Understanding the John Deere 1435 Parts Diagram

Understanding the intricate workings of a lawn maintenance machine is essential for ensuring optimal performance and longevity. This section delves into the various elements that make up such machinery, offering insight into their arrangement and function. Knowledge of these components can empower operators and technicians to address issues more effectively and maintain the equipment in peak condition.

Whether you’re a seasoned professional or a casual user, familiarizing yourself with the internal and external mechanisms is beneficial. Each element serves a specific purpose, contributing to the overall efficiency of the machine. Recognizing how these parts interact can aid in troubleshooting and repair, as well as enhance your operational capabilities.

In this exploration, we will outline the essential features and configurations that characterize these machines. A comprehensive understanding of the different sections will enable you to navigate maintenance tasks with confidence and precision, ensuring that your equipment remains a reliable ally in your landscaping endeavors.

Visual representations of components play a crucial role in the maintenance and repair of machinery. These illustrations provide clarity, helping users understand the structure and organization of various elements within a machine. By offering a clear layout, they facilitate efficient troubleshooting and assembly processes.

Enhanced Understanding

Utilizing visual aids allows individuals to grasp complex configurations easily. Here are some benefits:

- Simplifies identification of individual elements

- Clarifies relationships between different components

- Aids in understanding assembly and disassembly procedures

Streamlined Maintenance

Properly labeled visuals contribute significantly to effective upkeep. Consider the following advantages:

- Improves accuracy in repairs

- Reduces the risk of errors during reassembly

- Enhances the overall efficiency of maintenance tasks

Key Components of the Model

This section focuses on the essential elements that contribute to the overall functionality and performance of the machine. Understanding these components is crucial for effective maintenance and operation, ensuring optimal efficiency in various tasks.

The engine serves as the heart of the machine, providing the necessary power for operation. Coupled with a robust transmission system, it allows for seamless control over speed and movement. The chassis plays a vital role in supporting the structure and enhancing stability, while the cutting mechanism is designed for precision and efficiency in various terrains.

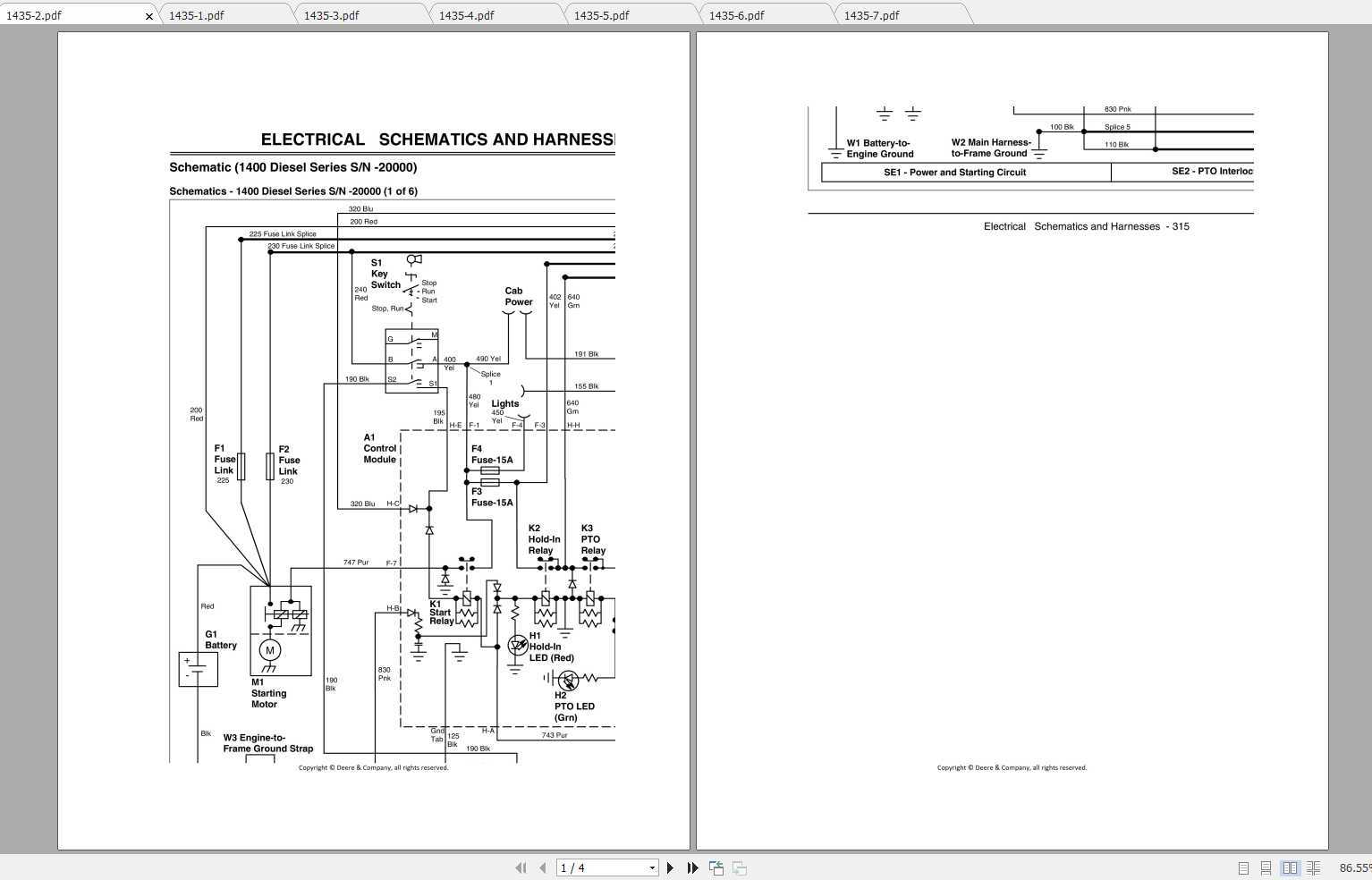

Additionally, the electrical system is integral for starting and powering various functions, ensuring reliability during operation. The wheels and tires are engineered for traction and maneuverability, enabling the machine to navigate different environments with ease. Each of these components works harmoniously to deliver a dependable and efficient performance.

Understanding the Parts Layout

Grasping the arrangement of components within a machine is essential for effective maintenance and operation. This overview provides insights into how various elements are positioned and interconnected, enabling users to comprehend the functionality of the entire system.

The configuration typically includes several key assemblies, each serving a specific purpose:

- Engine Assembly: The core that powers the equipment.

- Transmission Unit: Facilitates movement and control.

- Hydraulic System: Enables various functions through fluid power.

- Chassis: Provides structural integrity and support for other components.

- Cutting Mechanism: Responsible for achieving desired results in landscaping or mowing tasks.

Recognizing how these assemblies are arranged allows for better troubleshooting and repair strategies. Users can identify potential issues more readily by understanding the layout.

When examining the layout, consider the following:

- Accessibility: Ensure that each component can be easily reached for maintenance.

- Safety Features: Identify any mechanisms designed to protect users during operation.

- Connection Points: Note how components link together, which is crucial for efficient repairs.

Ultimately, familiarizing oneself with the configuration of the system enhances overall efficiency and effectiveness in its operation.

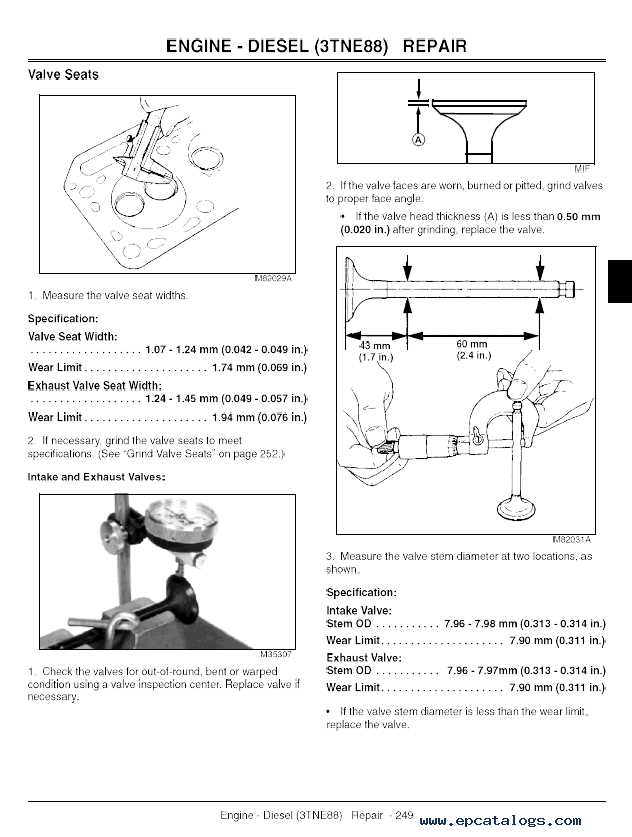

Engine Specifications and Parts

This section explores the key characteristics and components that define the engine of the mentioned machinery. Understanding these specifications is essential for maintenance and performance optimization, ensuring efficient operation in various tasks.

Key Engine Features

- Engine Type: Liquid-cooled, four-stroke engine designed for durability.

- Displacement: Offers ample capacity for increased power output.

- Power Rating: Capable of delivering significant horsepower for demanding applications.

- Fuel System: Equipped with a reliable fuel delivery mechanism for optimal performance.

Essential Components

- Cylinder Head: Houses critical valves and facilitates combustion.

- Piston Assembly: Converts fuel energy into mechanical motion.

- Crankshaft: Transforms linear motion into rotational energy.

- Cooling System: Maintains ideal operating temperatures to prevent overheating.

- Ignition System: Initiates combustion at the correct timing for efficiency.

Transmission System and Components

The transmission system is a vital aspect of any machinery designed for efficient power transfer and performance. It encompasses various elements that work together to facilitate the movement and control of the vehicle. Understanding these components is essential for maintaining optimal functionality and ensuring longevity.

Key components of the transmission system include gears, shafts, and clutches. These parts play a crucial role in transmitting torque from the engine to the wheels, enabling smooth operation across different terrains. Gears are particularly important as they determine the speed and power of the vehicle, while shafts provide the necessary connection between the engine and the drive wheels.

Additionally, the system may include various fluid reservoirs and filters that help maintain proper lubrication and cooling, ensuring efficient operation under varying conditions. Regular inspection and maintenance of these components can significantly enhance performance and reduce the risk of failure.

Maintenance and Repair Guidelines

Ensuring the longevity and optimal performance of equipment requires regular upkeep and timely repairs. By following systematic procedures, operators can minimize downtime and enhance functionality. This section outlines essential practices that can assist in maintaining and restoring machinery effectively.

Routine Inspections: Conduct frequent examinations to identify wear and tear. Check fluid levels, belts, and hoses for signs of damage. Early detection can prevent more extensive issues and costly repairs.

Cleaning and Lubrication: Keep components clean and well-lubricated to reduce friction and prevent overheating. Utilize appropriate cleaning agents and lubricants to ensure compatibility with materials.

Parts Replacement: Replace worn or damaged components promptly. Utilizing high-quality replacements can improve performance and extend the lifespan of the machinery.

Consultation of Manuals: Always refer to the manufacturer’s guidelines for specific maintenance intervals and repair techniques. Manuals provide crucial information on recommended procedures and specifications.

Professional Assistance: If issues persist or are beyond the scope of personal expertise, seeking help from qualified professionals is advisable. Their experience can be invaluable in resolving complex problems efficiently.

Common Issues and Solutions

When operating a lawn maintenance machine, users may encounter a variety of challenges that can hinder performance and efficiency. Understanding these common problems and their respective solutions can enhance the overall experience and prolong the lifespan of the equipment.

Engine Performance Problems

Issues related to engine performance are prevalent and can stem from various factors, such as fuel quality, air filter condition, or ignition system malfunctions. Regular maintenance and timely interventions are key to preventing these issues.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Faulty battery or starter | Check and replace battery or starter if needed. |

| Unusual noises | Worn-out components | Inspect and replace worn parts to ensure smooth operation. |

| Stalling during operation | Clogged fuel filter | Replace fuel filter and ensure fuel lines are clear. |

Cutting Issues

Another frequent concern is related to cutting performance. Dull blades, incorrect height settings, or damaged components can significantly impact the quality of work.

| Issue | Possible Cause | Solution |

|---|---|---|

| Uneven cut | Improper blade height | Adjust the height settings for uniform cutting. |

| Grass clumping | Dull blades | Sharpen or replace blades for better cutting performance. |

| Frequent jamming | Debris build-up | Clean the cutting deck regularly to prevent clogs. |

Parts Replacement Procedures

Replacing components in machinery is essential for maintaining optimal performance and extending the lifespan of equipment. This process involves several steps to ensure proper installation and functionality. Understanding the necessary tools, techniques, and safety measures can greatly enhance the efficiency and effectiveness of the replacement process.

Preparation and Tools Needed

Before starting the replacement, gather all required tools and components. Common tools include wrenches, screwdrivers, and pliers, along with specific equipment designed for the particular assembly. Ensure the workspace is clean and organized to facilitate a smooth operation. Additionally, reviewing any manuals or guides related to the machinery can provide valuable insights and instructions.

Steps for Component Replacement

Begin the replacement process by disconnecting any power sources and ensuring the machine is safe to work on. Carefully remove the old component, taking note of how it is installed for accurate reassembly. Install the new piece, ensuring it is secure and correctly positioned. After completing the installation, double-check all connections and perform a functional test to verify that the machinery operates as intended.

Finding Replacement Parts

Locating suitable components for machinery can be a straightforward process with the right approach. Understanding the essentials of your equipment and knowing where to look can save time and ensure you acquire the correct items for maintenance or repairs.

Here are some effective methods to find the necessary components:

- Consult the manufacturer’s manual: The manual often contains valuable information regarding specifications and compatible components.

- Visit authorized retailers: These vendors typically offer genuine items and can provide guidance on the most suitable replacements.

- Utilize online marketplaces: Numerous websites specialize in equipment parts, allowing for convenient comparisons and user reviews.

- Join online forums or communities: Engaging with other users can yield recommendations and insights on where to find quality components.

By following these strategies, you can simplify the process of sourcing components and ensure your machinery continues to operate effectively.

Authorized Dealers and Retailers

Finding reliable sources for machinery components is essential for maintaining optimal performance. Authorized dealers and retailers play a crucial role in providing access to high-quality items and expertise. These professionals are equipped to assist customers in identifying the appropriate components needed for various machinery models, ensuring compatibility and reliability.

Benefits of Authorized Retailers

Purchasing from certified retailers offers numerous advantages. First and foremost, these establishments often provide genuine components, which ensures durability and functionality. Additionally, authorized dealers have trained staff who can offer valuable insights and support, guiding customers in making informed decisions about their purchases.

How to Locate Authorized Dealers

To find a trustworthy dealer, it is advisable to visit official websites or contact local distributors. Many manufacturers provide lists of authorized retailers, allowing customers to verify their legitimacy. Engaging with reputable dealers not only guarantees product quality but also enhances overall customer satisfaction.

Online Resources for Parts

In today’s digital age, finding components for machinery has become more accessible than ever. Numerous platforms and websites offer extensive catalogs of various elements, ensuring that users can easily locate the items they need. These resources not only provide detailed listings but also often include specifications, compatibility information, and user reviews to aid in making informed decisions.

Manufacturer Websites

Visiting the official websites of manufacturers is a reliable way to access genuine components. These sites typically feature comprehensive inventories, ensuring users can find the correct items for their specific models. Moreover, many manufacturers provide detailed specifications, installation guides, and maintenance tips, enhancing the overall user experience.

Online Marketplaces

Popular e-commerce platforms serve as a valuable resource for those seeking a wide range of components. These marketplaces allow users to compare prices, read reviews, and view seller ratings, fostering confidence in purchasing decisions. Additionally, many sellers offer used or refurbished items, providing budget-friendly alternatives for those looking to save on expenses.

Tips for Proper Maintenance

Regular upkeep is essential to ensure equipment runs efficiently and lasts longer. Adopting a consistent care routine helps identify potential issues early, preventing larger problems that can lead to downtime. It’s important to follow proper procedures and use the right tools when conducting maintenance, as this ensures safety and reliability.

Lubrication is a key step in maintaining the longevity of mechanical systems. Ensuring that all moving components are properly lubricated reduces friction and wear, leading to smoother operation. Make sure to use high-quality lubricants that are appropriate for the specific system.

Inspect for Wear and Tear regularly to catch any signs of damage. Pay close attention to parts that experience frequent use, as these are more likely to degrade over time. Replacing worn components before they fail entirely can prevent breakdowns and improve overall performance.

Finally, cleaning equipment thoroughly after each use prevents buildup of dirt and debris, which can cause blockages and reduce efficiency. A clean machine operates more smoothly and is less likely to suffer from preventable malfunctions.