Comprehensive Guide to John Deere 4430 Parts Diagram

The intricate world of farming equipment encompasses a variety of essential elements that ensure optimal performance and reliability. Exploring the intricate relationships between these components can greatly enhance one’s ability to maintain and operate such machinery effectively.

For enthusiasts and professionals alike, having access to a comprehensive overview of these mechanisms allows for informed decision-making. The ability to visualize and understand the structure and function of each piece is critical in troubleshooting and ensuring longevity.

In this guide, we will delve into the specifics of a well-known model, highlighting its crucial components and their interactions. By mastering this knowledge, operators can achieve the ultimate efficiency and effectiveness in their agricultural endeavors.

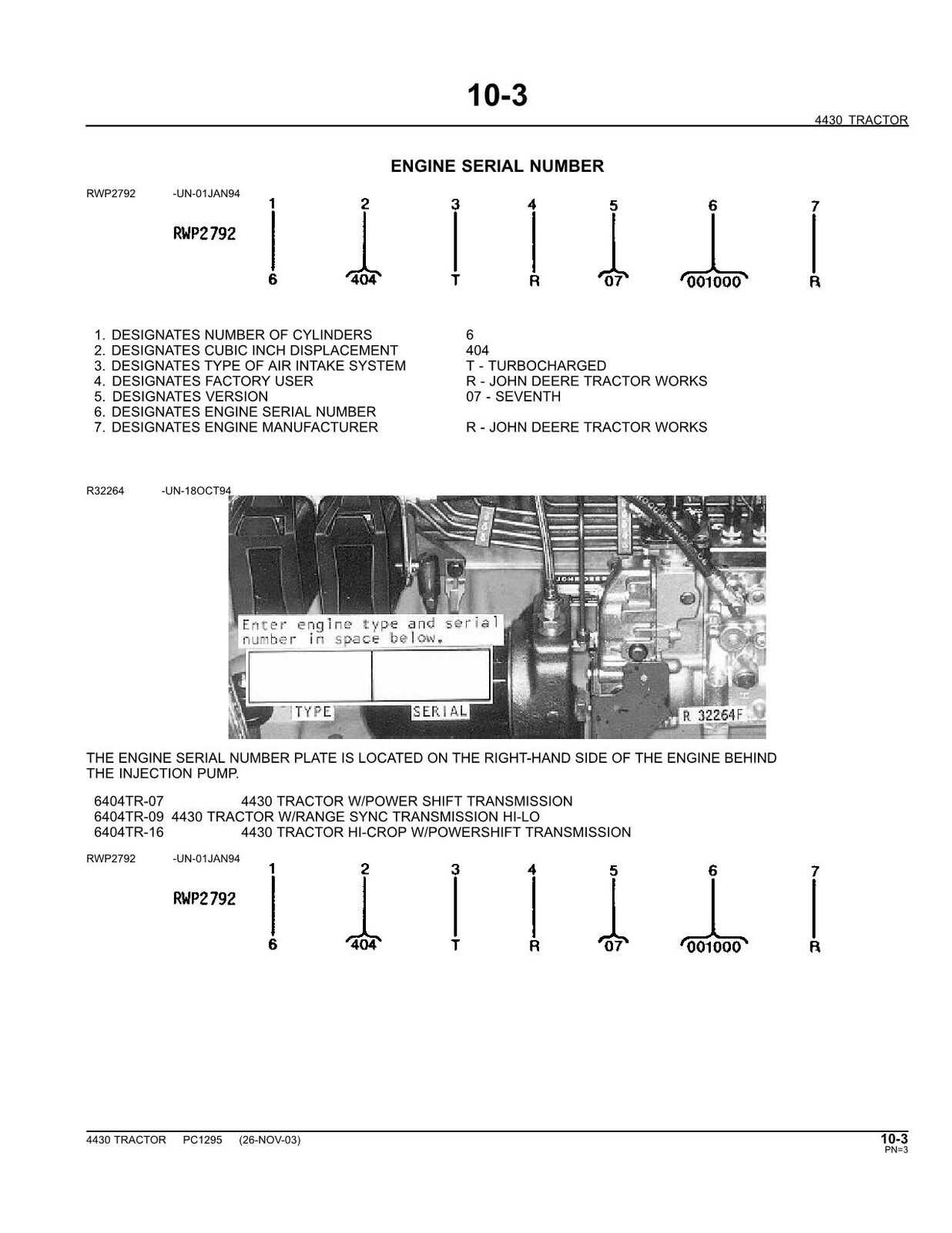

Understanding the John Deere 4430

This section aims to provide insights into a significant agricultural machine known for its versatility and performance. Recognized for its robust design and efficiency, it plays a crucial role in various farming operations.

Key features of this model include:

- Powerful engine capable of handling heavy tasks

- Advanced hydraulic system for enhanced control

- Durable construction ensuring longevity in demanding environments

Maintenance is vital to ensure optimal functionality. Regular checks and servicing help in prolonging the life of the equipment. Consider the following aspects:

- Fluid levels and quality

- Wear and tear on components

- Adjustment of operational settings

Understanding the specifications and operational capabilities can greatly improve productivity and efficiency on the farm. Familiarity with each feature will empower operators to maximize the utility of this valuable machinery.

Key Features of the 4430 Model

This model stands out in the agricultural machinery sector due to its robust design and versatile capabilities. It is engineered to enhance productivity while ensuring reliability across various farming tasks. Users appreciate its balance of power and efficiency, making it a preferred choice among many operators.

Powerful Engine Performance

One of the most notable attributes is its exceptional engine performance. The powertrain is designed to deliver substantial horsepower, allowing for efficient operation in demanding conditions. This capability ensures that the machine can handle various implements with ease, from tillage to planting.

User-Friendly Operation

The machine is also recognized for its intuitive controls and ergonomic layout. Operators benefit from a well-thought-out design that minimizes fatigue during extended use. Additionally, maintenance is simplified, with accessible components that facilitate routine checks and repairs. Overall, the combination of power and usability makes this model a reliable asset in any agricultural setting.

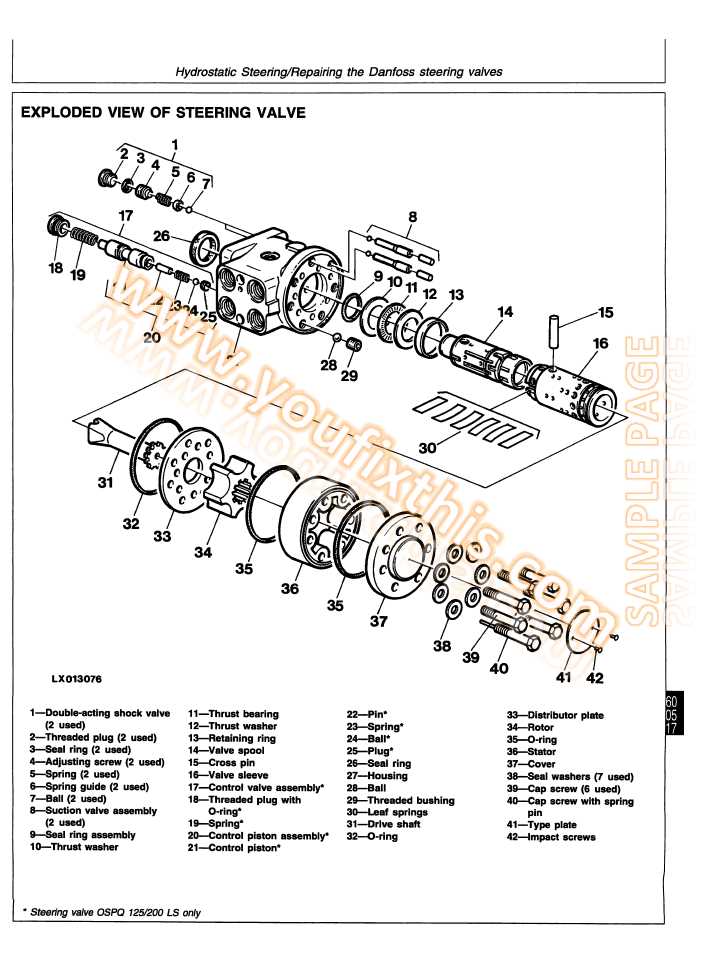

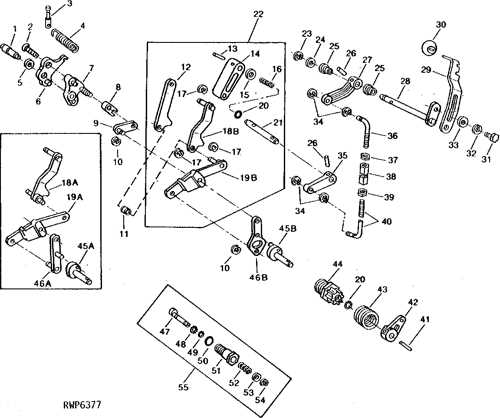

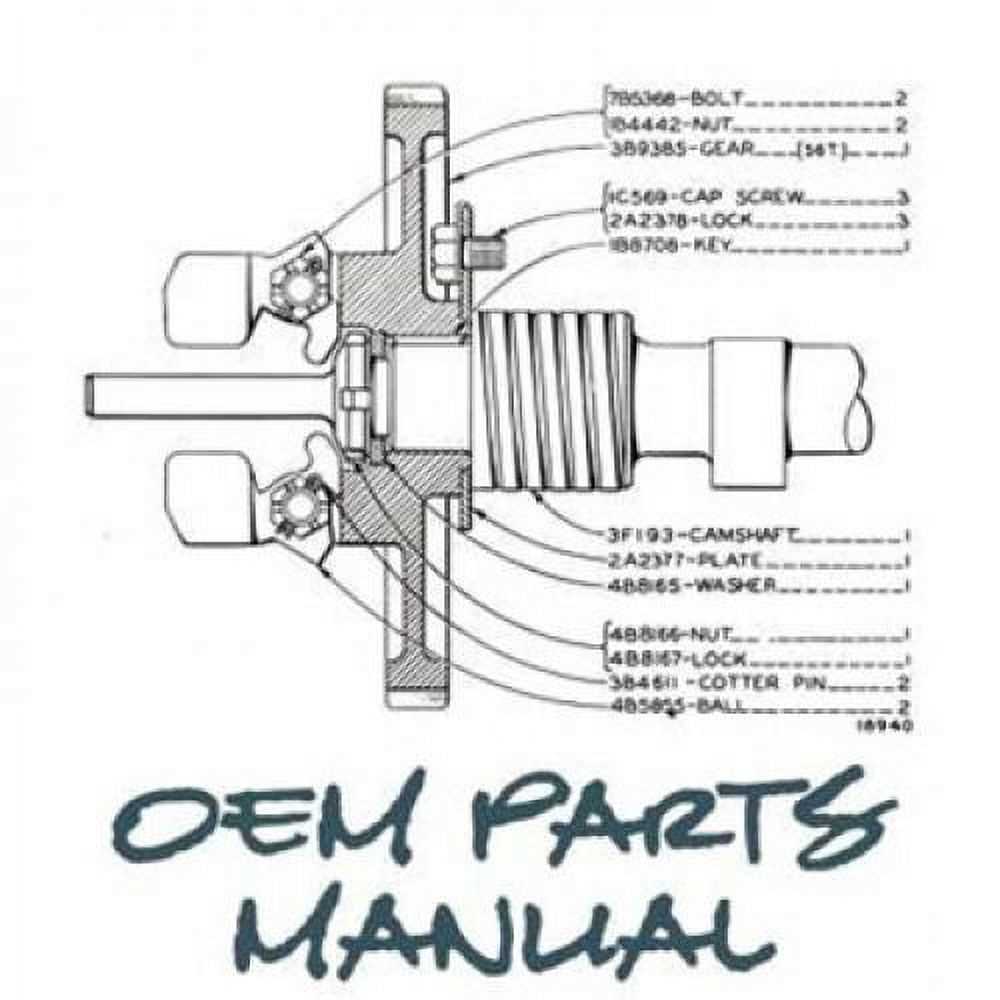

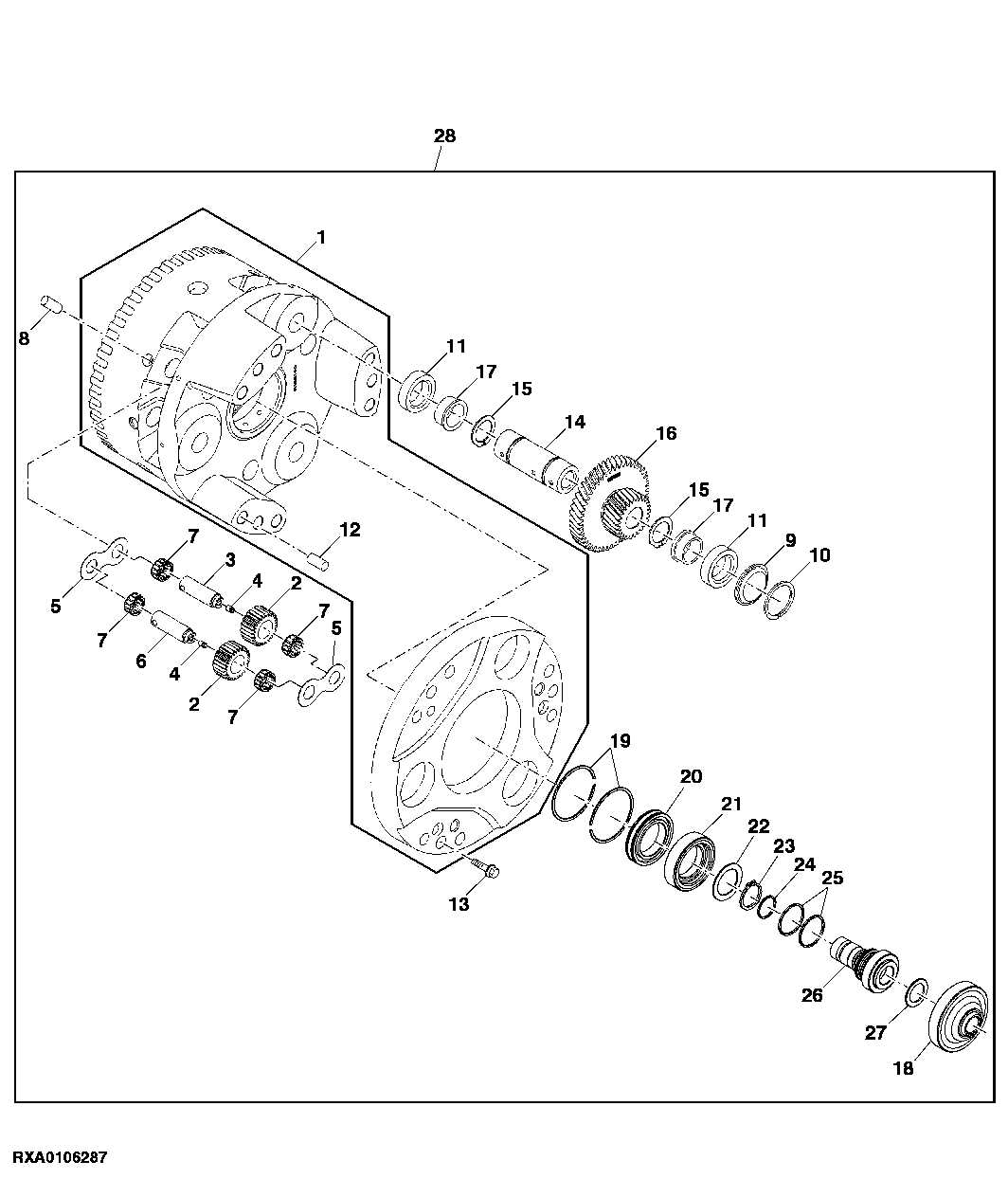

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding machinery and equipment. They provide clarity on assembly, maintenance, and repairs, ensuring efficient operation.

- Enhances comprehension of complex structures.

- Facilitates accurate identification of individual elements.

- Simplifies troubleshooting and repair processes.

Moreover, these illustrations can:

- Improve efficiency in sourcing replacements.

- Assist technicians in performing precise maintenance.

- Minimize downtime by expediting repairs.

Ultimately, these visual aids are invaluable for anyone involved in the upkeep of machinery, ensuring optimal performance and longevity.

Common Issues with 4430 Components

When it comes to machinery maintenance, certain components frequently present challenges that can affect performance and longevity. Understanding these common problems can help operators anticipate issues and implement effective solutions. Below are some prevalent concerns related to the machinery’s elements.

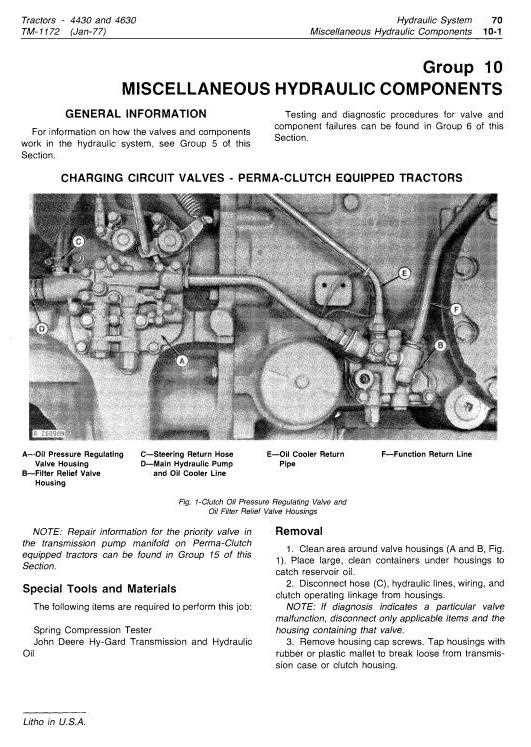

1. Hydraulic System Failures

The hydraulic system is critical for various functions, and issues here can lead to significant operational disruptions. Common failures include:

- Leaks in hoses and fittings

- Contamination of hydraulic fluid

- Faulty hydraulic pumps

2. Electrical Malfunctions

Electrical issues can impede performance and lead to unexpected breakdowns. Key problems include:

- Corroded connections

- Faulty sensors and switches

- Battery failures

Addressing these common concerns promptly can enhance the efficiency and reliability of the equipment, ensuring smoother operation and reducing downtime.

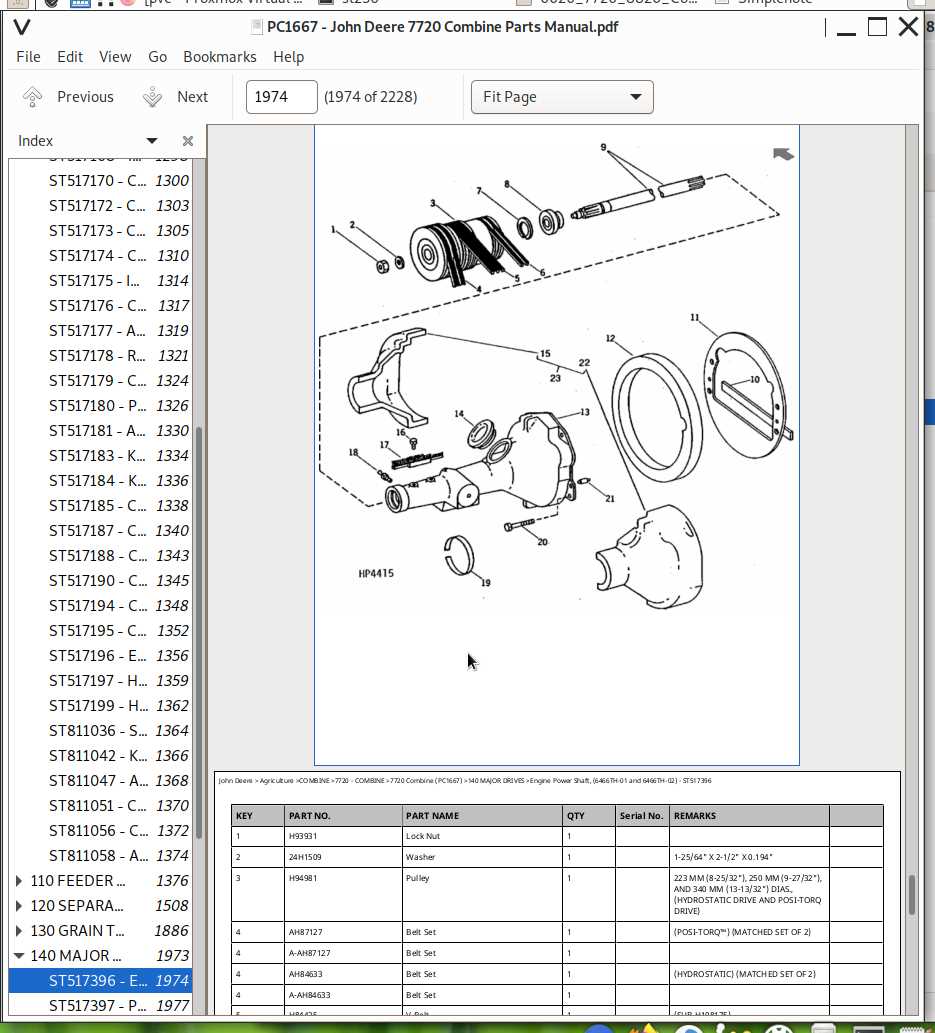

Finding Replacement Parts Easily

Locating suitable components for your machinery can be a straightforward process when you know where to look. With a wealth of resources available online and offline, you can quickly access the necessary items to keep your equipment running smoothly. The key is to utilize reliable sources and understand the specific needs of your machinery.

Online Marketplaces: Numerous websites specialize in offering a vast array of components. These platforms often feature user-friendly search options, enabling you to filter results based on your equipment model or specifications. Customer reviews can also guide you toward quality products and trustworthy sellers.

Local Dealers: Building a relationship with local distributors can be beneficial. They possess in-depth knowledge about various models and can recommend compatible components. Plus, purchasing locally may provide quicker access and support when needed.

Community Forums: Engaging with fellow machinery enthusiasts can yield valuable insights. Online forums and social media groups often have discussions about sourcing components, and members are typically eager to share their experiences and recommendations.

Maintenance Manuals: Having access to the maintenance manuals for your equipment is essential. These documents often include detailed information on specifications and compatibility, making it easier to identify what you need and where to find it.

By leveraging these resources, you can simplify the process of acquiring necessary components, ensuring your machinery remains in optimal condition and minimizing downtime.

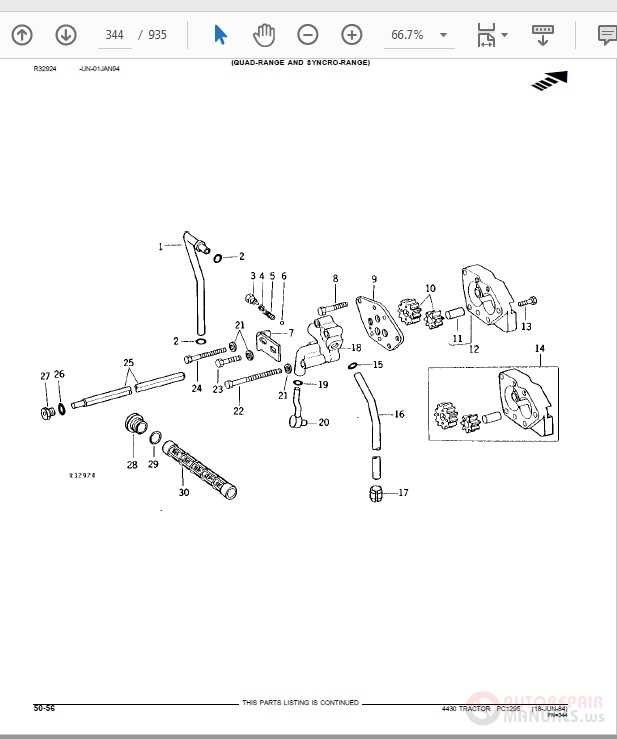

How to Read Parts Diagrams

Understanding schematic illustrations is essential for efficient maintenance and repairs. These visual representations provide a clear view of components and their interconnections, allowing for quick identification and troubleshooting.

Here are some key steps to effectively interpret these visuals:

- Familiarize Yourself with the Symbols:

- Learn the standard symbols used for various components.

- Identify unique markings that may indicate specific functions.

- Identify the Layout:

- Recognize the overall arrangement of parts.

- Understand how parts are grouped based on function or location.

- Follow the Connections:

- Trace the lines that connect different elements to understand their relationships.

- Pay attention to arrows that indicate the flow of operation or energy.

- Refer to Annotations:

- Look for notes or labels that provide additional context or specifications.

- Use the reference numbers or codes to locate parts in catalogs or inventories.

By mastering these techniques, anyone can confidently navigate through technical illustrations, enhancing their ability to conduct repairs or replacements effectively.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficient performance of machinery. Regular maintenance not only extends the lifespan of equipment but also enhances productivity and reduces unexpected breakdowns. Below are some practical tips to keep your machinery in optimal condition.

| Tip | Description |

|---|---|

| Regular Inspections | Conduct frequent checks for wear and tear to identify issues before they escalate. |

| Fluid Changes | Replace oils and lubricants according to manufacturer guidelines to ensure smooth operation. |

| Clean Components | Keep all parts clean to prevent dirt buildup, which can cause damage over time. |

| Follow Operating Guidelines | Adhere to recommended practices to avoid misuse that can lead to premature failure. |

| Store Properly | When not in use, store machinery in a sheltered environment to protect against the elements. |

Aftermarket vs. OEM Parts

When considering replacement components for machinery, understanding the differences between various sources is essential for optimal performance and reliability. The choice between original equipment manufacturer products and alternatives can significantly impact functionality and longevity.

Advantages of OEM Components

- Guaranteed compatibility with the machinery.

- High-quality standards, ensuring durability.

- Manufacturer support and warranty availability.

Benefits of Aftermarket Options

- Cost-effective solutions for budget-conscious users.

- Variety of choices, often with enhanced features.

- Availability in multiple locations and online platforms.

Ultimately, the decision hinges on individual needs, budget, and the specific requirements of the equipment in question.

Tools Needed for Repairs

Undertaking maintenance and repairs on heavy machinery requires a variety of specialized instruments. Having the right tools at your disposal not only streamlines the process but also ensures that tasks are completed efficiently and safely. Below is a list of essential equipment needed for effective servicing.

| Tool | Description |

|---|---|

| Wrench Set | A collection of various sizes to accommodate different fasteners. |

| Screwdriver Set | Includes both flathead and Phillips types for versatility. |

| Pliers | Useful for gripping, twisting, and cutting wires or components. |

| Socket Set | Essential for loosening and tightening bolts and nuts. |

| Torque Wrench | Ensures fasteners are tightened to the manufacturer’s specifications. |

| Impact Gun | Speeds up the process of removing stubborn bolts. |

| Diagnostic Tool | Helps in identifying issues and monitoring performance. |

| Safety Gear | Includes gloves, goggles, and protective clothing to ensure worker safety. |

Equipped with these tools, you will be better prepared to tackle maintenance challenges, enhancing the longevity and performance of your equipment.

Where to Buy Parts Online

Finding the right components for your machinery can be a daunting task, but the internet offers a plethora of options. Various platforms provide an extensive selection of items, making it easier to locate exactly what you need without leaving the comfort of your home. This section explores some reliable sources where you can procure high-quality replacements.

Trusted Online Retailers

Reputable e-commerce sites specialize in agricultural equipment and accessories. These platforms often feature detailed product descriptions and customer reviews, which can help you make informed decisions. Look for vendors that offer a comprehensive warranty and easy return policies to ensure peace of mind with your purchase.

Manufacturer Websites

Visiting the official websites of equipment manufacturers can also be beneficial. They typically offer genuine components and often provide resources such as manuals and installation guides. Additionally, many manufacturers have dedicated sections for customer support, which can assist you in identifying the right items for your machinery.

Customer Reviews on 4430 Parts

This section explores feedback from users regarding components related to the 4430 model, emphasizing the quality, durability, and overall performance of these items. Customers share their experiences, providing valuable insights for potential buyers.

Quality and Performance

Many users praise the durability of the components, noting that they withstand heavy usage and provide reliable performance over time. One reviewer highlighted, “I’ve been using these parts for years, and they still perform like new!”

Installation and Compatibility

Installation is often described as straightforward, with several customers mentioning how well these components fit their machinery. A common sentiment expressed is, “Everything lined up perfectly, making the installation a breeze!”

Comparative Analysis with Similar Models

This section delves into the assessment of a specific agricultural machine in relation to its contemporaries. By evaluating key characteristics, performance metrics, and design features, we aim to provide insights that highlight the strengths and weaknesses of various models within the same category.

Performance Metrics

When comparing the operational capabilities of different machines, factors such as horsepower, fuel efficiency, and load capacity come into play. The model in focus boasts impressive power output, enabling it to handle challenging tasks with ease. In contrast, similar models may offer competitive specifications but could lag in efficiency or durability under heavy use. Evaluating these metrics allows potential buyers to make informed decisions based on their specific agricultural needs.

Design Features

The ergonomic design and user interface of agricultural equipment significantly impact usability and operator comfort. This particular model features an intuitive dashboard and adjustable seating, enhancing the overall experience during long hours of operation. Comparatively, other machines may prioritize ruggedness over comfort, which can lead to operator fatigue. Understanding the design nuances provides insight into which model may be best suited for various farming environments.