John Deere 210 Parts Diagram Overview

In the realm of farming equipment, a comprehensive grasp of machinery components is essential for efficient maintenance and operation. Each element plays a crucial role in ensuring that equipment functions optimally, contributing to productivity and reliability in agricultural practices.

By delving into the intricate details of these components, users can better navigate the complexities of machinery repair and enhancement. Familiarity with specific parts allows for informed decisions, minimizing downtime and maximizing efficiency.

This exploration provides an insightful look into the various elements that constitute essential machinery. By understanding their configurations and functions, operators can effectively manage their equipment, ensuring longevity and superior performance in the field.

Understanding the John Deere 210 Model

This section provides insights into a specific agricultural machine that has gained recognition for its reliability and versatility. With a focus on its design and functionality, the aim is to explore how this equipment serves various tasks in farming and landscaping. By examining its features, operators can better appreciate the advantages it offers in different operational scenarios.

Key Features and Benefits

The machine boasts a range of essential characteristics that enhance its performance. A powerful engine ensures efficient operation, while ergonomic controls contribute to user comfort. Additionally, its robust build quality makes it suitable for various terrains, enabling users to tackle a wide array of projects with confidence. The combination of durability and ease of use makes this model a valuable asset for both professionals and hobbyists.

Maintenance and Care

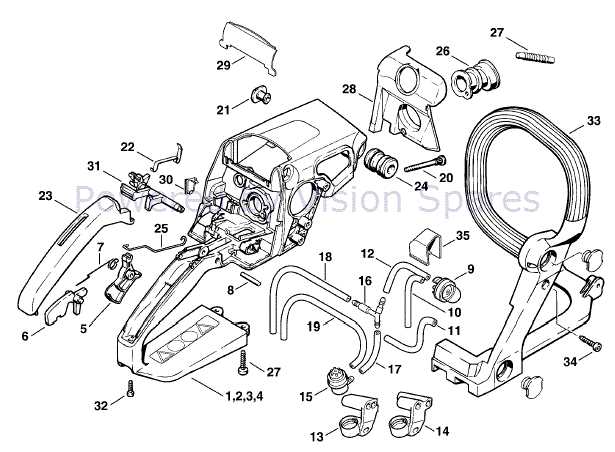

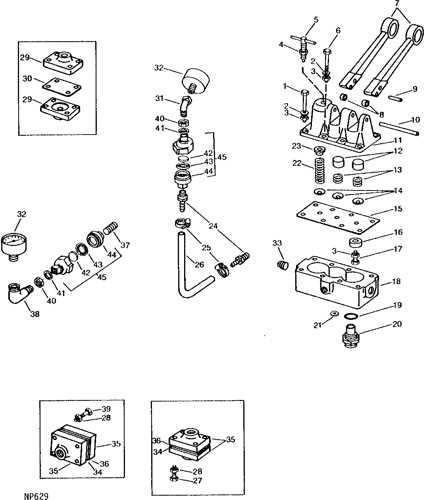

Importance of Parts Diagrams

Understanding the layout of components within machinery is crucial for effective maintenance and repair. Visual representations serve as a valuable resource, guiding users through complex systems. They enhance clarity and ensure that each element is easily identifiable, fostering a smoother workflow.

Facilitating Repairs

Visual aids streamline the troubleshooting process by allowing technicians to quickly locate and assess the condition of individual elements. This reduces downtime and minimizes the risk of misdiagnosis, ultimately leading to more efficient repairs.

Enhancing Learning and Training

For newcomers and seasoned professionals alike, illustrations of mechanical setups provide a foundational understanding of how systems operate. These resources are essential in training programs, enabling learners to grasp intricate concepts and apply their knowledge in practical scenarios.

Common Issues with John Deere 210

Machines of this kind are known for their reliability, but they can still encounter a range of challenges over time. Understanding these common problems can help owners maintain optimal performance and prolong the lifespan of their equipment.

- Engine Difficulties:

- Hard starting due to fuel delivery issues.

- Overheating caused by cooling system failures.

- Transmission Problems:

- Slipping gears or difficulty in shifting.

- Fluid leaks that can lead to performance issues.

- Electrical Failures:

- Batteries that drain quickly or fail to charge.

- Faulty wiring leading to intermittent operation of components.

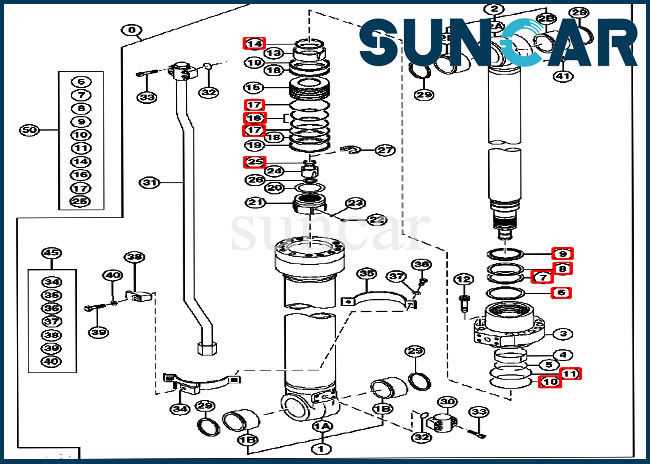

- Hydraulic System Issues:

- Leaking hoses or seals affecting lifting capacity.

- Poor performance due to contaminated fluid.

- Deck and Blade Problems:

- Uneven cutting height due to worn blades.

- Blockages caused by debris accumulation.

By being aware of these frequent issues, operators can take proactive measures to address them, ensuring their machinery remains effective and efficient in its operations.

Where to Find Parts Diagrams

Locating the necessary visual references for machinery components can be essential for effective maintenance and repair. Various resources are available that provide detailed illustrations and lists, making it easier for users to identify and source specific items. Understanding where to find these references can streamline the troubleshooting process and enhance overall equipment longevity.

Online Resources

The internet is a valuable asset for accessing a wide range of visual guides. Many manufacturers and third-party websites host extensive libraries of schematics. Simply searching for the model and the term “schematic” or “exploded view” can yield fruitful results. Additionally, forums dedicated to equipment enthusiasts often share valuable insights and links to reputable resources.

Service Manuals

Another effective avenue is the use of service manuals. These documents typically contain comprehensive breakdowns of components, along with detailed images and descriptions. They can often be purchased directly from manufacturers or found in local libraries. Utilizing these manuals can provide not only the necessary visuals but also essential instructions for repairs and maintenance.

Identifying Components in Diagrams

Understanding the various elements within a schematic representation is crucial for effective maintenance and repair tasks. These visual guides serve as blueprints, allowing individuals to pinpoint specific items, comprehend their functions, and ascertain how they interrelate within the larger system. Familiarity with these representations enhances troubleshooting efficiency and ensures that replacements are accurate and timely.

Common Symbols and Their Meanings

Each representation employs a standardized set of symbols to convey information about different components. Recognizing these symbols is the first step in deciphering the layout. For instance, a circle may denote a connection point, while a rectangle could signify a mechanical part. By familiarizing oneself with these symbols, one can quickly navigate through the illustration, reducing the likelihood of errors during the identification process.

Understanding Connections and Relationships

In addition to recognizing individual elements, comprehending how they are interconnected is essential. Arrows and lines often illustrate the relationships between components, indicating the flow of power or information. Analyzing these connections provides insight into the operational dynamics of the entire assembly, enabling more informed decision-making when addressing issues or performing upgrades.

Essential Tools for Repairs

Having the right instruments is crucial for effective maintenance and troubleshooting. A well-equipped toolkit not only enhances efficiency but also ensures that repairs are completed safely and accurately. Below are key tools that every technician should consider for their repair endeavors.

- Wrenches: Adjustable and socket wrenches are essential for loosening and tightening bolts.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will help in accessing different types of fasteners.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping, twisting, and cutting wires.

- Socket Set: A comprehensive socket set allows for the efficient handling of various nut and bolt sizes.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specified torque settings.

Investing in high-quality tools is advisable as they tend to last longer and provide better results. Additionally, maintaining your tools in good condition will significantly enhance their performance and lifespan.

- Regularly clean tools after use.

- Store them in a dry, organized space to prevent damage.

- Inspect tools for wear and replace them when necessary.

With the right tools at hand, any repair task can become manageable, ensuring that equipment remains in optimal working condition.

Ordering Genuine John Deere Parts

When it comes to maintaining the performance and longevity of your equipment, sourcing authentic components is essential. These original elements ensure optimal functionality and reliability, ultimately protecting your investment. Understanding the process of acquiring these items can save you time and effort while enhancing the overall efficiency of your machinery.

Here are some key steps to consider when ordering authentic components:

| Step | Description |

|---|---|

| 1 | Identify the specific component needed for your machinery. Refer to the owner’s manual or consult a professional if necessary. |

| 2 | Locate an authorized dealer or online retailer that specializes in genuine components. Ensure they have a good reputation for quality and service. |

| 3 | Provide the dealer with the correct model and serial numbers. This information is crucial for ensuring compatibility. |

| 4 | Review the pricing and availability of the components. Consider placing an order only when you are satisfied with the terms. |

| 5 | Once your order is placed, monitor the shipping status to ensure timely delivery, allowing for smooth repairs or replacements. |

Following these steps can facilitate a seamless experience in acquiring authentic components, thus ensuring your equipment remains in peak condition.

Aftermarket vs. OEM Parts

When it comes to equipment maintenance, choosing between original and alternative components can significantly impact performance and longevity. Each option has its own advantages and considerations, making it essential to understand the differences to make an informed decision.

Understanding the Options

- Original Equipment Manufacturer (OEM): These components are produced by the original manufacturer of the equipment. They are designed to meet specific standards and are often synonymous with quality and reliability.

- Aftermarket: These are produced by third-party companies and are not affiliated with the original manufacturer. They can vary widely in quality and price, offering a range of alternatives for consumers.

Advantages and Disadvantages

- Quality Assurance:

- OEM components typically offer guaranteed quality and compatibility.

- Aftermarket options may provide good quality, but the variance can be significant.

- Cost:

- OEM items usually come at a premium price.

- Aftermarket alternatives often provide a more budget-friendly solution.

- Availability:

- OEM components can sometimes be hard to find, especially for older models.

- Aftermarket options are often more readily available across various retailers.

Ultimately, the choice between original and alternative components depends on individual needs, budget, and desired quality. Each type has its own merits, making it crucial to assess specific requirements before making a purchase.

Step-by-Step Repair Guide

This section provides a comprehensive approach to effectively troubleshoot and repair equipment. By following the outlined steps, users can gain insights into the necessary procedures, ensuring a smooth and efficient restoration process.

Understanding the Equipment

Before commencing any repair, it is essential to familiarize yourself with the machinery’s components and their functions. Refer to the operational manual for detailed descriptions and illustrations. This knowledge lays the foundation for identifying potential issues and understanding how different parts interact.

Repair Process

Start by gathering the required tools and replacement components. Safety first: always wear protective gear and ensure the machine is powered down. Begin with a thorough inspection, checking for visible damage or wear. If necessary, consult the reference materials to locate specific elements that may need attention.

Once the problem is identified, carefully dismantle the affected sections, keeping track of all screws and parts. Replace any faulty components with new ones, ensuring a proper fit. After reassembly, conduct a test run to verify that the issue is resolved and the equipment functions correctly.

Regular maintenance is vital for longevity, so consider implementing a routine check-up schedule to prevent future complications.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the extended life of any machinery. By implementing a few key practices, you can enhance performance, reduce downtime, and minimize the need for costly repairs. Here are some effective strategies to consider.

Regular Inspections: Conduct frequent checks on your equipment to identify any signs of wear or damage. Addressing small issues promptly can prevent them from escalating into major problems.

Routine Cleaning: Keeping your machinery clean helps maintain optimal functionality. Remove dirt, debris, and any buildup that could hinder performance. Regularly washing external components can also prevent rust and corrosion.

Fluid Changes: Ensure that all necessary fluids are changed at recommended intervals. This includes engine oil, hydraulic fluid, and coolant. Clean fluids facilitate smooth operation and protect internal components.

Filter Maintenance: Replace or clean filters as needed to ensure that the system operates efficiently. Clogged filters can lead to overheating and reduced performance.

Follow Manufacturer Guidelines: Always adhere to the maintenance schedule and guidelines provided by the manufacturer. These recommendations are tailored to maximize the lifespan and efficiency of your equipment.

Storage Practices: When not in use, store machinery in a sheltered environment to protect it from the elements. This can significantly reduce wear and prolong its life.

Professional Servicing: Consider periodic professional inspections and servicing. Experienced technicians can provide insights and address potential issues that may not be immediately visible.

By following these maintenance tips, you can ensure that your machinery remains reliable and efficient for years to come.

Frequently Asked Questions

This section addresses common inquiries related to the components and maintenance of agricultural machinery. Here, users can find valuable insights and solutions to frequently encountered issues.

General Inquiries

Many operators have questions about the compatibility and availability of various elements for their equipment. Understanding these aspects can significantly enhance the efficiency of machinery operations.

Maintenance and Support

Proper upkeep is crucial for optimal performance. Below are some common questions regarding maintenance practices and support options.

| Question | Answer |

|---|---|

| What should I do if a component fails? | Assess the damage and consult your user manual for troubleshooting steps or replacement options. |

| Where can I find replacement parts? | Replacement components are available through authorized dealers or online marketplaces. |

| How often should I perform maintenance? | Regular maintenance should be conducted based on the manufacturer’s recommendations, typically every few hundred operating hours. |

| Is there a warranty on parts? | Most components come with a warranty; please check the specifics with your supplier. |

Online Resources and Communities

In today’s digital age, enthusiasts and professionals alike have access to a wealth of information and support through various online platforms. These resources not only provide technical documentation and schematics but also foster connections among individuals with shared interests. Engaging with these communities can enhance knowledge and facilitate problem-solving.

Many dedicated websites offer comprehensive guides, including schematics and tutorials tailored to specific machinery. These platforms often include forums where users can ask questions, share experiences, and offer advice based on their expertise. Social media groups and discussion boards serve as valuable spaces for networking and exchanging tips on maintenance and repairs.

Additionally, video-sharing platforms feature a plethora of instructional content, allowing users to visualize processes and learn through practical demonstrations. Online marketplaces also provide easy access to components, making it simpler to source the necessary items for repairs or upgrades. Engaging with these resources and communities can significantly streamline the experience of maintaining and restoring equipment.

Expert Recommendations for Upgrades

Enhancing the performance and efficiency of your equipment can significantly extend its lifespan and improve productivity. By implementing strategic upgrades, operators can achieve better functionality, reduce maintenance costs, and optimize overall performance. Here are some expert suggestions for essential enhancements that can make a noticeable difference.

First and foremost, consider investing in high-quality filters and fluids. Upgrading to advanced filtration systems can ensure cleaner operation and longer intervals between servicing. Additionally, using premium lubricants can reduce friction, leading to smoother operation and improved fuel efficiency.

Another effective enhancement is the incorporation of modern technology. Implementing GPS tracking and telemetry systems can provide real-time data on performance metrics, enabling better decision-making and maintenance scheduling. This can lead to significant improvements in operational efficiency.

Furthermore, enhancing safety features is crucial. Installing advanced lighting systems or additional protective elements can increase visibility and reduce the risk of accidents. Operators should also explore ergonomic upgrades that improve comfort and reduce operator fatigue during long working hours.

Finally, regular inspections and updates to critical components, such as the drivetrain and hydraulic systems, can prevent unexpected failures and costly repairs. Investing in quality replacement components ensures reliability and maintains the overall integrity of the machine.