Parts Diagram for John Deere 2350

In the realm of agricultural equipment, the intricate assembly of various components plays a crucial role in ensuring optimal performance and longevity. A comprehensive exploration of these elements provides valuable insights for both operators and enthusiasts alike. Recognizing how each part functions and interacts within the larger system can enhance maintenance practices and improve operational efficiency.

Visual aids serve as essential tools in grasping the layout and connectivity of different sections of machinery. They allow users to pinpoint specific components quickly, facilitating troubleshooting and repairs. This knowledge not only aids in routine upkeep but also empowers users to make informed decisions regarding replacements and upgrades.

As we delve into the specifics, it becomes evident that familiarity with the structure of such machinery is vital for anyone engaged in agricultural practices. Whether you are a seasoned professional or a newcomer, understanding these components can greatly influence your approach to machinery care and enhance your overall experience in the field.

Understanding the John Deere 2350

This section explores the essential features and components of a well-known agricultural machine, highlighting its significance in modern farming practices. A comprehensive grasp of its design and functionality can enhance operational efficiency and maintenance.

Key Features

The machine is renowned for its robust construction and reliability. Equipped with a powerful engine, it provides the necessary torque for various tasks, from plowing to harvesting. Its user-friendly controls enable operators to work with precision and ease, significantly improving productivity on the field.

Maintenance Considerations

Regular upkeep is crucial for optimal performance. Understanding the main assemblies and their roles allows for timely interventions, reducing downtime. Familiarity with common wear items helps in planning replacements before they lead to larger issues, ensuring the machine remains operational throughout the season.

Conclusion

A thorough knowledge of this machine’s construction and functionality not only aids in effective usage but also fosters a deeper appreciation for its role in agriculture. Whether you are an operator or a technician, understanding these elements can lead to enhanced performance and longevity of the equipment.

Key Features of the 2350 Model

The model in focus is renowned for its exceptional design and performance capabilities, making it a favorite among operators in various agricultural settings. Its features are tailored to enhance productivity and ease of use, catering to the diverse needs of modern farming.

- Robust Engine: The powerful engine delivers reliable performance, ensuring efficient operation even under demanding conditions.

- Efficient Transmission: The advanced transmission system provides smooth gear shifting, improving overall driving experience and control.

- Durable Build: Constructed with high-quality materials, the equipment is designed to withstand rigorous use and harsh environments.

- Versatile Implements: Compatible with a wide range of attachments, allowing for various tasks, from tilling to hauling.

- Comfortable Cab: The operator’s compartment is designed for maximum comfort, featuring ergonomic controls and ample visibility.

These attributes not only enhance functionality but also ensure that operators can achieve optimal results with less effort, ultimately making the equipment a valuable asset in the field.

Importance of Parts Diagrams

Understanding the intricate details of machinery requires clear visual representations of their components. These illustrations serve as essential tools for maintenance, repair, and assembly, allowing users to identify individual elements and their functions. A well-organized visual guide enhances efficiency, reduces errors, and ultimately prolongs the life of equipment.

Facilitating Repairs

When machinery malfunctions, quick access to detailed visual guides simplifies the troubleshooting process. Users can pinpoint issues with greater accuracy, ensuring that repairs are carried out effectively. This clarity minimizes downtime, allowing for a swift return to operational status.

Enhancing Maintenance Practices

Regular upkeep is crucial for optimal performance. Visual representations help technicians understand maintenance routines, illustrating which components require attention and at what intervals. This proactive approach not only prevents costly breakdowns but also ensures that machines operate smoothly over time.

Common Issues with John Deere 2350

Understanding the frequent challenges associated with this specific model can greatly enhance the efficiency and longevity of the machine. Operators often encounter a range of mechanical and electrical issues that, if addressed promptly, can prevent costly repairs and downtime.

Mechanical Problems

One of the most prevalent mechanical issues includes hydraulic system failures. This can manifest as reduced lifting power or slow response times. Additionally, wear and tear on the transmission can lead to gear shifting difficulties, which can affect overall performance.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Hydraulic Failure | Slow lift, unresponsive controls | Check fluid levels, inspect hoses |

| Transmission Problems | Difficulty shifting gears, unusual noises | Inspect transmission fluid, adjust linkage |

Electrical Issues

Electrical malfunctions can also arise, including battery drainage and issues with the starter motor. These problems often result in the machine failing to start or experiencing intermittent power loss during operation.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Battery Drain | Difficulty starting, dim lights | Check connections, replace battery |

| Starter Motor Failure | Clicking sound, no engine turnover | Inspect starter, replace if necessary |

Where to Find Parts Diagrams

Locating detailed schematics for machinery components can significantly enhance repair and maintenance efforts. These visual guides provide invaluable information about each element’s placement and functionality, making the restoration process more efficient and precise.

Official Manufacturer Websites: The first and most reliable source for obtaining these illustrations is the official website of the equipment manufacturer. Many companies offer online resources, including user manuals and interactive schematics that can be accessed for free or for a nominal fee.

Online Forums and Communities: Engaging with fellow enthusiasts in online forums or community groups can yield fruitful results. Members often share their own resources or direct you to sites where you can find comprehensive visuals and additional support.

Parts Retailers: Numerous retailers specialize in machinery components and often provide access to helpful visuals. These platforms usually feature search functions that allow users to locate specific components quickly.

Service Manuals: Purchasing or downloading service manuals is another effective way to gain access to detailed visuals. These manuals not only include diagrams but also offer step-by-step instructions for assembly and disassembly.

Libraries and Archives: Local libraries or online archives may house technical manuals and historical documents related to machinery. These resources can be a treasure trove for those seeking specific schematics and related information.

Utilizing these various sources will ensure you have the necessary visuals to successfully navigate the complexities of machinery repair and maintenance.

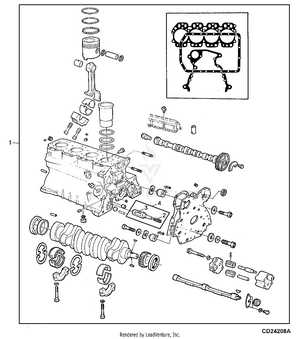

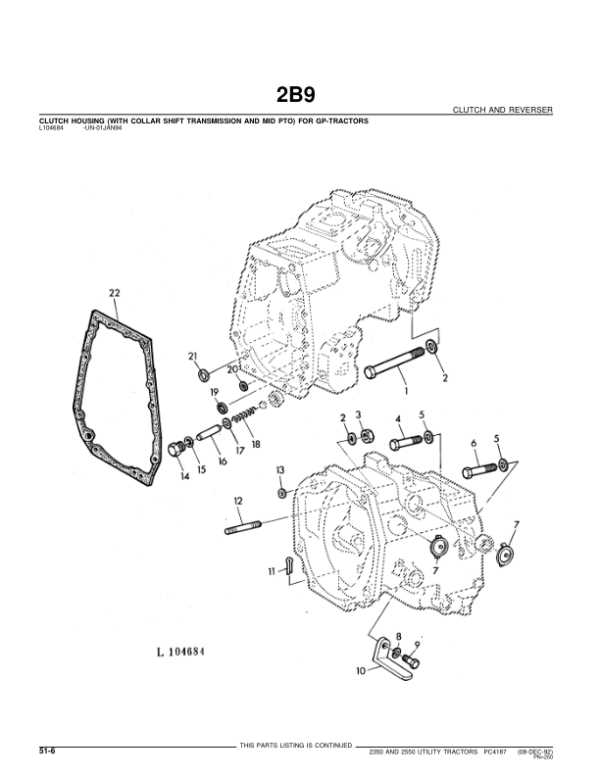

Components of the 2350 Tractor

This section provides an overview of the essential elements that make up the machinery, highlighting their functionality and interconnectivity. Each component plays a crucial role in ensuring efficient operation and reliability during agricultural tasks.

Engine: The powerhouse of the machine, this component converts fuel into mechanical energy, driving all other systems. Its efficiency and power output are critical for optimal performance in the field.

Transmission: This system manages the power transfer from the engine to the wheels. It allows for various speed settings, enabling the operator to adapt to different terrain and workload demands.

Hydraulics: Essential for lifting and operating attachments, this system uses fluid pressure to perform tasks such as raising implements or steering. Proper maintenance of hydraulic components is vital for effective operation.

Chassis: The sturdy frame supports all other components, ensuring stability and durability. Its design impacts the tractor’s overall weight distribution and maneuverability.

Electrical System: This includes the battery, wiring, and various sensors. It powers all electrical components, from ignition to lighting, ensuring smooth operation of the machinery.

Wheels and Tires: These components provide traction and stability. The right type of tire is crucial for different soil conditions and types of work, affecting the tractor’s performance significantly.

Cab: This enclosed space protects the operator from the elements and houses controls for managing the various systems. Comfort and visibility from the cab are important for prolonged use.

Tips for Using Parts Diagrams

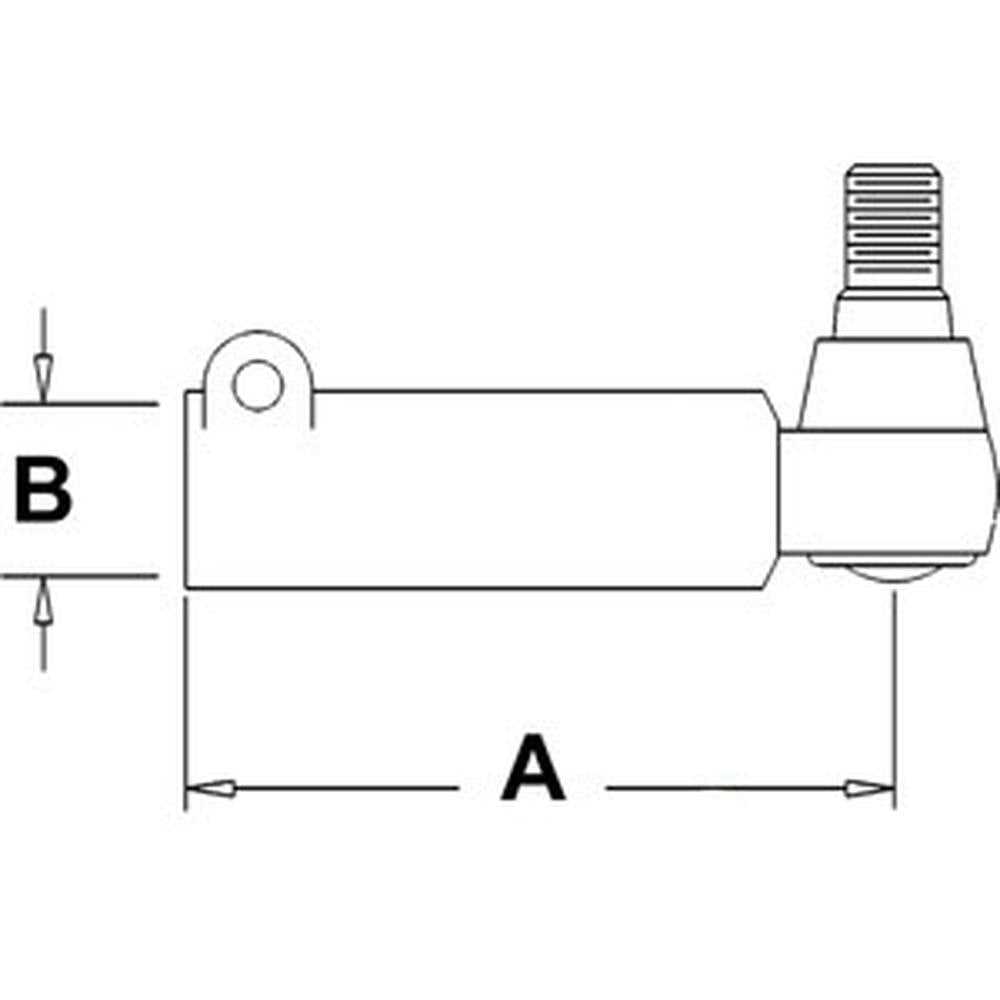

Utilizing visual schematics can greatly enhance your understanding of equipment components and their interrelations. These illustrations serve as invaluable tools for identifying specific elements, making repairs, or sourcing replacements. To maximize their effectiveness, consider the following recommendations.

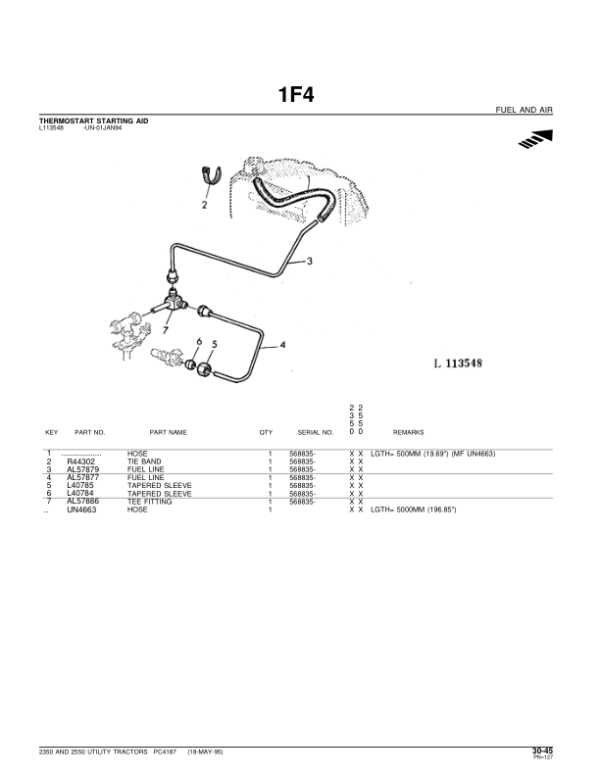

First, familiarize yourself with the layout of the schematic. Understanding how the various sections are organized will help you navigate the image more efficiently. Pay attention to labels and numbering systems, as they provide essential references for each part.

Next, cross-reference the visual representation with a detailed list of specifications. This approach ensures you have accurate information about sizes, compatibility, and material requirements, reducing the risk of errors during procurement or installation.

Additionally, take note of any assembly instructions that may accompany the visual aid. These guidelines can offer insights into the order of operations, which is crucial for efficient assembly or disassembly.

Finally, keep the diagram accessible during your work. Whether in digital format on a device or printed out, having a clear reference at hand will streamline your process and minimize downtime, ultimately leading to more successful maintenance or repair efforts.

Aftermarket vs. Original Parts

When it comes to maintaining machinery, the choice between factory-manufactured components and alternative options often arises. Understanding the benefits and drawbacks of each can significantly influence the longevity and efficiency of equipment. While original components are typically designed to meet specific standards, aftermarket solutions can provide cost-effective alternatives without compromising quality.

Advantages of Original Components

Factory-manufactured items are engineered to fit precisely, ensuring optimal performance and reliability. They often come with warranties and support from the manufacturer, providing peace of mind for operators. Additionally, using original components can help preserve the resale value of the equipment, as it demonstrates a commitment to quality maintenance.

Benefits of Aftermarket Solutions

Alternative options frequently offer greater affordability, making them an appealing choice for budget-conscious users. Many aftermarket manufacturers produce high-quality items that rival original products, often incorporating innovations that enhance performance. Furthermore, a wider selection can make it easier to find specific solutions tailored to unique needs, ensuring that operators have access to the best possible options.

Maintenance Recommendations for the 2350

Regular upkeep is essential for ensuring optimal performance and longevity of agricultural machinery. Implementing a consistent maintenance routine not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Understanding key practices can significantly contribute to the machine’s reliability and effectiveness in the field.

Routine Inspections

Conducting frequent inspections is crucial for identifying potential issues before they escalate. Check fluid levels, belts, and filters regularly. Look for signs of wear and tear, and ensure that all components are functioning correctly. Keeping a log of these inspections can help track any recurring problems.

Scheduled Servicing

Adhering to a service schedule is vital for the longevity of the equipment. Follow the manufacturer’s guidelines for oil changes, filter replacements, and other critical servicing tasks. Utilize high-quality lubricants and fluids to maintain performance standards. Staying proactive in servicing can prevent costly repairs and extend the life of the machinery.

How to Identify Part Numbers

Identifying component numbers is essential for ensuring accurate replacements and repairs. Proper recognition of these identifiers allows for streamlined procurement and enhances maintenance efficiency. By understanding the format and structure of these numbers, you can simplify the process of locating the required items for your machinery.

Step 1: Begin by examining the manual or catalog specific to your equipment model. These documents typically contain valuable information about the various components and their respective identifiers.

Step 2: Look for any labels or engravings on the parts themselves. Manufacturers often imprint or attach tags with the necessary identifiers, which can significantly aid in accurate identification.

Step 3: Utilize online databases or manufacturer websites. Many companies provide searchable databases where you can enter descriptions or other details to find the corresponding numbers.

Step 4: Consult with a dealer or specialist. Professionals in the field can provide insights and assistance in recognizing the correct identifiers, ensuring you obtain the right components.

By following these steps, you can efficiently navigate the complexities of component identification, ultimately leading to improved performance and longevity of your equipment.

Resources for Tractor Repair

Repairing agricultural machinery requires access to various materials that aid in understanding and fixing equipment. Having the right references can significantly enhance the repair process, ensuring efficiency and effectiveness.

- User Manuals: Detailed guides provided by manufacturers that include operating instructions, maintenance schedules, and troubleshooting tips.

- Online Forums: Communities where enthusiasts and professionals share their experiences, solutions, and advice related to equipment repairs.

- Video Tutorials: Visual resources available on platforms like YouTube, demonstrating step-by-step repair techniques.

- Replacement Part Suppliers: Websites and local stores that specialize in aftermarket components, often providing catalogs and diagrams to assist in identifying needed items.

- Technical Service Bulletins: Official documents released by manufacturers that provide insights into common issues and recommended fixes.

Utilizing these resources not only aids in the repair process but also empowers operators with the knowledge necessary to maintain their machinery effectively.