Comprehensive Guide to John Deere 2550 Parts Diagram

When it comes to maintaining agricultural equipment, having a clear understanding of the various components and their arrangements is essential. This knowledge not only aids in efficient repairs but also enhances the overall performance of the machinery. A detailed representation of the various elements involved can serve as a valuable reference for both novice and experienced operators alike.

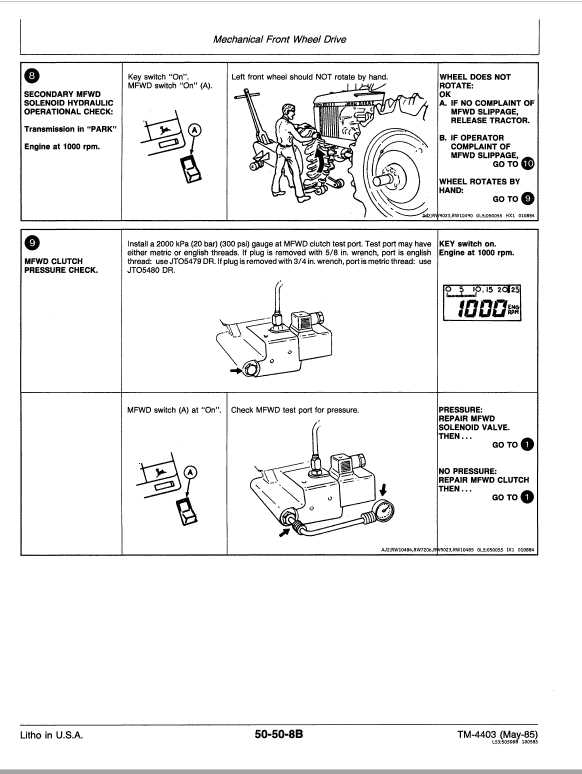

Within the realm of mechanical systems, visual aids play a crucial role in demystifying complex assemblies. By examining these illustrative layouts, users can quickly identify the necessary components, their functions, and how they interact with one another. This clarity can significantly reduce downtime and streamline the maintenance process, allowing for a more productive workflow.

Furthermore, possessing a comprehensive overview of the individual elements contributes to better troubleshooting capabilities. When a malfunction occurs, understanding the configuration of components empowers operators to pinpoint issues swiftly and accurately. This proactive approach not only saves time but also minimizes the risk of further damage, ensuring the machinery remains in optimal condition.

Understanding John Deere 2550 Parts

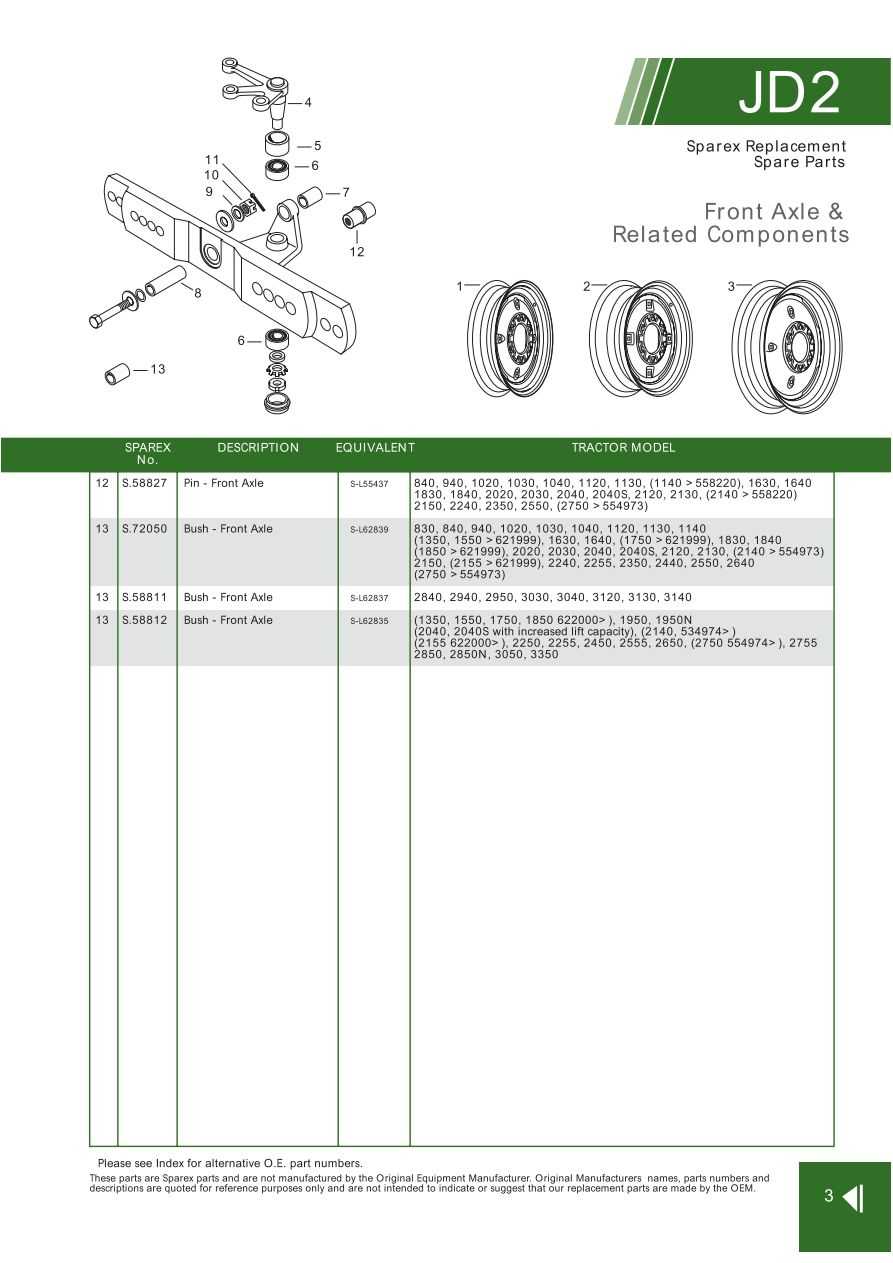

Grasping the intricacies of agricultural machinery components is essential for effective maintenance and repair. Familiarity with individual elements not only enhances operational efficiency but also prolongs the lifespan of the equipment. A thorough comprehension of these elements aids in troubleshooting issues and streamlining replacement processes, ensuring that the machinery functions at its best.

Key Components and Their Functions

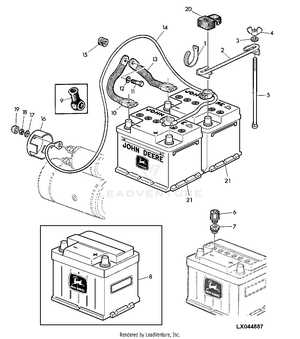

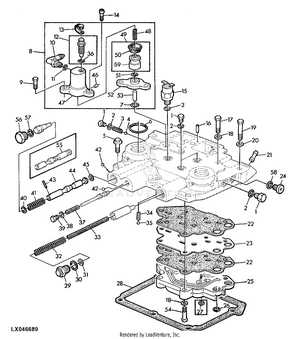

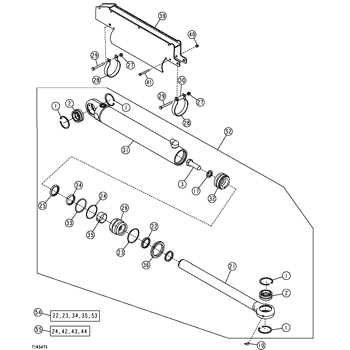

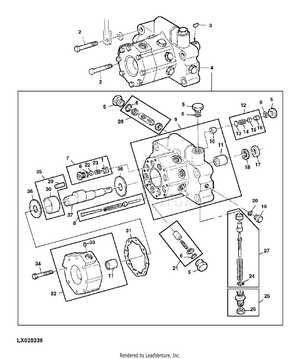

The essential elements of a tractor play a pivotal role in its overall performance. From the engine assembly to the hydraulic systems, each component contributes to the machine’s capability to perform various agricultural tasks. Understanding how these components interact allows operators to identify potential failures and optimize their usage.

Maintenance and Repair Considerations

Regular upkeep is crucial for sustaining the functionality of the machinery. Knowing the specific elements that require attention can prevent costly breakdowns and extend operational life. Detailed knowledge of the various components facilitates informed decision-making regarding repairs, ensuring that replacements are made swiftly and accurately.

Importance of Accurate Parts Diagrams

Having precise illustrations of components is crucial for efficient maintenance and repairs. Such visuals serve as essential guides, helping technicians and operators quickly identify the necessary elements needed for specific tasks. This clarity minimizes errors and enhances productivity, ensuring that machinery operates smoothly and effectively.

Benefits of Detailed Visuals

- Enhanced Understanding: Clear representations allow users to grasp complex assemblies, reducing confusion during repair processes.

- Time Efficiency: Quick identification of components leads to faster troubleshooting and minimizes downtime.

- Cost-Effectiveness: Accurate visuals help avoid purchasing incorrect items, saving money and resources.

Impact on Maintenance Practices

- Improved Workflow: Streamlined processes lead to better organization and efficiency.

- Increased Safety: Proper identification reduces the risk of mishaps during repairs.

- Longevity of Equipment: Timely and correct maintenance prolongs the life of machinery.

Common Issues with John Deere 2550

In the realm of agricultural machinery, certain models encounter recurring challenges that can hinder performance and efficiency. Understanding these prevalent problems can aid operators in troubleshooting and maintaining their equipment effectively. This section delves into some typical issues faced by users of a specific tractor model, providing insights for better management.

Engine Performance Problems

One of the most significant concerns revolves around engine efficiency. Operators often report issues such as poor starting, irregular idling, and unexpected stalling. These symptoms may stem from a variety of factors, including fuel quality, air filter blockages, or ignition system failures. Regular maintenance checks can mitigate these issues, ensuring the engine runs smoothly.

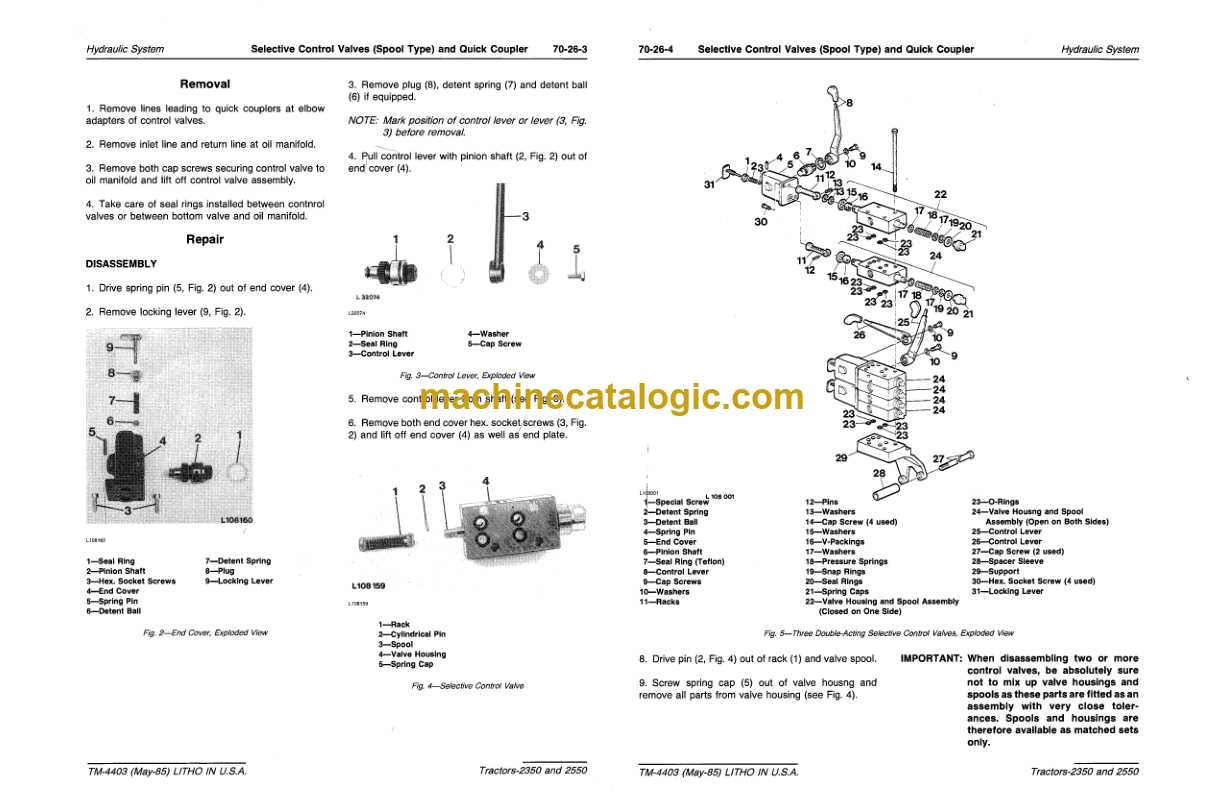

Hydraulic System Failures

The hydraulic system is crucial for numerous functions in agricultural machinery. Common failures include leaks and poor lifting power, which can drastically affect operational capabilities. These issues may arise from worn seals or hoses, necessitating timely inspections and replacements. Addressing hydraulic problems promptly can prevent more severe complications and maintain productivity.

Where to Find Parts Diagrams

Locating detailed schematics for machinery components can significantly simplify the repair and maintenance process. These visual guides provide essential information about the assembly and individual pieces, ensuring that users can effectively address issues without unnecessary complications.

Here are several reliable sources to consider:

- Manufacturer Websites: Many manufacturers offer online resources that include downloadable guides and illustrations.

- Online Retailers: E-commerce platforms often host comprehensive catalogs with visual aids for each item.

- Service Manuals: Official service manuals usually contain detailed breakdowns and can be purchased or accessed through authorized dealers.

- Forums and Community Groups: Enthusiast forums often share valuable resources, including diagrams contributed by fellow users.

Utilizing these sources will enhance your ability to find the necessary information quickly and efficiently, ultimately supporting better maintenance practices.

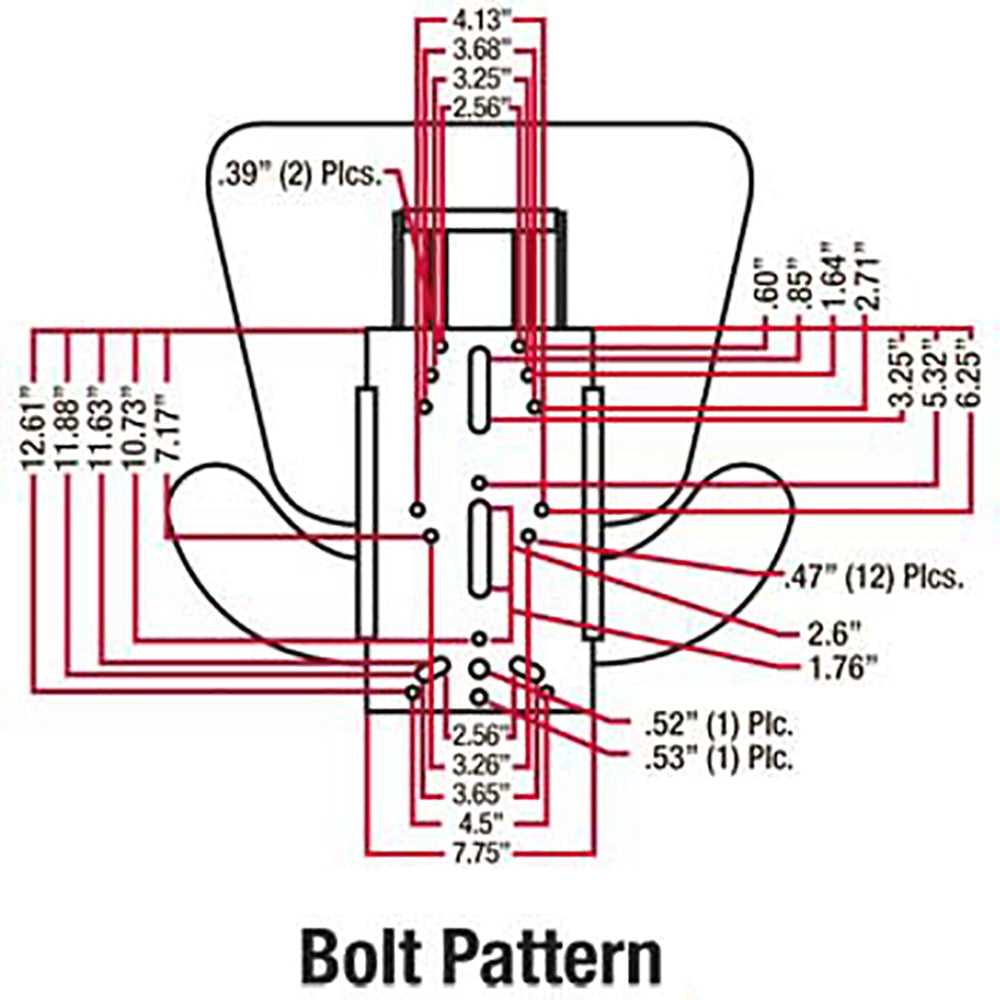

How to Read a Parts Diagram

Understanding an assembly illustration is essential for effective maintenance and repairs. These visual representations provide a detailed overview of components and their relationships within a machine, making it easier to identify the necessary items for specific tasks. By familiarizing yourself with the symbols and layout, you can streamline the process of locating and ordering components.

Familiarize Yourself with the Symbols

Each illustration uses standardized symbols to denote various elements, such as fasteners, connectors, and specific parts. Take time to review the legend or key often provided alongside the visual. This will help you decode the information quickly and accurately, ensuring you know what each symbol represents before diving into the repair process.

Follow the Flow of the Assembly

Most illustrations are organized in a logical manner, typically following the order of assembly or disassembly. Pay attention to how components are grouped together and the sequence in which they connect. This understanding will not only aid in repairs but also help you visualize the entire system, making it easier to troubleshoot issues effectively.

Key Components of the 2550 Model

The intricacies of agricultural machinery hinge on several essential elements that work in concert to ensure optimal performance. Understanding these fundamental parts is crucial for effective maintenance and operation, as each component plays a vital role in the overall functionality of the equipment.

Engine and Transmission

The heart of any farming vehicle lies in its engine, which provides the necessary power to operate various implements. Paired with a robust transmission system, these two components ensure smooth power delivery and enhanced maneuverability, making it easier to tackle diverse terrains and tasks.

Hydraulic System

An efficient hydraulic system is indispensable for the operation of attachments and implements. This system enables precise control and responsiveness, allowing operators to execute various functions with ease, from lifting heavy loads to adjusting the angle of implements.

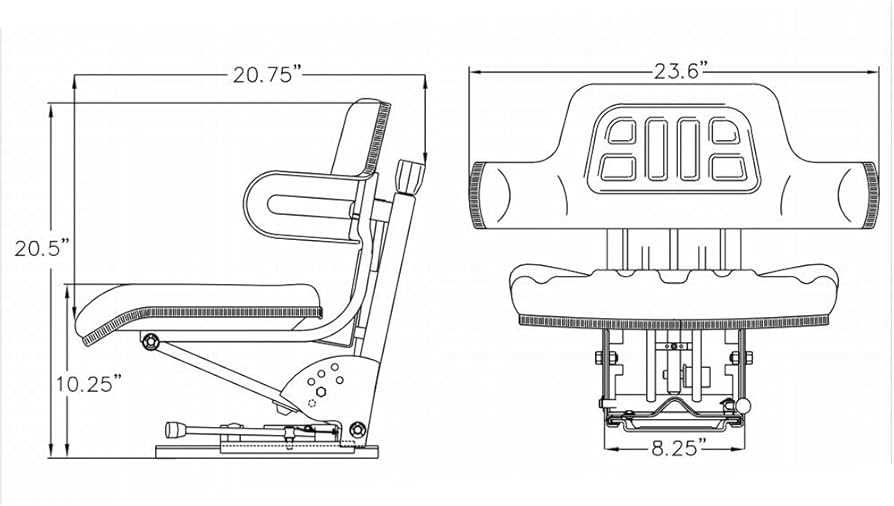

Replacement Parts: What You Need

When it comes to maintaining agricultural machinery, understanding the essential components is crucial. Proper upkeep often involves replacing worn or damaged elements to ensure optimal performance. This guide provides insights into the types of replacements that may be necessary for efficient operation.

Common Components for Maintenance

Various elements require regular inspection and potential replacement. Key categories include:

| Component | Description |

|---|---|

| Filters | Ensure clean fuel and air flow to the engine for improved efficiency. |

| Belts | Vital for transferring power between components; regular checks can prevent failures. |

| Seals | Prevent leaks and protect against dirt and moisture intrusion. |

| Hydraulic Hoses | Critical for fluid transfer; inspect regularly for signs of wear. |

Choosing Quality Replacements

Selecting high-quality substitutes is paramount for ensuring longevity and reliability. Consider sourcing from reputable manufacturers that specialize in agricultural equipment to avoid compatibility issues and enhance performance.

Maintenance Tips for John Deere 2550

Regular upkeep is essential for the longevity and efficiency of agricultural machinery. Proper care not only enhances performance but also reduces the likelihood of unexpected failures. Adopting a systematic maintenance routine ensures that the equipment operates smoothly throughout its lifespan.

Routine Checks

- Inspect fluid levels regularly, including engine oil, coolant, and hydraulic fluids.

- Examine filters and replace them as needed to maintain optimal airflow and fluid quality.

- Check tire pressure and tread wear to ensure safe and efficient operation.

- Look for signs of wear on belts and hoses, replacing any that show significant deterioration.

Seasonal Maintenance

- Before winter, clean the machine thoroughly and store it in a sheltered area to prevent weather-related damage.

- During spring, perform a complete inspection to prepare for the busy season, addressing any issues identified during the off-season.

- Regularly sharpen and adjust cutting implements to achieve the best performance during operations.

- Lubricate moving parts frequently to minimize friction and wear, following the manufacturer’s guidelines.

Cost Factors for Replacement Parts

When considering the acquisition of components for agricultural machinery, several variables can influence the overall expenditure. Understanding these elements is crucial for effective budgeting and ensuring optimal performance of the equipment.

Quality and Brand Reputation

The quality of a replacement component significantly affects its price. Higher-quality products often come from reputable manufacturers, which may charge a premium. Investing in reliable brands can lead to better longevity and efficiency, ultimately saving costs in the long run.

Availability and Sourcing

The source of the components can greatly impact pricing. Items that are readily available through local suppliers may be less expensive due to lower shipping costs and reduced lead times. Conversely, specialized or rare components may require longer sourcing times and increased costs.

| Cost Factors | Description |

|---|---|

| Quality | Higher-quality components typically command higher prices. |

| Brand | Renowned brands may charge more due to their reputation. |

| Availability | Locally available items tend to be less expensive than rare ones. |

| Shipping | Costs can increase based on shipping distances and methods. |

| Market Demand | High demand can lead to inflated prices for specific items. |

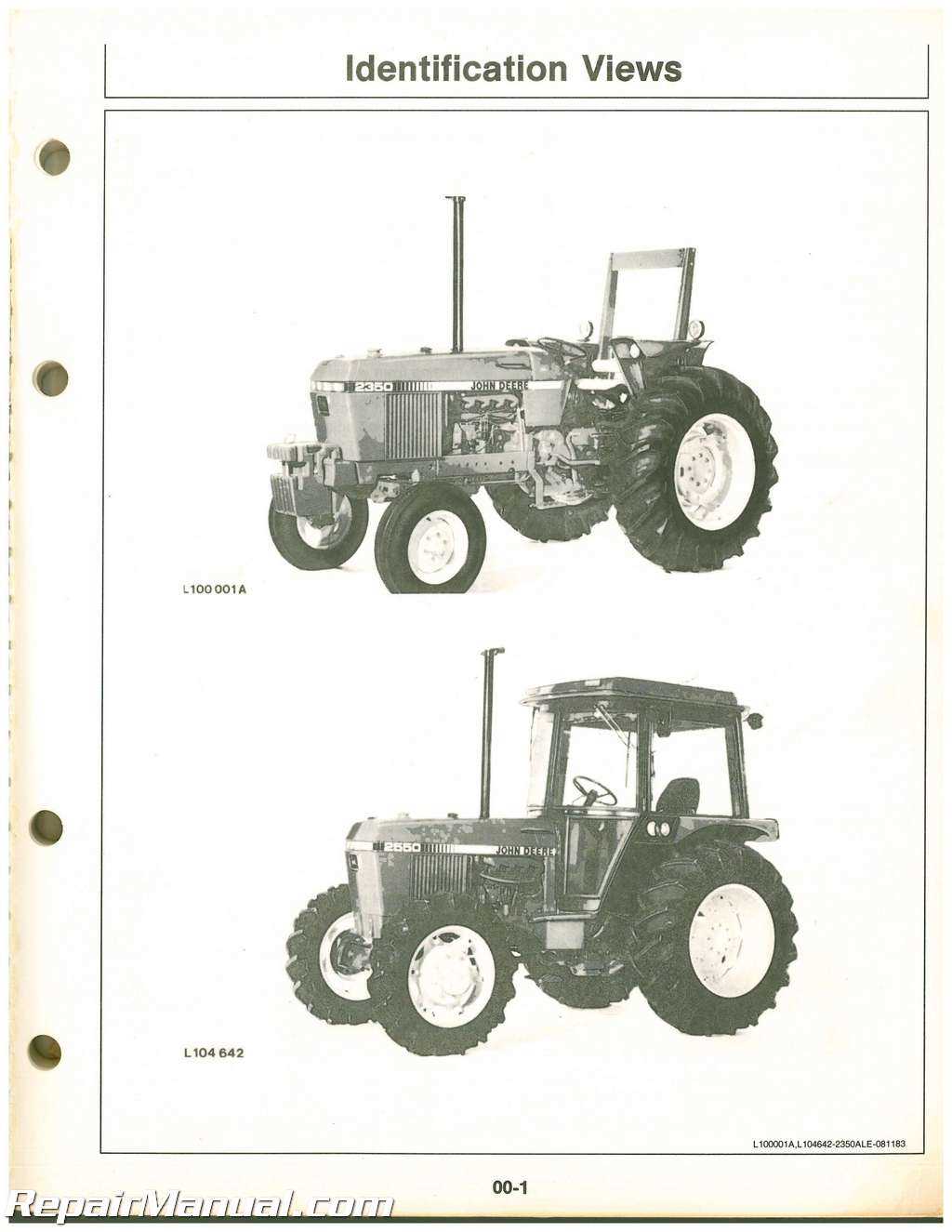

Comparison with Other Models in the Series

Exploring the differences and similarities among various models in the same series reveals insightful nuances and distinctions that are crucial for making informed decisions. This section aims to highlight how each model in the series varies in terms of functionality, design features, and performance metrics, thereby aiding users in selecting the most suitable option based on their specific needs.

Each model in this lineup stands apart from the others due to its unique set of characteristics and operational capabilities. Understanding these distinctions allows users to pinpoint the model that best aligns with their requirements, whether prioritizing efficiency, power output, or specialized functionalities.

Moreover, a comparative analysis provides clarity on which model may offer enhanced reliability, ease of maintenance, or advanced technological integrations. By evaluating these factors, potential buyers can confidently determine which model represents the optimal choice for their agricultural or industrial endeavors.

Resources for DIY Repairs

Engaging in do-it-yourself repairs can be both rewarding and cost-effective. Access to reliable resources is crucial for successful projects, allowing enthusiasts to troubleshoot issues, find compatible components, and gain confidence in their skills. This section explores various tools and platforms that can aid in the repair process.

Online Forums and Communities

Joining online forums and communities dedicated to machinery maintenance can provide invaluable support. These platforms allow users to share experiences, seek advice, and find solutions to common problems. Participants often post step-by-step guides, making it easier for newcomers to follow along and complete their repairs.

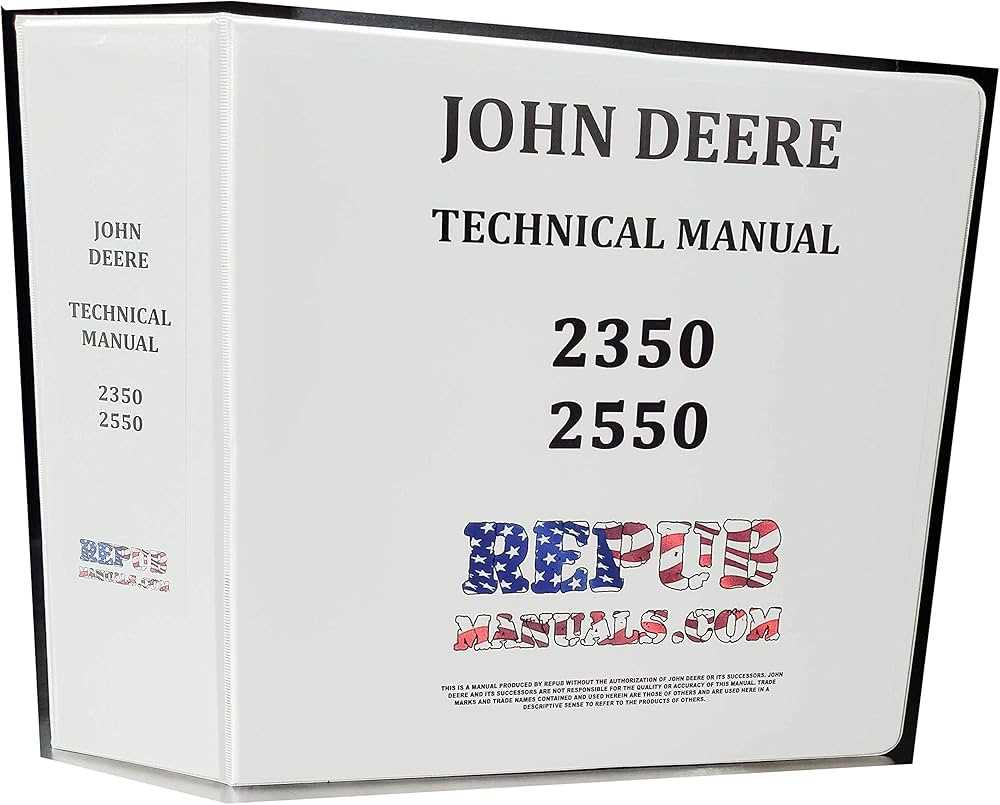

Manufacturer Manuals and Guides

Manufacturer manuals are essential resources for anyone undertaking repairs. These documents typically include detailed information on assembly, troubleshooting, and maintenance procedures. Accessing digital versions of these guides can streamline the repair process, ensuring that users have the right information at their fingertips.