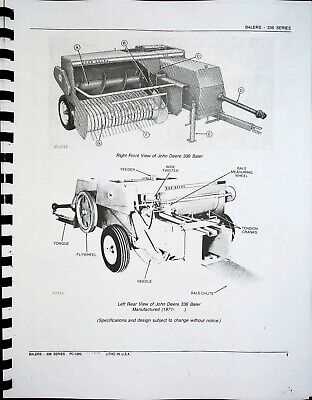

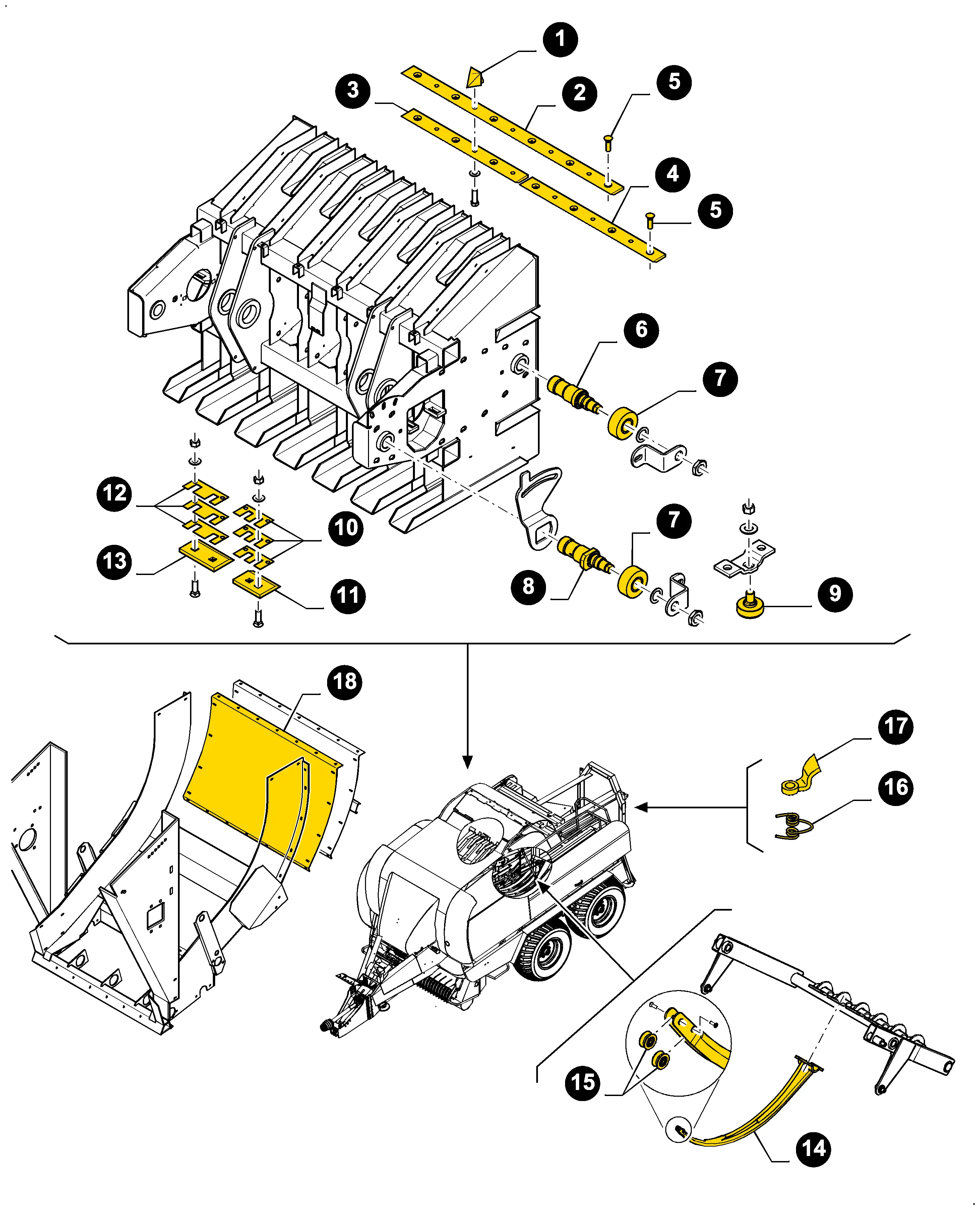

John Deere 535 Baler Parts Diagram Guide

This section provides a comprehensive overview of the crucial elements involved in the machinery used for harvesting and processing agricultural materials. Understanding these components is vital for efficient operation and maintenance.

Visual aids play a significant role in grasping the structure and function of various segments within the equipment. Familiarity with these elements helps in identifying potential issues and ensuring optimal performance.

Access to a well-organized reference can facilitate effective troubleshooting and enhance overall productivity. By recognizing the significance of each component, operators can maintain their machines with confidence and precision.

Understanding John Deere 535 Baler Parts

Familiarizing oneself with the components of agricultural machinery is crucial for optimal performance and maintenance. This section provides an overview of the essential elements involved in a particular model, focusing on their functions and significance. Knowledge of these elements can aid in troubleshooting, repairs, and ensuring longevity.

Key components to consider include:

- Frame: The structural backbone that supports all other components.

- Feeding Mechanism: This assembly facilitates the intake of materials, ensuring a steady flow for processing.

- Compression System: Essential for compacting the collected material into bales, enhancing transport efficiency.

- Twine System: Responsible for binding the finished product, securing the load for handling.

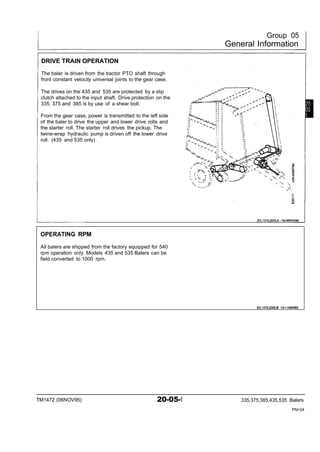

- Power Transmission: A critical network that transfers energy from the engine to various parts of the machine.

Understanding these components helps in performing maintenance checks and repairs effectively, leading to improved efficiency and reduced downtime.

Overview of Baler Components

This section provides a comprehensive look at the essential elements involved in the operation of a hay harvesting machine. Understanding these components is crucial for effective maintenance and troubleshooting, ensuring optimal performance during use.

- Frame: The structural backbone that supports all other parts and provides stability.

- Feed System: Responsible for guiding the material into the chamber for processing.

- Compression Chamber: Where the material is compacted into manageable sizes.

- Power Source: Supplies the necessary energy for operation, typically an engine or motor.

- Twine or Net Wrap System: Used to secure the finished bales, ensuring they maintain their shape during transport.

- Discharge Mechanism: Facilitates the release of completed bales from the machine.

Each of these components plays a vital role in the overall functionality and efficiency of the equipment, highlighting the importance of regular inspections and maintenance to avoid downtime.

Key Features of John Deere 535

This section explores the notable attributes of a well-regarded agricultural implement designed for effective hay management. The model is appreciated for its robust construction and user-friendly characteristics, making it an excellent choice for farmers seeking efficiency in their operations.

Durability and Reliability

Constructed with high-quality materials, this machinery offers exceptional durability. Key aspects include:

- Sturdy Frame: Built to withstand heavy usage and challenging conditions.

- Long Lifespan: Designed for longevity, reducing the need for frequent replacements.

Operational Efficiency

This implement is designed to enhance productivity in the field. Features that contribute to its efficiency are:

- Quick Setup: Easy assembly allows for rapid deployment in various tasks.

- Efficient Processing: Capable of handling large volumes, minimizing downtime during operation.

- Adjustable Settings: Customizable settings enable optimization based on specific needs.

Importance of Maintenance and Repair

Regular upkeep and servicing are crucial for ensuring the longevity and efficiency of machinery. Neglecting these aspects can lead to diminished performance and, ultimately, costly breakdowns. By prioritizing maintenance, operators can not only enhance the reliability of their equipment but also extend its lifespan significantly.

Benefits of Routine Care

Implementing a consistent maintenance schedule helps identify potential issues before they escalate. This proactive approach can prevent unexpected failures, allowing for smooth operation and minimizing downtime. Additionally, routine care contributes to optimal performance, ensuring that machinery operates at its best.

Cost-Effectiveness

Investing in regular repair and maintenance services proves to be cost-effective in the long run. By addressing minor problems promptly, operators can avoid extensive repairs that often come with higher expenses. This practice not only saves money but also boosts productivity, making it an essential aspect of machinery management.

Common Issues with Baler Parts

When operating agricultural machinery, it’s crucial to be aware of frequent challenges that can arise with various components. Understanding these issues can help in maintaining optimal performance and prolonging the lifespan of the equipment. Below are some typical concerns that users may encounter.

- Wear and Tear: Over time, certain components may experience significant wear, leading to decreased efficiency.

- Misalignment: Incorrect installation or adjustment can cause misalignment, resulting in operational difficulties.

- Blockages: Debris accumulation can lead to blockages, hindering the machine’s performance.

- Fluid Leaks: Seals and gaskets may deteriorate, causing leaks that affect functionality.

- Electrical Failures: Issues with wiring or connectors can disrupt the electrical system, affecting operation.

Regular inspection and maintenance can mitigate these challenges, ensuring smoother operation and reducing the likelihood of costly repairs.

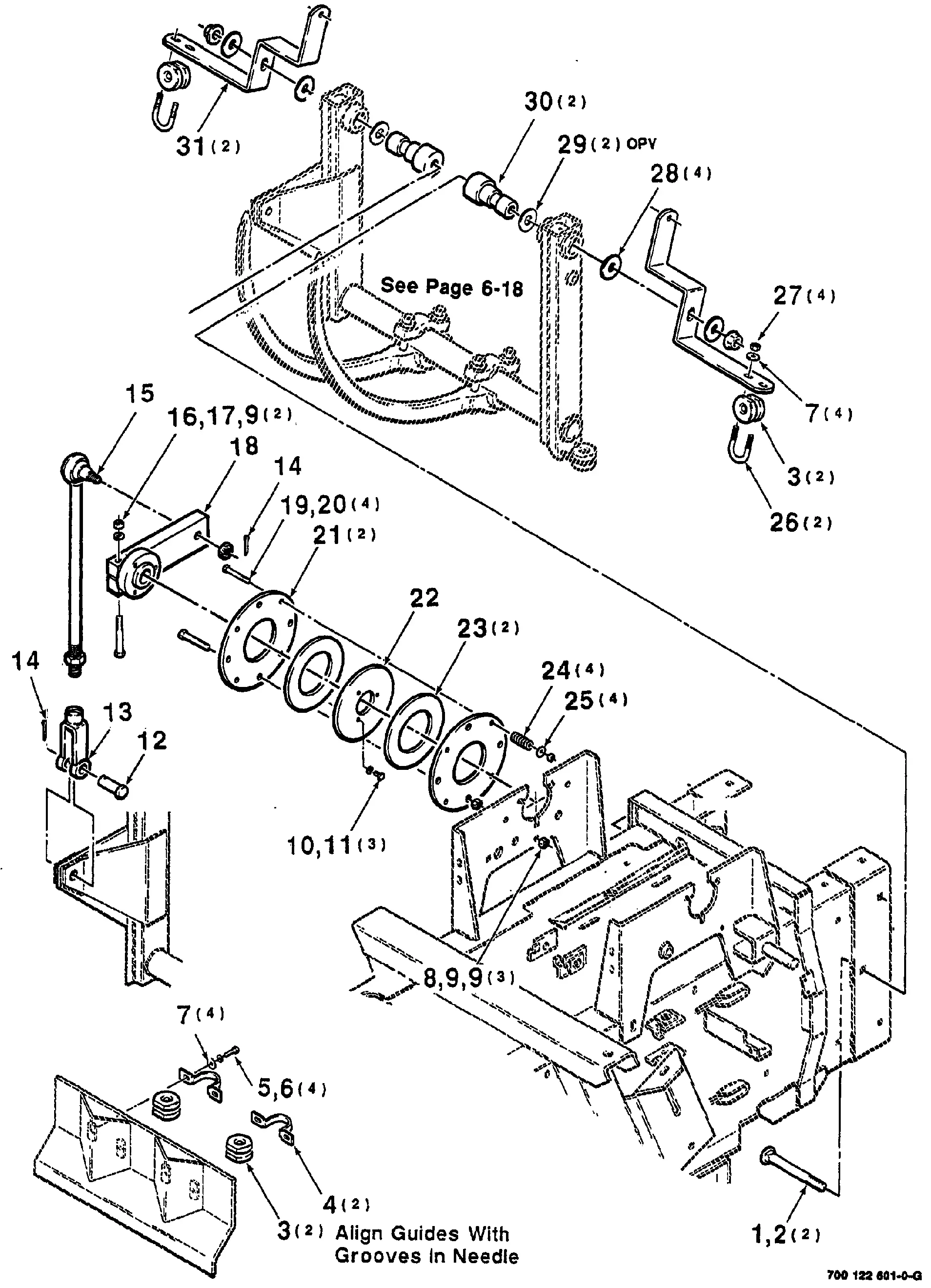

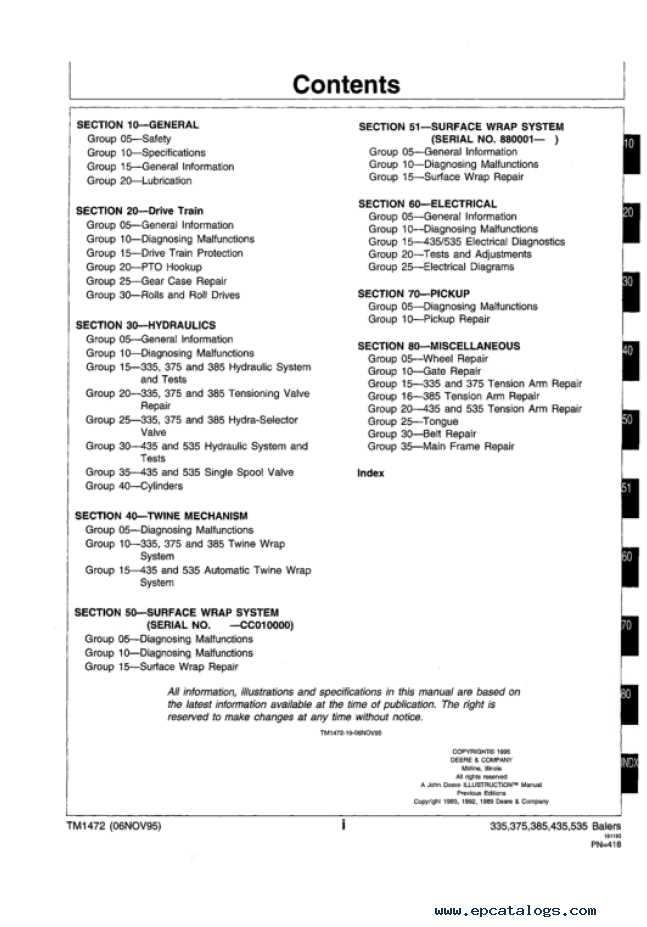

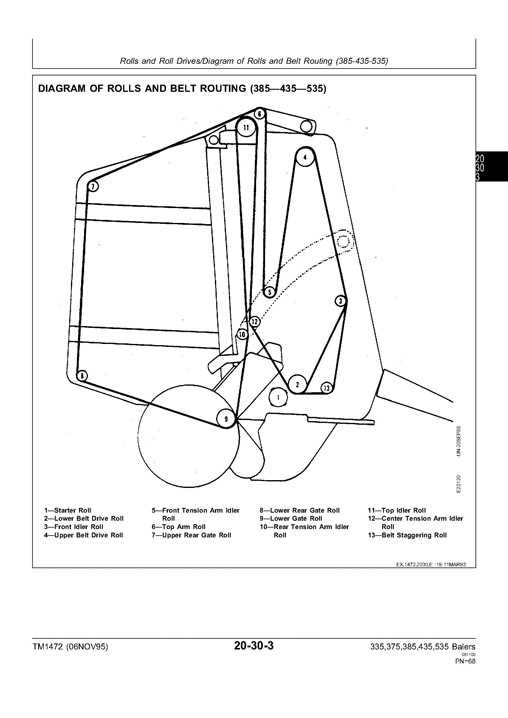

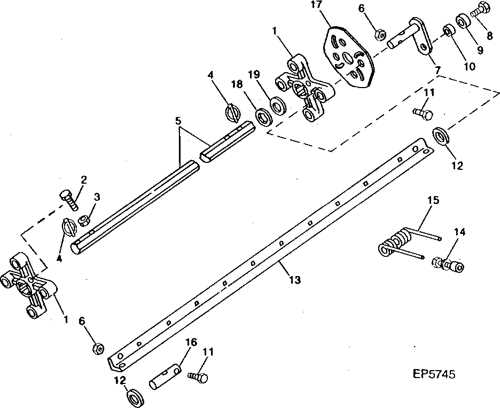

How to Read Parts Diagrams

Understanding schematics is essential for effective maintenance and repair of machinery. These visual representations serve as valuable tools for identifying components and their functions. By mastering the art of reading these illustrations, users can enhance their troubleshooting skills and streamline the repair process.

Identifying Components

The first step in interpreting these visuals is to familiarize yourself with the symbols and labels used. Each element usually has a specific designation, allowing users to distinguish between different items. Pay attention to the legends or keys, as they provide essential information regarding each symbol’s meaning.

Following Connections

Once you understand the components, observe how they are interconnected. Lines or arrows typically indicate relationships and connections between elements. This insight is crucial for diagnosing issues, as it helps users trace the flow of operations and pinpoint potential problem areas.

Essential Tools for Baler Repairs

Having the right equipment is crucial for effective maintenance and repair tasks. Various implements facilitate the repair process, ensuring efficiency and safety. Understanding these essentials helps operators manage repairs with confidence, minimizing downtime and enhancing productivity.

Basic Hand Tools

Basic hand tools form the foundation for any repair job. Common items include wrenches, pliers, and screwdrivers. These tools allow for adjustments, tightening, and loosening of components. Having a well-organized toolkit ensures that all necessary tools are readily accessible when repairs are needed.

Diagnostic Equipment

Diagnostic tools are vital for identifying issues. Devices such as pressure gauges and electronic testers help monitor performance and troubleshoot problems. Utilizing such equipment enables operators to pinpoint malfunctions accurately, leading to more effective solutions.

Step-by-Step Repair Instructions

This section provides a comprehensive guide to effectively addressing issues with your equipment. Following these instructions will help ensure that repairs are carried out efficiently and safely.

Before beginning the repair process, gather all necessary tools and materials. This preparation will facilitate a smooth workflow and minimize potential interruptions.

Required Tools and Materials

- Wrench set

- Screwdriver set

- Pliers

- Replacement components

- Lubricant

Repair Steps

- Safety First: Disconnect the power source to prevent any accidental activation during repairs.

- Inspect the Equipment: Examine the machinery for visible wear, damage, or loose parts that may require attention.

- Remove Faulty Components: Use appropriate tools to carefully detach any malfunctioning parts.

- Install New Parts: Align and secure replacement items according to manufacturer specifications.

- Lubricate Moving Parts: Apply lubricant to ensure smooth operation and reduce wear.

- Reconnect Power: Once all repairs are complete, restore the power supply and test the equipment to verify proper functionality.

Following these structured instructions will help maintain your equipment in optimal condition. Regular checks and timely repairs can significantly extend the lifespan of your machinery.

Where to Find Replacement Parts

Finding suitable components for your agricultural machinery can be crucial for maintaining its efficiency and functionality. There are various resources available to assist in locating the right items needed for repairs or upgrades. Understanding where to look can save both time and money.

Online Retailers and Marketplaces

Numerous online platforms specialize in agricultural equipment. These websites often provide a wide selection of components, ranging from essential replacements to advanced upgrades. Additionally, many platforms offer user-friendly search features that allow for easy navigation.

Local Dealers and Distributors

Visiting local dealerships or distributors can be beneficial, as they typically stock a variety of components and accessories. These establishments often have knowledgeable staff who can provide guidance on selecting the appropriate items based on specific needs.

| Resource Type | Description |

|---|---|

| Online Retailers | Wide selection, easy navigation, competitive pricing |

| Local Dealers | Immediate availability, expert advice, potential for discounts |

| Manufacturer Websites | Direct access to authentic components, product information |

Comparing OEM and Aftermarket Parts

When it comes to machinery maintenance, choosing the right components is essential for optimal performance and longevity. There are two primary categories of components available in the market: original equipment manufacturer (OEM) components and aftermarket alternatives. Each option has its own set of advantages and considerations, making it crucial for users to understand their differences.

Advantages of OEM Components

- Quality Assurance: OEM components are specifically designed for particular machines, ensuring a precise fit and compatibility.

- Warranty Protection: Many manufacturers offer warranties on OEM products, providing peace of mind against potential defects.

- Consistent Performance: These components are rigorously tested to meet the manufacturer’s standards, promoting reliable functionality.

Benefits of Aftermarket Alternatives

- Cost-Effectiveness: Aftermarket options are often more affordable, making them an appealing choice for budget-conscious consumers.

- Wide Variety: The aftermarket sector offers a diverse range of components, catering to various needs and preferences.

- Availability: Many aftermarket parts are readily accessible through numerous retailers, ensuring quick replacement options.

Ultimately, the choice between OEM and aftermarket components depends on individual preferences, budget considerations, and specific operational requirements. Careful evaluation of these factors can lead to informed decisions that enhance equipment performance and durability.

Cost Considerations for Baler Repairs

Repairing agricultural machinery can involve various financial aspects that should be carefully assessed. Understanding the overall expenses associated with maintenance and part replacement is essential for effective budget management. This segment delves into key factors influencing repair costs, helping operators make informed decisions.

Labor Expenses

Labor costs can significantly impact the total expenditure on repairs. Skilled technicians may charge higher hourly rates, and the complexity of the task can further influence labor time. It is advisable to obtain multiple quotes to ensure competitive pricing while ensuring quality service.

Replacement Components

The cost of replacement components varies based on brand, quality, and availability. Investing in high-quality parts can reduce the likelihood of future breakdowns, although they may come at a premium price. Exploring different suppliers can yield better deals without compromising on reliability.

Benefits of Regular Inspections

Conducting routine assessments of machinery plays a crucial role in ensuring optimal performance and longevity. Regular evaluations help identify potential issues before they escalate, allowing for timely maintenance and repairs. This proactive approach not only enhances efficiency but also contributes to overall productivity in agricultural operations.

Preventive Maintenance: By routinely checking equipment, operators can detect wear and tear early, which reduces the likelihood of unexpected breakdowns. This practice minimizes downtime and ensures that operations run smoothly.

Cost Savings: Addressing minor issues during inspections can prevent costly repairs in the future. By investing time in regular evaluations, users can save significant amounts on repairs and replacements down the line.

Safety: Regular inspections contribute to a safer working environment. Ensuring that machinery is functioning correctly helps prevent accidents and injuries, protecting both operators and bystanders.

Enhanced Performance: Routine assessments can lead to improved efficiency. Well-maintained equipment often performs better, leading to higher output and better quality of work.

Compliance: Regular evaluations may also be necessary to meet industry standards and regulations. Keeping equipment in good condition ensures compliance with safety and operational guidelines.

Contacting John Deere Support Services

When seeking assistance regarding machinery and equipment, reaching out to customer support can provide valuable guidance. The dedicated team is equipped to address inquiries related to product functionality, troubleshooting, and maintenance.

For efficient communication, it’s advisable to have relevant details on hand, such as model numbers and any specific issues encountered. This information enables support representatives to offer precise solutions tailored to your needs.

Support services can be accessed through various channels, including phone, email, and online chat options. Each method ensures that users receive prompt responses to their concerns, enhancing the overall experience.

Hours of Operation: Make sure to check the operational hours to ensure timely assistance. Availability may vary by region.

Online Resources: In addition to direct support, numerous online resources, including FAQs and troubleshooting guides, can be found on the official website. These tools can help users resolve common issues independently.