Exploring John Deere 3032E Parts Diagrams for Optimal Maintenance

In the realm of farming equipment, comprehending the various elements that constitute machinery is crucial for effective maintenance and operation. This section aims to illuminate the intricate web of components, providing insights into their functionalities and interconnections.

Whether you’re a seasoned operator or a newcomer to the agricultural world, familiarity with these essential parts enhances your ability to troubleshoot and optimize your equipment. A thorough understanding paves the way for better performance and longevity of your machinery.

Moreover, visual representations play a vital role in grasping how different elements fit together. By exploring these illustrations, you can delve into the details that lead to the ultimate efficiency of your agricultural tools, ensuring you make informed decisions in your farming endeavors.

Understanding John Deere 3032E Parts

Gaining insight into the components of agricultural machinery is essential for effective maintenance and operation. Each element plays a crucial role in ensuring optimal performance and longevity. By familiarizing oneself with these integral pieces, users can better troubleshoot issues and implement necessary replacements.

Familiarity with these components not only aids in identifying problems but also enhances overall functionality. A well-informed operator can make informed decisions regarding repairs and upgrades, leading to improved efficiency and reduced downtime.

Additionally, understanding the relationships between various elements can illuminate how they work together to achieve the ultimate goal of productivity in the field. This comprehensive knowledge fosters a proactive approach to machine care and helps prevent potential failures.

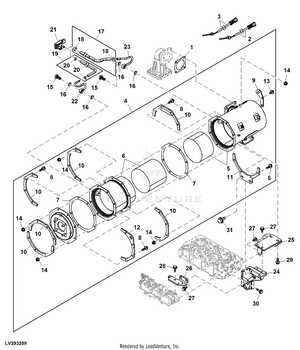

Importance of Parts Diagrams

Understanding the layout and composition of machinery is essential for effective maintenance and repairs. Visual representations of components serve as crucial tools for technicians, enabling them to identify, locate, and replace elements with precision.

Effective maintenance relies heavily on accurate illustrations. These resources facilitate quick reference, allowing users to navigate complex assemblies without confusion. Furthermore, they promote efficiency by reducing downtime during repairs.

In addition, having a clear visual guide aids in the training of new personnel. Novices can quickly grasp how various elements interact, leading to a smoother onboarding process. Ultimately, well-structured visual aids enhance overall productivity and ensure machinery operates at its best.

Key Components of the 3032E

This section highlights the essential elements that contribute to the functionality and performance of this compact utility machine. Understanding these components can enhance maintenance and operational efficiency.

Powertrain

- Engine: A reliable power source that ensures optimal performance.

- Transmission: Facilitates smooth gear changes and enhances control.

- Drive System: Delivers power to the wheels for effective movement.

Hydraulic System

- Pump: Generates hydraulic fluid pressure for various attachments.

- Cylinders: Assist in lifting and lowering implements efficiently.

- Valves: Regulate fluid flow for precise control of operations.

How to Access Diagrams Online

Finding detailed illustrations for machinery can significantly enhance maintenance and repair efforts. With the right resources, you can easily locate these visuals to better understand components and their arrangements. The following guide outlines effective methods for accessing these essential resources online.

Utilizing Manufacturer Websites

Many manufacturers provide a wealth of information on their official sites. Navigate to the support or resources section, where you can often find downloadable manuals or interactive models. Registration may be required, but this step grants access to valuable documentation.

Exploring Online Forums and Communities

Engaging with online forums can yield useful insights. Enthusiasts and professionals frequently share links to resources, including diagrams and maintenance tips. Participating in discussions can also lead to discovering unique solutions or references not readily available elsewhere.

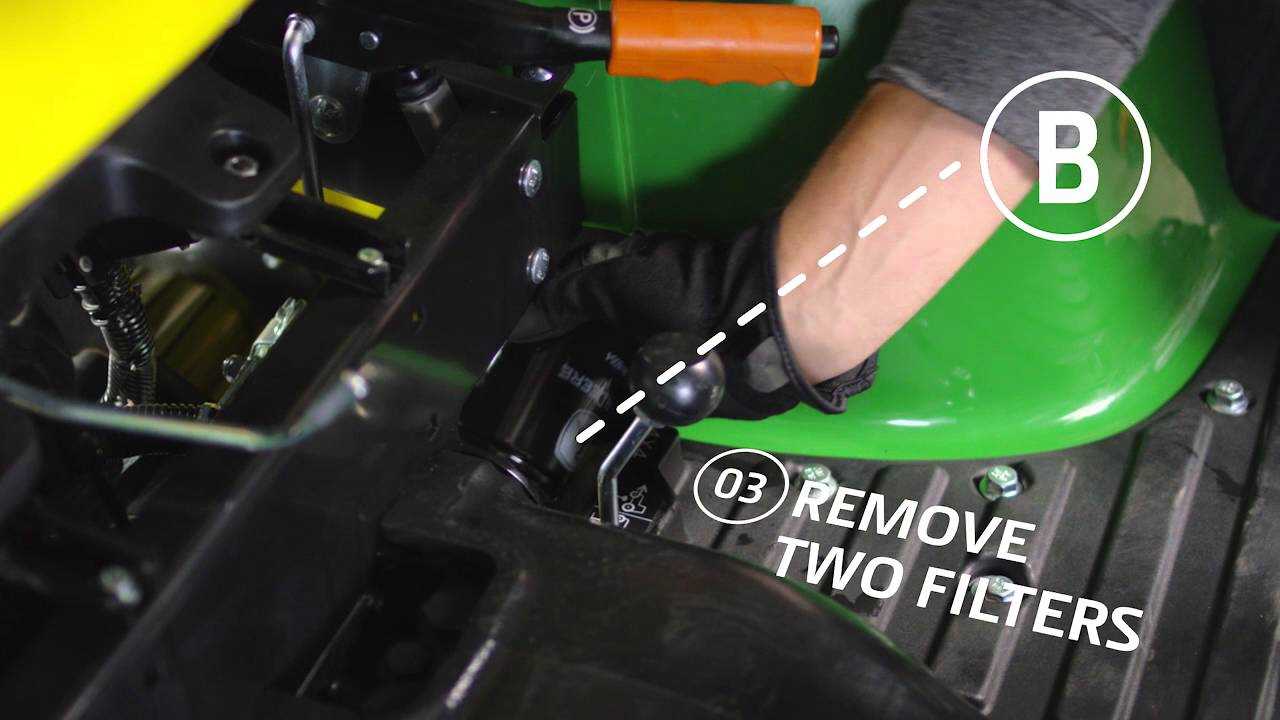

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your machinery requires consistent attention and care. Implementing regular maintenance practices not only enhances performance but also extends the lifespan of equipment.

- Regular Inspections: Conduct routine checks to identify wear and tear early.

- Fluid Changes: Change oils and other fluids as recommended to keep systems clean and efficient.

- Clean Filters: Regularly clean or replace air and fuel filters to maintain optimal airflow and performance.

- Tire Maintenance: Monitor tire pressure and tread to ensure proper traction and safety.

- Battery Care: Inspect battery terminals and connections, keeping them clean and secure.

By following these guidelines, operators can significantly improve reliability and reduce the likelihood of unexpected breakdowns.

Common Replacement Parts Explained

Understanding the essential components of machinery is crucial for maintenance and longevity. This section explores frequently needed elements that ensure optimal performance and reliability, providing insights into their functions and significance.

Engine Components

Key engine elements, such as filters and gaskets, play a vital role in maintaining efficiency and preventing contamination. Regular inspection and timely replacement of these components can significantly enhance engine lifespan.

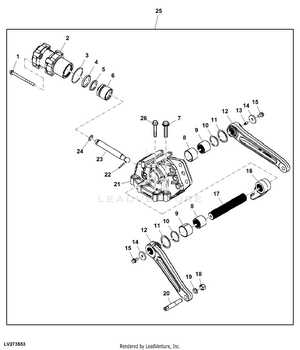

Transmission and Drive Elements

Transmission components, including belts and seals, are essential for smooth operation and power transfer. Ensuring these parts are in good condition helps prevent operational disruptions and extends overall equipment durability.

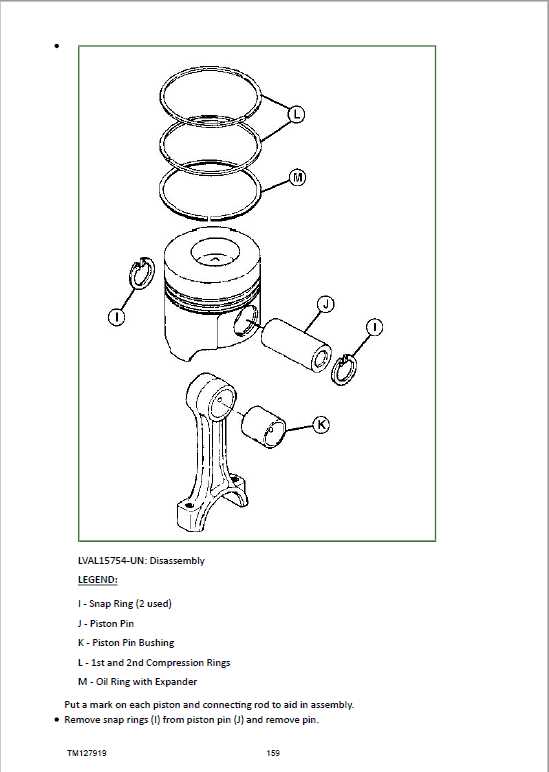

Identifying Parts Using Diagrams

Understanding the components of machinery can greatly enhance maintenance and repair efforts. Visual representations serve as invaluable tools, allowing users to pinpoint specific elements efficiently. By familiarizing oneself with these illustrations, one can streamline the identification process and ensure accurate assembly or replacement.

Importance of Visual References

Utilizing visual references not only simplifies the task of recognizing various components but also reduces the likelihood of errors. Detailed illustrations provide context and clarity, making it easier to comprehend the relationship between different pieces and their functionalities.

Steps to Efficient Identification

Begin by closely examining the visual guide, noting key features of each component. Cross-referencing with manuals or specifications can further enhance understanding, ensuring a comprehensive grasp of the machinery. This methodical approach facilitates quicker diagnostics and repairs.

Purchasing Genuine John Deere Parts

When it comes to acquiring authentic components for machinery, ensuring quality and compatibility is paramount. Using original replacements not only enhances performance but also extends the lifespan of equipment. This section will guide you through the importance and advantages of selecting genuine items for your agricultural needs.

Benefits of Authentic Components

- Superior Quality: Crafted to meet specific standards.

- Optimal Performance: Designed for seamless integration.

- Warranty Assurance: Often covered by manufacturer guarantees.

Where to Find Genuine Items

- Authorized Dealers: Visit local representatives for reliable sourcing.

- Online Retailers: Many websites specialize in authentic equipment.

- Manufacturer’s Website: Direct purchasing options often available.

Aftermarket Options: Pros and Cons

Exploring alternative components for machinery can offer both advantages and disadvantages. Many operators consider these substitutes as a viable way to save costs and improve performance. However, understanding the implications of using non-original products is crucial for making informed decisions.

One significant benefit of opting for alternatives is the potential for cost savings. Aftermarket products often come at a lower price point compared to their original counterparts, making them an attractive choice for budget-conscious individuals. Additionally, a wide variety of options allows for customization, enabling users to select components that may better fit their specific needs.

On the flip side, the use of non-original parts can lead to concerns about quality and reliability. These substitutes may not meet the same rigorous standards as original items, potentially resulting in decreased performance or shorter lifespans. Furthermore, compatibility issues may arise, which can lead to costly repairs or operational downtime.

Ultimately, while aftermarket options present opportunities for savings and customization, it is essential to weigh these against the potential risks involved. Careful consideration of both sides will help users make choices that align with their operational goals and maintain the longevity of their equipment.

Tools Needed for Parts Replacement

When undertaking maintenance or repairs on machinery, having the right equipment is crucial for efficient and safe operations. Proper tools not only facilitate the task but also ensure that components are handled correctly, minimizing the risk of damage. This section outlines essential instruments required for effective component substitution.

Essential Tools

First and foremost, a quality set of wrenches and sockets is indispensable. These tools allow for the secure loosening and tightening of bolts and fasteners. Additionally, a sturdy screwdriver set is necessary for various screws that may be encountered during the replacement process. Having both flathead and Phillips options is advisable to accommodate different types.

Specialized Equipment

In certain cases, specialty tools may be required. For instance, a torque wrench is critical for ensuring that bolts are tightened to the manufacturer’s specifications, preventing over-tightening that can lead to failures. Furthermore, a pneumatic impact wrench can expedite the removal of stubborn fasteners, saving valuable time. Finally, having a reliable multimeter on hand is essential for diagnosing electrical issues that may arise during the replacement process.

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient maintenance and repair. These illustrations serve as guides to identify, locate, and manage various elements within machinery.

Key Components of the Visual Representation

- Labels: Each section is often labeled for easy identification.

- Symbols: Different shapes indicate specific types of components.

- Connections: Lines show how parts are linked or interact with one another.

Steps to Interpret the Illustrations

- Begin by examining the overall layout to grasp the arrangement of components.

- Focus on labels to find the specific element you need to address.

- Trace connections to understand how each piece functions within the system.

- Cross-reference with the accompanying information for detailed descriptions.

Frequently Asked Questions on Parts

This section aims to address common inquiries regarding components and their specifications, helping users make informed decisions when seeking replacements or upgrades. Understanding the essentials can significantly enhance maintenance and repair efforts.

What should I consider when selecting components?

When choosing replacements, evaluate compatibility, quality, and manufacturer recommendations. Ensuring these elements align with your equipment’s requirements will enhance performance and longevity.

How can I find the right specifications?

Utilizing online resources, user manuals, and consulting with professionals are effective ways to obtain accurate specifications. These sources provide essential information to help you locate the correct items for your needs.