Comprehensive Guide to John Deere 1010 Parts Diagram

Exploring the intricacies of machinery used in agriculture reveals a complex interplay of various elements working in harmony. Each segment plays a crucial role in ensuring optimal performance and efficiency, contributing to the overall functionality of the equipment. Recognizing how these individual components interact can significantly enhance maintenance and repair processes.

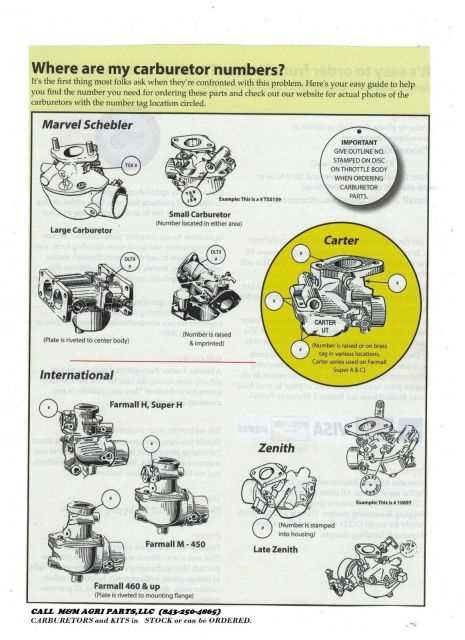

Visual aids serve as invaluable tools for comprehending the structure and arrangement of these crucial elements. By examining a detailed representation, one can easily identify specific sections and understand their significance within the larger assembly. This knowledge empowers operators and technicians alike to make informed decisions regarding upkeep and improvements.

In-depth exploration of these components fosters a deeper appreciation for the engineering behind modern agricultural solutions. As we delve into the specifics, it becomes evident that understanding these frameworks not only aids in troubleshooting but also promotes a more efficient approach to equipment management.

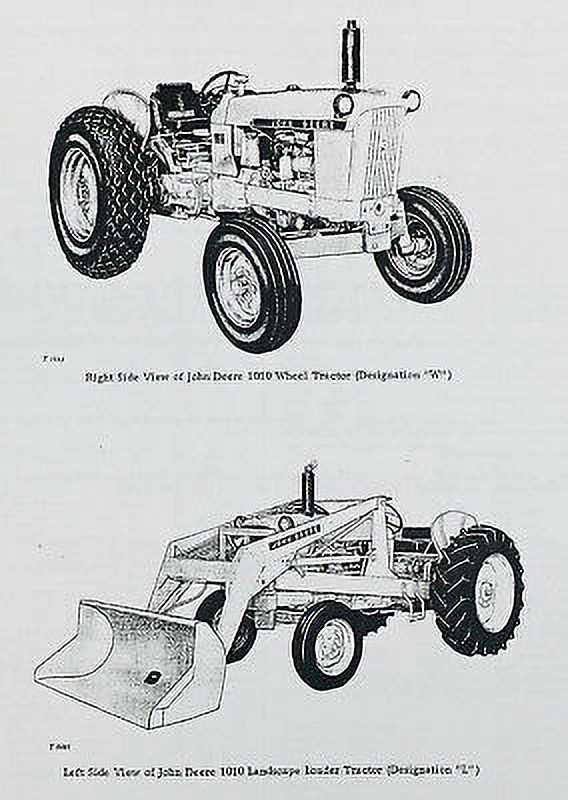

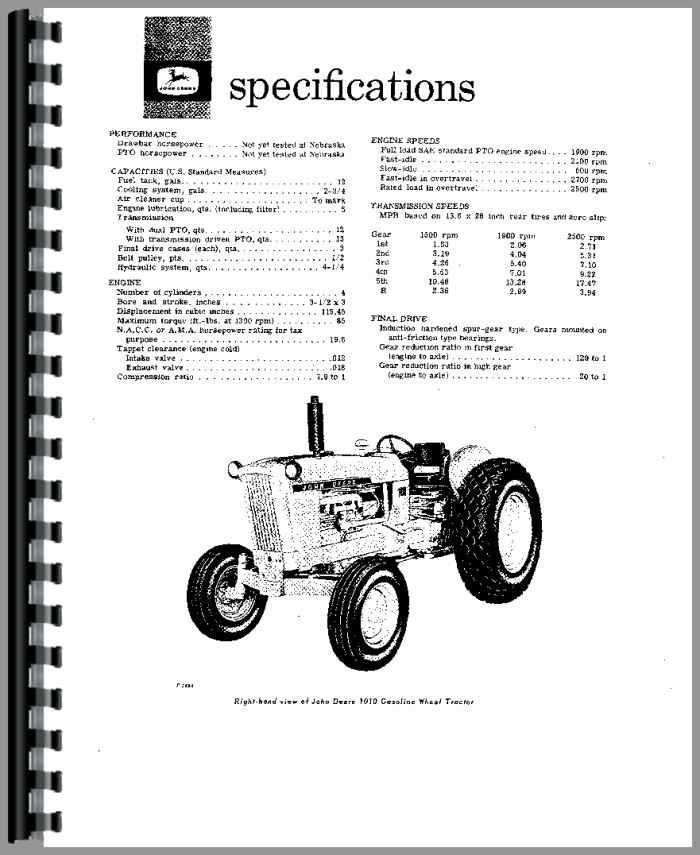

Understanding the John Deere 1010

This section delves into the intricacies of a specific agricultural machinery model known for its reliability and performance. By exploring its components and functionality, we aim to provide valuable insights for enthusiasts and professionals alike. Knowledge of this machinery can enhance operational efficiency and maintenance practices.

Key Features

- Robust construction designed for heavy-duty tasks.

- Efficient engine performance that ensures optimal power output.

- User-friendly controls that simplify operation.

Maintenance Tips

- Regularly check fluid levels to ensure proper functioning.

- Inspect belts and hoses for signs of wear and tear.

- Keep the exterior clean to prevent rust and damage.

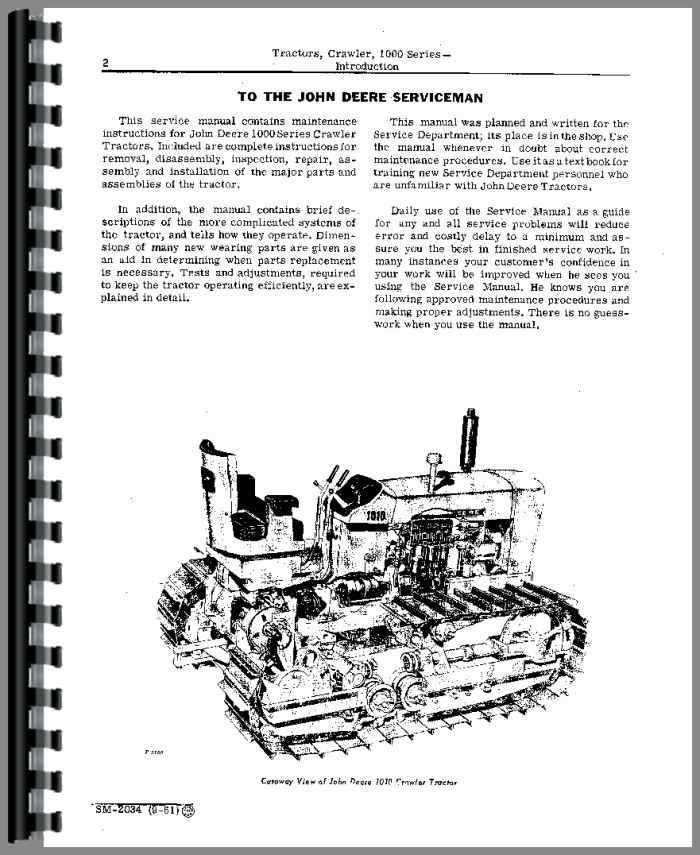

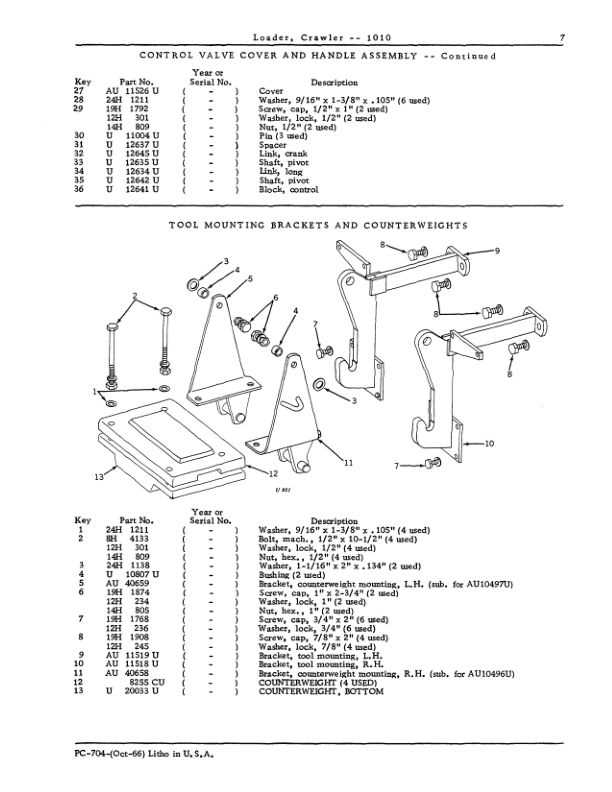

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide a clear overview of the various elements involved, facilitating easier identification and understanding of each segment’s function. Such illustrations serve not only as guides for assembly and disassembly but also help in locating specific items during repairs.

Enhanced Understanding

Using visual aids significantly improves comprehension of complex systems. Users can quickly grasp the relationships between different components, leading to more efficient troubleshooting. When mechanics can visualize how parts fit together, they are less likely to make errors during maintenance.

Efficient Repair Processes

Having access to detailed visual references can drastically reduce the time spent on repairs. Technicians can locate the necessary elements swiftly, minimizing downtime. This efficiency ultimately translates into cost savings and improved productivity for operators.

| Benefit | Description |

|---|---|

| Clarity | Provides a clear view of all components. |

| Accuracy | Reduces the chances of mistakes during repairs. |

| Time-saving | Speeds up the repair process significantly. |

| Cost-effective | Minimizes downtime, leading to financial savings. |

Key Components of the 1010

The machinery in question comprises various essential elements that contribute to its overall functionality and efficiency. Understanding these core components is vital for proper maintenance and operation, ensuring longevity and peak performance.

| Component | Description |

|---|---|

| Engine | Provides the necessary power to operate the equipment, featuring advanced design for optimal fuel efficiency. |

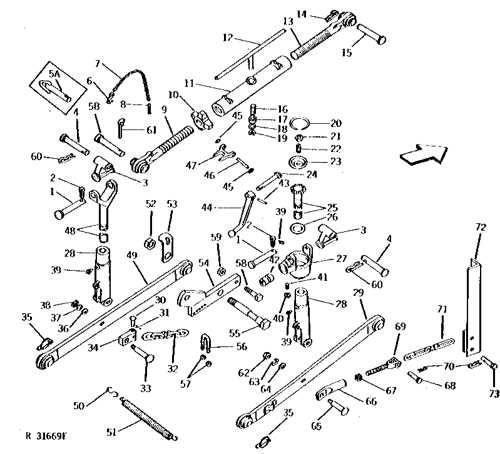

| Transmission | Facilitates smooth gear shifts, allowing for enhanced control and adaptability across different terrains. |

| Hydraulic System | Enables precise movements and operations, utilizing fluid power to drive attachments and other mechanisms. |

| Chassis | Serves as the structural framework, supporting all components and ensuring stability during operation. |

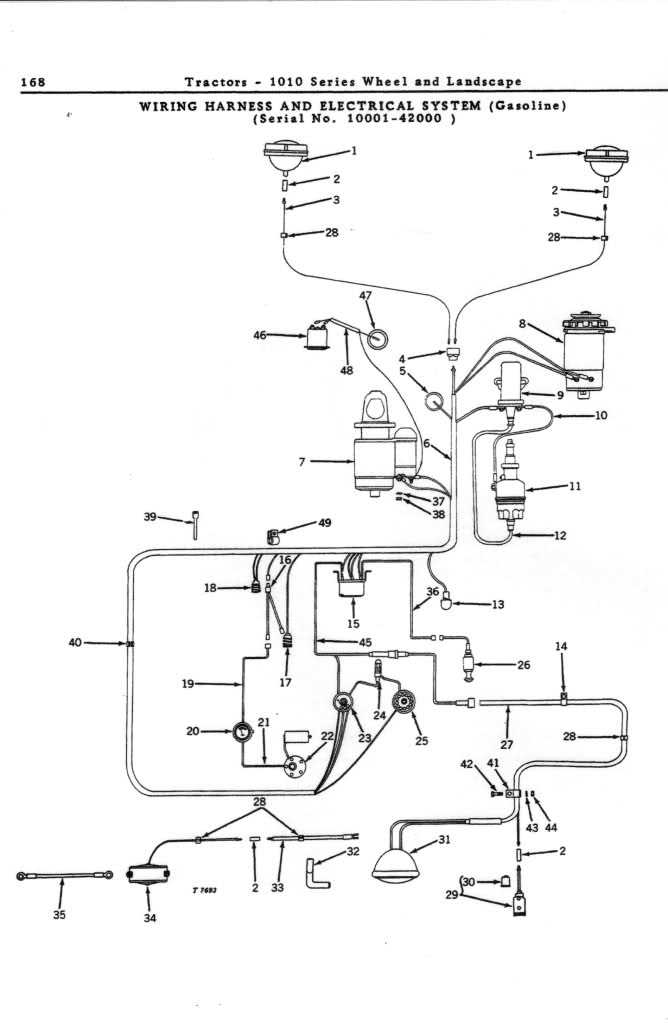

| Electrical System | Controls various functions, including starting, lighting, and accessory operations, ensuring reliability and safety. |

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. These illustrations serve as guides, providing insights into how various elements fit and function together, facilitating a clearer approach to troubleshooting and part replacement.

Familiarize Yourself with Symbols

Every illustration uses specific icons and labels that denote various components and their relationships. Take time to study the legend or key, as it will help you decode the symbols and grasp the layout more efficiently.

Identify Sections and Groupings

Components are often organized into sections that reflect their function or location. Recognizing these groupings allows you to locate the necessary parts swiftly and understand how they interact within the overall assembly.

Common Issues with 1010 Parts

Maintaining agricultural machinery can often present various challenges. Understanding the typical problems that may arise with specific components is essential for effective upkeep and smooth operation. Below are some common concerns that users may encounter.

- Wear and Tear: Regular use can lead to deterioration of key elements, impacting functionality and efficiency.

- Misalignment: Components may shift over time, causing irregular performance and increased strain on machinery.

- Corrosion: Exposure to moisture and harsh conditions can result in rust, compromising structural integrity.

- Fluid Leaks: Seals and gaskets may degrade, leading to fluid loss that affects overall operation.

Addressing these issues promptly can prolong the life of the equipment and ensure optimal performance. Regular inspections and timely replacements are key strategies to mitigate potential complications.

- Perform routine maintenance checks.

- Keep components clean and free from debris.

- Replace worn parts before they fail.

By being proactive and attentive to these common challenges, operators can maintain their machinery in peak condition and avoid costly repairs.

Where to Find Replacement Parts

Locating suitable components for your equipment can significantly enhance its performance and longevity. Several resources are available to assist you in sourcing these essential items, ensuring your machinery operates smoothly.

Online Retailers

Many online platforms specialize in machinery components, offering a wide selection at competitive prices. Websites dedicated to agricultural equipment often provide detailed catalogs, making it easy to identify and order what you need.

Local Dealers and Salvage Yards

Visiting local distributors can also yield valuable finds. Authorized dealers usually stock genuine items, while salvage yards may offer affordable options for older models. Building relationships with these suppliers can provide ongoing support for your equipment needs.

Maintenance Tips for John Deere 1010

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. By following a few key practices, you can enhance performance and reduce the likelihood of unexpected breakdowns.

- Check Fluid Levels: Regularly inspect oil, coolant, and hydraulic fluids. Maintaining optimal levels can prevent overheating and reduce wear on internal components.

- Inspect Filters: Clean or replace air and fuel filters as needed. Clogged filters can impede airflow and fuel delivery, affecting overall performance.

- Examine Belts and Hoses: Look for signs of wear, cracks, or fraying on belts and hoses. Replacing damaged components promptly helps avoid more significant issues.

- Sharpen Blades: Keeping blades sharp improves cutting efficiency and reduces strain on the engine. Regular sharpening can lead to cleaner cuts and healthier grass or crops.

- Grease Moving Parts: Lubricate joints and pivot points to reduce friction and prevent rust. Regular greasing extends the lifespan of mechanical components.

By adhering to these practices, you can ensure your machinery operates smoothly and reliably. Consistent maintenance not only improves performance but also enhances safety during use.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance ensures optimal performance and longevity. These original elements are designed to fit seamlessly, providing reliability and enhancing overall efficiency.

| Benefit | Description |

|---|---|

| Quality Assurance | Authentic components are manufactured to meet strict quality standards, ensuring superior durability. |

| Perfect Fit | Designed specifically for the equipment, they guarantee compatibility and prevent malfunctions. |

| Improved Performance | Using genuine parts enhances the operational efficiency of the machinery, resulting in better output. |

| Warranty Protection | Most manufacturers’ warranties require the use of original components to maintain coverage. |

| Safety | Authentic parts minimize the risk of failure, ensuring safe operation during use. |

Tools for Working on the 1010

Maintaining and repairing agricultural machinery requires a specific set of instruments to ensure efficiency and precision. Having the right equipment not only facilitates the task but also enhances safety and prolongs the life of the machine. In this section, we will explore essential tools that every operator should consider when engaging with their equipment.

Wrenches and Sockets: A comprehensive assortment of wrenches and sockets is vital for loosening and tightening bolts and nuts. Adjustable wrenches and ratchet sets are particularly useful for accessing hard-to-reach areas.

Diagnostic Equipment: Utilizing electronic diagnostic tools can greatly assist in identifying issues within the machinery. These devices can read error codes and monitor performance metrics, allowing for informed decision-making during repairs.

Torque Tools: Ensuring that bolts are tightened to the manufacturer’s specifications is crucial. A torque wrench is an indispensable tool for achieving the correct tension, preventing damage from over-tightening.

Cutting Tools: Sharp cutting tools, such as saws and snips, are necessary for modifying components or removing damaged sections. Keeping these tools well-maintained is essential for safety and efficiency.

Safety Gear: Protecting oneself while working on machinery cannot be overstated. Quality gloves, goggles, and helmets should be worn to guard against potential hazards associated with maintenance tasks.

Equipping yourself with the appropriate tools not only streamlines the maintenance process but also ensures that you can tackle any challenges that arise effectively. Prioritizing quality and safety in your toolkit will lead to better outcomes in the long run.

DIY Repairs for John Deere Models

Engaging in self-repairs for agricultural machinery can be both rewarding and cost-effective. With the right knowledge and tools, enthusiasts can tackle various issues that may arise during regular use. Understanding the mechanisms involved is crucial for successful maintenance.

Essential Tools are a must for any repair job. Having a reliable set of wrenches, screwdrivers, and diagnostic equipment can make the process smoother. It’s advisable to gather all necessary items before starting the project.

Common Issues often include engine troubles, hydraulic leaks, and electrical failures. By identifying these problems early on, operators can prevent further damage and save on repair costs. Thorough inspection and regular maintenance can extend the life of machinery significantly.

Step-by-Step Guides are invaluable resources for DIY repairs. Many online platforms provide detailed instructions for specific models, helping individuals to understand the intricacies of their machinery. Utilizing these guides ensures that repairs are done correctly and efficiently.

Ultimately, taking the initiative for repairs not only enhances one’s skill set but also fosters a deeper appreciation for the equipment. With practice and dedication, any operator can master the art of maintaining their machinery effectively.