Complete Guide to John Deere 245 Parts Diagram

In the realm of agricultural equipment, comprehending the intricate arrangement of various elements is essential for effective maintenance and repair. A clear visual representation of these components can significantly enhance the understanding of how each part interacts within the larger system. This knowledge is vital for operators and technicians alike, ensuring smooth operations and minimizing downtime.

Exploring these layouts provides valuable insights into the functionality and design of the machinery. By delving into detailed schematics, users can identify specific elements, facilitating informed decision-making when it comes to repairs or replacements. Such resources serve as a guide, enabling efficient troubleshooting and promoting longevity in the lifespan of the equipment.

Moreover, the availability of comprehensive visual aids allows individuals to familiarize themselves with the various components, leading to a deeper appreciation of the technology behind modern farming tools. Understanding the relationships between different sections can also spark innovations in maintenance strategies, ultimately contributing to enhanced productivity in agricultural practices.

Understanding John Deere 245 Parts

Grasping the components of a specific model is essential for effective maintenance and repair. Each element plays a crucial role in ensuring optimal performance and longevity of the machinery. A comprehensive understanding of these individual components can greatly enhance operational efficiency and facilitate troubleshooting.

Key Components Overview

When delving into the various elements of this model, it is important to identify the major groups and their functions. These sections work together seamlessly, contributing to the overall functionality of the equipment.

| Component | Function |

|---|---|

| Engine | Powers the machine and drives performance. |

| Transmission | Transfers power from the engine to the wheels. |

| Hydraulic System | Enables lifting and maneuvering heavy loads. |

| Chassis | Provides the structural framework and support. |

| Electrical System | Controls various electrical functions and safety features. |

Importance of Maintenance

Regular upkeep of these components ensures reliability and minimizes the risk of unexpected breakdowns. By understanding how each part functions, operators can better manage routine checks and timely replacements, ultimately extending the lifespan of their machinery.

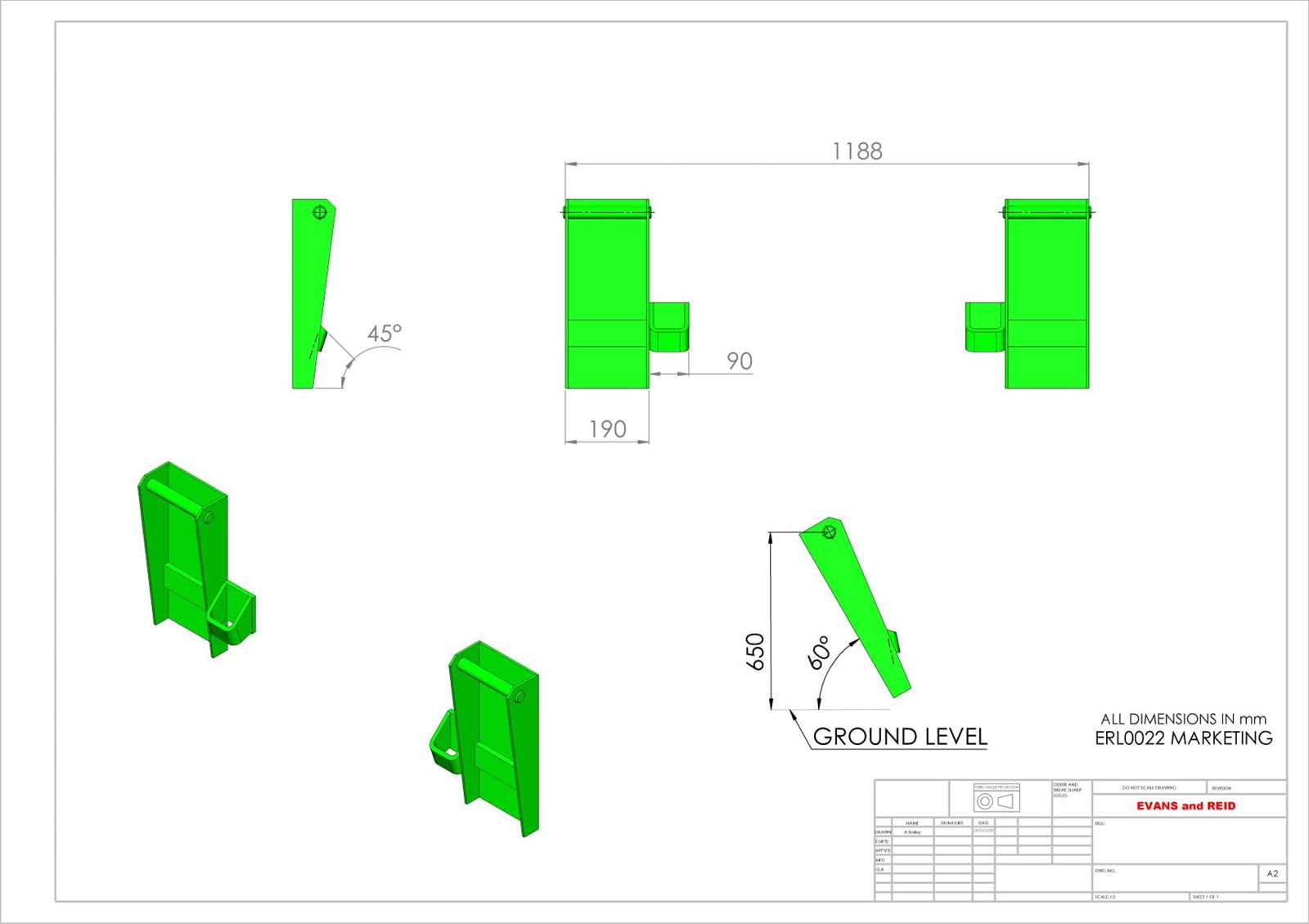

Overview of the 245 Model

The model in question is a notable piece of agricultural machinery that has earned recognition for its reliability and efficiency in various tasks. Designed to meet the demands of modern farming, it incorporates advanced technology and robust engineering, making it a preferred choice among professionals in the field.

Key features of this machine include a powerful engine, exceptional maneuverability, and a range of attachments that enhance its versatility. These attributes allow operators to tackle different agricultural operations with ease, from tilling and plowing to seeding and harvesting.

Additionally, ergonomic design elements contribute to user comfort, ensuring that long hours of operation do not lead to fatigue. The model is also praised for its low maintenance requirements, allowing farmers to focus more on productivity and less on upkeep.

Overall, this agricultural powerhouse exemplifies the ideal balance between performance and practicality, making it a vital asset in the toolkit of any serious farmer.

Common Issues with 245 Components

Every machinery model comes with its set of challenges, particularly concerning its individual elements. Understanding the typical complications can aid in effective maintenance and prolong the lifespan of the equipment. Identifying these issues early on is crucial for ensuring optimal performance and minimizing downtime.

Mechanical Failures

One of the most frequent problems involves mechanical breakdowns. Wear and tear can lead to components not functioning as intended, causing unexpected malfunctions. Regular inspections can help in identifying signs of fatigue or damage, allowing for timely replacements or repairs.

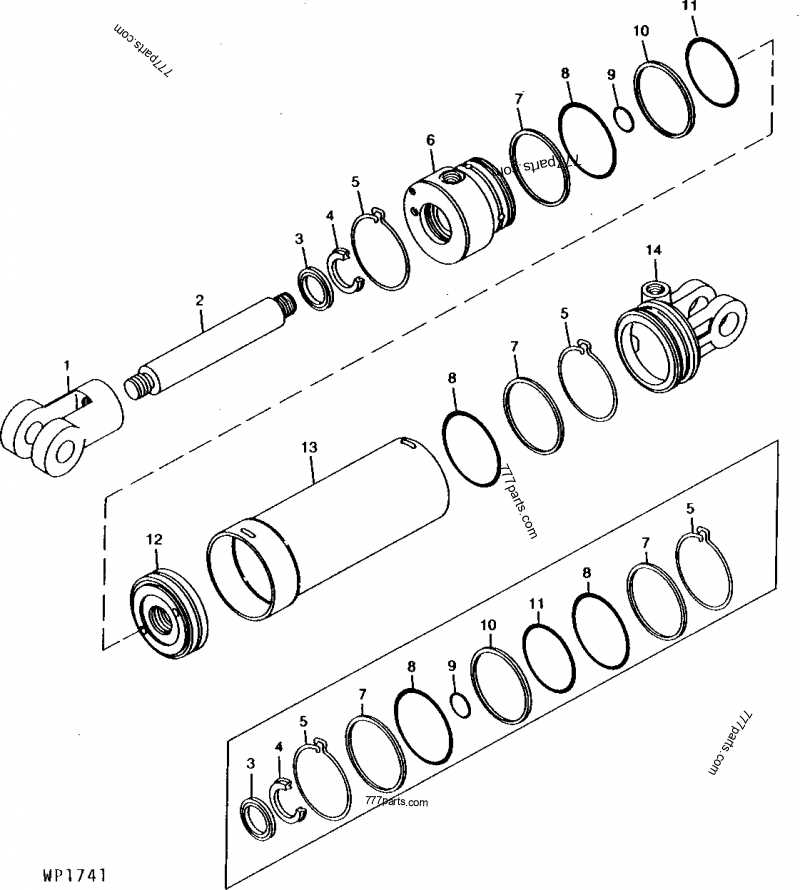

Hydraulic System Issues

Hydraulic systems are vital for the effective operation of many machines. Common concerns include leaks or pressure drops, which can hinder performance. Regular checks for fluid levels and system integrity can mitigate these risks, ensuring that the hydraulic components operate smoothly and efficiently.

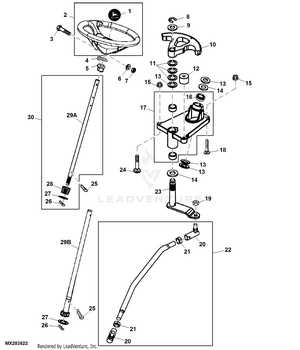

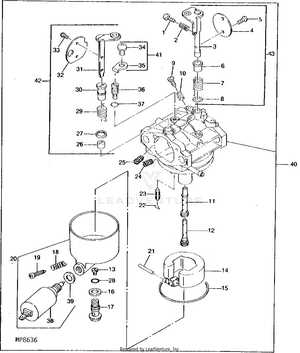

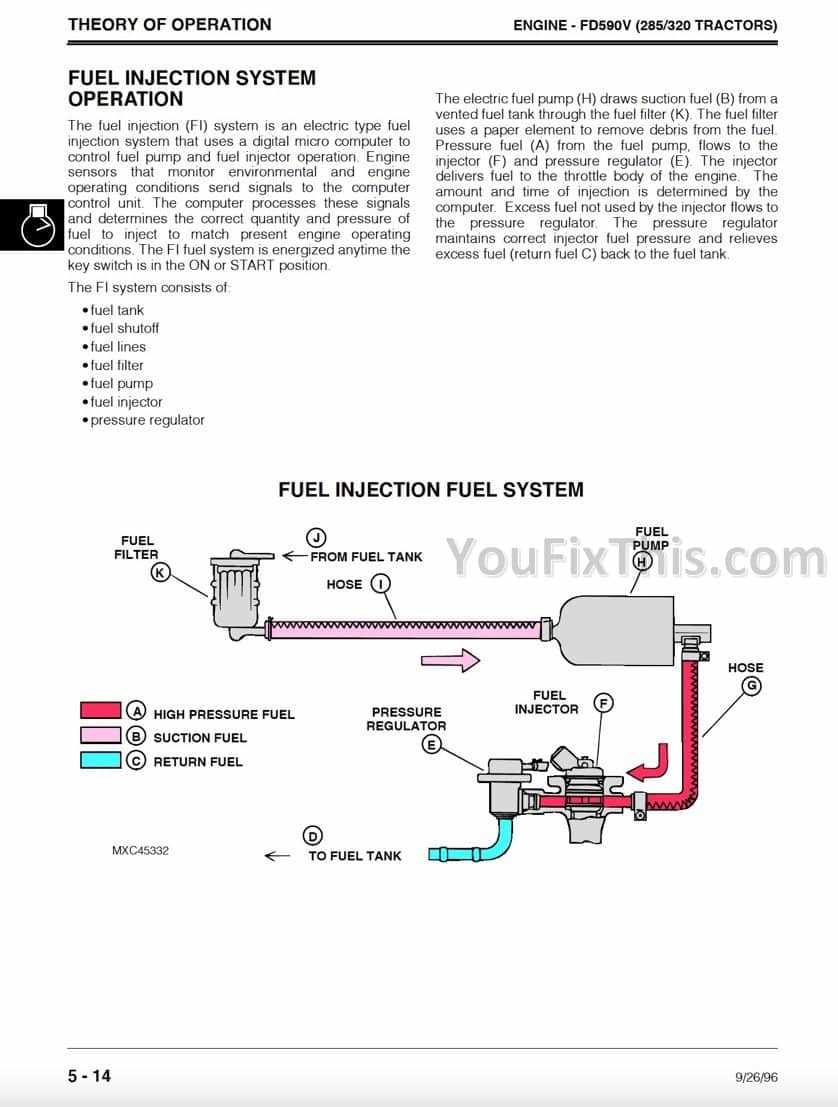

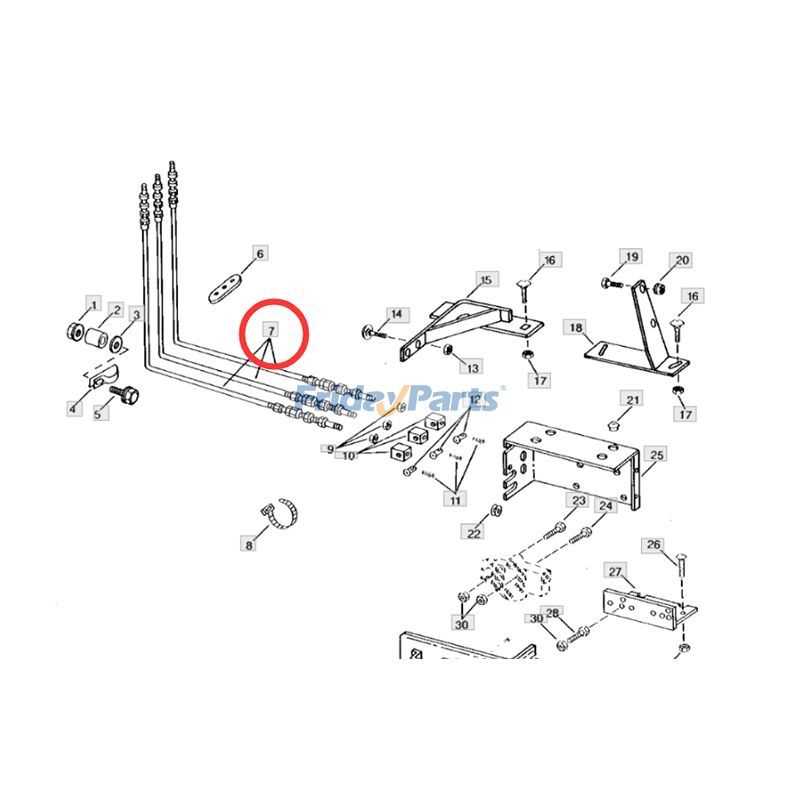

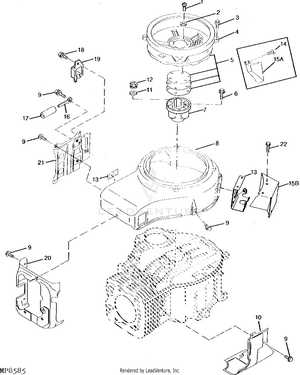

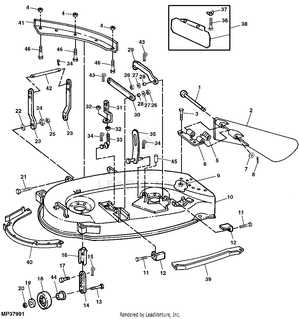

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for efficient maintenance and repair. Visual representations that detail the arrangement of individual elements provide clarity, aiding technicians in identifying necessary components and their functions. This knowledge ultimately enhances the longevity and performance of equipment.

Moreover, these illustrations facilitate quicker troubleshooting by allowing users to pinpoint issues without extensive disassembly. They serve as a crucial reference for both experienced mechanics and novices, streamlining the repair process and reducing downtime.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Visual aids simplify understanding of complex machinery. |

| Efficient Repairs | Quick identification of parts accelerates troubleshooting. |

| Training Resource | Illustrations serve as valuable tools for educating new technicians. |

| Improved Maintenance | Regular reference to visuals promotes proactive upkeep. |

Identifying Key Components Easily

Understanding the essential elements of machinery is crucial for efficient maintenance and operation. By recognizing these components, operators can ensure optimal performance and address issues swiftly. This section will guide you in pinpointing significant parts, enhancing your ability to manage equipment effectively.

Common Elements to Recognize

- Engine: The heart of the machinery, responsible for power generation.

- Transmission: This system transfers power from the engine to the wheels or implements.

- Hydraulic System: Vital for controlling various attachments and functionalities.

- Chassis: The frame that supports all other components.

- Wheels/Tires: Critical for movement and stability on various terrains.

Tips for Effective Identification

- Familiarize yourself with the user manual, which often includes detailed illustrations and descriptions.

- Utilize online resources and forums to gather insights from experienced operators.

- Regularly inspect machinery to become acquainted with its components.

- Label parts during maintenance for easier future identification.

By mastering the identification of these fundamental elements, you will enhance your ability to maintain and operate machinery efficiently, reducing downtime and ensuring productivity.

Where to Find Parts Diagrams

Locating detailed schematics for machinery components is crucial for effective maintenance and repair. These visual aids provide insights into the arrangement and functioning of various elements, enabling users to identify what they need for a successful restoration or upgrade.

One of the best resources for these illustrations is the manufacturer’s official website. Often, they offer comprehensive guides and visual references for their products. Additionally, specialized forums and online communities dedicated to machinery enthusiasts can be invaluable, as members frequently share links and resources.

Furthermore, third-party retailers and suppliers often have extensive catalogs that include illustrations and descriptions, making it easier to find the necessary items. For those who prefer printed materials, local libraries and bookstores may carry repair manuals that feature these essential visuals. Utilizing these various sources will enhance your ability to maintain and improve your equipment effectively.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers several advantages that can significantly enhance the performance and longevity of your machinery. These parts are specifically designed to meet the exact specifications of the equipment, ensuring a perfect fit and optimal function.

- Quality Assurance: OEM components are produced to strict quality standards, guaranteeing reliability and durability.

- Perfect Compatibility: These components are engineered to integrate seamlessly with your equipment, minimizing the risk of malfunction.

- Enhanced Performance: Using original parts can improve the overall efficiency and effectiveness of your machinery.

- Warranty Protection: Many manufacturers provide warranties on equipment that uses OEM components, offering additional peace of mind.

- Resale Value: Maintaining equipment with original parts can help preserve its value, making it more attractive to potential buyers.

Incorporating OEM components into maintenance routines not only promotes superior performance but also ensures long-term reliability and satisfaction.

Aftermarket Parts: Pros and Cons

When it comes to maintaining and enhancing machinery, the choice between original and alternative components can significantly impact performance and cost. Aftermarket solutions often provide a viable option for users seeking to balance quality and expense. However, they come with their own set of advantages and disadvantages that warrant careful consideration.

| Advantages | Disadvantages |

|---|---|

| Cost-effective options often available | Quality may vary between manufacturers |

| Wider selection of components and accessories | Potential for compatibility issues |

| Innovative features may be offered | Limited or no warranty coverage |

| Availability from multiple suppliers | Support and customer service can be lacking |

Ultimately, weighing these factors can aid in making an informed decision that aligns with both operational needs and budget constraints.

Step-by-Step Repair Guide

Repairing heavy machinery can be a daunting task, but with a structured approach, it becomes manageable. This guide provides a detailed procedure to help you navigate the complexities of fixing equipment, ensuring that you have all the necessary information at your fingertips.

1. Gather Your Tools

Before starting any repair, collect all essential tools and materials. This includes wrenches, screwdrivers, pliers, and replacement components. Having everything organized will streamline the process and minimize interruptions.

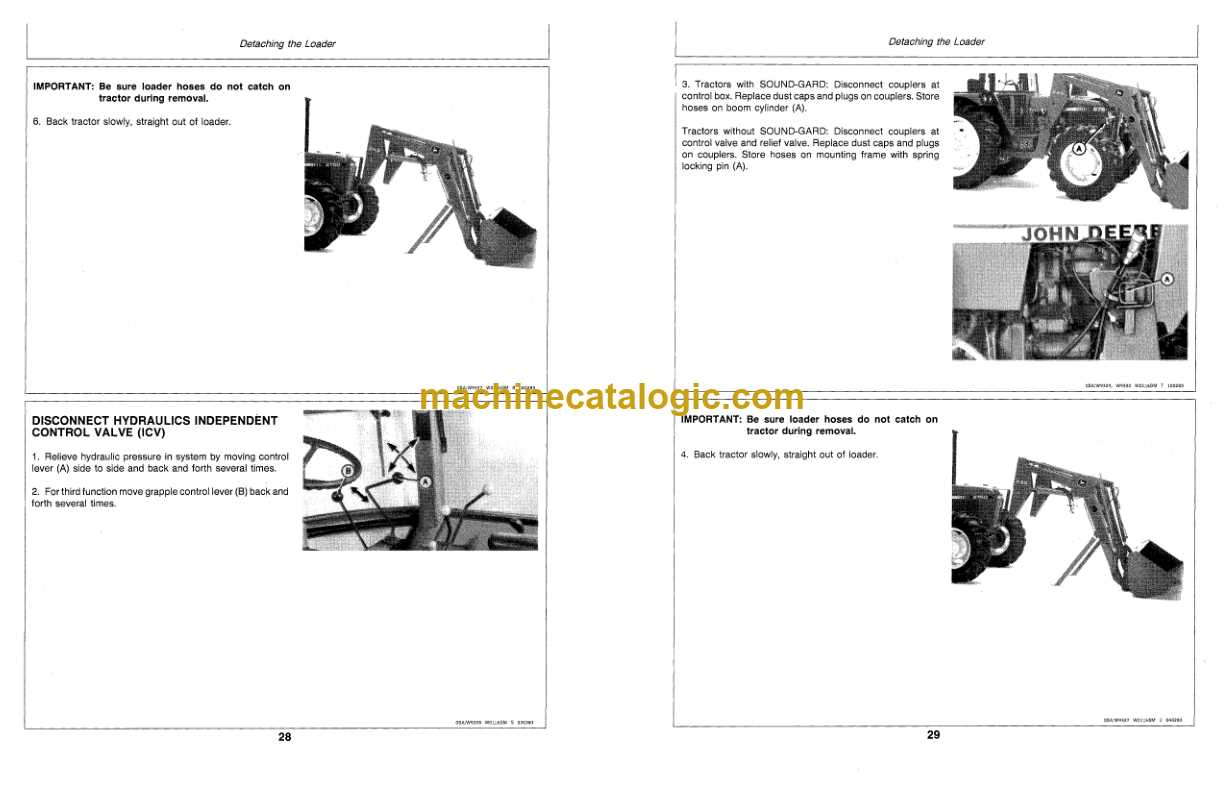

2. Consult the Manual

Refer to the equipment’s manual for specific instructions and diagrams. Understanding the layout and function of various parts is crucial for effective repairs. This documentation often contains troubleshooting tips and recommended procedures.

3. Assess the Problem

Identify the issue at hand by conducting a thorough inspection. Look for visible damage, unusual noises, or performance issues. Taking notes during this phase can help in tracking your progress and formulating a repair plan.

4. Disassemble Carefully

When ready to begin, start disassembling the affected areas. Take care to follow the order of disassembly as outlined in the manual. Labeling components as you go can prevent confusion during reassembly.

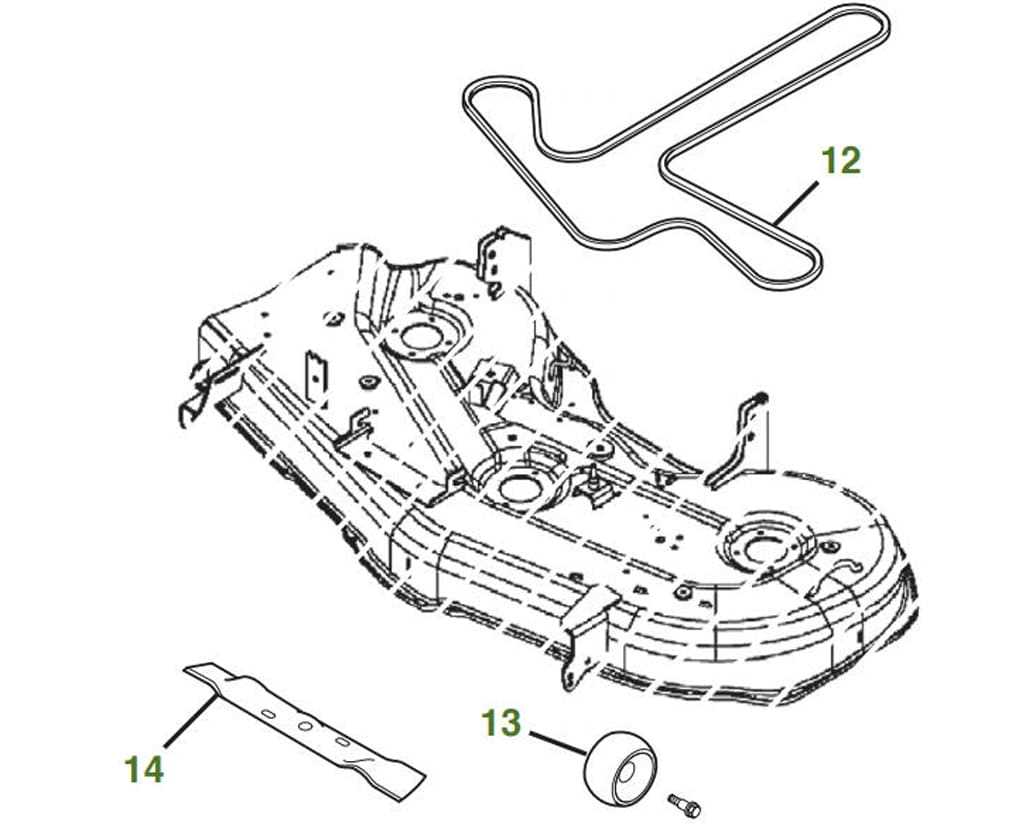

5. Replace or Repair Components

Once disassembled, assess each part for wear or damage. Replace any faulty components with new ones, ensuring they meet the manufacturer’s specifications. If repairs are feasible, clean and fix parts as necessary.

6. Reassemble with Precision

Carefully reassemble the equipment, following the reverse order of disassembly. Double-check that all connections are secure and that no parts are left loose. This step is critical for ensuring optimal performance.

7. Test the Equipment

After reassembly, conduct a thorough test to confirm that the issue has been resolved. Observe the machinery during operation to ensure it runs smoothly and efficiently. If problems persist, revisit the previous steps for further troubleshooting.

By following this structured approach, you can effectively manage repairs on your machinery, ensuring longevity and reliable performance.

Maintaining Your John Deere 245

Proper upkeep of your machinery is essential for ensuring longevity and optimal performance. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency and productivity. By following a systematic approach, you can keep your equipment in top condition and ready for any task.

Here are some key maintenance tasks to consider:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours | Replace engine oil and filter to ensure smooth operation. |

| Air Filter Inspection | Every 50 hours | Check and clean or replace the air filter to maintain optimal airflow. |

| Tire Check | Monthly | Inspect tire pressure and tread wear to ensure safe handling. |

| Battery Maintenance | Every 3 months | Clean terminals and check fluid levels to avoid electrical issues. |

| Fuel System Cleaning | Annually | Flush the fuel system to prevent clogging and improve performance. |

By adhering to these maintenance practices, you can extend the life of your equipment and ensure it operates at peak efficiency. Regular attention to these details will save you time and money in the long run.

Finding a Reliable Parts Supplier

When it comes to maintaining machinery, sourcing high-quality components is crucial for optimal performance and longevity. A dependable supplier can make all the difference, ensuring that you have access to the necessary resources without compromising on quality. This section will guide you through the essential factors to consider when searching for a trustworthy vendor.

Key Considerations

- Reputation: Look for suppliers with positive reviews and a solid track record in the industry.

- Quality Assurance: Ensure that the vendor provides guarantees for their products and adheres to strict quality standards.

- Availability: Check if the supplier maintains a robust inventory and can quickly fulfill orders.

- Customer Support: Evaluate the level of assistance offered, including pre-sales advice and post-purchase service.

Researching Suppliers

- Seek recommendations from industry peers or online forums.

- Investigate suppliers’ websites for product offerings and certifications.

- Request samples or product specifications to assess quality.

- Compare pricing while considering the balance between cost and quality.

By carefully assessing these factors, you can find a supplier that meets your needs and supports your machinery effectively.

Customer Reviews on 245 Parts

This section explores user feedback regarding components for a popular agricultural machine. Understanding the experiences of other operators can provide valuable insights into quality, performance, and reliability.

Overall Satisfaction

- Many users express a high level of satisfaction with the durability of the components.

- Several reviews highlight the ease of installation, making replacements hassle-free.

- Operators appreciate the cost-effectiveness of various items, noting their long lifespan.

Common Concerns

- Some customers reported delays in shipping, impacting their operational schedules.

- A few users mentioned compatibility issues with certain aftermarket options.

- There were instances of receiving incorrect items, leading to frustration in repairs.

In conclusion, while the majority of feedback is positive, potential buyers should be mindful of the concerns raised to make informed decisions.

Tips for Efficient Repairs

Effective maintenance is crucial for prolonging the lifespan of machinery and ensuring optimal performance. With the right approach and knowledge, repairs can be completed more swiftly and accurately, minimizing downtime and costs.

Preparation and Planning

- Gather all necessary tools and equipment before starting the repair process.

- Consult manuals or online resources for detailed instructions specific to the equipment.

- Create a checklist of components that may need attention to avoid overlooking critical areas.

Execution of Repairs

- Work methodically; follow a step-by-step approach to avoid confusion.

- Document the process, taking notes or photos to aid future repairs.

- Test the equipment thoroughly after completing repairs to ensure functionality.