Comprehensive Guide to John Deere 348 Baler Parts Diagram

In the realm of modern farming, the efficiency of machinery plays a crucial role in optimizing productivity. A thorough comprehension of the various elements that constitute these machines can significantly enhance their operation and maintenance. This section aims to provide insight into the intricate relationships between different components, ensuring that operators can troubleshoot issues effectively and maximize the lifespan of their equipment.

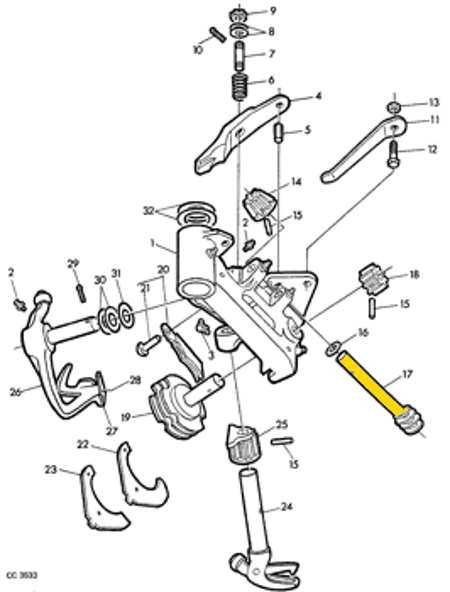

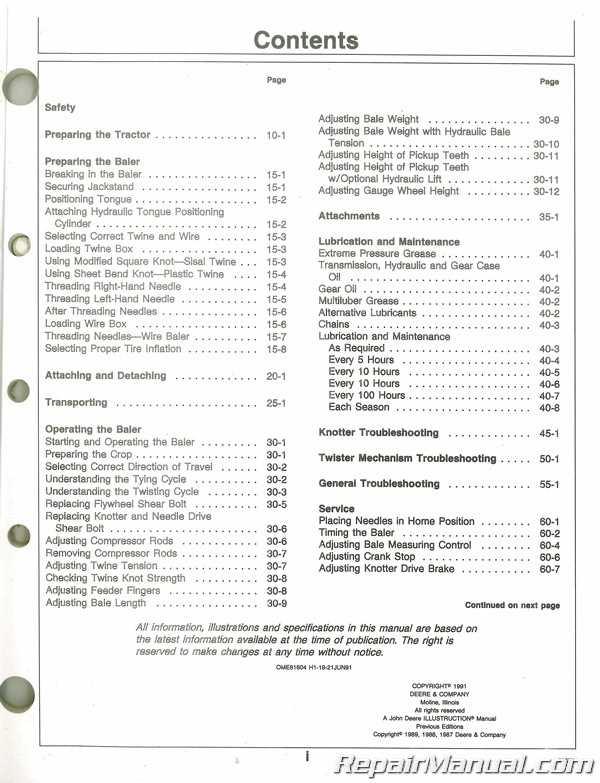

Visual representations of machine elements are invaluable tools for anyone involved in agricultural operations. They not only facilitate a clearer understanding of how each piece functions within the larger system but also aid in identifying potential wear and tear. By analyzing these schematics, users can develop a more profound appreciation for the design and engineering behind their tools, leading to more informed decisions regarding repairs and upgrades.

Moreover, grasping the arrangement of various machine parts encourages a proactive approach to maintenance. Regular inspections and timely interventions can prevent costly breakdowns and ensure that the equipment operates at peak performance. This knowledge empowers users, enabling them to take charge of their machinery and fostering a culture of diligence and care in agricultural practices.

Understanding John Deere 348 Baler

This section explores the essential aspects of a particular agricultural machine known for its efficiency in hay and straw management. By examining its functionality, components, and maintenance practices, users can gain a comprehensive understanding of its role in modern farming operations.

Key Features

- Robust construction for durability

- Efficient tying mechanisms

- Adjustable settings for different materials

Maintenance Tips

- Regularly check and replace wear parts.

- Keep the machine clean to prevent clogs.

- Inspect hydraulic systems for leaks.

Key Components of the Baler

Understanding the essential elements of this agricultural machinery is crucial for efficient operation and maintenance. Each part plays a vital role in the overall functionality, contributing to the effectiveness of the entire system.

| Component | Function |

|---|---|

| Feeding System | Directs material into the compression chamber for processing. |

| Compression Chamber | Compresses the material into manageable shapes. |

| Twine or Net Wrap System | Secures the compressed material for easy handling and transport. |

| Drive Mechanism | Powers the moving parts and ensures proper operation. |

| Discharge System | Releases the finished product for collection. |

Maintenance Tips for Longevity

Ensuring the extended lifespan of agricultural machinery requires consistent care and attention. Regular maintenance not only enhances performance but also prevents costly repairs, allowing for smooth operations in the field.

Routine Inspections

- Check for wear and tear on components regularly.

- Inspect belts and chains for proper tension.

- Look for signs of rust or corrosion.

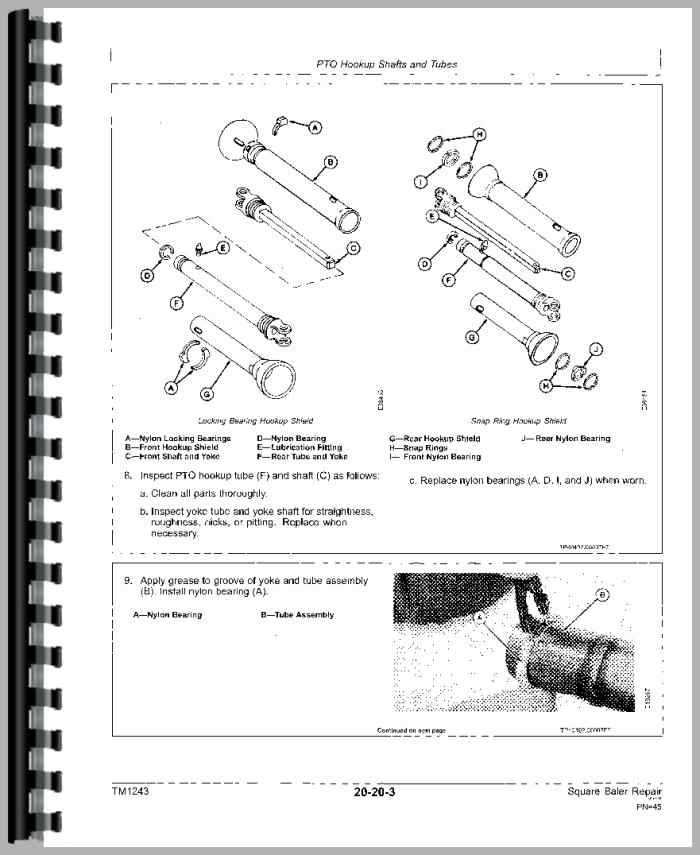

Lubrication Practices

- Apply appropriate grease to moving parts.

- Utilize oil where necessary to reduce friction.

- Follow manufacturer guidelines for lubrication intervals.

Common Issues and Solutions

When operating agricultural machinery, encountering problems is not uncommon. Understanding typical challenges and their resolutions can enhance efficiency and reduce downtime. Below are some frequent issues and practical solutions that operators may face.

-

Blockages:

Clogs can occur in the feeding mechanism, preventing smooth operation. Regularly check for debris and ensure the feed path is clear.

-

Uneven Bales:

Bales may come out inconsistently, affecting quality. Adjusting the tension settings and ensuring uniform feeding can help mitigate this problem.

-

Worn Components:

Parts can wear down over time, leading to decreased performance. Inspect and replace any worn-out components as necessary.

-

Failure to Tie:

If the tying mechanism fails, bales will not form correctly. Check the twine and the tying assembly for proper functioning and replace any faulty parts.

By addressing these common issues promptly, operators can maintain optimal performance and extend the lifespan of their equipment.

Parts Replacement Guide

Maintaining optimal performance of agricultural machinery requires timely and accurate replacements of various components. Understanding the necessary steps for replacing key elements ensures efficiency and prolongs the life of the equipment.

Follow this guide to effectively replace essential components:

- Identify the components that need replacement.

- Gather the necessary tools for the task.

- Refer to the manual for specific instructions related to each component.

- Carefully remove the old components.

- Install the new parts, ensuring they fit securely.

- Conduct a thorough check to confirm proper installation.

It is important to maintain a checklist to keep track of which components have been replaced, ensuring that all necessary replacements are made over time. Regular maintenance checks can help identify worn parts before they lead to equipment failure.

- Keep a record of replacement dates.

- Monitor the condition of surrounding components to avoid unexpected issues.

- Consult with professionals for advice on specific replacements if needed.

Following these guidelines will contribute to a reliable and efficient machine, enhancing productivity on the field.

Operational Guidelines for Efficiency

To achieve optimal performance and longevity of agricultural machinery, it’s essential to adhere to specific operational protocols. By following these guidelines, operators can enhance productivity, minimize downtime, and ensure the machinery operates smoothly during critical tasks.

Regular Maintenance Practices

- Conduct routine inspections to identify wear and tear.

- Ensure lubrication of moving parts to reduce friction.

- Replace worn-out components promptly to avoid operational issues.

- Keep the equipment clean to prevent dust and debris buildup.

Best Operating Procedures

- Familiarize yourself with the operator’s manual for detailed instructions.

- Adjust settings based on material type and moisture content for optimal results.

- Monitor machine performance regularly and make adjustments as necessary.

- Follow safety protocols to protect both the operator and the machinery.

How to Read Parts Diagrams

Understanding schematic illustrations is essential for effective maintenance and repair tasks. These visual aids help users identify components, their relationships, and functions within a machine. Familiarity with these visuals can streamline troubleshooting processes and facilitate the ordering of necessary items.

Here are some key steps to help interpret these illustrations:

- Familiarize Yourself with Symbols: Different components are represented by specific symbols. Learning these can enhance comprehension.

- Identify Sections: Most schematics are divided into sections, each representing a specific area of the machinery. Focus on one section at a time.

- Read Annotations: Pay attention to notes or labels, as they often provide critical information regarding assembly or operation.

- Refer to the Legend: Many illustrations include a legend that explains symbols or color codes used, making it easier to understand the representation.

- Follow Connections: Trace lines that connect various components to understand how they interact and function as a unit.

By applying these strategies, users can effectively navigate schematic illustrations, enabling them to perform repairs and maintenance tasks with greater confidence.

Where to Find Authentic Parts

Locating genuine components for agricultural machinery is essential for maintaining optimal performance and longevity. Ensuring that you acquire quality replacements can significantly impact the efficiency of your equipment. Here are several avenues to explore when searching for authentic replacements.

Official Retailers and Dealerships

Authorized retailers are a reliable source for original replacements. They typically offer a wide selection of components and accessories tailored to your machinery’s specifications. Engaging with these dealers guarantees access to manufacturer-backed products and expertise.

Online Marketplaces and Forums

Various online platforms and community forums provide opportunities to connect with other users and sellers. These platforms often feature listings for authentic components, alongside user reviews that can guide your purchasing decisions.

| Source | Description | Advantages |

|---|---|---|

| Official Dealers | Authorized sellers offering genuine components. | Quality assurance, expert advice. |

| Online Marketplaces | Websites featuring various sellers and products. | Wide selection, user feedback. |

| Community Forums | Platforms for discussing and buying machinery-related items. | Peer recommendations, access to hard-to-find items. |

Comparison with Other Baler Models

When evaluating various models in the market, it is essential to consider their unique features and how they stack up against one another. Each design offers distinct advantages tailored to specific agricultural needs, making it vital for users to assess which machine best meets their operational requirements.

Performance and Efficiency

Different models exhibit varying levels of performance, particularly regarding speed and bale density. Some machines are engineered for high-throughput operations, allowing users to complete tasks more quickly. In contrast, others may prioritize quality, producing denser bales that are easier to handle and transport. Understanding these differences can significantly impact productivity and efficiency in the field.

Maintenance and Serviceability

Another critical factor in the comparison of machinery is the ease of maintenance and availability of service components. Certain models may be designed with user-friendly maintenance features, allowing for quicker repairs and reduced downtime. Additionally, the accessibility of replacement components can influence long-term ownership costs, making it crucial for users to consider these aspects when selecting their preferred machine.

Upgrades for Enhanced Performance

Improving the efficiency and output of agricultural machinery can significantly impact productivity. Implementing strategic enhancements can lead to better operation, reduced downtime, and overall increased yield. Upgrading specific components can optimize performance, ensuring that equipment runs smoothly and meets the demands of modern farming practices.

Key Component Enhancements

One of the most effective ways to boost functionality is by focusing on crucial elements such as the cutting system and feeding mechanisms. Upgrading blades to high-performance materials can enhance cutting efficiency, while advanced feed rollers can ensure a consistent and reliable material flow. These adjustments not only improve output but also minimize wear and tear, extending the lifespan of the machinery.

Technology Integration

Incorporating modern technology can revolutionize the way agricultural equipment operates. Implementing precision agriculture tools such as GPS tracking and automated monitoring systems can provide real-time data, allowing for informed decision-making. Additionally, software upgrades for control systems can enhance user interface and increase operational control, ultimately leading to more efficient and effective farming practices.

Benefits of Regular Inspections

Conducting routine assessments of machinery is crucial for maintaining optimal performance and ensuring longevity. By regularly examining equipment, operators can identify potential issues before they escalate into major problems, thereby minimizing downtime and repair costs.

Enhancing Efficiency

Regular evaluations allow for adjustments and fine-tuning that enhance operational efficiency. When equipment functions at its best, productivity increases, leading to improved output and profitability.

Safety Assurance

Frequent inspections are essential for maintaining a safe working environment. By identifying worn or faulty components, operators can prevent accidents and ensure the safety of personnel, thus fostering a culture of responsibility and care within the workplace.