Understanding the John Deere 5105 Parts Diagram

The efficiency and longevity of farming equipment significantly rely on the availability and understanding of its various components. This section aims to provide a comprehensive overview of essential machinery parts, facilitating better maintenance and optimization of performance.

In the realm of agricultural tools, recognizing each component’s function is crucial for operators. By exploring detailed schematics and understanding their relationships, users can enhance their machinery’s functionality and prevent costly downtimes.

Whether you are a seasoned farmer or a newcomer, delving into the specifics of these essential elements will empower you to make informed decisions regarding repairs and replacements. Ultimately, this knowledge serves as a valuable resource for anyone seeking to maximize their equipment’s potential.

Understanding John Deere 5105 Parts

Familiarizing oneself with the components of agricultural machinery is essential for efficient maintenance and repair. A thorough understanding of each element not only ensures optimal performance but also extends the lifespan of the equipment. By delving into the intricacies of these vital pieces, operators can identify issues early and implement necessary solutions.

Each component plays a crucial role in the overall functionality, from the engine to the transmission system. Knowledge of how these parts interact enables users to troubleshoot effectively and enhances their ability to carry out repairs independently.

| Component | Description |

|---|---|

| Engine | The power source, providing the necessary energy to operate various functions. |

| Transmission | Facilitates the transfer of power from the engine to the wheels, enabling movement. |

| Hydraulic System | Manages fluid power for lifting and operating attachments. |

| Electrical System | Controls lighting, ignition, and various electronic components. |

| Chassis | The framework that supports all other components and provides structural integrity. |

Understanding these elements not only empowers operators but also promotes a proactive approach to machinery care. This knowledge is invaluable for anyone looking to enhance their operational efficiency and ensure long-term reliability.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for efficient maintenance and repair. Visual representations serve as essential tools for identifying elements and ensuring everything functions optimally.

- Facilitate quick identification of components.

- Enhance troubleshooting processes.

- Support proper reassembly after disassembly.

- Provide clarity in maintenance schedules.

- Assist in ordering the correct replacements.

Ultimately, these illustrations simplify complex machinery, allowing users to delve deeper into their understanding of mechanical systems.

Overview of John Deere 5105

This section provides an insightful look into a renowned agricultural vehicle, highlighting its features and capabilities. Designed for efficiency and reliability, this machine serves various farming needs with precision.

Key Features

- Powerful engine for optimal performance

- Robust design ensuring durability

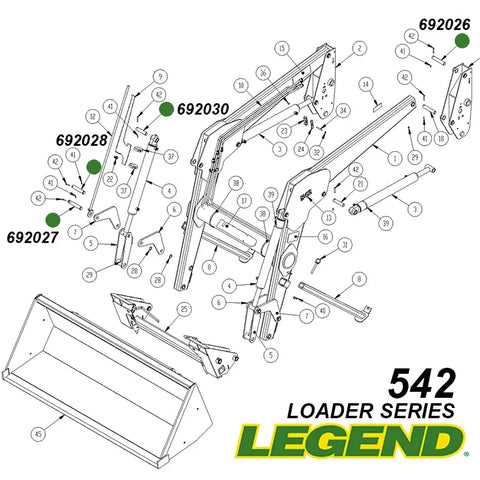

- Versatile attachments for multiple tasks

- User-friendly controls for easy operation

Applications

- Plowing and tilling soil

- Hauling materials across farms

- Maintaining landscapes and fields

- Supporting various agricultural implements

Key Components Explained

Understanding the essential elements of agricultural machinery is crucial for effective operation and maintenance. This section delves into the main features that enhance performance and ensure longevity, providing insights for users and technicians alike.

Engine and Transmission

- Engine: Powers the machine, converting fuel into mechanical energy.

- Transmission: Facilitates speed and torque adjustments, ensuring optimal performance across various tasks.

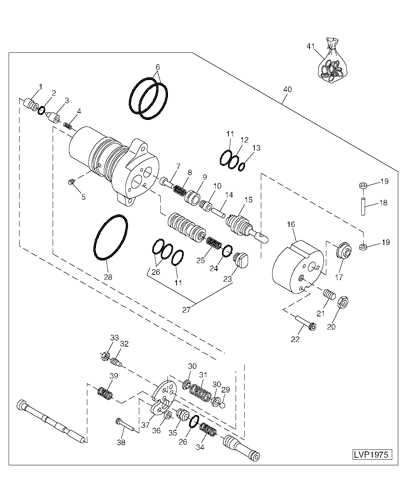

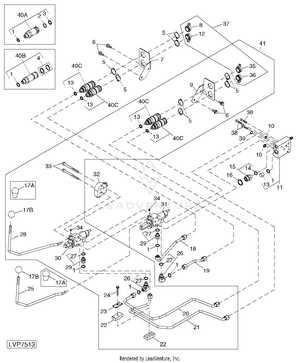

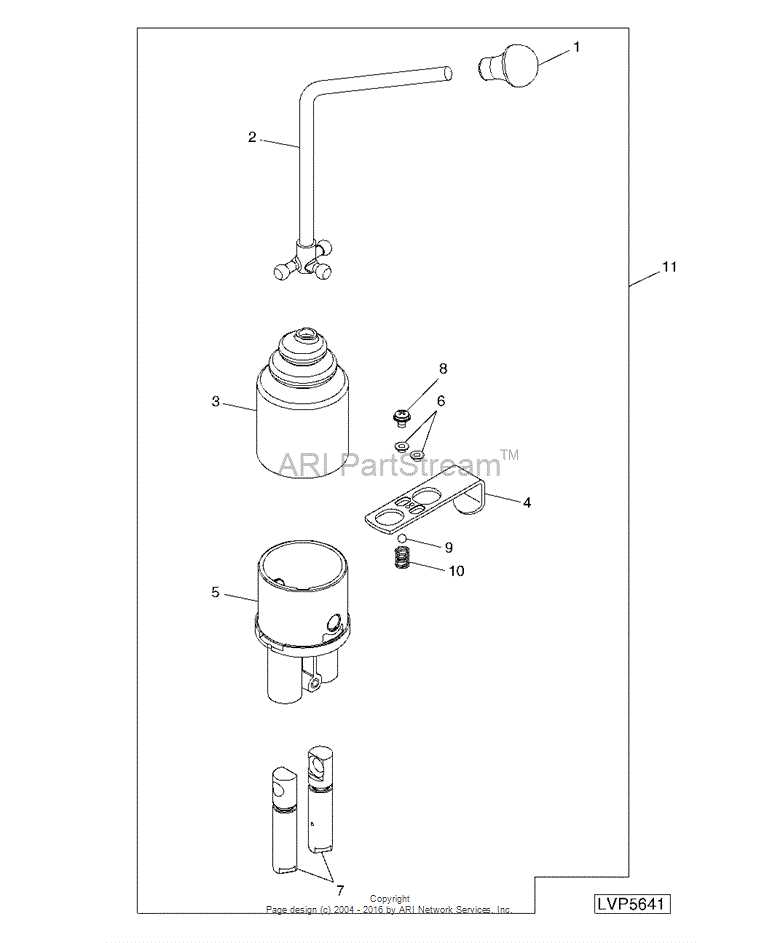

Hydraulic System

- Pumps: Generate hydraulic pressure for various functions.

- Cylinders: Convert hydraulic energy into mechanical force.

- Hoses: Transport hydraulic fluid between components, enabling seamless operation.

Where to Find Diagrams

Locating accurate schematics for machinery is essential for effective maintenance and repair. Various resources can provide detailed illustrations that help users identify components and understand assembly. Exploring these avenues will enhance your ability to manage equipment efficiently.

Here are some recommended sources for obtaining comprehensive illustrations:

| Resource Type | Description |

|---|---|

| Manufacturer Websites | Official sites often offer downloadable resources, including detailed layouts and manuals. |

| Online Forums | Community-driven platforms can be valuable for sharing files and tips regarding specific models. |

| Specialized Retailers | Certain vendors provide schematics as part of their customer service, aiding in repairs and purchases. |

| Technical Books | Printed manuals and repair guides frequently contain visual aids that can simplify troubleshooting. |

| Video Tutorials | Platforms like YouTube often feature instructional content that visually demonstrates equipment assembly. |

Benefits of Using Diagrams

Visual representations serve as powerful tools that enhance understanding and facilitate communication. They break down complex information into digestible formats, allowing individuals to grasp intricate concepts more easily. This approach not only aids in learning but also streamlines troubleshooting processes.

One significant advantage of utilizing visual aids is their ability to clarify relationships between various components. By depicting how elements interact, these representations enable users to identify potential issues swiftly and devise effective solutions. This clarity ultimately leads to improved efficiency and productivity.

Furthermore, visuals cater to diverse learning styles, making information accessible to a broader audience. People who may struggle with text-based explanations often find graphical depictions more intuitive. This inclusivity enhances collaboration and ensures that everyone is on the same page.

In summary, employing visual aids significantly enhances comprehension, streamlines communication, and fosters a collaborative environment. Their role in simplifying complex information makes them indispensable in various fields.

Common Issues with Parts

When it comes to machinery, various components can present challenges that affect performance and longevity. Understanding these common issues can help users troubleshoot effectively and maintain optimal functionality.

Wear and Tear: Over time, certain elements may degrade due to constant use, leading to reduced efficiency. Regular inspections can help identify these worn-out components before they fail.

Compatibility: Not all replacements are created equal. Using incompatible components can result in poor performance or even damage to the machine. Always ensure that replacements meet the specific requirements of the model.

Installation Errors: Improper installation can lead to misalignments and malfunctions. Following the manufacturer’s guidelines carefully is crucial to avoid such issues.

Corrosion: Exposure to moisture and harsh environments can cause rust and corrosion, particularly in metal components. Protective coatings and regular maintenance can mitigate these effects.

Supply Chain Challenges: Availability of specific components can fluctuate, impacting timely repairs. Being proactive in sourcing and maintaining a stock of essential parts can minimize downtime.

Addressing these common issues not only enhances the efficiency of machinery but also prolongs its lifespan, ensuring better performance for years to come.

Replacement Parts Availability

Ensuring the functionality of agricultural machinery often relies on the accessibility of quality components. Timely access to these crucial items is essential for maintaining performance and extending the lifespan of equipment. This section explores the resources available for acquiring necessary replacements, ensuring that operators can keep their machines running smoothly.

Sources for Quality Components

Multiple suppliers provide an extensive range of options for obtaining necessary components. Both online retailers and local dealerships offer diverse inventories, enabling users to select items that best fit their needs. It’s advisable to consider options that guarantee authenticity and quality, as this can significantly affect the performance of the machinery.

Considerations for Procurement

When seeking replacements, users should evaluate factors such as compatibility, warranty, and cost-effectiveness. Utilizing reputable sources not only enhances the chances of finding the right items but also supports long-term reliability. It’s beneficial to compare various suppliers and read customer reviews to ensure a satisfactory purchasing experience.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of agricultural machinery requires regular attention and care. Proper maintenance practices not only enhance efficiency but also extend the lifespan of equipment. Here are some essential tips to consider for keeping your machinery in top shape.

- Regular Inspections: Schedule frequent checks for wear and tear on various components. Look for signs of damage or malfunction.

- Fluid Checks: Monitor and change oils, hydraulic fluids, and coolant levels regularly to maintain smooth operation.

- Cleanliness: Keep the machine clean from dirt and debris. Regular washing helps prevent corrosion and blockages.

- Greasing: Apply lubricant to moving parts as specified in the owner’s manual to reduce friction and wear.

- Filter Replacements: Change air and fuel filters as recommended to ensure efficient operation and protect engine components.

- Storage Practices: Store equipment in a dry, sheltered location to prevent exposure to harsh weather conditions.

- Battery Care: Check battery terminals for corrosion and ensure the battery is charged to avoid starting issues.

- Follow Manufacturer Guidelines: Adhere to the maintenance schedule provided by the manufacturer for optimal performance.

By implementing these maintenance strategies, you can enhance the reliability and longevity of your agricultural machinery, ensuring it remains a valuable asset for years to come.

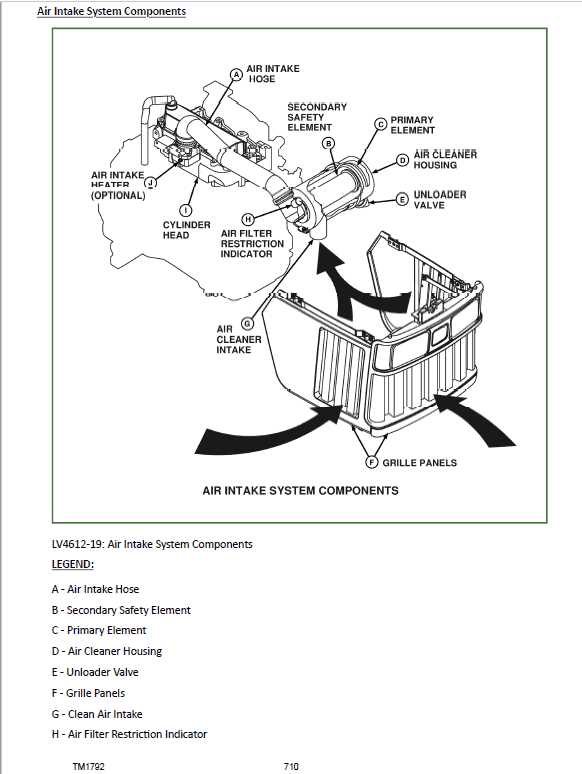

How to Interpret Diagrams

Understanding illustrations that depict mechanical systems is essential for effective maintenance and repair. These visuals provide a wealth of information about components, their relationships, and functions. Properly interpreting them can streamline the troubleshooting process and enhance overall efficiency.

Key Elements to Focus On

When analyzing these visuals, pay attention to specific features that can guide your understanding:

| Element | Description |

|---|---|

| Labels | Identify each component clearly, often with numbers or letters. |

| Connections | Examine how elements are linked, indicating flow or movement. |

| Symbols | Recognize common representations that indicate functionality or type. |

| Orientation | Understand the layout, which may reflect how parts fit together in reality. |

Practical Tips for Interpretation

To effectively utilize these visuals, consider these strategies:

- Cross-reference with manuals for clarity on complex components.

- Take notes while interpreting to reinforce memory of the parts.

- Consult experts if certain aspects remain unclear, ensuring a comprehensive understanding.

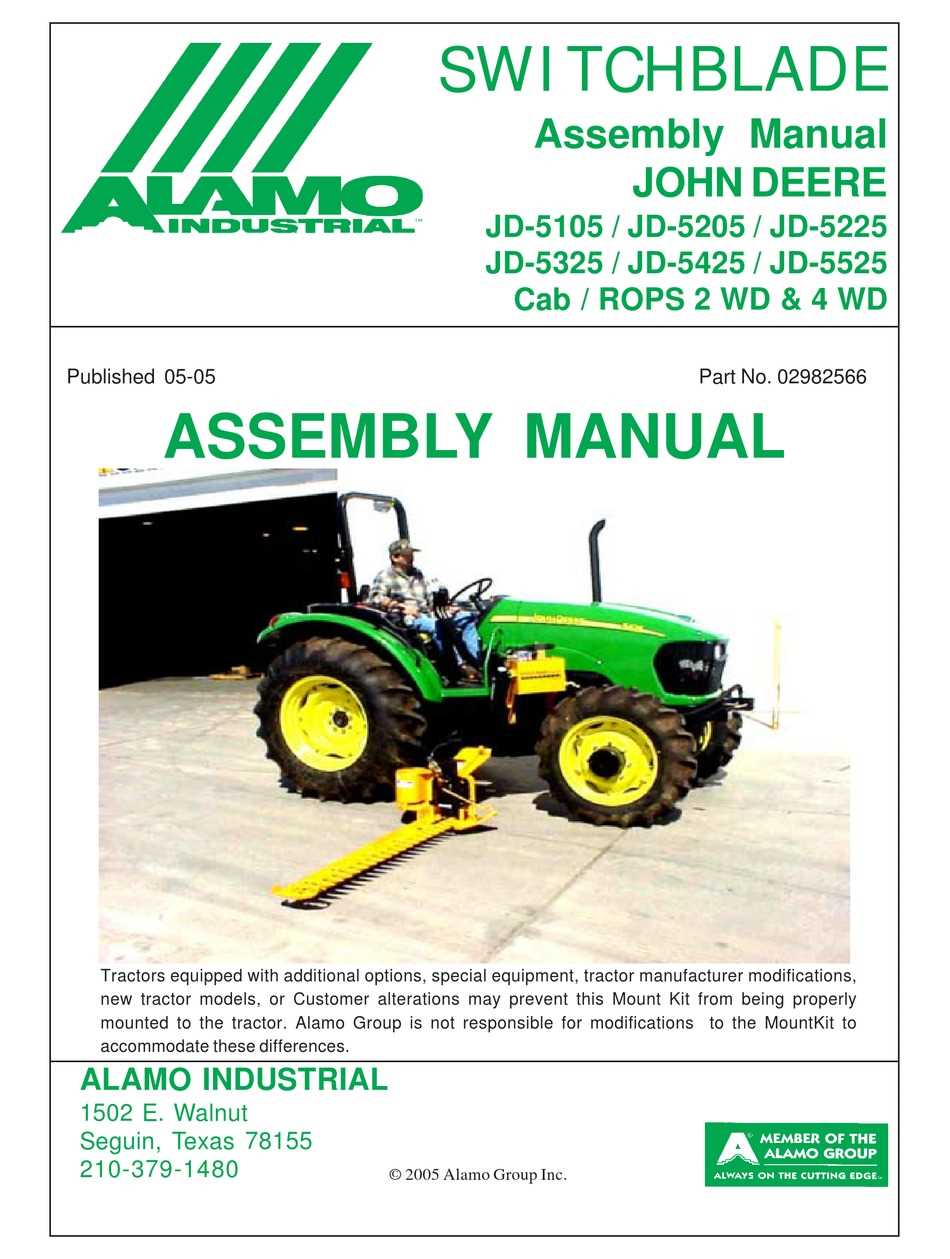

Upgrading Your Equipment

Enhancing your machinery can significantly improve efficiency and performance in various tasks. By investing in modern components and accessories, you not only boost productivity but also extend the lifespan of your equipment.

Identifying the Right Upgrades is crucial. Start by assessing your current setup and determining which areas require improvement. Consider factors such as functionality, ease of use, and compatibility with existing systems.

Researching available options is the next step. Look for advanced features that can streamline operations, such as improved engines, transmission systems, or ergonomic enhancements. Prioritize upgrades that align with your specific needs and operational goals.

Finally, implementation is key. Ensure that all upgrades are installed correctly and are well-integrated into your existing equipment. Regular maintenance and monitoring post-upgrade will help maximize performance and longevity.

Resources for Further Learning

Expanding your knowledge about machinery maintenance and components can greatly enhance your understanding and efficiency. There are numerous resources available that provide valuable information, from manuals to online courses. Engaging with these materials can help you gain insights into the intricacies of equipment and improve your hands-on skills.

Recommended Books

| Title | Author | Focus Area |

|---|---|---|

| The Machinery Handbook | Erik Oberg | General Engineering |

| Fundamentals of Machinery | David A. Madsen | Mechanical Design |

| Understanding Tractors | Mike E. Smith | Tractor Operations |

Online Courses

Several platforms offer courses that delve into machinery operation and maintenance. These courses often feature interactive content, video tutorials, and assessments to enhance your learning experience.

| Platform | Course Title | Duration |

|---|---|---|

| Coursera | Machinery Basics | 6 Weeks |

| Udemy | Equipment Repair Fundamentals | 4 Hours |

| edX | Mechanical Systems | 8 Weeks |

FAQs About John Deere 5105 Parts

This section addresses common inquiries regarding components related to a specific agricultural machine. Understanding these elements can significantly enhance maintenance and repair practices.

What are the most commonly replaced components? Essential items often include filters, belts, and hydraulic parts, as these experience the most wear over time.

Where can I find authentic replacements? It’s advisable to seek reputable dealers or authorized distributors to ensure you acquire genuine items that guarantee compatibility and durability.

How can I identify the right component? Referencing the machine’s manual or consulting with professionals can provide clarity on the appropriate specifications required.

What should I consider before purchasing? Factors such as quality, warranty, and cost-effectiveness should influence your decision-making process to ensure optimal performance.

Are there any maintenance tips? Regular inspections and timely replacements are crucial to prolonging the lifespan of essential machinery components.