Understanding the John Deere 110 TLB Parts Diagram for Efficient Maintenance

In the realm of heavy machinery, comprehending the various elements that contribute to optimal performance is essential for effective maintenance and repair. A detailed visual representation of these components serves as an invaluable tool for operators and technicians alike.

By exploring the intricate layout of each segment, users can gain insights into assembly and functionality, ensuring their equipment remains in peak condition. This knowledge not only facilitates troubleshooting but also enhances the longevity of the machinery.

Mastering the intricacies of your machine’s structure ultimately empowers you to address issues proactively. With this information at your fingertips, you’re better equipped to navigate the complexities of upkeep and repairs, leading to more efficient operation.

Understanding John Deere 110 TLB

The robust machine in question is designed for versatility and efficiency in various tasks. Its structure combines power and functionality, making it suitable for both construction and agricultural projects. Users benefit from its ability to navigate different terrains while offering essential features for digging, lifting, and moving materials.

Key attributes include a user-friendly interface and reliable components that enhance performance. The thoughtful engineering ensures that maintenance is manageable, allowing operators to focus on their tasks rather than on troubleshooting.

To delve deeper into this machine’s specifications, one must consider its operational capabilities and the ultimate benefits it provides in real-world applications. By understanding these aspects, users can maximize the potential of their equipment for a range of demanding projects.

Key Features of the 110 TLB

This compact yet powerful machine is designed for versatility and efficiency, making it an ideal choice for various construction and landscaping tasks. With a combination of innovative engineering and robust performance, it stands out in its category, offering users a range of capabilities tailored to their needs.

Performance and Power

Engineered with a robust powertrain, this model delivers exceptional performance. The hydraulic system is optimized for efficiency, allowing for smooth operation of attachments and implements, enhancing overall productivity on job sites.

Operator Comfort and Control

The operator’s station is designed with user comfort in mind, featuring an intuitive layout that ensures easy access to controls. This ergonomic design minimizes fatigue during extended use, making it easier to manage various tasks throughout the day.

| Feature | Description |

|---|---|

| Engine Power | Delivers strong performance for heavy-duty tasks. |

| Hydraulic System | Enhanced efficiency for quick attachment operation. |

| Ergonomic Design | Comfortable operator station for reduced fatigue. |

| Versatility | Compatible with various attachments for diverse applications. |

Importance of Parts Diagrams

Understanding the structure and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, enabling technicians and enthusiasts to identify and locate various elements within a system.

- Enhances clarity: Visual guides simplify complex arrangements.

- Facilitates troubleshooting: Easy identification of malfunctioning components.

- Streamlines repairs: Reduces time spent searching for specific items.

- Improves communication: Standardized references help teams collaborate efficiently.

- Supports inventory management: Aids in tracking necessary replacements.

In conclusion, these visual aids are fundamental for maintaining machinery performance, ensuring longevity, and reducing downtime.

Common Replacement Parts Overview

Understanding the frequently needed components for maintenance is crucial for ensuring optimal performance and longevity of your machinery. Certain elements require regular attention and replacement to prevent breakdowns and maintain efficiency. This section highlights the key items that often need to be addressed during servicing.

Key Components

Here are some vital components commonly replaced during maintenance:

| Component | Description | Function |

|---|---|---|

| Filters | Oil and air filters | Prevent contaminants from affecting engine performance |

| Batteries | Lead-acid or maintenance-free types | Provide necessary power to start the engine |

| Belts | Drive and timing belts | Transfer power from the engine to other components |

| Hoses | Hydraulic and coolant hoses | Facilitate fluid movement for cooling and operation |

Maintenance Recommendations

Regular checks and timely replacements of these components can greatly enhance operational reliability. Staying proactive in maintenance ensures that the equipment functions smoothly, reducing the likelihood of costly repairs in the future.

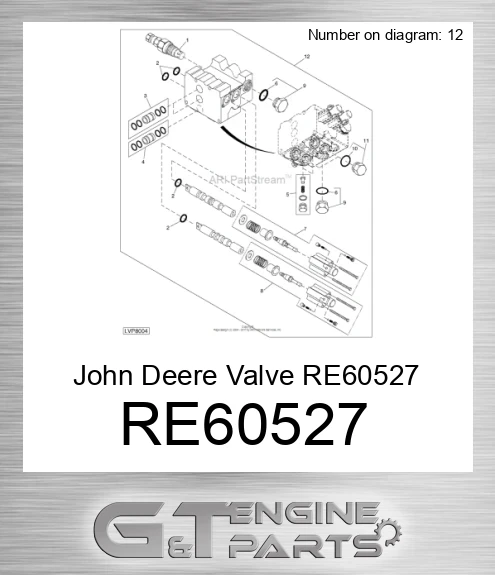

How to Read Parts Diagrams

Understanding the visual representation of components is essential for effective maintenance and repair. This guide will help you navigate these illustrations with ease, enhancing your ability to identify and acquire necessary elements.

- Familiarize Yourself with Symbols: Different shapes and icons represent specific items. Take time to learn their meanings.

- Identify the Sections: Diagrams are often divided into segments based on functionality. Locate the relevant section for your task.

- Refer to the Legend: Most visuals include a legend or key. Use it to decode any unfamiliar terms or symbols.

- Trace the Connections: Follow lines to see how components are linked. This helps in understanding how to dismantle or reassemble.

- Cross-Reference with Manuals: Always compare the visual with your maintenance manual for detailed descriptions and instructions.

By following these steps, you can effectively interpret the illustrations and make informed decisions during repairs.

Locating Genuine John Deere Parts

Finding authentic components for your equipment is essential for maintaining performance and longevity. Genuine parts ensure compatibility and reliability, enhancing the overall efficiency of your machinery.

Here are several effective strategies to help you source original components:

- Visit authorized dealerships: These locations specialize in offering genuine products and often have knowledgeable staff to assist you.

- Explore online marketplaces: Reputable websites provide a platform for purchasing authentic components, often with detailed descriptions and reviews.

- Utilize manufacturer websites: Official online resources often have sections dedicated to locating and ordering genuine items.

- Join community forums: Engaging with other equipment owners can provide insights and recommendations for reliable suppliers.

By employing these methods, you can ensure that you are acquiring the best components for your machinery, thereby supporting its optimal function and durability.

Maintenance Tips for Longevity

Proper upkeep of machinery is essential for maximizing performance and extending its lifespan. Regular attention to specific areas can prevent premature wear and ensure optimal functioning over time.

Regular Inspections

- Check fluid levels regularly.

- Inspect belts and hoses for signs of wear.

- Look for leaks and address them promptly.

Scheduled Servicing

- Follow the manufacturer’s service intervals.

- Replace filters and fluids as recommended.

- Clean air intakes and exhaust systems to prevent blockages.

By committing to these practices, users can delve deeper into the maintenance process and achieve ultimate efficiency from their equipment.

Troubleshooting Common Issues

When operating heavy machinery, encountering problems is inevitable. Understanding how to identify and address these challenges can significantly enhance performance and extend the lifespan of the equipment. Common concerns often stem from mechanical failures, electrical issues, or operational errors.

For mechanical difficulties, checking for unusual noises or vibrations can pinpoint the source of the problem. If the equipment fails to start, inspecting the battery and electrical connections is crucial. Furthermore, fluid leaks may indicate worn seals or damaged hoses, requiring immediate attention.

In cases where the machinery operates inefficiently, examining filters and fluid levels can often resolve performance issues. Regular maintenance checks, including greasing joints and tightening bolts, can prevent many complications from arising. Keeping a maintenance log helps track recurring problems, allowing for timely interventions.

Ultimately, addressing these common issues promptly can lead to improved functionality and reduced downtime, ensuring that the machinery operates at its best.

Benefits of OEM vs. Aftermarket Parts

Choosing between original equipment manufacturer components and those from third-party suppliers can significantly impact performance and longevity. Each option presents distinct advantages that can affect maintenance costs and overall efficiency.

Advantages of OEM Components

- Precision Engineering: Designed specifically for compatibility, ensuring optimal performance.

- Warranty Protection: Often backed by comprehensive warranties, offering peace of mind.

- Consistent Quality: Maintained production standards lead to reliable functionality.

Benefits of Aftermarket Alternatives

- Cost-Effectiveness: Generally more affordable, providing budget-friendly options.

- Variety of Choices: A wider range of options available for specific needs.

- Innovation: Often incorporate newer technologies and features not found in OEM versions.

Ultimately, the decision should consider specific requirements, usage, and budget constraints, allowing for a more informed choice between these two types of components.

Ordering Parts Online: A Guide

In today’s digital age, acquiring necessary components for machinery has never been easier. With just a few clicks, you can access a vast array of items from various suppliers, ensuring that you find exactly what you need for your equipment. This guide will explore the essential steps to successfully navigate online ordering.

1. Identify Your Requirements: Begin by determining the specific components needed for your machinery. Consult the manual or any available resources to ensure you have the correct specifications.

2. Choose Reputable Suppliers: Look for well-reviewed online vendors that specialize in machinery components. Check ratings and customer feedback to avoid potential pitfalls.

3. Utilize Search Tools: Use search filters on websites to streamline your options. Input relevant details such as model numbers or descriptions to quickly locate the desired items.

4. Verify Compatibility: Ensure that the items you plan to purchase are compatible with your machinery. Cross-reference with the specifications to prevent any mismatches.

5. Review Shipping Policies: Before finalizing your order, check the shipping options and delivery times. Understanding these details can help you plan your maintenance schedule effectively.

6. Keep Records: After placing your order, save receipts and confirmation emails. This documentation will be valuable for tracking shipments and handling any potential returns.

By following these steps, you can delve into the world of online purchasing with confidence, ultimately streamlining your maintenance and repair efforts.

Popular Accessories for Enhanced Performance

Enhancing the functionality of your equipment can significantly improve productivity and efficiency. Various accessories are available that not only elevate performance but also extend the capabilities of your machine, making it more versatile for different tasks. These enhancements can transform standard operations, allowing for greater ease and effectiveness in various applications.

Performance-Boosting Attachments

One of the most sought-after additions includes specialized attachments designed to increase the operational range of your equipment. For instance, a robust loader can facilitate material handling, while a backhoe attachment enables efficient digging and trenching. These accessories are crafted to maximize the power of the base unit, ensuring that every job is completed with precision and speed.

Utility Enhancements

Incorporating utility accessories can also lead to a remarkable enhancement in performance. Options such as auxiliary hydraulic systems allow for the use of multiple attachments simultaneously, streamlining workflows. Additionally, comfort upgrades like ergonomic seats and advanced control systems can improve operator experience, reducing fatigue and enhancing overall productivity during extended use.

Resources for Further Research

This section provides valuable references and materials for those looking to enhance their understanding of machinery components and their functionalities. Exploring these resources can deepen your knowledge and assist in effective maintenance and repairs.

| Resource Type | Description | Link |

|---|---|---|

| Manuals | Comprehensive guides detailing specifications and maintenance procedures. | Access Manuals |

| Forums | Online communities for discussions and troubleshooting advice. | Join Forums |

| Videos | Tutorials and demonstrations on repairs and part installations. | Watch Videos |

| Suppliers | Information on reliable vendors for acquiring components. | Find Suppliers |