John Deere 3720 Parts Diagram Overview

In the realm of agricultural equipment, the effective functioning of machinery heavily relies on the intricate assembly of its various components. Each machine is designed with a specific configuration that optimizes its performance in the field. Analyzing the layout of these elements can significantly enhance maintenance practices and improve overall operational efficiency.

Exploring the structural arrangement of a particular model not only aids in identifying essential features but also assists in troubleshooting common issues. Knowledge of where each segment fits within the larger framework allows operators to make informed decisions regarding repairs and replacements. Furthermore, a well-documented configuration can serve as a vital reference for both experienced technicians and novices alike.

As we delve deeper into the specifics of a popular agricultural machine, we will uncover the relationships between various components and their functions. Understanding these connections empowers users to maximize the utility of their equipment and ensure longevity in its service. Whether for routine maintenance or significant overhauls, familiarizing oneself with the organization of parts is crucial for achieving optimal performance.

Overview of John Deere 3720

This section provides a comprehensive look at a specific model within the agricultural machinery range. Known for its versatility and efficiency, this machine is designed to meet the needs of both professionals and enthusiasts in various farming and landscaping tasks.

The machine boasts a robust build, ensuring durability and reliability in demanding environments. Its advanced features enhance productivity, allowing users to tackle a wide array of tasks with ease. This model is particularly favored for its user-friendly interface and efficient operation, making it suitable for both experienced operators and newcomers to the field.

Additionally, the machine’s design emphasizes comfort and control, enabling users to work for extended periods without fatigue. The integration of modern technology ensures optimal performance, further solidifying its reputation as a top choice for those in the agricultural sector.

Key Features of the 3720 Model

This section highlights the significant characteristics that define this particular machine, showcasing its design and functionality that appeal to users in various agricultural and landscaping applications. Understanding these features can help potential buyers make informed decisions regarding their investment.

Power and Performance

- Equipped with a robust engine that delivers impressive horsepower.

- Enhanced torque output ensures efficient handling of challenging tasks.

- Optimal fuel efficiency minimizes operational costs over time.

Versatility and Attachments

- Compatible with a wide range of implements, making it suitable for various applications.

- Quick-connect attachment system allows for easy switching between tools.

- Compact size facilitates maneuverability in tight spaces without compromising power.

Understanding Parts and Components

Comprehending the various elements and assemblies of machinery is essential for effective maintenance and operation. Each segment plays a significant role in ensuring the overall functionality and performance of the equipment. By familiarizing oneself with these components, operators can enhance their efficiency and troubleshoot issues more effectively.

When exploring the intricate structure of machinery, it is beneficial to categorize the elements into distinct groups. Here are some common classifications:

- Engine Components:

- Fuel system

- Cooling system

- Lubrication system

- Transmission Elements:

- Gearbox

- Clutch assembly

- Drivetrain

- Hydraulic Systems:

- Pumps

- Valves

- Hoses and fittings

- Electrical Components:

- Batteries

- Wiring harness

- Switches and relays

Each category contains specific items that contribute to the smooth operation of the equipment. Understanding the functions and interactions of these components is crucial for effective troubleshooting and repair. Regular maintenance checks should focus on these segments to ensure optimal performance and longevity.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in the maintenance and repair of complex machinery. These visual representations facilitate a better understanding of components and their relationships, ensuring that users can effectively address any issues that arise.

Enhanced Clarity: Clear and accurate visuals eliminate ambiguity, allowing technicians to quickly identify elements and understand their functions. This clarity reduces the likelihood of errors during assembly or disassembly, which can save time and resources.

Improved Efficiency: When operators have access to well-structured visuals, they can work more efficiently. An accurate representation helps streamline processes, enabling quicker troubleshooting and repairs, which ultimately leads to increased productivity.

Cost Savings: Utilizing precise illustrations can lead to significant cost savings. By minimizing mistakes and ensuring proper handling of components, organizations can avoid unnecessary expenses related to repairs, replacements, or even downtime.

In conclusion, investing in high-quality visuals is essential for effective machinery management. Accurate representations are not just useful tools; they are vital assets that enhance understanding, efficiency, and cost-effectiveness in various operational contexts.

Commonly Replaced Parts

Maintaining the functionality of agricultural machinery often involves replacing certain components that experience wear and tear over time. Understanding which elements are most frequently substituted can help operators ensure their equipment runs smoothly and efficiently. This section will explore the common items that users typically change during maintenance or repair procedures.

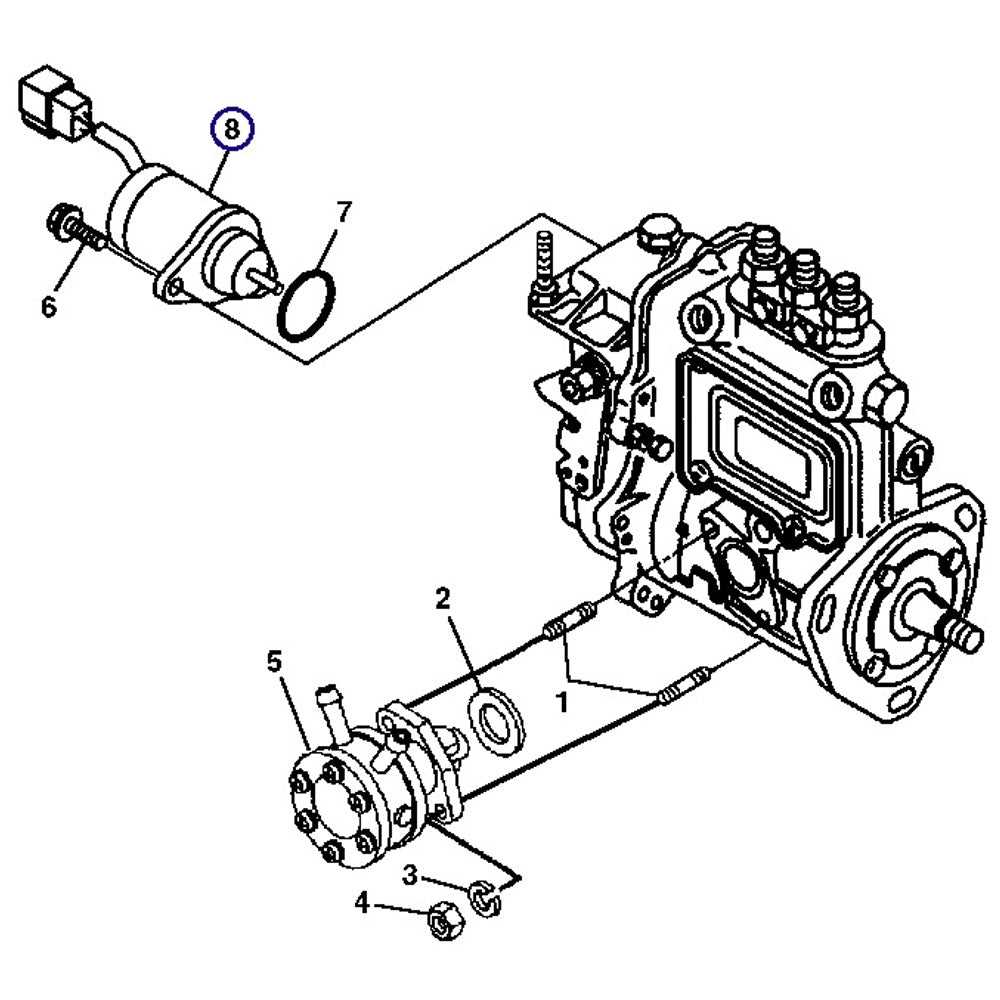

Engine Components

The engine is the heart of any machinery, and several elements may require replacement to maintain optimal performance. Key items include filters, gaskets, and seals, which are essential for proper functioning and preventing leaks. Regular inspection and timely replacement of these components can significantly extend the life of the engine.

Hydraulic System Elements

The hydraulic system plays a crucial role in the operation of various functions. Commonly replaced elements in this system include hoses, cylinders, and pumps. These components are subject to pressure and movement, making them susceptible to damage. Routine checks and replacements ensure that the hydraulic system operates at peak efficiency, enhancing the overall performance of the equipment.

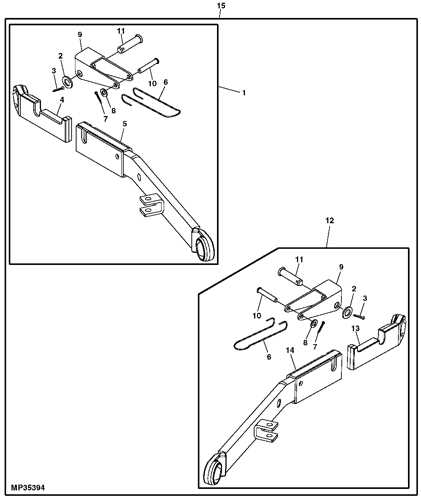

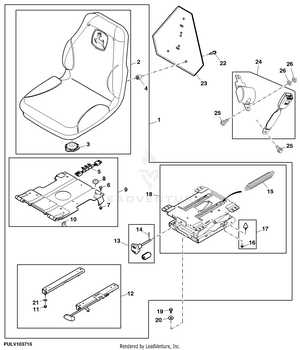

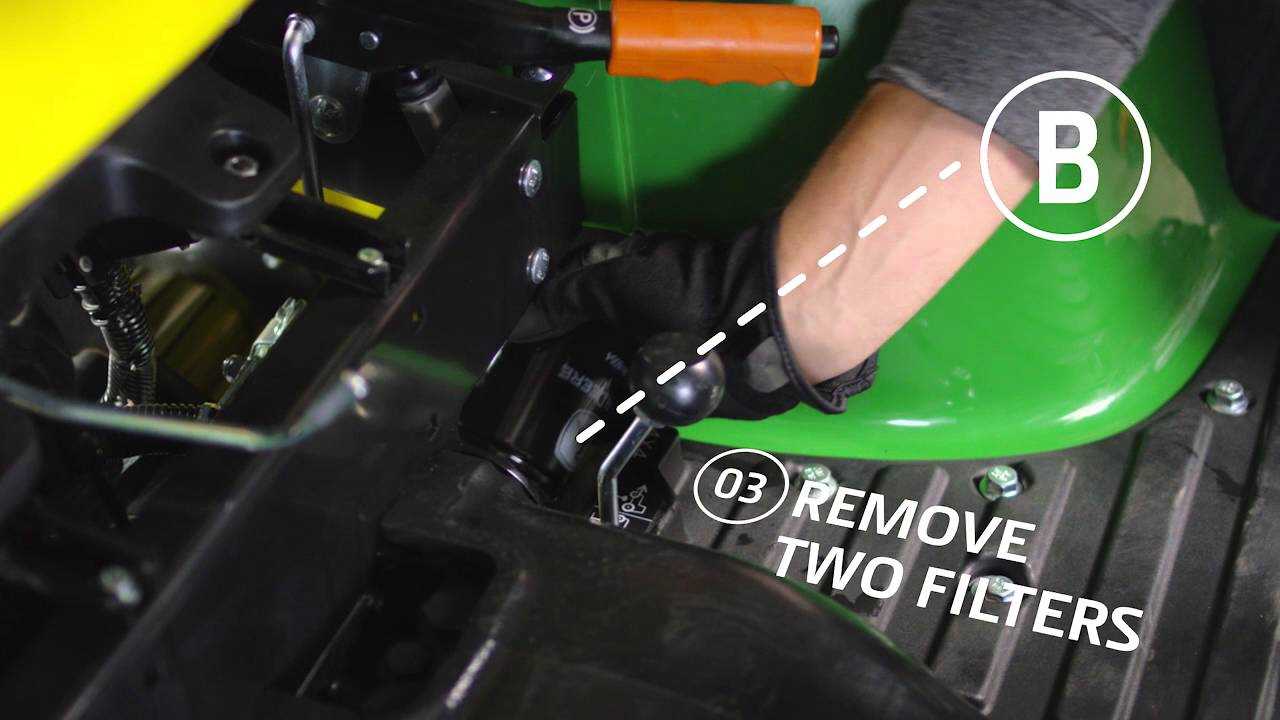

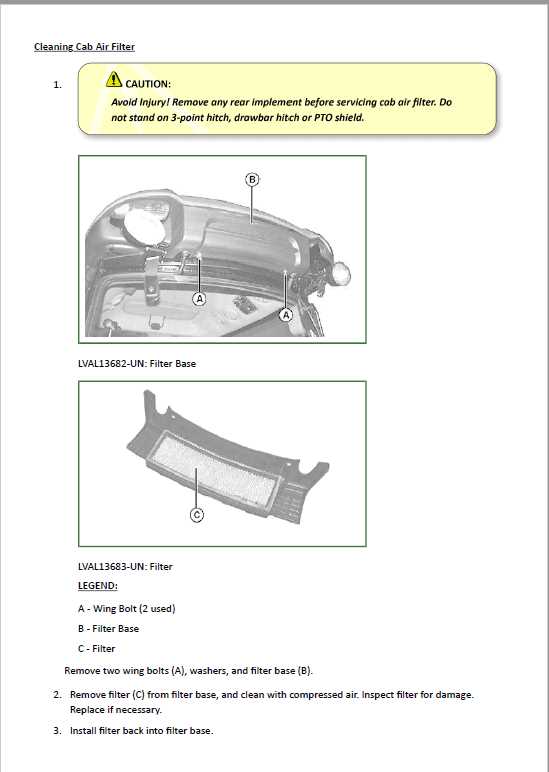

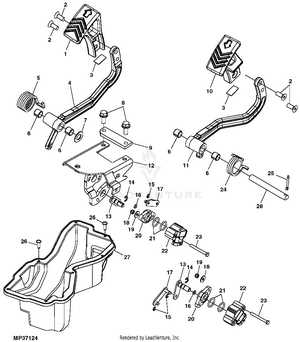

How to Use Parts Diagrams

Understanding the visual representations of component assemblies is crucial for effective maintenance and repair of machinery. These illustrations provide a detailed view of how individual elements fit together, enabling users to identify necessary components for replacements or upgrades. By mastering the art of interpreting these visuals, you can streamline your workflow and enhance your equipment’s performance.

Familiarize Yourself with the Symbols

Every illustration has its own set of symbols and notations that convey specific information. Take time to familiarize yourself with these elements, as they are essential for understanding the relationships between various components. Often, a legend accompanies the visual, explaining the meaning of different symbols, which can be invaluable in your analysis.

Identify Key Components

Begin by pinpointing the crucial elements within the assembly. Recognizing which parts are most relevant to your needs will help you focus your attention effectively. This targeted approach allows you to quickly gather the information you require, whether for troubleshooting or enhancement purposes.

Cross-Reference with Manuals

To gain a deeper understanding, cross-reference the illustrations with the accompanying manuals. These guides often provide additional context, including installation instructions and maintenance tips. Utilizing both resources will enhance your knowledge and ensure you are well-prepared for any task.

Utilize Digital Resources

In the digital age, many resources are available online, offering interactive features that can make your experience even more efficient. Look for platforms that allow you to zoom in on specific areas or search for particular components. These tools can greatly improve your ability to navigate the complexities of the assembly.

Practice Makes Perfect

The more you engage with these visual tools, the more adept you will become at using them. Regular practice will build your confidence and proficiency, allowing you to quickly and accurately assess any machinery assembly you encounter.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of machinery requires regular upkeep and attention. By implementing a few essential maintenance strategies, users can enhance the reliability and efficiency of their equipment. These practices not only minimize the risk of unexpected breakdowns but also extend the overall lifespan of the machinery.

Regular Inspection

Conducting routine inspections is vital for identifying potential issues before they escalate into significant problems. Check for wear and tear on essential components, such as belts, filters, and fluids. This proactive approach allows for timely repairs and replacements, ensuring optimal functionality.

Proper Lubrication

Lubricating moving parts is crucial for reducing friction and wear. Use high-quality lubricants recommended by the manufacturer, and follow the specified schedules for application. Proper lubrication helps prevent overheating and prolongs the life of vital components, contributing to smoother operation.

Sources for OEM Parts

When seeking original equipment manufacturer components, it is essential to explore reliable and reputable sources. Access to quality materials ensures that machinery operates efficiently and maintains its longevity. Numerous avenues exist for acquiring these essential elements, each with its unique advantages.

Authorized Dealers: One of the most dependable options is to purchase from authorized dealers. These establishments specialize in providing genuine components and often have knowledgeable staff who can assist with specific inquiries.

Online Retailers: The rise of e-commerce has opened up a plethora of online platforms dedicated to offering original components. These websites often feature extensive inventories and competitive pricing, making it easy to find the necessary items from the comfort of home.

Manufacturer Websites: Many manufacturers maintain their own online stores where customers can directly purchase original equipment components. This ensures that the items are authentic and come with the manufacturer’s warranty.

Local Repair Shops: Local repair facilities often have access to OEM components and can be a convenient source. Establishing a relationship with these businesses can provide insight into the best options for acquiring quality materials.

Parts Catalogs: Utilizing parts catalogs can greatly assist in identifying the correct components needed for specific machines. These catalogs often include diagrams and part numbers, streamlining the process of locating and ordering the necessary items.

Identifying Parts by Serial Number

Understanding the significance of a unique identification number is essential for ensuring the accurate selection and ordering of components for your equipment. This numeric code serves as a vital reference that can help pinpoint specific elements, their characteristics, and compatibility. By using this identifier, owners can efficiently navigate through catalogs and databases to find what they need.

The Importance of Serial Numbers

Each item manufactured carries a distinct sequence of digits, which provides crucial information about its model, production date, and manufacturing location. Recognizing this sequence can greatly simplify the process of sourcing replacement elements or upgrades. Whether you’re a professional technician or a dedicated enthusiast, knowing how to utilize this identifier can save time and reduce frustration.

How to Locate the Serial Number

The location of this identification code varies depending on the equipment type. Commonly, it can be found on the main body or near the engine compartment. Familiarizing yourself with these locations enhances the efficiency of identifying and procuring necessary components. Once located, cross-referencing this number with manufacturer resources will lead to accurate results in your search.

DIY Repairs and Upgrades

Engaging in self-sustained maintenance and enhancements can significantly extend the lifespan and performance of machinery. Whether addressing minor issues or implementing upgrades, a hands-on approach can lead to cost savings and a deeper understanding of equipment functionality.

Before initiating any repairs, it is essential to gather the necessary tools and materials. Proper preparation ensures a smoother process and minimizes the risk of errors. Below is a table outlining common tools and their purposes, which can be invaluable for successful do-it-yourself projects.

| Tool | Purpose |

|---|---|

| Wrench Set | Tightening or loosening bolts and nuts |

| Screwdriver Set | Removing and securing screws |

| Pliers | Gripping, twisting, or cutting wire |

| Jack | Elevating equipment for maintenance access |

| Multimeter | Testing electrical connections and components |

By acquiring the right tools and understanding their functions, enthusiasts can confidently tackle repairs and upgrades, ensuring efficient operation and improved capabilities.

Comparing 3720 with Other Models

This section aims to provide a comprehensive comparison of a specific tractor model with other variants in the same series. By analyzing various features, specifications, and functionalities, users can make informed decisions based on their unique requirements and preferences.

Key Features to Consider

- Engine Power: Evaluate the horsepower and torque across different models.

- Transmission Options: Compare the types of transmissions available and their impact on performance.

- Hydraulic System: Assess the efficiency and capacity of hydraulic systems for various applications.

- Weight and Stability: Look into how the weight distribution affects maneuverability and stability during operation.

Performance Metrics

- Fuel Efficiency: Review how each model performs in terms of fuel consumption.

- Load Capacity: Compare the maximum load each tractor can handle effectively.

- Versatility: Analyze the range of attachments and implements compatible with different models.

By understanding these aspects, potential buyers can better align their choices with specific agricultural or industrial needs, ensuring optimal performance and value for their investment.

Cost Considerations for Repairs

When it comes to maintaining machinery, understanding the financial implications of repair work is crucial. Various factors can influence the overall expenses associated with fixing equipment, and being aware of these elements can help in planning and budgeting effectively.

Labor costs play a significant role in the total expense of repairs. Skilled technicians may charge varying rates depending on their expertise and the complexity of the job. Additionally, repair duration can impact costs; longer jobs naturally lead to higher labor fees.

The price of replacement components is another critical aspect to consider. Genuine parts often come at a premium, but they can provide reliability and durability. On the other hand, aftermarket options may offer savings but could compromise quality.

Regular maintenance can significantly reduce unexpected repair costs. Implementing preventive measures allows operators to identify potential issues before they escalate, leading to lower long-term expenses. Overall, budgeting for repairs requires a comprehensive understanding of both immediate and future financial commitments.