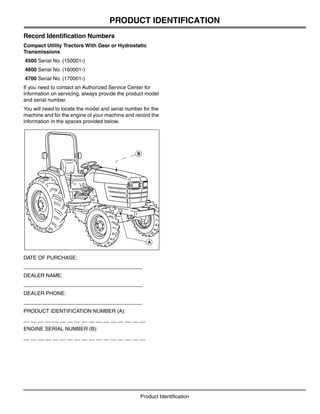

Understanding the John Deere 4500 Parts Diagram for Effective Maintenance

In the realm of agricultural equipment, comprehending the intricate layout of machinery is essential for effective maintenance and operation. A clear representation of the various elements within a specific model can greatly enhance efficiency and longevity. This guide aims to shed light on the essential features and structure of a prominent agricultural machine.

By exploring the specific arrangement and functionalities of the components, users can better appreciate how each piece contributes to the overall performance. Knowing how these elements interconnect can ultimately facilitate troubleshooting and repairs, ensuring that the equipment remains in peak condition.

For enthusiasts and operators alike, having access to detailed illustrations of the machinery can serve as an invaluable resource. It allows for a deeper dive into the mechanics, paving the way for informed decisions regarding upgrades, replacements, and routine care. Understanding these visual aids is crucial for anyone looking to maximize their investment in such vital tools.

Understanding John Deere 4500 Parts

Gaining insights into the components of machinery is essential for effective maintenance and operation. Familiarity with these elements can enhance performance and longevity, making it easier to address any issues that arise.

Key areas to consider include:

- Engine components

- Transmission systems

- Hydraulic systems

- Electrical parts

- Structural elements

Each category encompasses various items that contribute to overall functionality. By exploring these categories, operators can ensure they have a comprehensive understanding of the equipment.

- Identify crucial components.

- Learn their functions.

- Explore common issues and solutions.

This knowledge serves as the foundation for efficient repairs and upgrades, ultimately leading to improved performance and reliability.

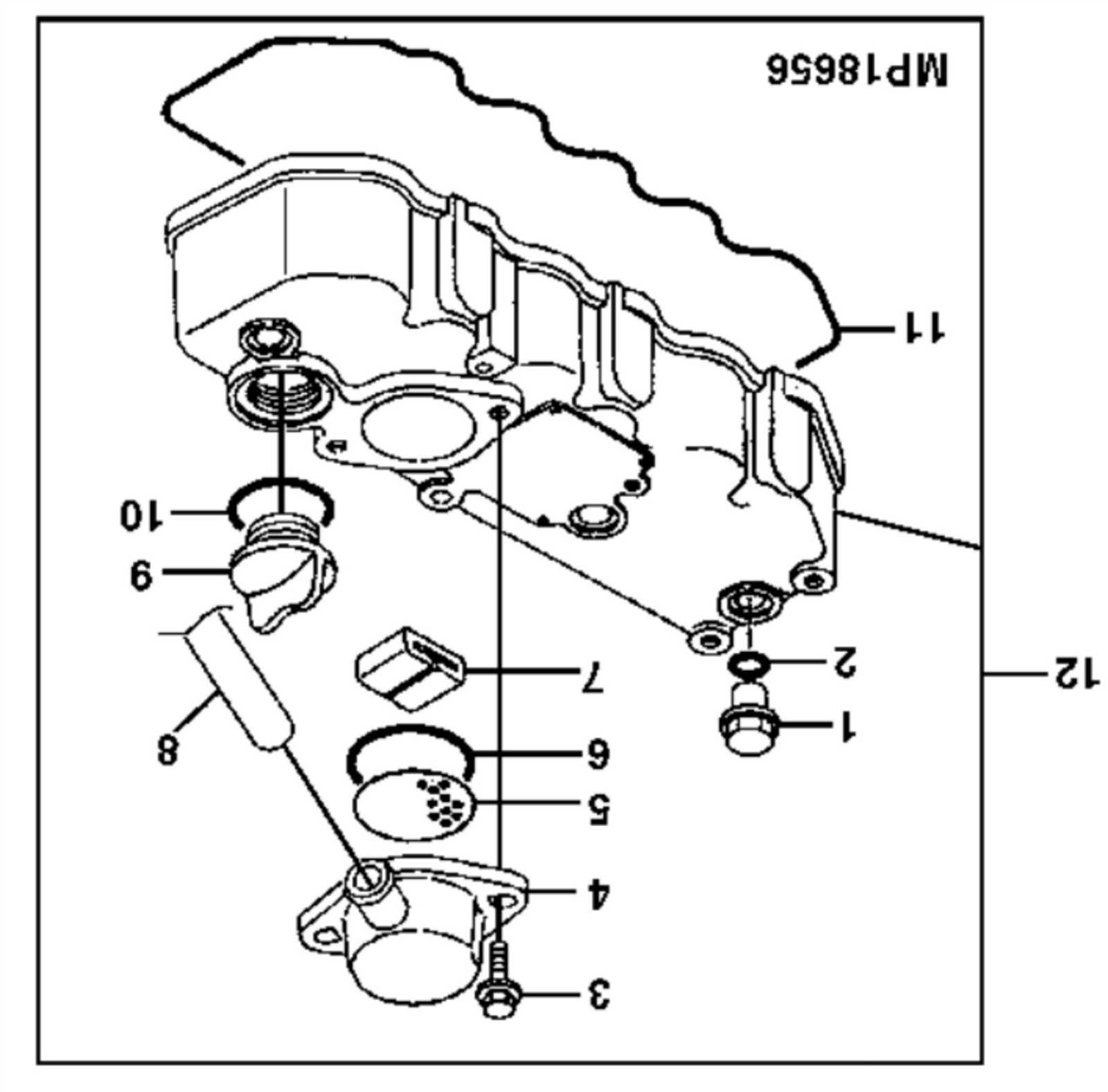

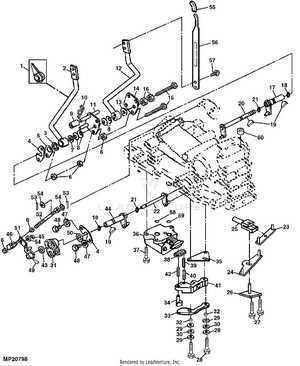

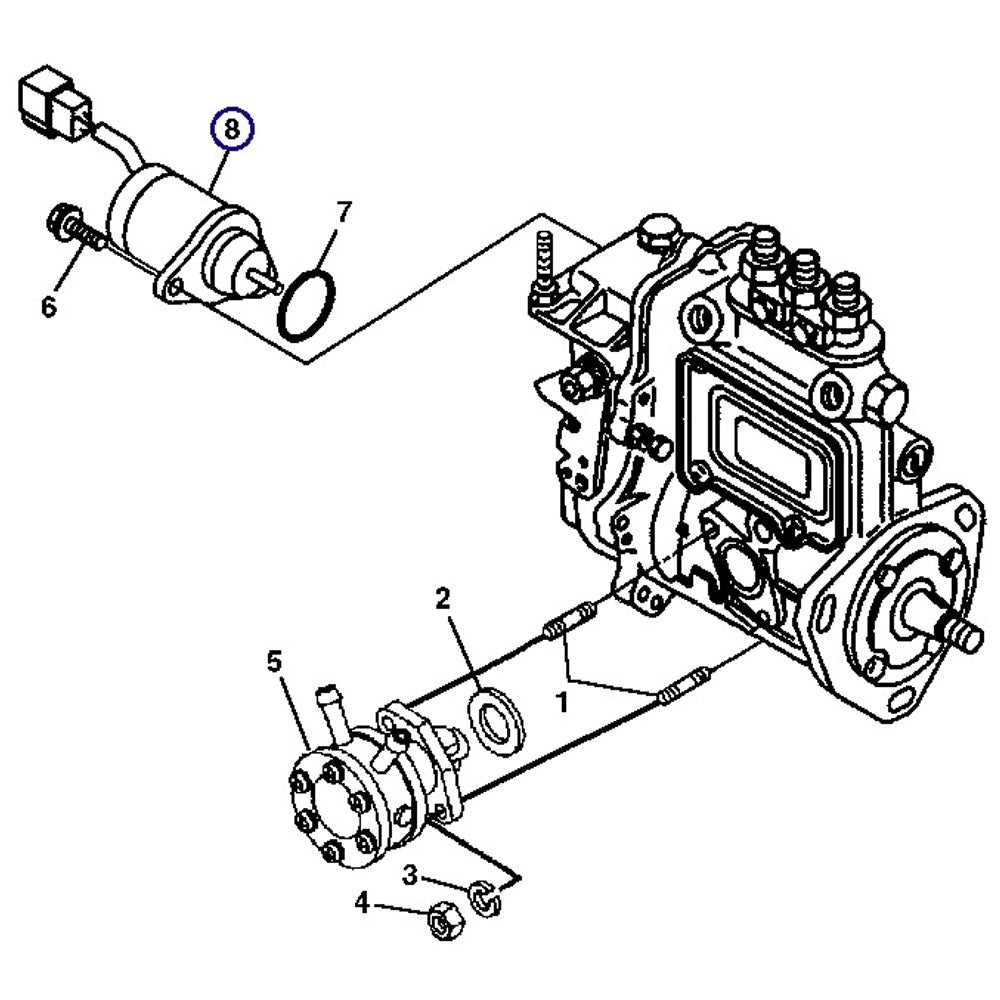

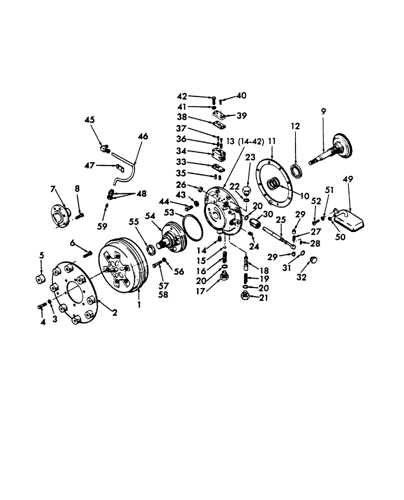

Importance of Accurate Parts Diagrams

Having precise visual representations of components is crucial for effective maintenance and repair. These illustrations serve as essential guides, allowing users to identify each element and its function within a system. Clarity in these visuals not only enhances understanding but also streamlines the repair process.

Accurate schematics enable technicians to quickly locate specific elements, reducing the time spent troubleshooting. Furthermore, they help ensure that all components are reassembled correctly, minimizing the risk of errors that could lead to further complications.

Ultimately, relying on well-crafted visuals contributes to improved efficiency and longevity of machinery. Investing time in understanding these representations can yield significant benefits in performance and reliability.

Key Components of the John Deere 4500

This section delves into the essential elements that contribute to the functionality and performance of this agricultural machinery. Understanding these core components is crucial for effective maintenance and operation.

Engine and Power System

- High-efficiency engine providing reliable power.

- Fuel system designed for optimal consumption.

- Cooling system ensuring temperature regulation.

Transmission and Drive Mechanism

- Advanced transmission for smooth shifting.

- Drive system ensuring traction and stability.

- Hydraulic components for enhanced control and responsiveness.

Each of these parts plays a vital role in the overall performance, ensuring that the machine meets the demands of various agricultural tasks effectively.

How to Access Parts Diagrams Online

Finding technical schematics online can streamline your maintenance and repair tasks significantly. Accessing these resources allows users to quickly locate the components they need, ensuring efficiency in troubleshooting and parts replacement.

| Step | Description |

|---|---|

| 1 | Search for Manufacturer Websites |

| 2 | Utilize Online Retailers |

| 3 | Visit Dedicated Parts Catalogs |

| 4 | Explore Forums and Community Resources |

By following these steps, you can efficiently navigate to the information you require, making your repair processes smoother and more informed.

Common Issues with John Deere 4500

Machinery can experience various challenges that may hinder performance and efficiency. Understanding these common problems helps in maintaining optimal functionality and prolonging lifespan.

- Hydraulic System Failures: Leaks or low fluid levels can lead to reduced lifting capacity and sluggish operation.

- Electrical Issues: Battery drain or faulty wiring often result in starting difficulties or intermittent power loss.

- Engine Performance: Overheating or poor fuel efficiency may signal issues with the cooling system or fuel injectors.

- Transmission Problems: Difficulty in shifting gears can indicate low fluid levels or internal wear.

Regular inspections and prompt repairs can mitigate these issues, ensuring the machinery operates at its best.

Identifying Replacement Parts Quickly

Efficiently locating the components needed for machinery maintenance can significantly enhance productivity. Understanding the structure and function of each element allows for faster identification and procurement, ensuring minimal downtime.

To streamline the process, consider the following strategies:

- Utilize Reference Guides: Consult manuals or online resources that provide clear illustrations and specifications.

- Organize by Categories: Group items based on their function or location to make searching more intuitive.

- Identify Common Issues: Familiarize yourself with frequently replaced components, which can help predict needs.

Moreover, leveraging technology can further assist in the identification process:

- Search Tools: Use digital platforms with search functionalities that allow you to input specific queries.

- Community Forums: Engage with online communities for insights and shared experiences related to specific machinery.

- Inventory Management Software: Implement systems that track components and usage patterns, helping to anticipate future needs.

By employing these methods, identifying essential elements becomes a more straightforward and efficient task, ultimately supporting effective machinery operation.

Comparing Aftermarket vs. OEM Parts

When it comes to machinery maintenance, the choice between original components and their alternative counterparts is a significant consideration. Each option presents distinct advantages and drawbacks that can influence performance, cost, and longevity.

Advantages of OEM Components

Original equipment components are specifically designed to meet the manufacturer’s standards. This ensures compatibility and reliability, often resulting in superior performance over time.

Benefits of Aftermarket Alternatives

Aftermarket options frequently offer cost savings and a wider range of choices. Many manufacturers provide enhanced features that can improve overall functionality, making them appealing for budget-conscious consumers.

| Factor | OEM Components | Aftermarket Alternatives |

|---|---|---|

| Cost | Generally higher | Often more affordable |

| Compatibility | Guaranteed fit | Varies by brand |

| Performance | Optimal | Variable |

| Warranty | Manufacturer warranty | Limited warranties |

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your machinery requires consistent care and attention. Regular maintenance not only extends the lifespan of the equipment but also enhances its performance, preventing costly breakdowns. By following a few essential practices, operators can safeguard their investment and ensure reliable operation over time.

1. Regular Inspections: Conducting routine checks on key components is crucial. Look for signs of wear, leaks, or damage. Addressing minor issues promptly can prevent them from escalating into major repairs.

2. Keep It Clean: Dirt and debris can cause significant harm to various systems. Regularly cleaning the exterior and interior parts of the machine helps maintain optimal performance and prevents premature wear.

3. Fluid Changes: Frequent replacement of oils and fluids is essential. Follow the manufacturer’s recommendations for intervals and types of fluids to ensure the equipment runs smoothly and efficiently.

4. Proper Lubrication: Lubricating moving parts reduces friction and wear. Use the appropriate lubricants and adhere to the suggested schedules for application.

5. Store Properly: When not in use, store the equipment in a dry, sheltered area. This protects it from environmental factors that can lead to corrosion and deterioration.

6. Follow Guidelines: Adhering to the manufacturer’s maintenance schedule and guidelines is vital. These recommendations are designed to optimize the equipment’s performance and longevity.

By implementing these practices, operators can significantly enhance the lifespan and reliability of their machinery, ensuring it continues to perform at its best for years to come.

Where to Buy Replacement Parts

Finding high-quality components for machinery can significantly enhance performance and extend its lifespan. It’s essential to source these items from reliable vendors to ensure compatibility and durability.

Here are several options to consider when searching for replacement components:

- Authorized Dealers: Purchasing from certified dealerships guarantees genuine items that meet manufacturer specifications.

- Online Retailers: Websites specializing in machinery supplies often provide a vast selection, competitive pricing, and customer reviews to aid decision-making.

- Local Supply Stores: Visiting nearby hardware or equipment stores can offer the advantage of immediate availability and personalized assistance.

- Used Parts Market: Exploring second-hand options can be a cost-effective way to find rare or discontinued components.

- Manufacturer’s Website: Directly checking the official website may provide access to exclusive offers and updated inventories.

Consider the warranty and return policies when making a purchase to ensure satisfaction with your selections.

Benefits of Using Official Diagrams

Utilizing authentic schematics for machinery provides numerous advantages that enhance efficiency and ensure optimal performance. These illustrations serve as invaluable resources for technicians and operators, enabling them to understand complex systems with ease.

- Accuracy: Official schematics are created by the manufacturer, ensuring that the information is precise and reliable. This reduces the risk of errors during maintenance and repairs.

- Comprehensive Detail: These visuals often include all components, allowing users to identify each part and its function, which is essential for effective troubleshooting.

- Improved Maintenance: Accessing correct diagrams facilitates routine checks and timely service, leading to prolonged equipment lifespan and reduced downtime.

- Streamlined Repairs: With detailed layouts, technicians can quickly locate and address issues, minimizing repair time and enhancing productivity.

- Enhanced Safety: Accurate representations promote a better understanding of machinery operations, contributing to safer working environments.

In conclusion, relying on official illustrations is crucial for anyone involved in the upkeep and operation of machinery, as they promote efficiency, safety, and reliability in various tasks.

Understanding Part Numbers and Codes

In the realm of machinery and equipment, identifying components accurately is essential for maintenance and repairs. A clear understanding of numerical identifiers and alphanumeric codes can greatly enhance efficiency when sourcing or ordering replacement elements. This section delves into the significance of these codes, highlighting their structure and utility in the procurement process.

Structure of Identification Codes

Identification codes typically consist of a series of numbers and letters that convey specific information about each component. These codes are designed to be both systematic and informative, allowing for quick recognition and categorization. Below is a breakdown of common elements found within these codes:

| Code Element | Description |

|---|---|

| Prefix | Often denotes the category or type of component. |

| Numeric Sequence | Indicates the unique identifier for the specific item. |

| Suffix | May provide additional information regarding variations or specifications. |

Importance of Accurate Identification

Correctly deciphering these codes is crucial for ensuring that the right components are acquired. Misidentification can lead to improper installations or even equipment malfunction. Familiarity with the coding system allows users to navigate inventories more effectively and reduces downtime during repairs. Understanding these identifiers is a key step towards effective maintenance and optimal performance.

FAQs About John Deere Parts

This section addresses common inquiries regarding components used in agricultural machinery, providing insights for owners and technicians alike. Understanding these queries can enhance maintenance practices and extend the life of equipment.

What should I consider when purchasing components?

When acquiring replacements, prioritize compatibility with your machinery model. Additionally, evaluate the quality of materials and check for warranties offered by suppliers, as these factors can influence durability and performance.

How can I find specific components for my machinery?

Utilize online resources, such as official manufacturer websites or trusted distributors, to search for specific items. Many platforms offer detailed catalogs, making it easier to locate the right parts based on model numbers or descriptions.