Comprehensive Guide to John Deere 120R Loader Parts Diagram

The efficient operation of heavy machinery relies on a thorough understanding of its individual elements. By analyzing the intricate configurations of these essential components, operators can enhance performance and ensure longevity.

In this section, we will explore the specific arrangements that contribute to the functionality of your machinery. Knowledge of these configurations enables users to make informed decisions regarding maintenance and repairs, ultimately maximizing efficiency.

Furthermore, recognizing the relationships between various elements can lead to a more seamless operational experience. A detailed examination of these layouts will provide insight into the best practices for upkeep and optimization of your equipment.

Understanding John Deere 120R Loader

This section delves into the essential components and mechanisms of a specific type of agricultural and construction equipment. Recognizing how these elements function together is crucial for efficient operation and maintenance. By exploring the intricacies involved, operators can enhance their understanding and optimize performance.

Key Features and Functions

The machinery is designed to assist with various tasks, including lifting, transporting, and grading materials. Its robust structure allows it to handle heavy loads, while its versatile attachments enable it to perform a wide range of operations. Familiarity with these features enhances the operator’s ability to utilize the equipment effectively.

Component Overview

A comprehensive understanding of the individual components is vital. Here’s a table highlighting some of the main parts and their functions:

| Component | Function |

|---|---|

| Bucket | Used for lifting and moving materials. |

| Arm | Connects the bucket to the main body, allowing movement. |

| Hydraulic System | Powers the movement and operation of attachments. |

| Chassis | Provides stability and support for the machine. |

Understanding these components and their roles helps ensure effective operation and prolongs the lifespan of the equipment. Regular maintenance and checks on these parts can prevent malfunctions and enhance overall productivity.

Key Features of the 120R Loader

This section explores the essential attributes of a versatile machine designed for efficiency and performance in various tasks. Its innovative design and advanced capabilities make it a valuable asset for professionals in agriculture and construction.

Performance and Efficiency

The equipment is engineered to deliver high performance while ensuring fuel efficiency. Its powerful hydraulic system allows for smooth operation and quick lifting capabilities, enhancing productivity in demanding environments.

Durability and Reliability

Constructed with robust materials, this machine is built to withstand harsh conditions. Its reliable components contribute to minimal downtime, making it suitable for continuous use in various applications.

| Feature | Description |

|---|---|

| Hydraulic System | Optimized for fast and efficient lifting and loading. |

| Build Quality | Made from high-strength materials for enhanced longevity. |

| Versatility | Compatible with a wide range of attachments for various tasks. |

| Ease of Use | Designed with user-friendly controls for intuitive operation. |

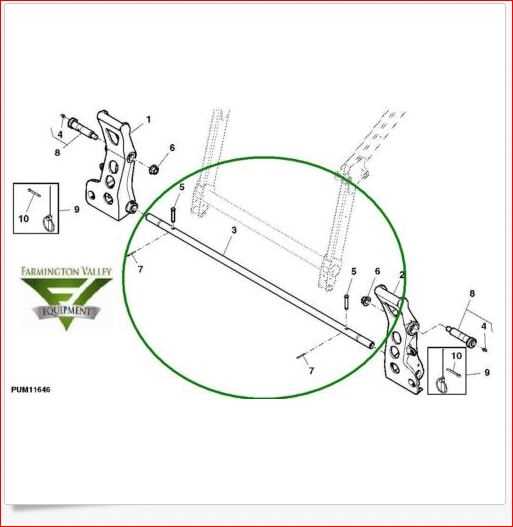

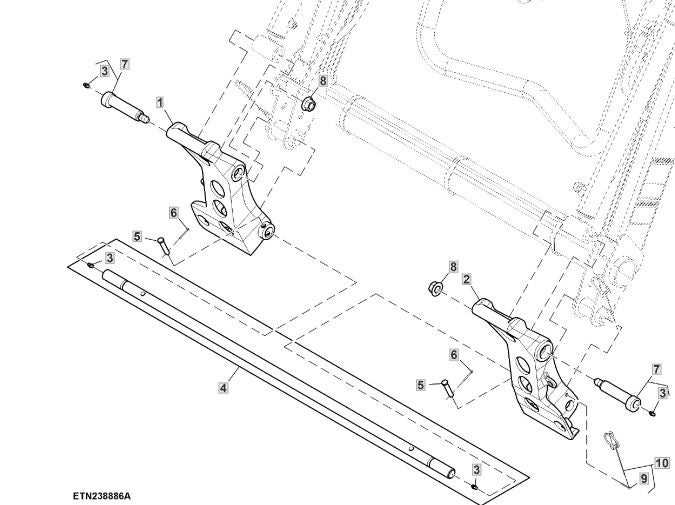

Importance of Parts Diagrams

Understanding the layout of components is essential for effective maintenance and repair. These visual representations serve as a vital tool for technicians, providing clarity and facilitating the identification of individual elements.

- Enhances efficiency in repairs

- Reduces the risk of errors

- Aids in inventory management

- Supports troubleshooting processes

By utilizing these visuals, professionals can delve deeper into the mechanics, leading to more informed decisions and quicker resolutions. This ultimately contributes to prolonged equipment life and optimal performance.

Common Issues with 120R Loaders

In the realm of agricultural equipment, several frequent challenges can arise that impact functionality and efficiency. Understanding these common concerns is vital for optimal performance and longevity.

Hydraulic Problems

- Leakages in hoses and fittings

- Inadequate fluid levels

- Faulty pumps affecting pressure

Mechanical Failures

- Wear and tear on attachment points

- Worn-out pivot pins and bushings

- Issues with the control system

Overview of Major Components

This section provides a comprehensive look at the key elements that contribute to the functionality and efficiency of the equipment. Understanding these components is essential for effective operation and maintenance.

Key Elements

At the heart of the system are several critical pieces that work in harmony. These include the hydraulic system, which facilitates lifting and maneuvering, as well as the attachment interface, designed for seamless tool integration. Each part plays a significant role in ensuring optimal performance.

Maintenance and Functionality

Regular upkeep of these components is vital for longevity and reliability. Routine inspections can help identify wear and tear, while proper lubrication and adjustments maintain the machine’s efficiency. Understanding the function of each part enables users to troubleshoot issues effectively.

Finding Replacement Parts Easily

Locating components for heavy machinery can be a straightforward task with the right approach. Understanding where to search and how to utilize available resources can save time and effort.

- Utilize online marketplaces specializing in machinery components.

- Consult with local dealers who carry a range of compatible items.

- Check manufacturer websites for official recommendations.

- Engage in community forums for shared experiences and advice.

By employing these strategies, you can delve into a wealth of options to find what you need efficiently.

Tools Needed for Repairs

When undertaking maintenance or fixing machinery, having the right instruments is essential for efficient and effective work. A well-equipped toolkit not only facilitates the repair process but also ensures that tasks are completed safely and accurately. Various types of equipment are necessary to handle different aspects of the job.

Basic Hand Tools: A collection of hand tools such as wrenches, screwdrivers, and pliers is fundamental. These instruments are crucial for loosening and tightening components, as well as for general assembly and disassembly tasks.

Power Tools: Depending on the complexity of the repairs, power tools like drills and impact wrenches may be required. These tools significantly reduce manual labor and increase efficiency, particularly in tasks that involve heavy-duty fastening or cutting.

Specialized Equipment: Some repairs may necessitate specialized tools designed for specific functions. Items such as torque wrenches, alignment tools, and hydraulic jacks can be invaluable in ensuring precision and safety during the repair process.

Safety Gear: Alongside tools, personal protective equipment such as gloves, goggles, and hard hats should not be overlooked. Safety gear is crucial in preventing injuries and ensuring a safe working environment.

Ultimately, investing in a comprehensive range of tools and equipment can significantly enhance the repair experience, allowing for more efficient problem-solving and extending the lifespan of machinery.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your equipment requires consistent care and attention. Regular maintenance not only enhances performance but also minimizes the risk of unexpected breakdowns.

Regular Inspections: Frequently check components for wear and tear. Identifying issues early can prevent more significant problems.

Cleanliness: Keep all surfaces free from dirt and debris. This prevents corrosion and promotes optimal operation.

Lubrication: Apply appropriate lubricants to moving parts. This reduces friction and extends the lifespan of mechanical elements.

Follow Manufacturer Guidelines: Adhere to recommended maintenance schedules. These guidelines are designed to optimize performance and durability.

Monitor Fluid Levels: Regularly check and maintain fluid levels to ensure smooth operation and prevent damage.

Store Properly: When not in use, store equipment in a sheltered environment to protect it from the elements.

Exploring Upgrades and Accessories

Enhancing your equipment’s capabilities can significantly improve its performance and efficiency. By integrating various accessories and modifications, users can tailor their machinery to better suit specific tasks and conditions, ultimately leading to increased productivity and versatility.

Below is a selection of popular upgrades that can elevate functionality:

| Upgrade/Accessory | Description |

|---|---|

| Attachment Kits | Various tools that can be attached to enhance capabilities, such as forks, buckets, or grapples. |

| Hydraulic Upgrades | Improving hydraulic systems for better lift capacity and speed. |

| Weight Kits | Additional weights to improve stability and traction during operation. |

| Lighting Solutions | Upgraded lighting for better visibility during low-light conditions. |

| Protective Gear | Durable covers and shields to safeguard against wear and tear. |

By considering these enhancements, operators can delve into the ultimate potential of their machinery, ensuring it meets both current and future needs effectively.

Cost Analysis of Replacement Parts

Understanding the financial implications of component replacement is crucial for maintaining equipment efficiency. By evaluating the costs associated with various elements, operators can make informed decisions that balance performance and budget. This section explores the factors influencing the pricing of these essential components, ensuring longevity and functionality in machinery.

Factors Influencing Costs

Several variables contribute to the pricing of replacement items, including brand reputation, material quality, and market demand. Higher quality components often come at a premium, reflecting their durability and reliability. Additionally, availability can affect pricing; limited stock may drive up costs, while competitive markets can lead to more favorable pricing options.

Long-Term Investment Considerations

When assessing the cost of replacements, it’s essential to consider long-term savings versus short-term expenditures. Investing in high-quality items may incur a larger upfront cost but can lead to decreased maintenance and repair expenses over time. Operators should weigh the immediate financial impact against potential future savings to make strategic choices for their machinery.

Where to Purchase Genuine Parts

Acquiring authentic components is crucial for maintaining the efficiency and longevity of your machinery. Genuine items ensure optimal performance and compatibility, providing peace of mind for operators.

Authorized Dealers

- Locate a certified distributor in your area.

- Verify their reputation and customer service ratings.

- Inquire about the availability of specific components.

Online Retailers

- Search for reputable e-commerce platforms specializing in equipment parts.

- Read reviews and check return policies before purchasing.

- Ensure that the site guarantees genuine products.

Customer Experiences and Reviews

This section aims to highlight the insights and opinions shared by users who have interacted with the equipment in question. Feedback from customers serves as a valuable resource for potential buyers, offering real-world perspectives on performance, reliability, and overall satisfaction.

Users frequently express appreciation for the durability and efficiency of the machinery, often noting how it meets their operational needs effectively. Many reviews emphasize the ease of use, making it accessible for both seasoned operators and newcomers alike.

Moreover, customer service experiences play a significant role in shaping overall satisfaction. Positive interactions with support teams can enhance the ownership experience, leading to higher recommendations among peers. Conversely, any challenges faced in obtaining assistance or parts can influence perceptions negatively.

In conclusion, examining customer feedback provides prospective users with a comprehensive understanding of what to expect, helping them make informed decisions based on shared experiences.