Comprehensive Guide to John Deere 2720 Parts Diagram

Exploring the intricate design of agricultural machinery can significantly enhance your maintenance and repair skills. This essential knowledge allows operators to navigate complex systems and identify various elements that contribute to the overall functionality of equipment. A comprehensive visual guide serves as an invaluable resource for anyone looking to optimize performance and extend the lifespan of their machines.

By breaking down the individual components and their relationships, users can gain insights into how each piece contributes to the machine’s efficiency. Whether you’re an experienced technician or a novice, understanding these connections will empower you to troubleshoot issues and perform repairs more effectively. Additionally, having a clear reference can streamline the process of ordering replacements when necessary.

With a detailed visual representation, it becomes easier to recognize parts and comprehend their specific roles within the machinery. This resource not only aids in maintenance but also fosters a deeper appreciation for the engineering behind agricultural technology. As you delve into this subject, you’ll uncover the nuances that make each component vital to the overall operation.

Understanding John Deere 2720 Parts

Grasping the components of this agricultural machine is crucial for effective maintenance and operation. A comprehensive understanding allows users to identify issues quickly and ensures optimal performance.

Key Components

- Engine

- Transmission

- Hydraulic System

- Chassis

Maintenance Tips

- Regularly check fluid levels.

- Inspect filters for clogs.

- Ensure all connections are secure.

- Consult the manual for specific service intervals.

Importance of Accurate Parts Diagrams

Having precise visual representations of components is crucial in various industries, especially in machinery maintenance and repair. These illustrations serve as vital resources, enabling technicians and operators to identify and source the necessary elements effectively. Accurate depictions facilitate seamless assembly and disassembly processes, ensuring optimal functionality of the equipment.

Enhancing Efficiency

When professionals work with clear and correct representations, they can significantly reduce downtime. Detailed visuals guide them in locating and replacing elements quickly, which is essential in maintaining productivity. This efficiency not only saves time but also minimizes labor costs associated with repairs.

Ensuring Safety

Correctly labeled and represented components are essential for safety. Misidentification can lead to incorrect installations, posing risks to operators and the machinery itself. Clear illustrations help mitigate these hazards by providing a reliable reference that ensures each piece is fitted properly.

| Benefit | Description |

|---|---|

| Reduced Downtime | Quick identification and replacement of components minimize operational interruptions. |

| Cost-Effective | Efficient repairs lower labor costs and prolong equipment lifespan. |

| Improved Safety | Accurate references decrease the likelihood of hazardous mistakes during maintenance. |

Overview of John Deere 2720 Features

This section provides a comprehensive look at the distinctive characteristics of a versatile agricultural implement designed for enhanced productivity. Emphasizing functionality and efficiency, this equipment is tailored to meet the diverse needs of modern farming practices.

Performance: The machinery boasts powerful capabilities that facilitate a range of tasks, from tilling to planting. Its robust engine ensures optimal operation even in challenging conditions.

Design: Ergonomically crafted, the unit features user-friendly controls that simplify the workflow for operators. The layout promotes ease of use while maximizing output.

Durability: Constructed from high-quality materials, this implement is built to withstand wear and tear, ensuring longevity and reliability throughout its service life.

Versatility: With various attachments available, it can adapt to multiple agricultural applications, making it an indispensable tool for farmers aiming for efficiency.

In summary, the discussed implement exemplifies a blend of power, design, and adaptability, positioning it as a top choice for those in the agricultural sector.

Common Issues with 2720 Components

When operating machinery, certain elements can encounter frequent challenges that may hinder performance and efficiency. Understanding these common complications is crucial for maintaining optimal functionality and extending the lifespan of equipment.

Wear and Tear: Regular use can lead to degradation of components, resulting in reduced effectiveness. Components should be routinely inspected for signs of fatigue.

Hydraulic Leaks: One of the most prevalent issues involves leaks in hydraulic systems, which can impact power and responsiveness. Prompt attention is necessary to prevent larger failures.

Electrical Failures: Wiring and connections can suffer from corrosion or damage, causing intermittent or complete failures. Regular maintenance of electrical systems can mitigate these risks.

Alignment Problems: Misalignment of parts can result in uneven wear and operational inefficiencies. Ensuring proper alignment during assembly and maintenance is essential.

How to Identify Genuine Parts

Ensuring the authenticity of components is crucial for optimal performance and longevity of machinery. Recognizing authentic items helps maintain efficiency and avoid potential pitfalls associated with counterfeit alternatives. This guide offers insights into distinguishing original products from imitations.

Key Features to Consider

When assessing authenticity, pay attention to several essential characteristics:

| Feature | Description |

|---|---|

| Branding | Look for clear logos and trademarks consistent with manufacturer specifications. |

| Packaging | Genuine items often come in high-quality, well-designed packaging that includes safety seals. |

| Material Quality | Original components are typically made from superior materials, enhancing durability. |

Verification Methods

Utilize various techniques to confirm authenticity, such as checking serial numbers, consulting authorized dealers, or reviewing customer feedback. Each method can provide valuable information about the legitimacy of the item in question.

Exploring Aftermarket Parts Options

When it comes to enhancing machinery functionality, the exploration of alternative components can offer both cost-effectiveness and improved performance. These substitutes provide an opportunity for users to customize their equipment while often delivering comparable or even superior quality compared to original manufacturer offerings.

Benefits of Choosing Alternatives

Opting for non-original components can lead to significant savings and a broader selection. Enhanced durability and innovative designs often characterize these alternatives, catering to specific user needs. Additionally, many aftermarket options come with extensive warranties, ensuring peace of mind for buyers.

Considerations for Selection

When delving into this market, it is crucial to assess compatibility and reliability. Researching reputable brands and reading customer reviews can guide you towards optimal choices. Prioritizing quality will ensure that your equipment continues to perform at its best, ultimately leading to more efficient operations.

Maintenance Tips for 2720 Parts

Proper upkeep of agricultural machinery is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents costly repairs down the line. Here are some essential strategies to ensure your equipment remains in top condition.

| Task | Frequency | Benefits |

|---|---|---|

| Check Fluid Levels | Weekly | Prevents overheating and ensures smooth operation. |

| Inspect Belts and Hoses | Monthly | Identifies wear and tear before failure occurs. |

| Clean Air Filters | Every 50 hours | Improves airflow and engine efficiency. |

| Sharpen Blades | Every 25 hours | Ensures effective cutting and reduces strain on the engine. |

| Check Tire Pressure | Weekly | Improves fuel efficiency and reduces wear. |

Adhering to these guidelines will not only enhance the performance of your machinery but also extend its operational lifespan. Consistency in maintenance is key to achieving reliability and effectiveness in agricultural tasks.

Ordering Parts: A Step-by-Step Guide

Acquiring components for your equipment can be a straightforward process if you follow a structured approach. This guide will help you navigate through the essential steps to ensure you obtain the right items efficiently and accurately.

1. Identify the Required Component

Start by determining which specific item you need. Refer to your equipment’s manual or online resources to pinpoint the exact name and specifications of the part.

2. Gather Essential Information

Collect all relevant details, such as model numbers, serial numbers, and any other identifiers that can assist suppliers in locating the correct item for your machinery.

3. Research Reliable Suppliers

Look for trustworthy vendors that specialize in machinery components. Read reviews and compare prices to find the best option that meets your needs.

4. Verify Availability

Once you’ve chosen a supplier, check if the item is in stock. Availability can vary, so it’s wise to confirm before proceeding with your order.

5. Place Your Order

Follow the supplier’s ordering procedure. This may involve filling out an online form or contacting customer service directly. Ensure you provide all necessary details to avoid delays.

6. Confirm Shipping Details

Before finalizing your order, double-check your shipping information. Accurate addresses and preferred delivery methods can prevent complications during transit.

7. Track Your Order

After placing your order, utilize tracking tools provided by the supplier to monitor the shipment’s progress. This will keep you informed about its estimated arrival time.

8. Inspect Upon Arrival

Once you receive your items, carefully inspect them for any damage or discrepancies. If everything is in order, proceed with the installation or usage as planned.

Following these steps can help streamline the process of obtaining components, ensuring that your machinery remains in optimal working condition.

Tools Required for Parts Replacement

When it comes to replacing components in machinery, having the right tools is essential for efficiency and safety. Proper equipment not only facilitates the process but also ensures that tasks are performed correctly, minimizing the risk of damage.

Essential Tools

Basic tools such as wrenches, screwdrivers, and pliers are fundamental. Additionally, a torque wrench is crucial for maintaining the appropriate tightness on fasteners. Having a set of sockets can also greatly enhance accessibility to hard-to-reach areas.

Safety Gear

Don’t forget safety equipment! Using gloves, goggles, and steel-toed boots can protect against injuries. A well-lit workspace is also important for visibility during the replacement process.

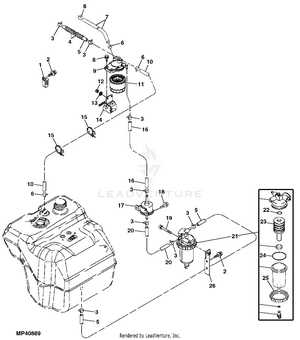

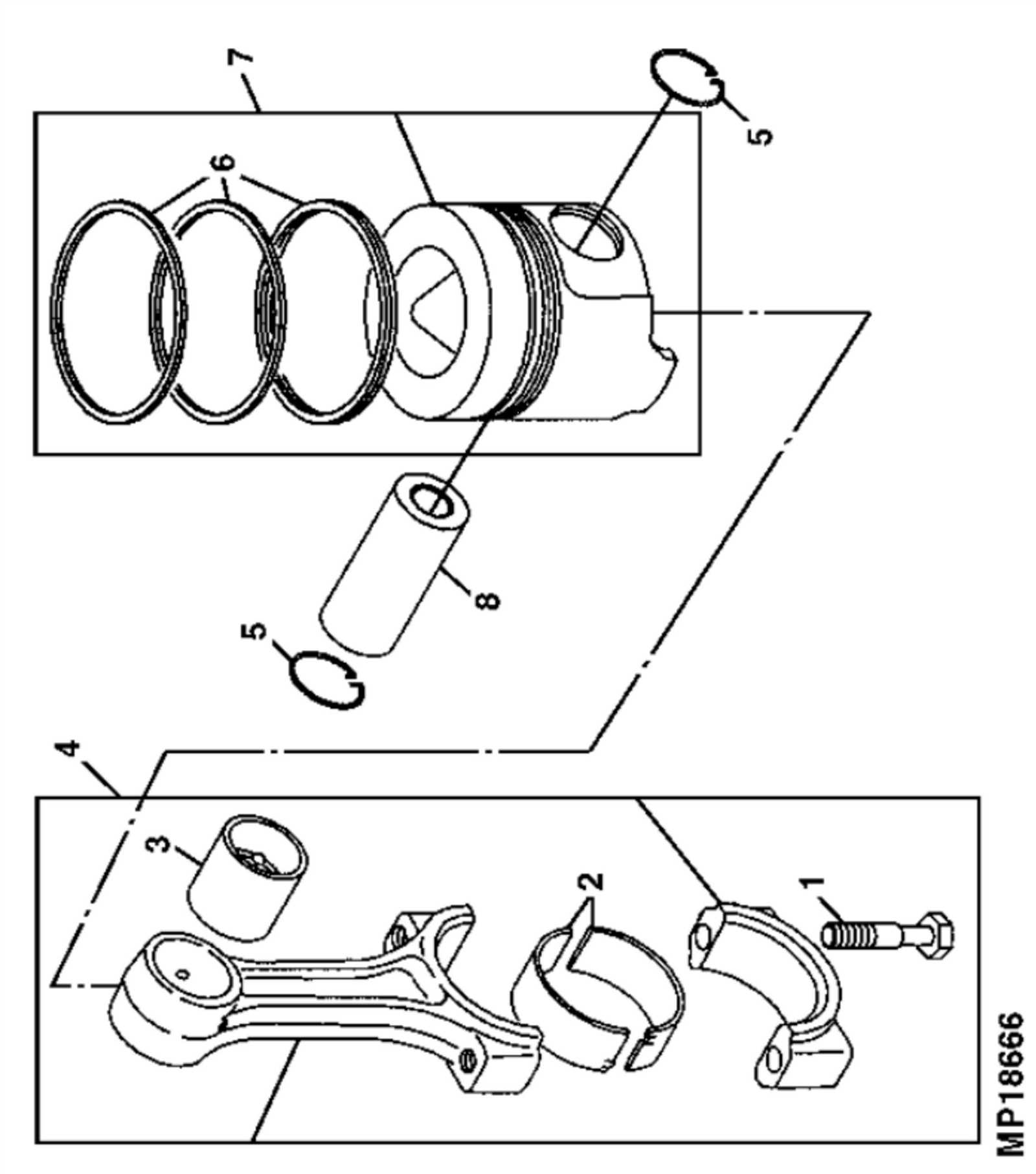

Reading the Parts Diagram Effectively

Understanding the visual representation of components is crucial for efficient maintenance and repairs. A well-organized illustration provides valuable insights into the arrangement and interaction of various elements, enabling users to identify what is needed for optimal functionality.

Start by familiarizing yourself with the layout; knowing how different sections are categorized can save time. Pay attention to the labels, as they guide you in locating specific items. Additionally, understanding the numbering system helps in correlating each piece with the manufacturer’s reference.

Utilizing a magnifying tool can enhance clarity, especially with intricate designs. Take notes on any parts that require replacement, as this will streamline your purchasing process. By dissecting the illustration in a methodical manner, you will ultimately grasp the full scope of what is necessary for successful repairs.

Frequently Asked Questions About Parts

This section addresses common inquiries related to components essential for maintaining and optimizing the performance of agricultural machinery. Understanding these elements can enhance efficiency and prolong the lifespan of equipment.

Common Queries

Many users often seek clarification on various topics regarding machinery components. Below are some of the most frequently asked questions and their corresponding answers.

| Question | Answer |

|---|---|

| How do I identify the correct component for my machinery? | Refer to the user manual or consult with your dealer for specific identification codes. |

| What should I do if I can’t find a replacement part? | Contact the manufacturer or authorized retailers to check for availability or alternatives. |

| Are aftermarket components reliable? | While some aftermarket options can be dependable, it’s essential to research the manufacturer’s reputation. |

| How often should I replace worn-out components? | Regular maintenance checks should be performed to determine the condition and necessary replacement intervals. |

Additional Resources

For further assistance, consider joining online forums or contacting local experts who specialize in machinery maintenance. These platforms can provide valuable insights and support for your specific needs.

Finding a Reliable Dealer

When it comes to acquiring components for your machinery, selecting a trustworthy supplier is crucial. A dependable vendor not only offers quality items but also provides exceptional service and support. The right dealer can make a significant difference in maintaining the efficiency and longevity of your equipment.

Begin your search by exploring local and online options. Look for dealers with a solid reputation in the industry. Customer reviews and testimonials can provide valuable insights into their reliability and the quality of their offerings. It’s also beneficial to check if the dealer specializes in the specific type of equipment you own, as this often indicates a higher level of expertise.

Inquire about warranty policies and return procedures, as these factors contribute to overall customer satisfaction. A reputable dealer will stand behind their products and be willing to assist you in case of any issues. Additionally, consider their customer service; prompt responses and knowledgeable staff can enhance your purchasing experience significantly.

Finally, building a relationship with a reliable dealer can lead to better deals and access to exclusive products. Investing time in finding the right supplier will pay off in the long run, ensuring you have the necessary resources to keep your machinery running smoothly.

Upgrades and Modifications for 2720

Enhancing machinery can significantly improve its efficiency and performance. By implementing various upgrades and modifications, operators can tailor their equipment to better suit specific tasks and challenges.

Performance Enhancements: Consider upgrading the engine for increased power and torque. This modification can lead to better productivity, especially in demanding conditions.

Attachments and Accessories: Adding specialized attachments can transform functionality. Options like advanced plows or seeders allow for a more versatile approach to land management.

Comfort Features: Improving the operator’s environment is crucial for prolonged use. Upgrading seats and control systems can enhance comfort, reducing fatigue during long hours of operation.

Safety Upgrades: Installing modern safety features, such as enhanced lighting and visibility aids, ensures a safer working environment, minimizing the risk of accidents.

By thoughtfully selecting modifications, operators can achieve their ultimate performance goals while maximizing the utility of their machinery.