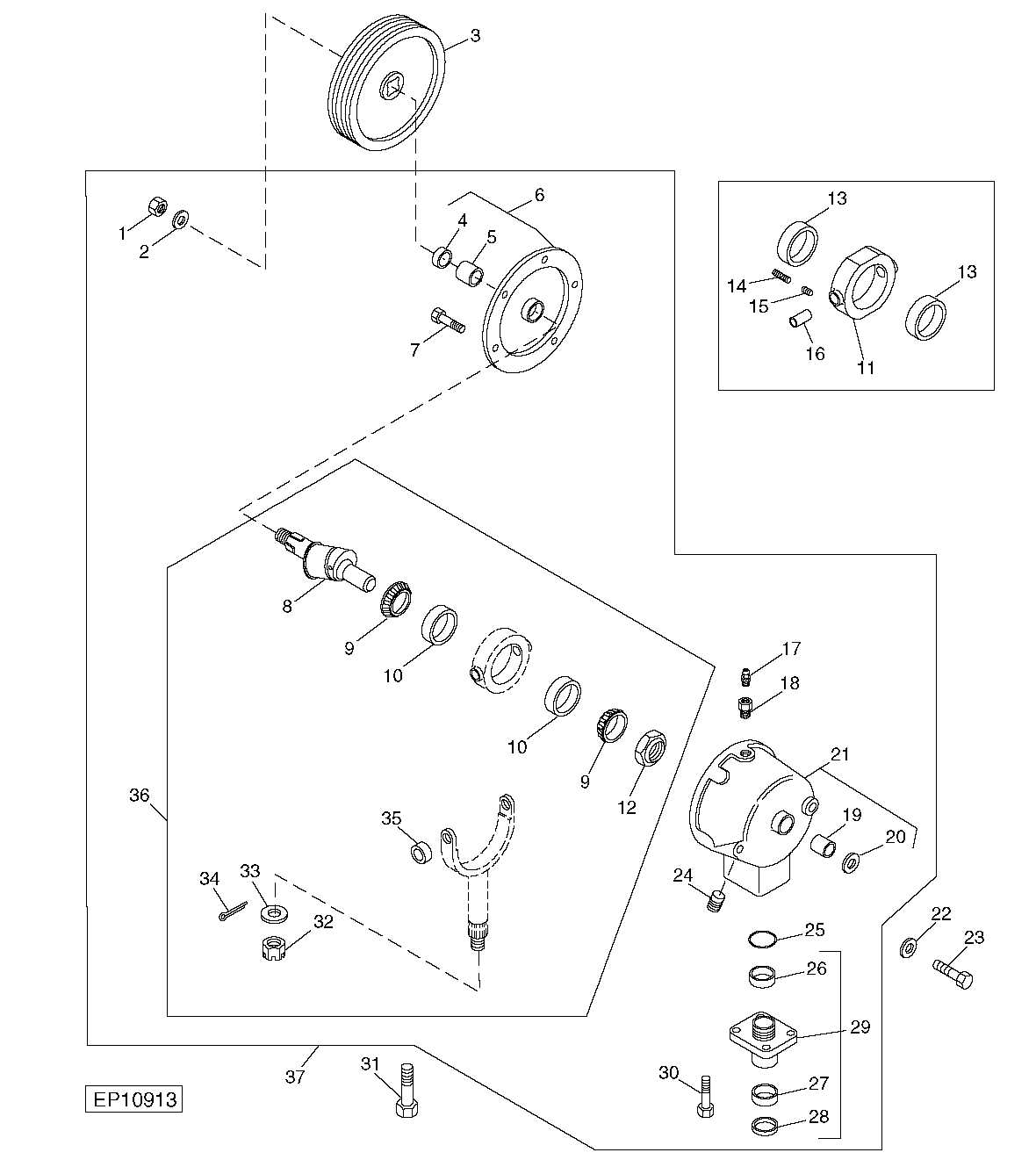

Complete Parts Diagram for John Deere 1209

The intricacies of agricultural equipment require a thorough understanding of their internal structures and assembly. When tackling maintenance or repairs, having a clear representation of each element is essential for effective operation. This article delves into the specifics of a certain model, providing insights into its design and functionality.

In the realm of farming tools, the precise arrangement of components can significantly influence performance and longevity. Grasping the relationships between various parts aids operators in making informed decisions regarding upkeep and troubleshooting. Through detailed exploration, one can uncover the nuances that contribute to optimal machinery operation.

Whether you are a seasoned professional or a newcomer to the field, familiarizing yourself with the intricate details of equipment assembly enhances your ability to manage tasks efficiently. This guide serves as a resource, illuminating the essential aspects necessary for a comprehensive understanding of the machinery in question.

Understanding John Deere 1209 Overview

This section aims to provide a comprehensive understanding of a specific agricultural machinery model that has gained recognition in the farming community. By exploring its key features, functionalities, and design elements, users can better appreciate its role in enhancing productivity and efficiency on the field.

The machine is renowned for its durability and performance, making it a reliable choice for various agricultural tasks. Its engineering reflects a commitment to quality, ensuring that farmers can rely on it for consistent operation under demanding conditions. With various attachments and accessories available, operators can tailor it to meet specific needs, maximizing its utility.

Moreover, this equipment is designed with user-friendliness in mind, allowing for straightforward maintenance and operation. Understanding its mechanics can empower users to troubleshoot issues and conduct necessary repairs, thereby prolonging its lifespan and ensuring optimal functionality.

Importance of Parts Diagrams

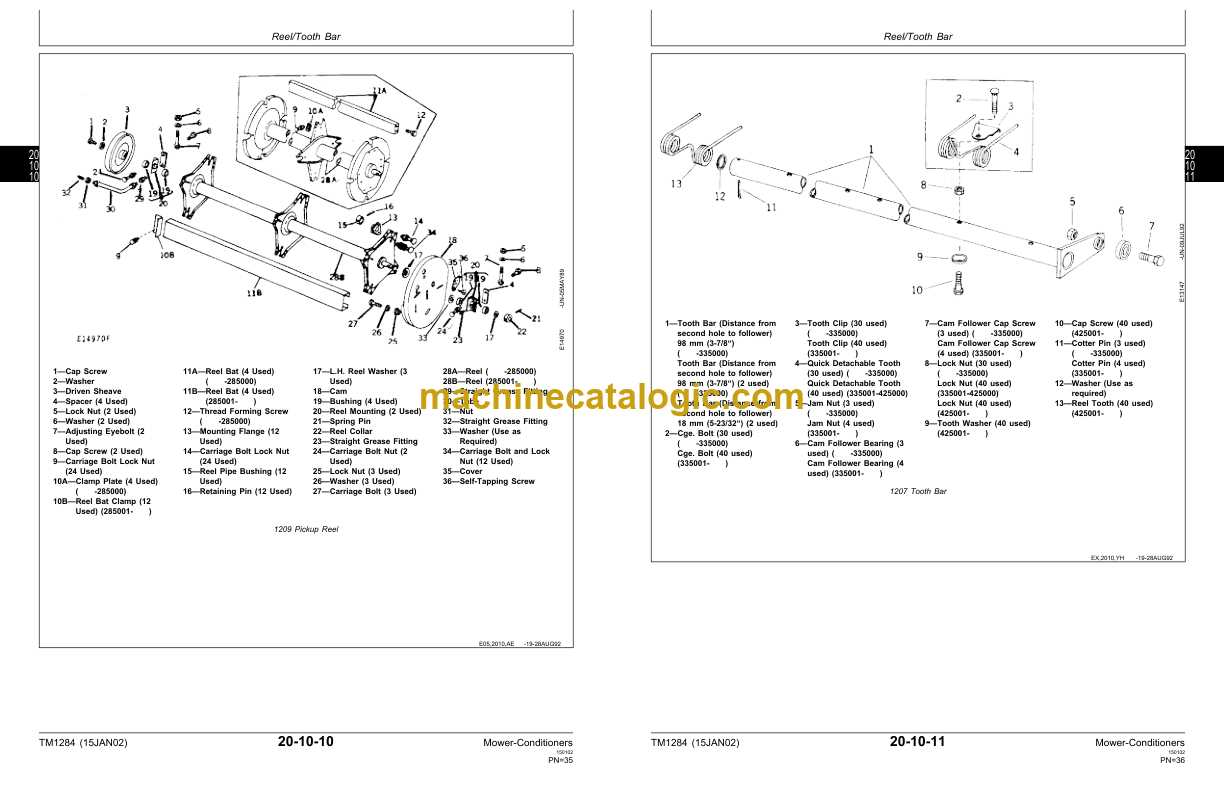

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide clear insights into the structure and arrangement of various elements, facilitating a better understanding of how each piece contributes to overall functionality. By utilizing these visual aids, operators and technicians can enhance their efficiency and accuracy during service procedures.

Enhanced Understanding

Such illustrations enable users to grasp the intricate relationships between different elements. When tackling repairs, having a comprehensive visual reference allows for quicker identification of required components and their specific locations. This clarity can significantly reduce the risk of errors, leading to more successful repairs and maintenance tasks.

Efficient Troubleshooting

In instances of malfunction, visual guides are invaluable for diagnosing issues. They provide step-by-step assistance, helping users pinpoint the source of a problem with greater precision. This efficiency not only saves time but also minimizes downtime, ensuring that equipment remains operational for longer periods.

Key Components of John Deere 1209

This section explores the essential elements of a popular agricultural machine, emphasizing their significance in enhancing efficiency and productivity. Understanding these vital components is crucial for optimal performance and maintenance, ensuring that the equipment operates smoothly in various farming applications.

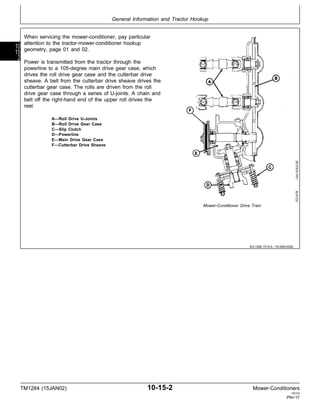

The cutting mechanism plays a pivotal role, featuring a series of blades designed for precision and speed. This allows for efficient crop harvesting, minimizing losses and maximizing yield. Additionally, the drive system, which transmits power from the engine, is engineered to ensure reliable operation under demanding conditions.

An important part is the frame structure, providing stability and support while facilitating maneuverability across diverse terrains. Coupled with this is the hydraulic system, essential for enabling various functionalities, from lifting to adjusting cutting heights, ensuring adaptability to different farming tasks.

Moreover, the feed system is designed to effectively gather and transport crops, optimizing the harvesting process. Lastly, operator controls are strategically positioned for ease of use, allowing for intuitive management of the machine’s operations, enhancing user experience and efficiency.

How to Access Parts Diagrams

Accessing detailed illustrations for machinery components can significantly enhance your understanding of equipment maintenance and repair. These visual guides provide crucial insights into the assembly and functionality of various elements, ensuring you can tackle any task with confidence.

Online Resources: Numerous websites offer comprehensive libraries of schematics. Official manufacturer sites typically feature searchable databases where users can enter model numbers to retrieve specific visual references.

Service Manuals: Many equipment providers publish detailed manuals that include illustrations and annotations. These documents can often be downloaded in PDF format, providing a handy reference for technicians and enthusiasts alike.

Local Dealers: Engaging with authorized dealers can be beneficial. They often have access to proprietary information and can provide printed materials or direct you to online resources tailored for specific models.

Online Forums: Community forums and discussion groups can be invaluable. Members frequently share their own experiences, and some may upload images of schematics or point you to where they can be found.

Workshops and Training: Participating in workshops or training sessions can also provide access to visual guides. Many training programs include comprehensive materials that cover the essential components of the equipment.

Common Issues with John Deere 1209

The machine in question, known for its reliability in agricultural tasks, can experience various challenges that users should be aware of. Identifying these issues early can help maintain efficiency and reduce downtime.

One frequent problem involves the cutting mechanism. Users often report uneven cuts or blockages due to wear and tear. Regular maintenance and timely replacement of worn components can mitigate these issues.

Another common concern is the drive system. It may experience slipping or loss of power, often linked to inadequate lubrication or damaged belts. Ensuring proper lubrication and inspecting belts regularly is essential for optimal performance.

Overheating can also occur, particularly during prolonged use. This may be caused by a buildup of debris or insufficient cooling. Keeping the machine clean and checking cooling systems can help prevent overheating.

Lastly, electrical issues, such as faulty wiring or dead batteries, can lead to operational failures. Routine checks of electrical components can help identify potential problems before they escalate.

Identifying Replacement Parts

Understanding how to locate the necessary components for agricultural machinery is essential for maintaining optimal performance. Proper identification ensures that equipment operates efficiently and reduces downtime. This section will guide you through the process of recognizing and sourcing the appropriate elements for your machinery.

When it comes to identifying the right components, familiarity with the machine’s structure is crucial. Begin by examining the model specifications and the components’ roles within the system. The following table outlines common categories of components along with their functions, aiding in the identification process.

| Component Category | Function |

|---|---|

| Cutting Elements | Responsible for harvesting and managing crop material. |

| Drive Systems | Transmit power from the engine to the working parts. |

| Frame Assemblies | Provide structural support and stability to the machine. |

| Hydraulic Components | Control movement and functionality through fluid power. |

| Electrical Systems | Manage operation controls and safety mechanisms. |

By understanding these categories and their functions, operators can more effectively locate and replace necessary components, ensuring that machinery remains in peak condition for agricultural tasks.

Maintenance Tips for Optimal Performance

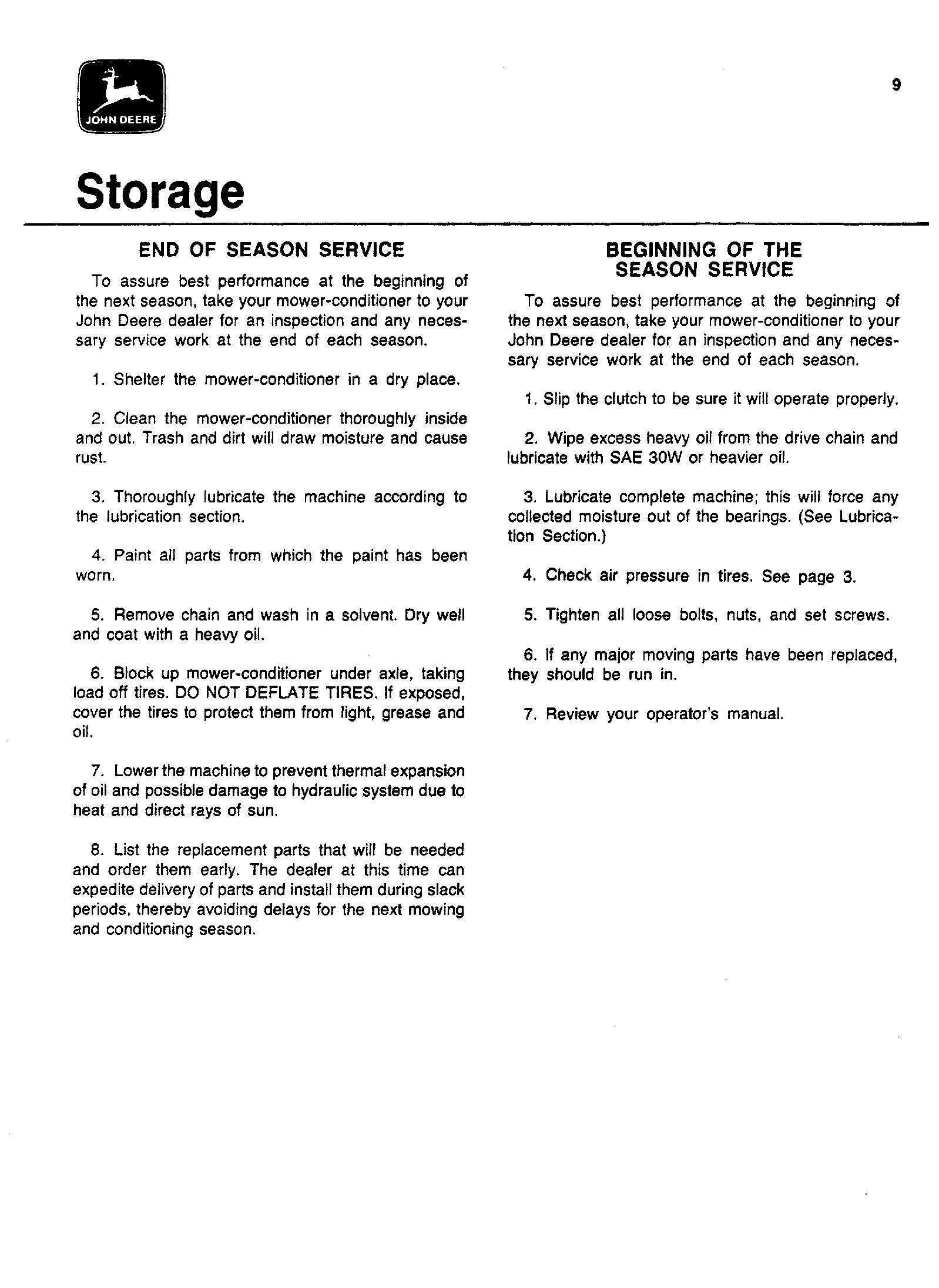

Ensuring peak functionality of your agricultural machinery requires consistent attention and care. Regular maintenance not only extends the lifespan of your equipment but also enhances its efficiency during operation. By following a structured maintenance routine, you can prevent potential issues and keep your machinery running smoothly.

Routine Inspection

Conducting frequent inspections is crucial for identifying wear and tear early. Here are key areas to focus on:

- Check fluid levels regularly, including oil, coolant, and fuel.

- Examine belts and hoses for signs of cracking or fraying.

- Inspect filters for clogs and replace them as needed.

- Look for loose bolts or connections that may affect performance.

Cleaning and Lubrication

Keeping your machinery clean is essential for optimal operation. Follow these steps:

- Wash the exterior to remove dirt and debris that can cause corrosion.

- Lubricate moving parts regularly to minimize friction and wear.

- Ensure that all grease fittings are properly serviced.

Implementing these maintenance strategies will help maintain high performance and reliability, ensuring your equipment remains ready for any task.

Where to Purchase Genuine Parts

Finding authentic components for your machinery is essential for maintaining optimal performance and longevity. The market offers various options, but choosing reliable sources is crucial to ensure quality and compatibility.

Authorized dealers are among the best places to obtain genuine items. These retailers are officially recognized and often carry a full range of products designed specifically for your equipment. Additionally, they can provide expert advice and support, ensuring you select the right components for your needs.

Online platforms have become increasingly popular for sourcing authentic items. Many reputable websites specialize in selling original equipment and often provide detailed information about each product. Customer reviews and ratings can also help guide your purchasing decision.

Local agricultural supply stores may also stock genuine components, allowing you to inspect items before buying. Building a relationship with these retailers can offer benefits such as tailored recommendations and potential discounts on future purchases.

Lastly, consider manufacturer websites for direct purchasing options. They typically provide comprehensive catalogs and the latest updates on available items, ensuring you have access to the most current offerings.

Comparing OEM and Aftermarket Options

When it comes to selecting components for machinery, the choice between original equipment manufacturer (OEM) products and aftermarket alternatives is crucial. Each option presents its own advantages and potential drawbacks, impacting performance, longevity, and cost-effectiveness. Understanding these differences can help operators make informed decisions that best suit their needs.

Advantages of OEM Components

OEM items are designed specifically for a particular machine, ensuring perfect compatibility and performance. These components often come with warranties and support from the manufacturer, providing peace of mind. Moreover, the quality assurance associated with OEM products often results in enhanced reliability and longevity, reducing the likelihood of breakdowns and maintenance issues.

Benefits of Aftermarket Alternatives

On the other hand, aftermarket options frequently offer significant cost savings. Many manufacturers produce parts that exceed OEM specifications, providing enhanced performance or durability. Additionally, the wider availability of aftermarket components can lead to quicker repairs and reduced downtime, a critical factor in maintaining productivity. However, it’s essential to choose reputable brands to avoid compromising on quality.

Installation Process for Key Parts

When it comes to assembling essential components of agricultural machinery, following a systematic approach is crucial. This ensures not only the proper functioning of the equipment but also enhances its longevity. The installation process typically involves several stages, each requiring attention to detail and precision.

Preparation is Key: Before starting the installation, it is important to gather all necessary tools and components. A clean and organized workspace will help streamline the process and minimize errors. Additionally, reviewing the user manual or assembly guide can provide valuable insights into specific requirements and safety precautions.

Step-by-Step Assembly: Begin by securing the primary framework of the machinery. This forms the backbone of your assembly. Once the framework is in place, proceed to attach auxiliary components, ensuring that each part is aligned correctly. Utilize the appropriate fasteners, and do not hesitate to use a torque wrench to achieve the manufacturer’s specifications.

Final Checks: After installation, conduct thorough inspections to ensure everything is securely attached. Testing the machinery in a controlled environment before full operation can prevent potential issues. Regular maintenance checks post-installation will also aid in identifying any wear or misalignment early on.

Understanding Warranty and Support

When investing in agricultural machinery, it is essential to comprehend the protection and assistance options available. Knowing your rights and the support mechanisms can enhance the longevity and efficiency of your equipment. This section delves into the critical aspects of warranty services and how to access effective customer support.

Warranty Details

A warranty serves as a safety net for buyers, ensuring that if issues arise within a specified timeframe, the manufacturer will address them without additional cost. Typically, warranties cover defects in materials and workmanship, but it is crucial to understand the specific terms and conditions that apply.

| Aspect | Description |

|---|---|

| Duration | Typically lasts from one to three years, depending on the product. |

| Coverage | Includes repairs or replacements for faulty components. |

| Exclusions | May exclude wear and tear, misuse, or unauthorized repairs. |

| Transferability | Some warranties are transferable, adding value when selling equipment. |

Accessing Support

Customer support plays a vital role in ensuring a smooth experience with your machinery. Knowing how to reach out for assistance and what resources are available can save time and enhance productivity. Most manufacturers provide multiple avenues for support, including hotlines, online chat, and dedicated service centers.

Benefits of Regular Maintenance Checks

Conducting routine inspections and upkeep on machinery is essential for ensuring optimal performance and longevity. These proactive measures not only enhance the efficiency of equipment but also prevent unexpected breakdowns that can lead to costly repairs and downtime.

Improved Performance

Regular maintenance contributes significantly to the overall performance of equipment. Key benefits include:

- Consistent operational efficiency.

- Enhanced fuel efficiency, reducing operating costs.

- Minimized risk of malfunctions during critical operations.

Cost Savings

Investing in routine checks can lead to significant financial advantages:

- Early detection of potential issues can prevent expensive repairs.

- Extended lifespan of machinery reduces the frequency of replacements.

- Lower energy consumption through optimized performance.

In conclusion, maintaining machinery through regular checks is a strategic approach that safeguards investments while maximizing productivity and efficiency.

Customer Experiences and Reviews

This section delves into the sentiments and feedback shared by users regarding their interactions with a specific agricultural machine model. Understanding the perspectives of those who have utilized this equipment can provide valuable insights into its performance, durability, and overall satisfaction.

Many customers have highlighted several key aspects in their reviews:

- Reliability: Users frequently mention the dependability of the machinery, noting that it consistently meets their operational needs.

- Ease of Use: A significant number of reviews praise the intuitive controls and straightforward setup process, making it accessible even for less experienced operators.

- Maintenance: Feedback often includes comments on the simplicity of upkeep, with many appreciating the availability of replacement components.

- Efficiency: Several users report enhanced productivity, emphasizing how the machine optimizes their workflow.

Despite the overwhelmingly positive feedback, some customers have shared areas for improvement:

- Weight: A few users pointed out that the weight of the equipment can be challenging in certain terrains.

- Cost of Accessories: Some reviews mention that additional attachments can be pricey, which may deter potential buyers.

Overall, the testimonials reveal a generally favorable reception, underscoring the machine’s reputation as a valuable asset in the field. Engaging with these experiences can assist prospective buyers in making informed decisions.