longevity. Using original items ensures compatibility and reliability, preventing issues that can arise from using substandard alternatives. Here are some reliable sources where you can acquire these necessary elements.

Authorized Dealers

One of the most dependable places to obtain original components is through authorized dealerships. These locations often provide:

- Certified products that meet manufacturer standards.

- Expert advice and support from knowledgeable staff.

- Warranty options on items purchased.

Online Retailers

In today’s digital age, numerous online platforms specialize in genuine components. When shopping online, consider:

- Reputable websites that specifically sell original items.

- Customer reviews and ratings to gauge the reliability of the seller.

- Return policies and customer service availability.

By choosing trusted sources, you can ensure that your equipment operates efficiently and remains in excellent condition for years to come.

Common Issues and Solutions

When operating outdoor machinery, users often encounter a range of common challenges that can affect performance and efficiency. Identifying these issues promptly is essential for ensuring longevity and reliability. Below are some typical problems and their corresponding solutions.

Engine Starting Difficulties: Many users report issues with the engine failing to start. This can often be attributed to a drained battery or a clogged fuel filter. Solution: Regularly check and replace the battery if needed, and ensure the fuel system is clean and free of obstructions.

Uneven Cutting Performance: A common complaint is that the cutting mechanism does not function evenly, resulting in a patchy appearance. This is frequently due to dull blades or incorrect height settings. Solution: Sharpen the blades regularly and adjust the cutting height to suit the terrain.

Overheating Issues: Machines may experience overheating, which can lead to serious damage. This problem is often linked to insufficient lubrication or a blocked cooling system. Solution: Regularly check oil levels and clean any debris from the cooling vents.

Unusual Noises: Unexpected sounds during operation can indicate mechanical problems. These noises may arise from loose components or worn bearings. Solution: Conduct routine inspections to tighten loose parts and replace any worn components as necessary.

Comparing D130 to Similar Models

This section explores how a specific lawn tractor compares to its peers in terms of features, performance, and user satisfaction. By analyzing the similarities and differences, potential buyers can make informed decisions based on their needs and preferences.

Key Features Comparison

- Engine Power: Review the horsepower ratings.

- Cutting Width: Assess the efficiency of different mowing decks.

- Transmission Types: Compare automatic vs. manual options.

User Experience Insights

- Ease of Operation: Consider user feedback on controls and handling.

- Maintenance Requirements: Examine how often maintenance is needed for each model.

- Durability: Evaluate long-term reliability and warranty offers.

Customer Reviews and Experiences

This section explores the insights and feedback from users who have interacted with various components for their machinery. Understanding their experiences can provide valuable guidance for potential buyers and enthusiasts alike.

Positive Feedback

- High quality and durability noted by several users.

- Ease of installation praised, making upgrades straightforward.

- Excellent customer service experiences reported.

Areas for Improvement

- Some users mentioned delays in shipping times.

- A few components were found to be incompatible with older models.

- Requests for more detailed installation guides were common.