Exploring the Parts Diagram for John Deere 1332DDE

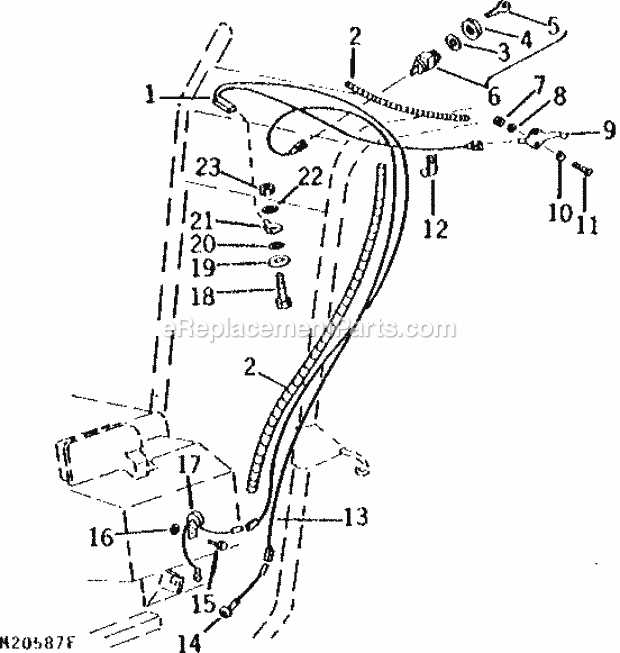

In the realm of machinery, comprehending the intricate assembly of individual elements is crucial for effective maintenance and repair. Each model comprises a unique configuration that dictates how various parts interact and function together. This knowledge not only aids in troubleshooting but also enhances overall operational efficiency.

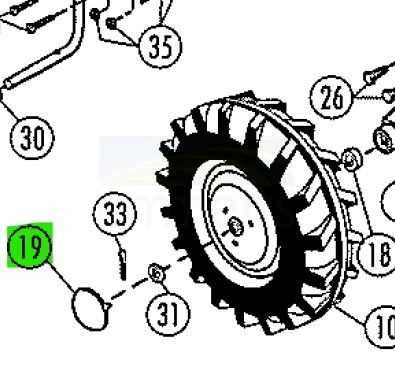

For those engaged in the upkeep of specific equipment, a clear visual representation of each component’s arrangement can be immensely beneficial. It serves as a guide, simplifying the process of identifying and accessing essential elements during servicing. By familiarizing oneself with these layouts, operators can ensure longevity and peak performance of their machinery.

Moreover, understanding the intricate relationships between different sections fosters a deeper appreciation of the engineering behind the design. Each segment plays a vital role in the overall functionality, and recognizing this interconnectedness can lead to more informed decision-making when it comes to repairs and upgrades. Emphasizing the importance of these visual aids, this discussion will delve into the specifics of component layouts and their significance in effective machine management.

Understanding John Deere 1332DDE Parts

Comprehending the components of a specific model is essential for effective maintenance and repairs. A detailed exploration of the elements that make up the equipment can enhance longevity and performance, ensuring optimal functionality throughout its lifespan.

Key elements to consider include:

- Engine Components: Understanding the inner workings and parts related to the engine is crucial for troubleshooting and ensuring efficient operation.

- Transmission System: Familiarity with the transmission elements aids in recognizing signs of wear and potential failures.

- Chassis and Frame: The structural components provide stability and support; knowledge of these can inform repair needs.

- Cutting Mechanism: Insight into the cutting assembly is vital for those using the equipment for landscaping or agricultural tasks.

When reviewing each category, it’s beneficial to:

- Refer to the manufacturer’s manual for specifications and recommendations.

- Identify common issues associated with each component.

- Utilize online resources for visual aids and further understanding.

By gaining a comprehensive grasp of these aspects, operators can enhance their efficiency and ensure the machine operates smoothly over time.

Overview of Parts Diagram Importance

Understanding the layout and components of machinery is crucial for effective maintenance and repair. An illustration that details these elements serves as an invaluable resource for both professionals and enthusiasts. It not only simplifies the identification of each segment but also enhances the overall efficiency of servicing tasks.

Facilitating Repairs and Maintenance

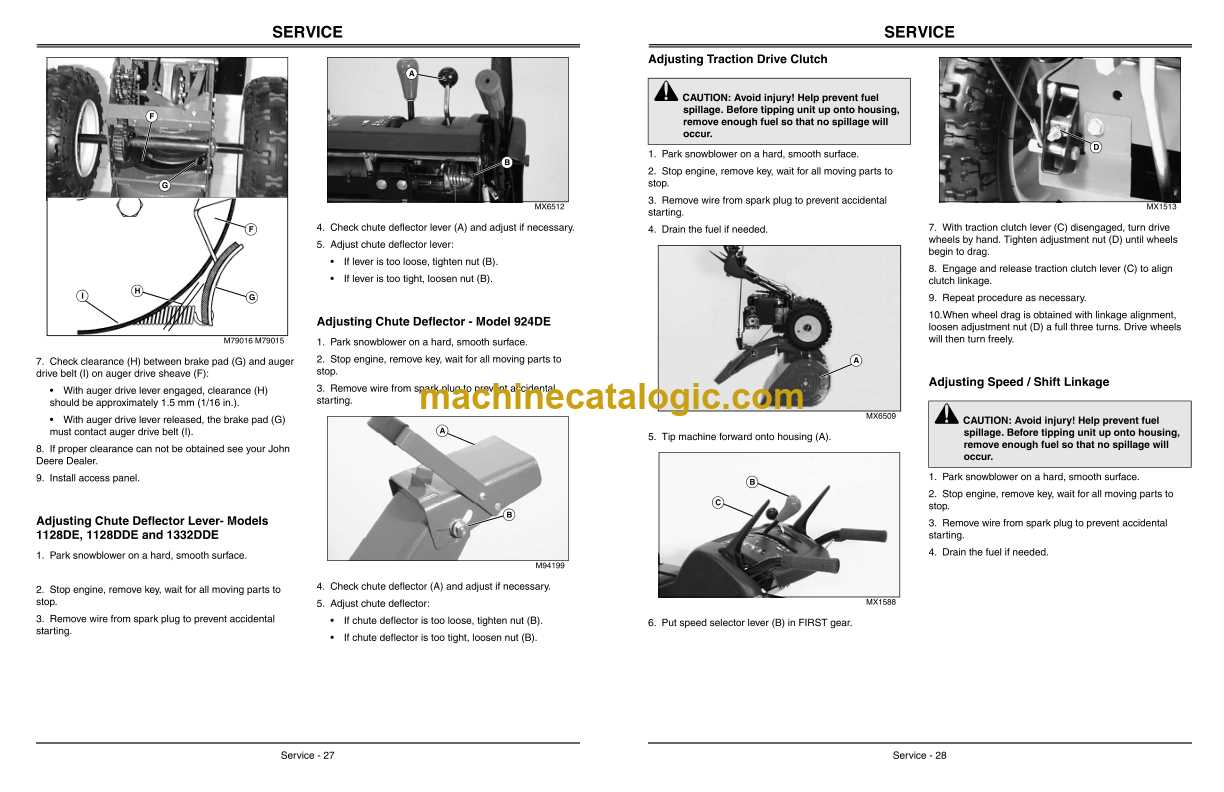

When dealing with complex equipment, a visual representation aids technicians in pinpointing specific sections that require attention. This clarity reduces the time spent on troubleshooting and ensures that repairs are executed with precision. Moreover, having a reference guide minimizes the risk of overlooking critical components, thereby promoting the longevity of the machinery.

Enhancing User Understanding

For operators and owners, familiarity with the inner workings of their equipment is essential. A detailed visual guide fosters a better understanding of how different parts interact, empowering users to make informed decisions regarding operation and care. This knowledge can lead to more effective use and improved performance over time.

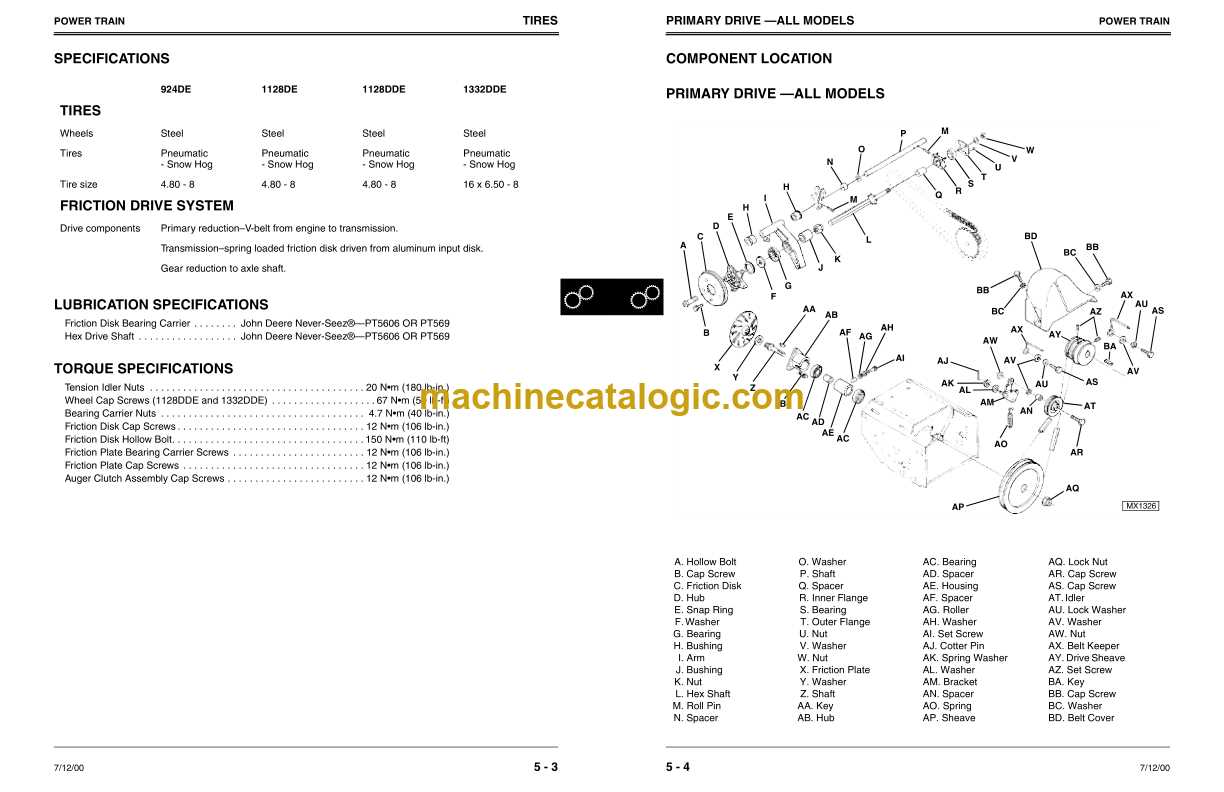

Key Components of the 1332DDE Model

The intricate design of this specific model showcases a variety of essential elements that contribute to its overall performance and functionality. Understanding these components is crucial for effective maintenance and optimal operation. Each part plays a significant role in ensuring reliability and efficiency, making it vital to familiarize oneself with their characteristics and functions.

Engine and Transmission

The engine serves as the powerhouse, providing the necessary energy for operation. Its robust construction ensures durability, while advanced technology enhances fuel efficiency. Coupled with the transmission, which efficiently transfers power to the wheels, these components work in harmony to deliver a smooth driving experience.

Chassis and Cutting Mechanism

The chassis forms the backbone of the machine, supporting all other elements while ensuring stability. Its design allows for easy maneuverability across various terrains. Complementing this is the cutting mechanism, engineered for precision and effectiveness. This assembly not only optimizes performance but also minimizes wear, ensuring longevity and high-quality results.

How to Access Parts Diagram Online

Finding the right components for machinery can be a straightforward task when you know where to look. Many manufacturers provide online resources that allow users to view detailed illustrations of their products, making it easier to identify the necessary elements for maintenance and repairs. This section will guide you through the steps to access these valuable resources effectively.

Steps to Locate the Resource

To access the schematic representation of the components, follow these steps:

| Step | Description |

|---|---|

| 1 | Visit the official website of the manufacturer. |

| 2 | Navigate to the support or resources section. |

| 3 | Look for the category related to your machinery model. |

| 4 | Select the link to view the illustrations. |

| 5 | Download or print the document for future reference. |

Tips for Efficient Navigation

When searching for the visual guide, consider using specific keywords related to your equipment. Additionally, ensure that your internet connection is stable to facilitate smooth access to the resources. Bookmarking the relevant page can also save time for future visits.

Common Issues and Replacement Parts

In the realm of outdoor machinery, certain challenges frequently arise that may hinder performance. Understanding these common problems and knowing the suitable components for replacement can ensure the longevity and efficiency of your equipment.

Several typical issues may be encountered:

- Engine Overheating: This can result from a blocked cooling system or low coolant levels.

- Starting Difficulties: Problems with the ignition system or battery can lead to trouble in getting the machine running.

- Unusual Noises: Sounds that deviate from the norm may indicate worn belts or damaged bearings.

- Fuel Leaks: Leaks can occur due to deteriorated seals or damaged fuel lines.

- Electrical Issues: Malfunctions in wiring can cause various operational failures.

To address these concerns, here are some commonly needed components for replacements:

- Cooling system components

- Ignition parts such as spark plugs and coils

- Belt kits for noise reduction

- Fuel line assemblies

- Electrical wiring harnesses

By being aware of these frequent complications and the necessary replacements, users can maintain their machinery in optimal condition, ensuring reliable performance for years to come.

Maintenance Tips for John Deere Models

Proper upkeep of equipment is essential for ensuring longevity and optimal performance. Regular attention to maintenance can prevent costly repairs and enhance efficiency. Implementing a systematic approach to care will help keep your machinery running smoothly throughout its operational life.

Routine Maintenance Practices

Establishing a regular maintenance schedule is vital. This includes tasks such as cleaning, lubrication, and inspection. Below are key practices to incorporate:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace engine oil and filter to ensure smooth operation. |

| Air Filter Check | Every 25 hours | Inspect and clean or replace the air filter for optimal airflow. |

| Blade Sharpening | Every 10 hours | Sharpen blades to improve cutting efficiency. |

| Tire Pressure Check | Weekly | Ensure proper tire inflation for better traction and fuel efficiency. |

Seasonal Preparations

Adapting maintenance practices to seasonal changes is equally important. Preparing your equipment for different conditions can prevent damage and ensure readiness for peak usage times.

Identifying Part Numbers Easily

Finding the correct identification numbers for machinery components can be a straightforward task with the right approach. A systematic method can streamline the process, making it easier to locate and order the necessary items without confusion. Utilizing clear resources and methods is essential for anyone involved in maintenance or repair.

Utilizing Resource Guides

One effective way to simplify identification is through the use of comprehensive resource manuals. These guides often contain detailed illustrations and descriptions that correspond to each component, allowing users to cross-reference and identify the exact specifications needed. Familiarity with these resources can significantly reduce the time spent on searches.

Leveraging Online Tools

In addition to physical guides, numerous online platforms offer searchable databases for component identification. By entering specific details or characteristics, users can quickly retrieve relevant information. Staying organized and keeping a list of frequently used resources can enhance efficiency in this process.

Where to Buy Genuine Parts

When it comes to maintaining and repairing equipment, sourcing authentic components is essential for optimal performance and longevity. Genuine replacements are crafted to meet specific standards and are often recommended by manufacturers to ensure compatibility and reliability. Knowing where to find these quality items can save time and money in the long run.

Authorized Dealers

One of the most reliable sources for authentic components is authorized dealerships. These establishments typically have a wide selection of items and staff who are knowledgeable about the products. Purchasing from an authorized dealer not only guarantees authenticity but also often comes with warranty options that can provide peace of mind.

Online Marketplaces

Another convenient avenue for acquiring legitimate components is through reputable online marketplaces. Websites that specialize in agricultural or industrial equipment frequently offer a vast inventory of authentic items. When shopping online, ensure that the seller is reputable and provides clear information about the product’s authenticity. Reading customer reviews can also help in making informed decisions.

Comparing OEM and Aftermarket Options

When it comes to replacement components for machinery, two primary categories often emerge: original equipment manufacturer (OEM) products and their aftermarket counterparts. Each option has its unique set of advantages and potential drawbacks, influencing the decision-making process for users seeking optimal performance and value.

Quality and Performance

OEM offerings are typically known for their high quality and reliability, as they are designed specifically for compatibility with original models. Aftermarket alternatives, while often more affordable, can vary significantly in quality. Users must weigh the benefits of potential cost savings against the risks of decreased performance or longevity.

Cost Considerations

One of the most compelling reasons to consider aftermarket alternatives is the cost savings they often provide. However, this can sometimes lead to trade-offs in quality. A careful evaluation of the overall expenditure, including installation and potential future repairs, is essential when comparing these two options.

| Factor | OEM | Aftermarket |

|---|---|---|

| Quality | High, tailored for specific models | Varies, may lack consistency |

| Cost | Generally higher | Usually lower, potential savings |

| Availability | Often limited to authorized dealers | Widely available through various retailers |

| Warranty | Comprehensive warranties | Varies, may offer limited coverage |

Step-by-Step Repair Guide

This guide provides a comprehensive approach to effectively addressing mechanical issues with your equipment. By following these detailed instructions, you can ensure a successful repair process that enhances performance and extends the lifespan of your machinery.

1. Preparation: Before starting any repair work, gather all necessary tools and safety equipment. Ensure that you have a clean, well-lit workspace to facilitate the task at hand.

2. Identify the Issue: Begin by diagnosing the problem. Look for visible signs of wear or damage and consult the user manual to understand the functionality of each component.

3. Disassembly: Carefully disassemble the affected parts. Take note of how components fit together by documenting the order of disassembly. This will simplify reassembly later.

4. Inspection: Examine each part for defects. Pay close attention to any areas showing signs of significant wear, cracks, or other forms of damage. Make a list of items that need replacement.

5. Replacement: Procure the necessary replacements. When installing new components, ensure they are compatible with your specific model. Follow manufacturer specifications for proper installation.

6. Reassembly: Once all replacements are in place, carefully reassemble the equipment in the reverse order of disassembly. Double-check that all connections are secure.

7. Testing: After reassembly, conduct a thorough test to confirm that the issue has been resolved. Observe the machinery in operation to ensure everything functions as expected.

8. Maintenance: Finally, implement a regular maintenance schedule to prevent future issues. Routine checks and timely replacements can significantly enhance the longevity and efficiency of your equipment.

Frequently Asked Questions about Parts

This section addresses common inquiries related to components and their maintenance. Understanding these aspects can enhance the longevity and efficiency of your equipment.

Common Inquiries

- What should I consider when selecting components?

- How can I ensure compatibility with my model?

- Where can I find reliable suppliers?

- What are the signs that a component needs replacement?

Maintenance Tips

- Regularly inspect components for wear and tear.

- Keep a record of replacements to track performance.

- Consult the manual for specific maintenance recommendations.

- Use quality components to avoid premature failure.

Resources for Further Learning

Expanding your knowledge about machinery maintenance and repair can be greatly beneficial. There are numerous resources available that provide detailed insights, technical illustrations, and comprehensive guides. These materials can help enthusiasts and professionals alike to deepen their understanding and enhance their skills.

Online forums and communities are excellent places to connect with experienced users and industry experts. Engaging in discussions can provide valuable tips and real-world advice. Additionally, instructional videos and webinars offer visual guidance, making complex concepts easier to grasp.

Books and manuals specific to various models can serve as indispensable references. These publications often include maintenance schedules, troubleshooting techniques, and safety protocols. Finally, manufacturer websites frequently offer downloadable resources, including technical specifications and operational guidance, ensuring you have access to the most accurate information.