Comprehensive Guide to John Deere 1130SE Parts Diagram

The intricate world of agricultural machinery is filled with diverse components that work in harmony to ensure optimal performance. Each element plays a crucial role in the overall functionality, and understanding their arrangement and relationship is essential for efficient maintenance and operation.

Exploring the layout of these vital elements allows operators and technicians to quickly identify issues, perform necessary repairs, and enhance the longevity of their equipment. Familiarity with the assembly can significantly streamline troubleshooting processes and reduce downtime.

In this guide, we will delve into the specific configurations of a notable model, offering insights into its construction and functionality. Whether you are a seasoned expert or a newcomer to the field, grasping these concepts will empower you to navigate the complexities of modern machinery with confidence.

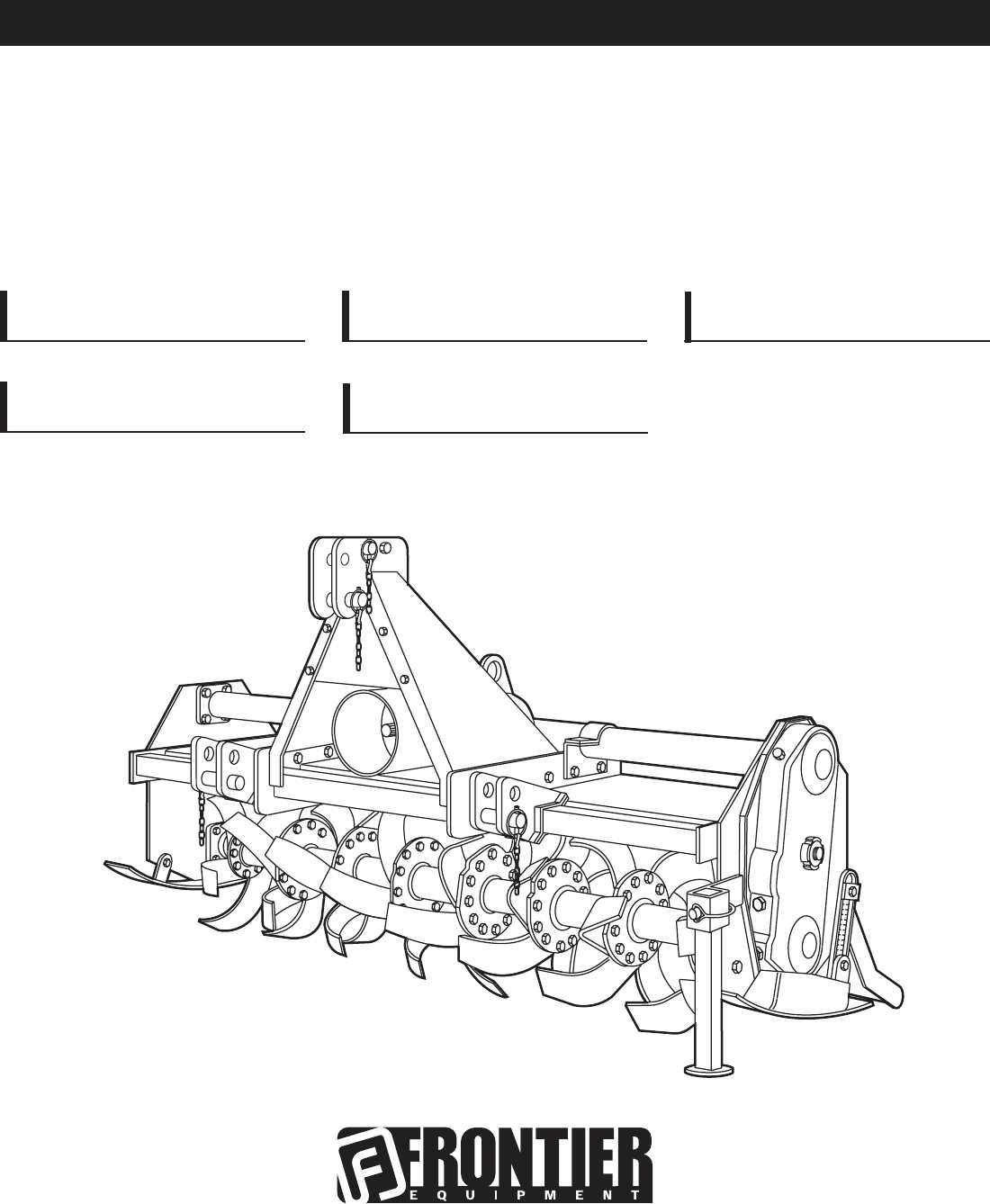

Overview of John Deere 1130SE

This section provides a comprehensive look at a particular model known for its robust performance and reliability. Designed for both agricultural and landscaping tasks, it combines efficiency with user-friendly features, making it a popular choice among enthusiasts and professionals alike.

Key features of this model include:

- Powerful engine capabilities for heavy-duty tasks

- Durable construction designed to withstand tough conditions

- Versatile attachments that enhance functionality

- Ergonomic design for operator comfort

Maintenance and servicing are crucial for optimal performance. Understanding the components and their functions can aid in proper upkeep:

- Regular checks on the engine and transmission systems

- Monitoring fluid levels and changing filters as needed

- Inspecting attachments for wear and tear

- Keeping the exterior clean to prevent rust and damage

This model exemplifies a blend of power and efficiency, making it an essential tool for various tasks in the field. Its design reflects a commitment to quality, ensuring that users can rely on its performance year after year.

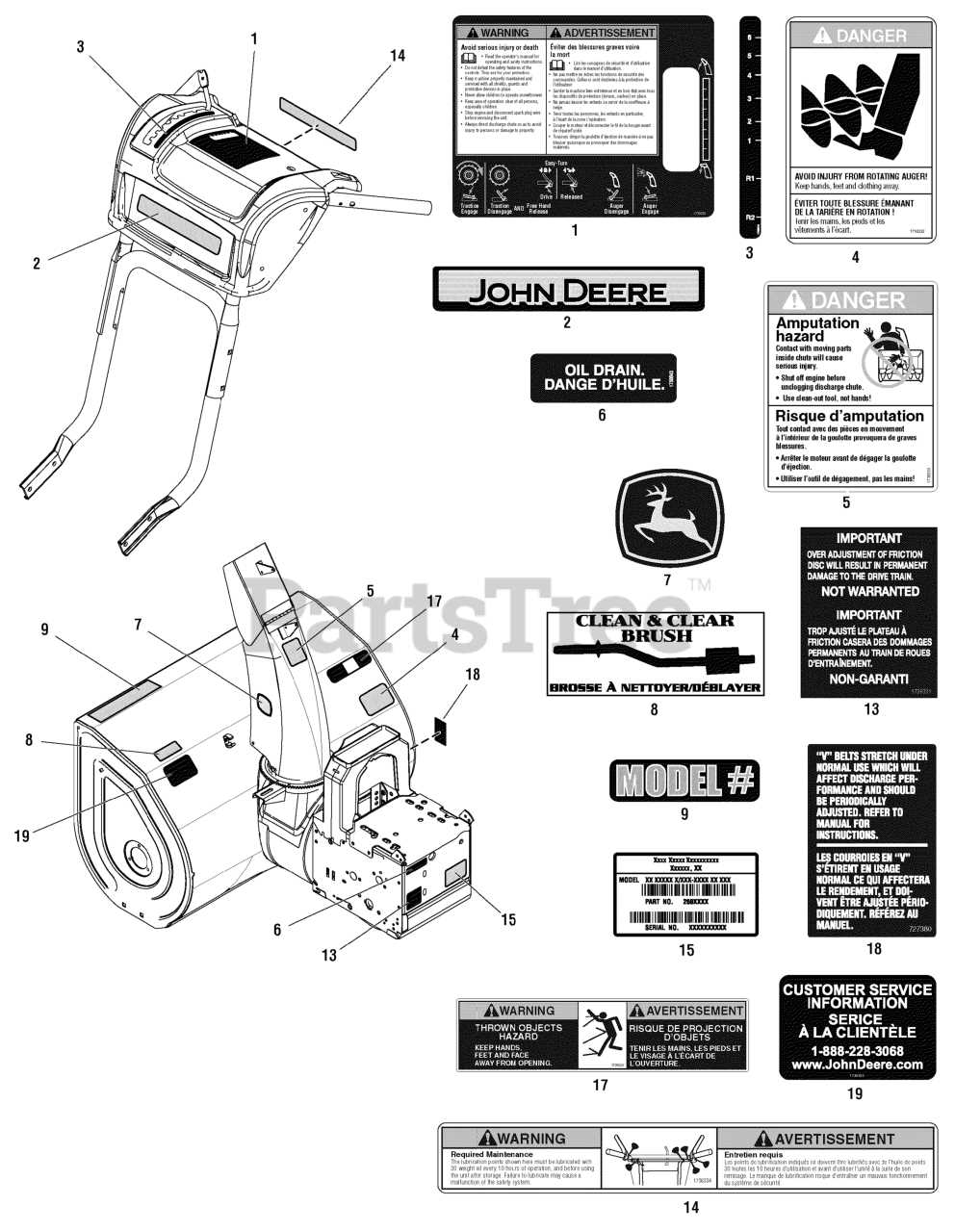

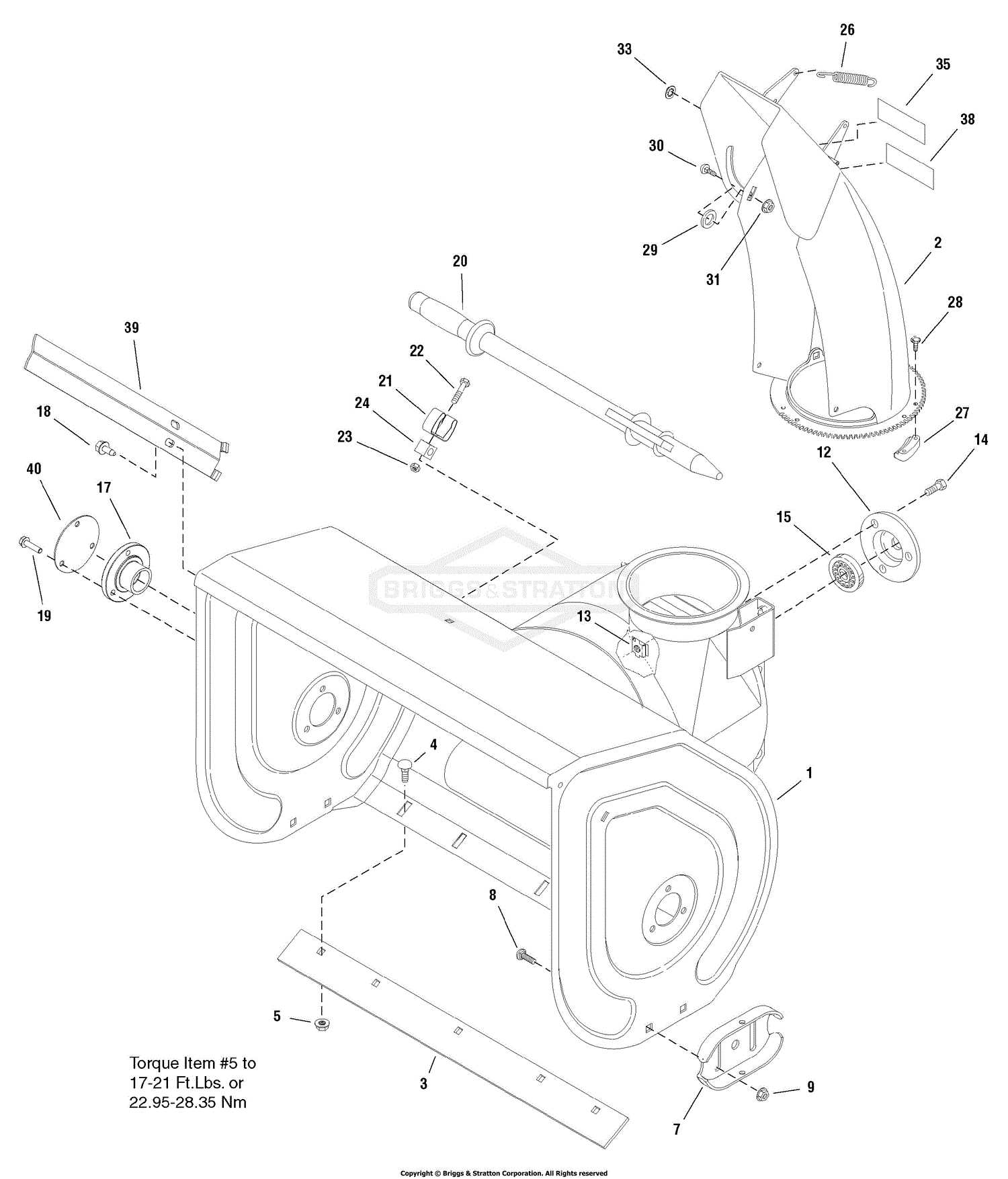

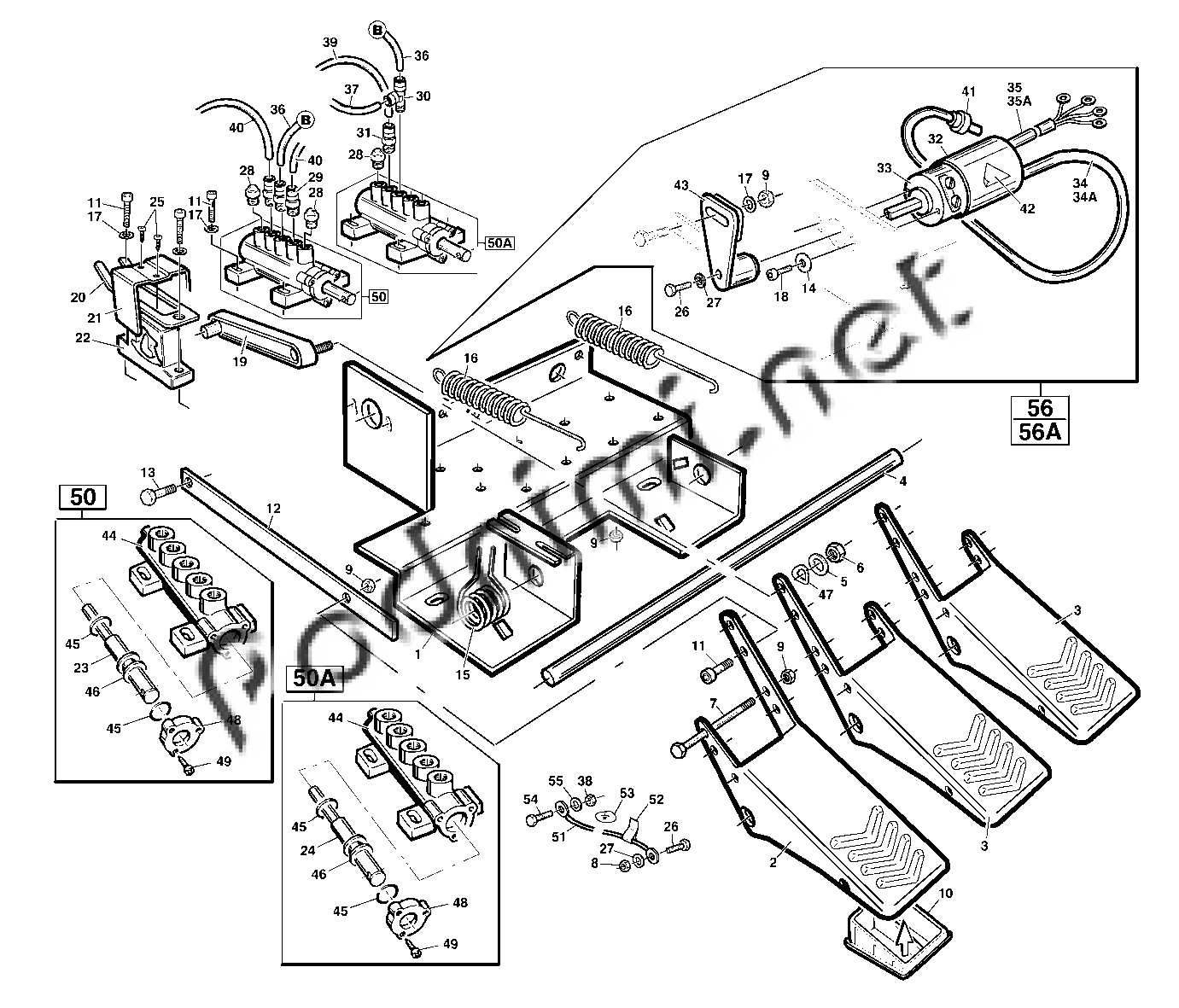

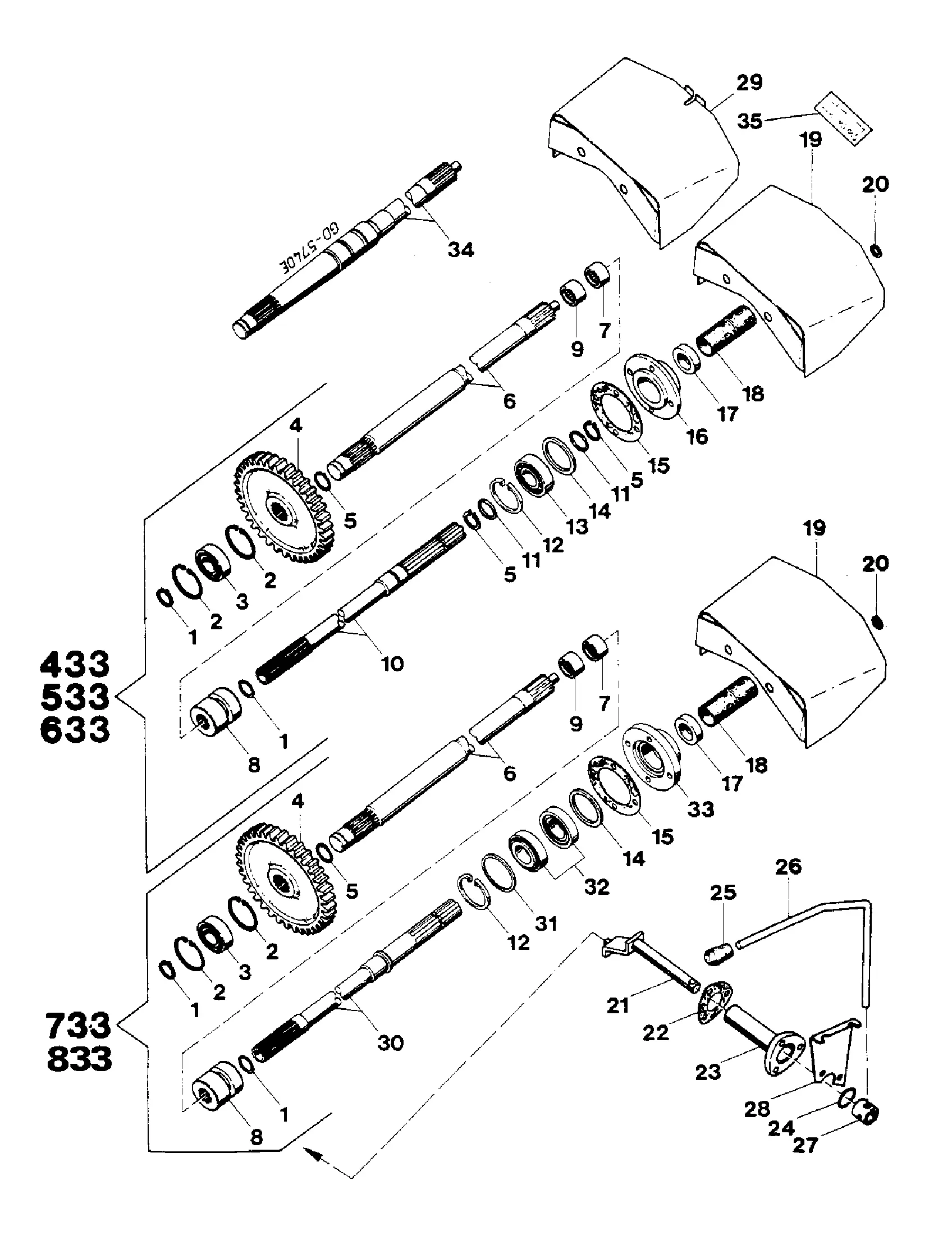

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide users with a clear understanding of how each element fits together, enhancing both efficiency and accuracy during servicing. Without these illustrations, identifying specific pieces can become a tedious and error-prone task.

Benefits of Visual Guides

- Enhanced Understanding: Illustrations simplify complex assemblies, making it easier for technicians to grasp the relationships between different elements.

- Streamlined Repairs: Quick reference to visual aids can significantly reduce the time spent searching for parts or understanding their functions.

- Reduced Errors: Clear visuals minimize the risk of incorrect installations or replacements, ensuring that the machine operates smoothly.

Applications in Maintenance

- Effective troubleshooting becomes possible as technicians can pinpoint malfunctioning components quickly.

- Ordering the correct replacements is simplified, preventing delays in repairs.

- Training new personnel is facilitated through the use of these visual resources, helping them learn faster and more efficiently.

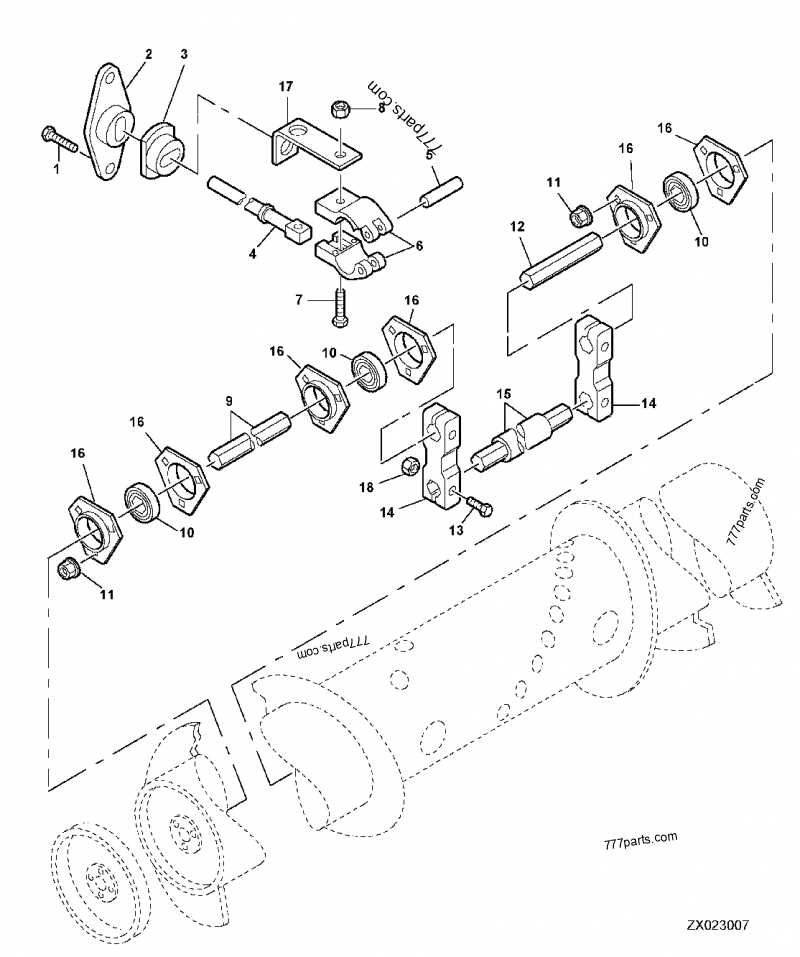

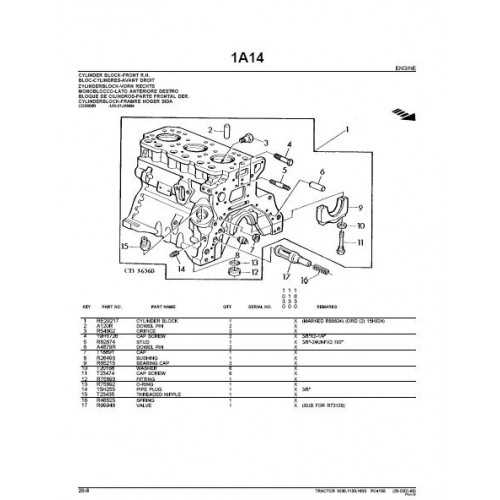

Identifying Key Components

Understanding the essential elements of agricultural machinery is crucial for effective maintenance and repair. Recognizing the primary components allows operators to troubleshoot issues efficiently and ensure optimal performance. This section highlights the vital parts that contribute to the functionality of these machines.

Core Elements

Among the main features, the engine serves as the powerhouse, providing the necessary energy for operation. The transmission system is equally significant, facilitating the transfer of power to the wheels. Additionally, the hydraulic system plays a pivotal role in controlling various implements, enhancing versatility and efficiency.

Auxiliary Parts

Other noteworthy components include the cooling system, which prevents overheating, and the electrical system that powers the lights and controls. Understanding these auxiliary parts not only aids in identifying potential issues but also helps in planning maintenance schedules effectively. Regular inspection of these key features ensures longevity and reliability of the equipment.

Understanding the Diagram Layout

Grasping the structure of a visual representation is crucial for efficient navigation and comprehension. This section aims to break down the components and organization of such visuals, allowing users to pinpoint specific elements and their relationships. A clear understanding enhances troubleshooting and maintenance, leading to more effective handling of machinery.

| Element | Description |

|---|---|

| Labeling | Each component is typically marked with identifiers that clarify its function or position within the system. |

| Connections | Lines or arrows illustrate how different parts interact, indicating flow or linkage between sections. |

| Grouping | Related components are often clustered together, simplifying the identification of subsystems. |

| Legends | A key or legend may be included to explain symbols, colors, or any additional notations used throughout the visual. |

| Scale | Understanding the size relationship between components can assist in accurate assessments and replacements. |

Common Issues with John Deere 1130SE

This section highlights prevalent challenges faced by users of this specific model. Understanding these issues can aid in effective maintenance and troubleshooting, ultimately enhancing performance and longevity.

| Issue | Description | Possible Solutions |

|---|---|---|

| Starting Problems | Difficulty in starting the engine can arise due to various electrical or fuel-related issues. | Check battery charge, inspect starter connections, and ensure fuel lines are clear. |

| Overheating | Overheating can lead to severe engine damage if not addressed promptly. | Ensure coolant levels are adequate, clean radiator, and inspect for leaks. |

| Loss of Power | Experiencing a decrease in power can affect overall efficiency during operation. | Inspect air filters, fuel filters, and perform regular maintenance on the engine. |

| Uneven Cutting | Uneven cutting patterns can occur, leading to unsatisfactory results in the field. | Check blade sharpness, ensure proper leveling of the deck, and adjust cutting height. |

Where to Find Replacement Parts

Locating suitable components for machinery can be a straightforward task if you know where to search. Various sources provide a wealth of options, ensuring that you can maintain your equipment in optimal condition. Understanding the best places to look can save you time and effort.

Online Retailers

The internet is a treasure trove for finding necessary components. Numerous websites specialize in offering a wide range of items for agricultural machinery. Some of the benefits of shopping online include competitive pricing and the convenience of home delivery.

Local Dealerships and Distributors

Visiting nearby dealerships or authorized distributors can yield positive results as well. These establishments often carry genuine components and can offer expert advice on compatibility and installation. Additionally, they may provide access to exclusive products that are not available elsewhere.

| Source Type | Advantages |

|---|---|

| Online Retailers | Wide selection, convenience, often lower prices |

| Local Dealerships | Genuine parts, expert assistance, exclusive products |

| Second-Hand Markets | Lower cost options, potential for rare finds |

| Manufacturer’s Website | Direct access to original components, reliable information |

Maintenance Tips for Longevity

Ensuring the durability of your machinery involves a combination of regular care and attention to detail. Implementing a structured maintenance routine can significantly enhance the performance and lifespan of your equipment. Here are some essential strategies to keep your machine running smoothly for years to come.

Regular inspections are crucial. Checking for wear and tear, loose components, and fluid levels should be part of your routine. Addressing minor issues promptly can prevent them from escalating into major problems that could result in costly repairs.

Keep your equipment clean. Dirt and debris can lead to overheating and mechanical failure. Regularly cleaning key areas will help maintain optimal functioning and allow you to spot potential issues early.

Use high-quality lubricants and fluids. Proper lubrication reduces friction and wear, which is vital for moving parts. Refer to the manufacturer’s recommendations for the right products to ensure compatibility and effectiveness.

Follow a scheduled maintenance plan. Establishing a timeline for services such as oil changes, filter replacements, and system checks will keep your equipment in top shape. Staying proactive is always better than waiting for problems to arise.

Finally, invest in training. Understanding how to operate and care for your machinery properly will empower you to maximize its potential. Knowledge is a powerful tool in maintaining equipment longevity.

Step-by-Step Repair Instructions

Repairing machinery requires a systematic approach to ensure efficiency and effectiveness. This section provides clear and concise guidelines to help you through the process of troubleshooting and fixing various components. By following these instructions, you can minimize downtime and enhance the performance of your equipment.

Preparation and Safety

Before beginning any repair work, it is crucial to prepare your workspace and gather necessary tools. Ensure you have the appropriate equipment and safety gear. Disconnect the power source to prevent accidental activation during repairs. Review the manufacturer’s guidelines for specific safety recommendations related to your machine.

Step-by-Step Procedure

Start by identifying the problem area. Inspect the components visually for any signs of wear or damage. Once you have located the issue, refer to the appropriate instructions for disassembly. Carefully remove any parts, keeping track of their order for reassembly. After replacing or repairing the defective component, reassemble everything in reverse order, ensuring all connections are secure. Finally, conduct a test run to verify that the machinery operates as expected.

Comparing Similar John Deere Models

When exploring various models from a well-known agricultural machinery brand, it becomes essential to understand the nuances that set each version apart. Analyzing features, performance, and specifications allows users to make informed decisions based on their specific needs. This section highlights key comparisons among similar units, providing insights into their design and functionality.

| Model | Engine Power (HP) | Cutting Width (inches) | Weight (lbs) | Key Features |

|---|---|---|---|---|

| Model A | 30 | 48 | 550 | Compact design, fuel-efficient engine |

| Model B | 35 | 54 | 600 | Enhanced stability, larger fuel tank |

| Model C | 40 | 60 | 650 | Advanced transmission, ergonomic controls |

Each of these models serves distinct purposes, making it crucial for potential buyers to evaluate their requirements against the unique attributes of each unit. Understanding these differences can significantly influence purchasing decisions, ensuring optimal performance for specific tasks.

Frequently Asked Questions

This section aims to address common inquiries related to machinery components and their functionalities. Understanding these aspects can enhance maintenance and repair processes, ensuring optimal performance and longevity of the equipment.

What should I do if I can’t find a specific component?

If you’re struggling to locate a particular element, consider checking with authorized dealers or specialized online resources. Many platforms offer detailed catalogs and may even provide support in identifying the right item for your machinery.

How often should I perform maintenance checks?

Regular maintenance is crucial for efficient operation. It’s recommended to inspect your equipment at least every few months, or more frequently if it is subjected to heavy use. This practice helps identify potential issues before they escalate, ultimately saving time and resources.